D15 engine block damage

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=198402

Printed Date: 11 Oct 2025 at 4:22am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

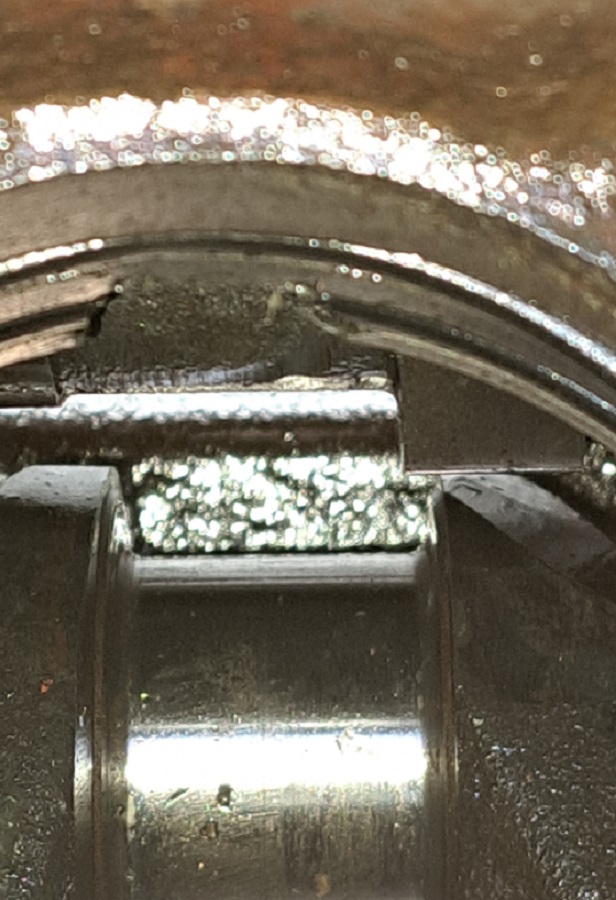

Topic: D15 engine block damage

Posted By: Dan73

Subject: D15 engine block damage

Date Posted: 26 Nov 2023 at 10:56am

My D15 broke the connecting rod and I didn't notice the damage to the block at the lower o ring. Can this be reassembled with only a single o ring? If not is the block repairable? |

Replies:

Posted By: Jim.ME

Date Posted: 26 Nov 2023 at 11:42am

|

Posted By: steve(ill)

Date Posted: 26 Nov 2023 at 1:02pm

|

There are two o-rings on a liner for a good guarantee that there will be no leaks... You COULD use one o-ring and get by if everything goes GOOD on the assembly and forms a good seal... There is no guarantee and nobody will be able to tell you for certain that it will work.... Long term, if you do it and then have a minor leak, you could put in some radiator sealer and let it finish things up. Many will complain about the nick in the journal.. That will not hurt as long as it is cleaned up and nothing sticking up above the round surface.. I would be more concerned about the journal being ROUND ..... Before going ahead with the crank and block, i would inspect everything very good to make sure you found all possible problems. ------------- Like them all, but love the "B"s. |

Posted By: DrAllis

Date Posted: 26 Nov 2023 at 1:29pm

| I assume that is a G-160/ Series 2 engine ?? Anyway, no one can repair that block as cheaply as just finding another block. |

Posted By: Dan73

Date Posted: 26 Nov 2023 at 1:54pm

|

Steve the engine got a comple overhaul kit put in it about 3 years ago. The crank was inspected then and everything measured good I installed all new sleeves and pistions at that point the motor was completely gone through. This started with a broken ring causing blow by I figured it would be ok to use it for a few weeks work I needed which proved wrong. As the rod broke at the wrist pin end. Dr,Allis the motor is definitely a 149 I made the mistake of ordering the 160 kit for it when I rebuilt the motor. The tractor was built out of 2 parts machines and the motor is serries 1 the first year of production iirc . |

Posted By: Codger

Date Posted: 26 Nov 2023 at 2:36pm

|

How would the inexperienced identify a G-149 block? There are two or three partial Allis engines in a warehouse I will be at tomorrow sometime and can look. What is the bore size, and is there a series of numbers? These are all partials but I think one is a relatively complete short block. No G-226 we found out early on. ------------- That's All Folks! |

Posted By: PaulB

Date Posted: 26 Nov 2023 at 3:43pm

|

I have some blocks available for the 149 engine. Maryland ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: Fred in Pa

Date Posted: 26 Nov 2023 at 5:04pm

|

I have blocks also , there are plenty 149 blocks out there not a real high $$$ block by far.

------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: DrAllis

Date Posted: 26 Nov 2023 at 6:45pm

| Just remember a D-15/G-149 block with full-flow oil. |

Posted By: Dan73

Date Posted: 26 Nov 2023 at 6:51pm

| Thanks Dr. Allis I definitely would have been able to get that wrong. |