D-17 IV versus G-226 serial numbers

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=198338

Printed Date: 31 Oct 2025 at 11:30pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D-17 IV versus G-226 serial numbers

Posted By: DrAllis

Subject: D-17 IV versus G-226 serial numbers

Date Posted: 22 Nov 2023 at 6:35pm

| One thing was always different about a series 4 gas or LPG engine over the series 3 and older engines. The difference was the crankshaft journal harness on the surface. The journal surfaces were hardened by a process A-C called "Tufftriding". Perkins engines called it "Nitriding" but it was the same process. I'd say 80% of every series 4 I got to overhaul for the very first time, I never had the crankshaft reground undersized. It hadn't worn if it had good regular maintenance. I always used -.001" on the mains and usually standard or -.001" on the rods, which A-C offered in those days. Anyway, the parts books or service manuals don't ever give a s/n break as to when the first G-226 engine got this better crankshaft. The parts system just subbed up the new better crank to replace any crank in any age engine because it fit. So, my goal here is to try and determine approximately when this happened. The first series 4 chassis was s/n 75001 in mid 1964. Who can provide me with the oldest series 4 chassis s/n and then give me the gas engine s/n ?? I have a good start with a very late 1965 s/n 80082 eng is 17-62194-M. The next one is a late summer/early fall 1966 s/n 84559 eng is 17-69525. So, you see building 4477 tractors they built 7331 gas engines that went into other applications. The last serial 4 chassis was 89213 according to Swinford's book. To give you an example of how things changed a lot, I had a mid-1963 D-17 S3 s/n 67425 and the engine was 17-42480-M. So, from mid 63 to late 65 they built 12,657 D-17 gas/diesel chassis and 19,714 gas engines !!! This could be interesting. Thanks to JoeO and Codger for their help on this. Anyone else who can help, please climb aboard !! Looking for the oldest S-4 gassers. |

Replies:

Posted By: tbran

Date Posted: 22 Nov 2023 at 7:24pm

|

Thats a lot more production that surprises me. What other units used the engines. E/EII Gleaners, Power Unts - anything else ? Be interesting to see the SN correspondence - will look on my WD - can you reprint the SN suffixs and their designated uses ? Also did the hardened cranks appear across the usage line or just in tractors ? ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 22 Nov 2023 at 7:46pm

| Gleaner E's number about 8,500 engines from late 1962 thru 1964 1/2 the way I count them. That time frame would be when the series 4 engine came out in Summer/Fall 1964. The engine in my antique D-17 puller has one of those cranks in it (stroked to 6.00") and I will get the eng s/n this weekend. As time went on in 65-66 looks like about 7500 more combines built. Serial numbers in 67-68 get a little skewed, as their beginning number looks chosen, not actual. But, I think 4,000 engines each full year would be close guess from late 1962 thru 1968 for 26,000 combine engines. Then, power units and everything else they got used for. Numbers I've crunched using Swinfords book indicate D-17 tractors were 80% gasoline powered over the 9++ years of production. Again, during the series 3 days, there was a huge bunch of actual tractor serial numbers missing from 1962 to 1963. My semi-educated guess would be, when they made the change to the crankshaft....EVERY engine from then on got the better crank. They didn't have a "cheap" crank like some of the Harvey engines. |

Posted By: RedHeeler79

Date Posted: 22 Nov 2023 at 8:11pm

|

Not the oldest series IV, as you requested… but just for information’s sake Pretty close to the 1966 serial number you posted above… D17 - 84217 17 - 69038 - M 342 units apart on tractor number 487 units apart on engine number Interesting…. |

Posted By: Marlyn nwia

Date Posted: 22 Nov 2023 at 8:25pm

|

I have an older one; 1964/1965 ? D-17-IV 76815 17 - 56097 - M

|

Posted By: DrAllis

Date Posted: 22 Nov 2023 at 8:36pm

| We're getting pretty darn close !!! Chassis s/n 77090 was the beginning of 1965. Yours is a late 1964. They started at 75001 and went until 77089 (in 64) for a total of 2088 units. 80% of that would be 1670 gas engines used in tractors. Looks to me like approx engine s/n of 17-54427 is for sure a Tufftrided crankshaft and then discount about 2,000 Gleaner combines for last part of 1964 lowers that number to around 17-52427 !!! We have certainly zeroed in pretty closely in not much time at all. Thank you. Any more info would still be great !!! |

Posted By: Lynn Marshall

Date Posted: 22 Nov 2023 at 8:40pm

| Those are interesting engine production numbers. Approximately how many engines, of all models, was the Harvey plant capable of making a year? Did they have separate lines for the gas and diesel or did they just produce one model of engine for awhile and then switch over to another model? I never got to tour the plant,but I bet it would have been interesting. |

Posted By: DrAllis

Date Posted: 22 Nov 2023 at 8:53pm

| I went thru Harvey in August of 1980. No gas engines made at that time, or maybe only special order. Someone posts on here who could tell you for sure. I envision four assembly lines....301-426-516 and the 731/844 engines. All the 4 cylinder B-C-CA-D10-12-14-15 engines and the WC-WF-WD-WD45-D17-170-175 were Milwaukee built. And one would then assume all those great big 4 cylinder UC-A-and E engines also Milwaukee ?? |

Posted By: Lynn Marshall

Date Posted: 22 Nov 2023 at 9:20pm

| Were most all of the parts for the early engines produced in house? Pistons, rods,cams, crankshafts, valves, bearings and even gaskets? Obviously electrical components and carburetors were farmed out. How about water pumps and clutch assemblies? |

Posted By: DrAllis

Date Posted: 22 Nov 2023 at 11:55pm

| I'm going to call the Harvey Engine Division an "assembly" plant. They had no foundry for casting blocks, heads or crankshafts. I remember probably a concrete 2 or 3 acre area just full of blocks and cranks sitting outside rusting, going thru so many days of "cure time" before they were cleaned and machined into the finished product. So, along that line of thinking, pistons/rings/sleeves/gaskets/valves/etc/etc were probably pretty much vendored out to companies whop did that sort of thing. I know cylinder heads for 2000 series engines later on had "France" cast into them. Connecting rods often times said JAPAN in the 1960's engines. Yes, I think as assembly plant best describes it. They did do their own injector work there for a long while I think, but even that went away in the 1978 and up K2/F2 engines switching to Bosch brands. |

Posted By: Lynn Marshall

Date Posted: 23 Nov 2023 at 7:28am

First off, Happy Thanksgiving to everyone. Doc,your last post was basically at midnight. Don't you ever rest?  Yes, the later engines had many different parts sources. Japan, France, and West Germany come to mind. I remember now that even the WD clutches were either Rockford or some other supplier. I still assume that the majority of the engine parts for the Milwaukee built engines were made in house. Considering the other products that Allis built in that time frame, those engine parts would have been small potatoes compared to the massive generators that they made. Yes, the later engines had many different parts sources. Japan, France, and West Germany come to mind. I remember now that even the WD clutches were either Rockford or some other supplier. I still assume that the majority of the engine parts for the Milwaukee built engines were made in house. Considering the other products that Allis built in that time frame, those engine parts would have been small potatoes compared to the massive generators that they made.

|

Posted By: tbran

Date Posted: 23 Nov 2023 at 7:56am

|

There was a story of a visit from the Japanese vendors who were given a tiny used drill bit that AC was so proud of that were used to drill the AC tips. Later that month they received a box from Japan that had one of their gift bits returned with a hole drilled in it. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: tbran

Date Posted: 23 Nov 2023 at 8:16am

|

I remember being at the West Allis plant in 75 or 76 and there were a plethora of G226 engine on racks on the west wall of the assembly plant about half way down. I was amazed there were still that many new engines. Knowing they were coming to an end I wonder if they batch built a bunch of engines and used them years later ? I ask wheree the engines were assembled and was told in the 'old line' that was now something else. The AC gas engines were all made at their foundry best I know. I saw pictures of engine blocks being machined. Even the crank pulleys and flywheels. The pistons and rings were sourced as were the barings, gaskets, seals, valves and springs. Many decades ago when the parts were shipped in cans and the seals were leather I think AC made some of these. They did make some oil filters in the early days of bypass filtering. (some claim AC 'invented' the oil filter - may be found in AC An industrial Heritage) . It would be interesting to know when the last gas engine was produced. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: orangeman

Date Posted: 23 Nov 2023 at 8:42am

|

Dr. Allis: I have a D17 Series IV - Serial # 84544 - there is no Engine # on the engine casting. Maybe escaped from the factory without an Engine Serial # ? I took wire brush to it - still nothing. I did see 4680-3 cast into the block on the opposing side above the oil filter base. HTH's ~ Orangeman

|

Posted By: DrAllis

Date Posted: 23 Nov 2023 at 10:14am

| No engine could never have left the factory without a serial number, located behind the carburetor/air cleaner hose. No s/n means the block has been replaced with a new block out of the parts system. Sometime the block was frozen or gotten overheated/hot and cracked, who knows. |

Posted By: Marlyn nwia

Date Posted: 23 Nov 2023 at 12:07pm

|

Dr. Allis; I still have the crankshaft from this engine. I rebuilt it at 5400-5800 hrs? in the late 1900s. The mechanic emphatically insisted we put in a new crank. I am beginning to suspect he knew what you are talking about. I always perceived some day I would machine it and reuse it. Perhaps it is time to junk it. The engine now has 8030 hrs. and will never be overhauled in my lifetime.

|

Posted By: DrAllis

Date Posted: 23 Nov 2023 at 3:25pm

| At that 5400 to 5800 hr mark, it probably needed to be reground -.010" on the mains. Maybe your dealership didn't have a local machine shop that could grind cranks or do a good job grinding cranks, so they just replaced with new. Not everyone of us had access to good "local" machine shops. |

Posted By: tbran

Date Posted: 23 Nov 2023 at 6:22pm

|

my E or EIII is 17-70771- Z I think ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 23 Nov 2023 at 8:13pm

| Should be an E-3 I think with Z code 8.0 to 1 compression +4 HP. |

Posted By: Les Kerf

Date Posted: 24 Nov 2023 at 5:34am

|

Just curious: how deep did the Tufftriding affect the material of the crankshaft? Would a -0.010" regrind remove all of the hardening? |

Posted By: IBWD MIke

Date Posted: 24 Nov 2023 at 5:38am

|

Les, my guess is that a .010" regrind would remove the treatment. Now, a freshly ground crank should be good for 4000 hours or more. Who is going to put enough hours on one to wear it out in this day and age? |

Posted By: DrAllis

Date Posted: 24 Nov 2023 at 5:41am

| First grind and it was gone. Only .002" to .003" thick I was told by a crank grinder Tech. It was a step forward from softer gasoline crankshafts, but not as deeply hard as a modern turbocharged diesel crankshaft. Process was somehow using liquid Nitrogen aimed at each journal (as it was rotated) which is minus -320 degrees F. EDIT: To clarify a bit. The first .002" or .003" was harder to resist wear and run more hours without wear. Once re-ground undersized it was gone and you were down to the wear properties of a non-nitrided crank. Still good and strong, just not as wear resist as the nitrided surface. For many owners, when time for the first OH came ( usually 3,500 to 4,000 hrs on a working gas tractor) that tractor didn't see many more hard use hours and had been retired to a "second" tractor doing lighter work. Crank wear was reduced because of less hours of hard work. |

Posted By: Les Kerf

Date Posted: 24 Nov 2023 at 7:13am

Not I, that's for sure!  The last sawmill I worked for had a Caterpillar 980 wheel loader that had a documented 45,000 hours on it; 15k new, 15k on first in-frame, 15k on second in-frame, then the engine was pulled for an out-of-frame major overhaul. The crankshaft was standard and still did not need ground. The Cat tech said that was not uncommon. These machines were meticulously maintained with regular used oil analysis, ran 16 hours per day 80 hours per week sorting and feeding logs to the mill. Tough machine!

|

Posted By: IBWD MIke

Date Posted: 24 Nov 2023 at 8:22am

|

My WD Grandpa bought new has never had the head off, let alone an overhaul! That's to the best of anyone's memory and most of those people are gone now. Grandpa never worked machines hard as I remember. He did try to wear out the cultivator however. It does not carry much for oil pressure now though I would really hate to tear into it and ruin the originality. It would be interesting to put a mic on the rod journals and see what they measure. I have a crank out of a WD that is standard but would need ground .020" to clean up, .010" wouldn't do it. |

Posted By: orangeman

Date Posted: 24 Nov 2023 at 9:34am

|

Dr. Allis: I was not aware that a non labeled engine serial number block was a replacement block. I was thinking that there would be some lettering or labeling that would denote that the block was a replacement block. I have seen Kohler engines with a stamped tag stating that the engine or block was a replacement block. As always, I appreciate the insights. ~ Respectfully, Orangeman

|

Posted By: Macon Rounds

Date Posted: 24 Nov 2023 at 1:53pm

|

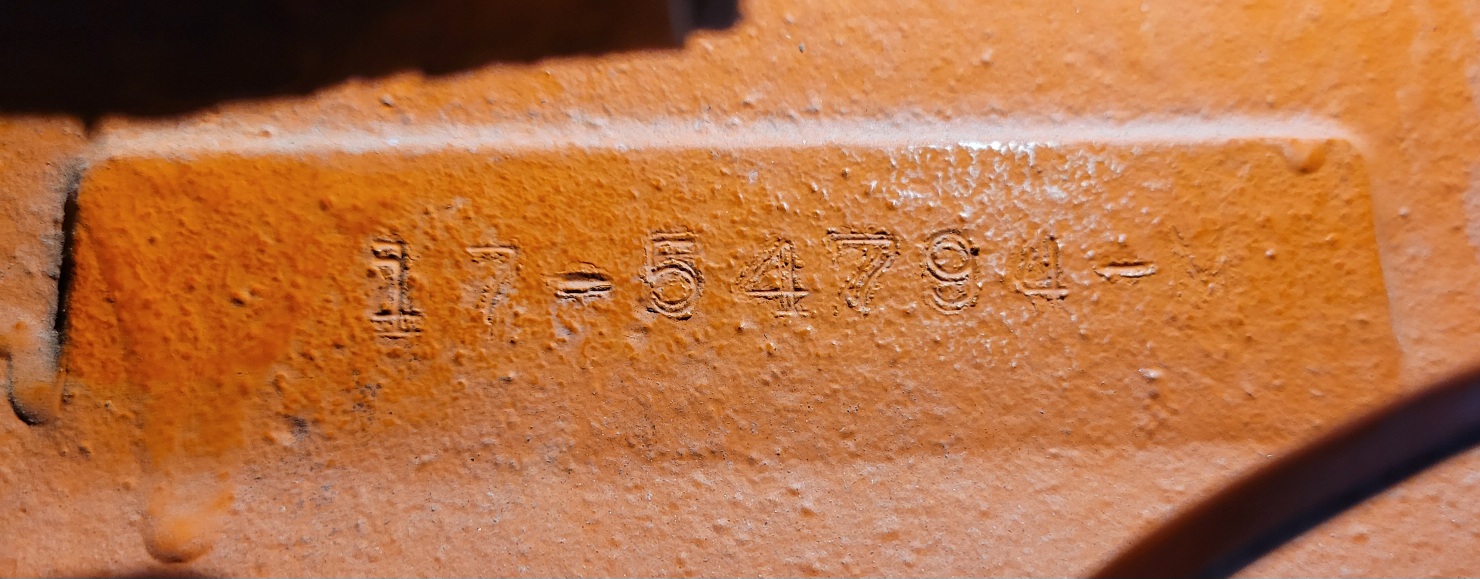

Here is a friend of mines D17 IV. Looks like a "v" at the end of the serial number.   ------------- The Allis "D" Series Tractors, Gravely Walk behind Tractors, Cowboy Action Shooting !!!!!!! And Checkmate |

Posted By: VaAllis1990

Date Posted: 24 Nov 2023 at 2:58pm

|

D17 75670- 17-54044-M D17 84970- 17-70165-M D17 78207- 17-58309-M D17 77091- 17-56654-V D17 86353- 17-72366-M The V engine serial number is an LPG. The rest are gas. |

Posted By: DrAllis

Date Posted: 24 Nov 2023 at 5:02pm

| VaAllis 1990 is the winner so far at 17-54044 engine in Chassis 75670 versus Marlyn nwia with 17-56097 in chassis 76815. Look how a tractor build spread of 1145 versus 2053 engines built. I was sent the name of a guy in southern Minnesota that maybe still has D-17- 75077. Will try to contact this individual to see if it's is still around. Looks pretty safe to say engine number 17- 54000 and up surely has the better wear crankshaft in it. |

Posted By: Glenn (NJ)

Date Posted: 25 Nov 2023 at 7:56am

|

I'm Late posting but just got back to where I have my tractors. Chassis D17 80284 Engine 17 - 82560 - M

|

IBWD MIke wrote:

IBWD MIke wrote: