New operator/Type B throttle speed questions

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=198219

Printed Date: 30 Oct 2025 at 4:17pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: New operator/Type B throttle speed questions

Posted By: resurrection20

Subject: New operator/Type B throttle speed questions

Date Posted: 14 Nov 2023 at 12:56pm

|

Hi all, I just got my first tractor, a 1946 Type B with a sickle bar mower, to do some brush control (mostly bramble thickets the horses won't eat) on a small horse pasture. I had a few operation questions after reading the official paper dealership manual as well as the military TM9-782 manual. I searched around quite a bit on DuckDuckGo and Google, but I haven't found anyone with such basic questions as I have. Apologies if they are answered somewhere else already. Oil type: The dealer manual says below 90 degrees to use SAE 20, but the military manual says SAE 30. I have 30 in it now because I went on tractordata.com and that's what it said— it seems reasonable because that's what my Willys calls for. Thoughts? Idling throttle speed: What throttle setting do people use at idle during warmup? The military manual says the 4th notch for starting, but offers no more advice. The dealership manual says during the break in period the tractor should "be operated at its rated RPM," which is "about three notches from the wide open position." But offers no more advice. Does it even matter? Driving throttle speed: Assuming that you're on a dry, straight well-graveled road with no major payload (in addition to the sickle bar mower, mine has a 100 gallon spray tank on the back, but it's empty), what do people like to use in each gear? Is three notches down a good all-around setting? Difficult terrain throttle speed: If you're in mud or on a hill or a very bumpy road, say, is it okay to putt-putt along in low throttle for a length of time? Implement throttle speed: The dealer manual says: "Operate engine at full throttle or nearly full throttle..." I don't want the poor old thing to bang apart. I'm assuming this is the same reason as not using overdrive when towing/hauling in a pickup: Lower RPMs equate to lower oil pressure and with a heavier-than-normal load on the engine, can cause a lot of extra wear on crankshaft bearings. And you have an easier time braking. It's better to be in high RPMs with better pressure, even if it generates more heat, kills your mileage, sounds scary, etc. Is it the same for tractors? Oh, and the pressure cap on the radiator is totally worthless. It steams after you park it and holds in zero pressure. It seems that 4 PSI is what 1942 and on Type B's use? The cap that's on it has no PSI rating. [Edit: But it IS still a pressure cap— just worn out.] I feel the need to apologize again for such an annoying post. But just remember, eventually the Andromeda Galaxy will collide with ours and if that doesn't destroy everything everywhere for everyone, our sun will explode after that, and nothing you or I or anyone has ever done in this solar system will matter.

|

Replies:

Posted By: steve(ill)

Date Posted: 14 Nov 2023 at 1:11pm

|

It is great that your interested, but your putting way too much effort and thought into this.. Engine oil is just like a car.. In 1945 your had 20w or 30 wt oil.... Today, you can stick with that or switch to 10w 30 and be good to go year round.. Winter and summer.. When you start up, it is a good idea to let the engine warm up for 30 seconds before GUNNING it wide open... I dont run the engines to max RPM most of the time.. Like you said, if you need 1000 rpm to get the job done, then do it. On the sickle mower, it seems to me that running the engine at 1500 rpm makes the mower run WAY TOO FAST.. YEP, i agree, its 75 years old.. Dont push it if you dont need it.. I run the motor about half speed - 900- 1000 rpm when i am using the sickle. Seems to cut fine and not flying apart.. Like you, i am not farming a wheat field for money.. Just mowing the road sides for maintenance.. If the mower works good at 300 RPM, no need to run 540... Late model Bs came with a pressure cap........... 4 psi is a good round number.

------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 14 Nov 2023 at 1:20pm

|

One thing you might want to consider sometime is oil change for the transmission/ differential .... and the final drive pans.. There are 3 of 1/2 inch pipe plugs under the transmission / bevel gear / pto housing.. Take out all 3 and you get about 8 quarts out. Dont be suprised if it is milky... they leak rain around the shift lever boot.... again, 20 wt is OK.. But most will use Universal Tractor fluid .... Trans / Hydraulic fluid ... etc.. The final drives are just a quart of gear lube in the bottom of the tin pan under the bull gear ( normally setting in the wheel rim... You take off 8-10 pan bolts and pull the pan off.. Will be full of BLACK/ CRUD / whatever....... wash everything out and reinstall with RTV wiped thin on the gasket.. You can probably use the old gasket or make one yourself.... Should be a pipe plug on the side of the pan.. shoot a quart of 80-90w gear lube in each side. ------------- Like them all, but love the "B"s. |

Posted By: DMac

Date Posted: 14 Nov 2023 at 9:14pm

| glad to see you got a b! Very durable little tractors. Steve’s advice is all good . Use a little judgement and you’ll be fine. If it lasted this long it must be tough . |

Posted By: resurrection20

Date Posted: 14 Nov 2023 at 11:05pm

|

Thank for the rapid response, my friend. Perhaps you are right and I should take my own chill out advice (last paragraph of my post). Maybe the reason I couldn't find any other information is because no one else is overthinking it so! I think I spend more time reading about than working on/driving cars. I have yet to go wide open throttle on this tractor and honestly, never planned to. From reading the manual it seems like you're supposed to let it warm up to 170 degrees before you even drive it. Speaking of the hand throttle notches: It won't run on the two lowest settings and farts pretty bad on the third. Fourth is okay, but it's kind of rough. It sounds reasonably smooth for its age on the fifth or six notches, when I've driven around, it's been on those. Do you have an aftermarket tachometer or do you just know your tractor that well? I've yet to actually test the sickle mower. It only seems to have one grease fitting and it seems like it's pretty low maintenance. The farmer I bought it from showed me how it works and it seems pretty simple (but dangerous). Maybe you could give me tips on maintenance or use of that if you have time? I tend to go very easy on equipment, which is why all of my old junkers still run. The way I would run this tractor would be to stay around half throttle most of the time, or where you get that nice, peaceful hum that engines get when they're in their happy place and only run it up if it starts bogging down. Basically, this farmer was retiring and this was his spray tractor. He had bigger and newer ones for field work. It's such a nice little tractor and it runs fairly well. I need it to mow a couple of acres a couple of times a year only. I'd just like to do right by it and keep it around.

|

Posted By: resurrection20

Date Posted: 14 Nov 2023 at 11:10pm

You are right, this is on my list of things to do. I didn't see any 20 WT for sale around here. I'm interested in this Universal Tractor Fluid, though... I appreciate the advice on final drives. I hadn't had time to think about that even yet. I was so stressed about the initial things. The milky transmission oil wouldn't surprise me. The crankcase oil was milky, but after two changes and a new filter, it's clean as a whistle. Thank you again for your advice!

|

Posted By: steve(ill)

Date Posted: 15 Nov 2023 at 8:10am

|

Tractor does not need to set and warm up to 170 degrees... That would be nice, but not practical... Same as you truck or lawn mower... Startup... Let it run 30 seconds to get oil and choke off, then GO.. Yes, dont RACE to full throttle... Just like your truck.. Motor should be about 1600 rpm ( some a little higher) for HIGH IDLE... So you can "GUESS" that a little over half speed is 1000 rpm... They will idle NICE at 500 -600 rpm.. YEs, you can make it run at 350- 400 rpm ( GUESS).. but nor really SMOOTH at that point. Most sickle mowers will have a long shaft from the rear pulley up to the mower area under the transmission / bell housing area.... There will be a big bearing at the rear and one at the front.. Should be a grease zerk for each on the TUBE, if you look close.. Next will be the rotating swivel socket that the wooden rod connects to... Should be a zerk on that bearing also... The other end is a ball socket and you should squirt or splash some oil on the ball, and along the blade / cutters prior to each use.. Engage the PTO and let the clutch out slowly and let the bar and cutters slide in and out a few revolutions to see that all is well, no binding... I use old oil drained from the truck as splash lube.. Do that and cut for 1-2 hours ... Lube again next time you use it.. If its old, the cutters are probably dull and will not do a great job, but you can test and see how things work.. No, you dont need a tack.. Just like your lawn mower.. Just be reasonable on your use. ------------- Like them all, but love the "B"s. |

Posted By: resurrection20

Date Posted: 16 Nov 2023 at 1:03pm

|

I have pretty good "going easy on stuff" judgement. If anything I tend to go too easy. So...a fluid like this is okay for all the transmission stuff? Nobody around here sells straight 20W. http://www.napaonline.com/en/p/NHF85401" rel="nofollow - http://www.napaonline.com/en/p/NHF85401 |

Posted By: resurrection20

Date Posted: 16 Nov 2023 at 1:24pm

|

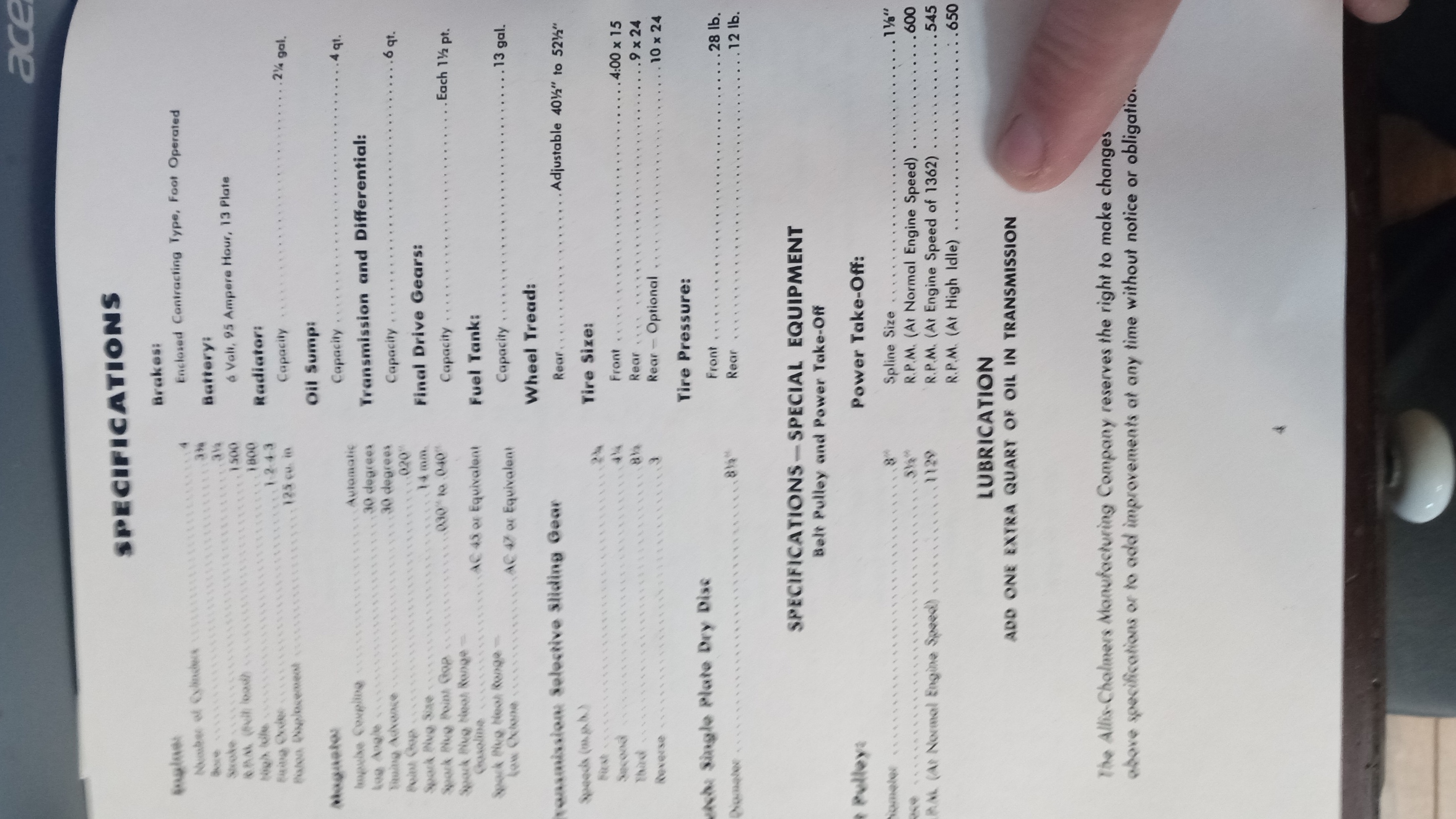

So, you're going to hate me for still overthinking...but it says to add one extra quart of oil to the transmission (where I'm pointing) in the dealer manual. I'm assuming that's only for using the PTO. The sickle mower uses it, I think, so how do you add an extra quart? The manual says to keep the transmission topped off to the drain plug. Obviously you can't add more because it'll just run back out. And apologies for the terrible cell phone photo. I dropped my phone in three feet of mud and it's never quite been the same.

|

Posted By: steve(ill)

Date Posted: 16 Nov 2023 at 1:28pm

|

Yes, that is fine... you might get a better deal on a 5 gallon bucket at the local Farm Store or Wal Mart... ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 16 Nov 2023 at 1:31pm

|

when you add HYDRAULICS to the tractor, you get a hydraulic pump / valve / cylinder... and that will take an extra quart.... EIther way, you fill the 1 inch pipe plug by your left foot to the bottom of the thread....

I think Wal Mart also sells 2.5 gallon ( 10 quart) jugs... if you dont want to have much left over setting around. ------------- Like them all, but love the "B"s. |

Posted By: resurrection20

Date Posted: 16 Nov 2023 at 1:38pm

|

Thanks, I won't worry about extra fluid, then. Damn...that is half the price of NAPA and significantly less than O'Reilly's (which is not surprising).

It doesn't say what viscosity it is. The NAPA one says 10w-20 and O'Reilly's brand is straight 30WT. Probably doesn't matter. Overthinking! It doesn't say what viscosity it is. The NAPA one says 10w-20 and O'Reilly's brand is straight 30WT. Probably doesn't matter. Overthinking! |

Posted By: steve(ill)

Date Posted: 16 Nov 2023 at 4:48pm

|

viscosity does not matter much in this application... Some os 20, some is 30, some is 10w30.... all OK.. ------------- Like them all, but love the "B"s. |

Posted By: resurrection20

Date Posted: 28 Dec 2023 at 11:04am

|

Sorry for the late reply. I have 18-month-old twins and it takes me a loooooong time to get to anything around here. I got the transmission fluid flushed out with the Wal-Mart brand. Engine oil. Coolant. I didn't have time to do the Final Drives properly. I topped them off with gear oil. They took about a quarter of a quart each. I actually managed to get out and do about an hour of mowing blackberries and pasture clearing. I did a week's worth of hand work in about an hour.

I did notice my sickle bar mower is pretty loud in one place in the middle and it's slightly curved down toward the skid thingy at the far end of it, causing a rubbing. There's a hole on the skid thingy, maybe, for a wheel? I looked at pictures online and didn't see any sickle mowers with wheels. It looks like the sickle bar is just bent from 78 years of mowing fields, not any sort of traumatic event. I'm wondering how big of a deal having a curved bar is, lol...and if anybody put a wheel on theirs? |

Posted By: steve(ill)

Date Posted: 28 Dec 2023 at 4:10pm

|

There is no wheel... The "skid" on the end rides over the ground or slightly above it.. The HOLE might be for a swath board of something that helps LAY DOWN the grass / wheat when your cutting crops. .... Should not be much of a CURVE in the bar.. probably got bent hitting something, or sometimes when you install new cutter , using rivets, and POUND on one side of the bar, it will BOW it... Long term, you could take it apart and bend back into position.. Also, putting a couple cups of used oil on the bar / slide prior to going to the field can help .. Sockets / balls on the ends should be greased or shoot some oil on them also.

Again, keep the engine speed just fast enough to CUT THE GRASS... Slower speed makes the mower arm speed slow down and can reduce the NOISE and VIBRATION... ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 28 Dec 2023 at 4:20pm

|

Here is a movie of a guy running his B sickle mower. Couple good shots of the bar and shoe..... At one spot is stopped the movie when he had a closeup of the throttle and the lever was basically straight UP.... so probably 900 - 1000 motor rpm on a 1600 rpm tractor.. the show starts about 45 second mark. https://www.youtube.com/watch?v=IB2rYv36x7E" rel="nofollow - https://www.youtube.com/watch?v=IB2rYv36x7E ------------- Like them all, but love the "B"s. |

Posted By: resurrection20

Date Posted: 29 Dec 2023 at 11:05pm

|

You're right, that is the swath bar hole. So, it's called a No. 5 Mower. The first video in that series has given me a whole new set of things to lay awake at night worrying about— but first I need to read that manual. I had no idea you could adjust the knife guides. It also looks like there's an adjustment for if the bar becomes concave. I realize all carbs are adjustable (and have varying levels of problems) and the throttle lever rod is adjustable, too, but mine won't run on one or two and idles very roughly on the third notch. Okay on four. Pretty good on five— though it sounds a little fast. I tend to drive around and mow on four or five Out of 12 notches, that's roughly 33-42 percent of maximum throttle (1,600), so...600-700 RPM? I'd actually prefer to run on 3...that'd be more like 500 RPM, I guess...but it can be a little sickly sounding and almost stalls a lot. I have a pretty technical field, I'm realizing, with a lot of obstacles and the grades are a lot steeper than I thought. I'm also finding that driving a tractor on anything but nice, flat land is rather terrifying. I wish there was a way to go slower or make the tractor creep along for safety reasons. At one point while mowing brambles I started to back up and the shoe on the end caught on a particularly big Himalayan blackberry root wad and the tractor turned sideways and the front wheels came off the ground. I slammed in the clutch and brake and eased it down. Scared the heck out of me and I've been pretty afraid of it since. I'm wondering if that's what bent my bar now that I think about it. I sort of assumed they were invincible.

|

Posted By: steve(ill)

Date Posted: 30 Dec 2023 at 7:49am

|

At one point while mowing brambles I started to back up and the shoe on the end caught on a particularly big Himalayan blackberry root wad and the tractor turned sideways and the front wheels came off the ground. I have had that happen also.. If your cutting wheat in a field you dont have that problem.. If your cutting a brush fields or road side, you can run into foreign obstacles....Like you said, its NORMAL, but you have to be aware of the possibility and quick on the clutch. I think your engine speed is OK... as you get more experience running the mower, it will seem less Scary.....Just dont get complacent. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 30 Dec 2023 at 7:55am

|

The guy in the movie has nice FLAT ground and cutting GRASS... Thats the easy stuff... Small brush / sticks / working on a slope , all are more of a challenge. I have thought about adding a side weight on the left side of the tractor to balance out the mower arm on the right.. Have not done that, but could be a benefit if the right side seems a bit tippy. ------------- Like them all, but love the "B"s. |

Posted By: resurrection20

Date Posted: 30 Dec 2023 at 11:56pm

|

I was thinking the same thing. His field looks pretty fun to mow. Sounds like you mostly mow roadsides and such? I was also thinking the same thing about adding a counterweight. I'm not sure how much the sickle bar actually imbalances the situation. I've toyed with getting front wheel weights just to keep more weight near the ground. They're a little pricey to order, but what's peace of mind worth... Speaking of weights...I got a rear flat today and lost all the calcium chloride in the tire. I'm going to have to take it to the nearest tire shop (Les Schwab's) and have them refill it. I'm kind of nervous they won't put the right amount in. That place isn't the greatest, but nobody else around wants to deal with agricultural equipment (that I know of). And another weird thought...when I was taking the rim off the rear wheel part (I guess that's what it's called) the rim got kind of funny shaped and jumped around a lot. It was egg-shaped for a second. I'm hoping maybe the rims just have a lot of flex in them... It seems weird to me that removing a wheel bolt and relieving tension would cause it to act so odd. The rim on the other side of the tractor is much newer. I'm wondering if I should just buy another rim. I'd hate for it to collapse or flex or do something weird and the whole thing tips over. Or for it to vibrate a bunch and kill my back. Thanks for your help and tips. It's made me feel a lot less alone and a lot better about my decision to buy an antique tractor. And it's fun to hear the things you have to say.

|

steve(ill) wrote:

steve(ill) wrote: