AC 175XTD is SOLD !!

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=196996

Printed Date: 09 Nov 2025 at 9:34am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: AC 175XTD is SOLD !!

Posted By: DrAllis

Subject: AC 175XTD is SOLD !!

Date Posted: 03 Sep 2023 at 7:11pm

|

Replies:

Posted By: captaindana

Date Posted: 03 Sep 2023 at 7:35pm

|

Can’t wait to hear….! ------------- Blue Skies and Tail Winds Dana |

Posted By: DrAllis

Date Posted: 03 Sep 2023 at 7:52pm

| The plan is to transplant this 95 flywheel HP Gleaner 4 cylinder 433-TI turbocharged engine into this 1974 model 175 gas chassis. It will have a new 12 inch foot clutch from a 100+ HP 7000 tractor. Injection pump will be freshened up. Brakes will be new. Seat suspension will be reconditioned and new seat cushions installed. This will make someone a pretty nice 67 HP (at 540 PTO speed) or 83 HP (at full throttle) modern and fuel efficient tractor. Hope to be done by early Spring. Stay tuned. Will be for sale as soon as it is completed. Thanks for watching. |

Posted By: DSeries4

Date Posted: 03 Sep 2023 at 8:12pm

|

Awesome! That will really wake up that 175! How are you going to run the hydraulic pump? That tractor has the front pump. Should be interesting to see! ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: DrAllis

Date Posted: 03 Sep 2023 at 8:22pm

| Front hydraulic pump under the radiator, yes. Just have to drill four holes in the crankshaft pulley to use the adapter from the gas engine. And, maybe the holes will already be there. Haven't got that far yet. |

Posted By: Don Jr NY

Date Posted: 04 Sep 2023 at 4:59am

| Hi Doc. I always wondered why they didn't do this instead of using the perkins engines in the 170 and 175 tractors. I'm not trying to be a pessamist or anything but shouldn't you use a 170 chassis instead of a 175? I only ask this because the 175 is the last gas model they built and according to Norm's bible there were only about 1009 gas models made. I would think that would make it a more collectable model than a 170 would be. I would like to add one to my collection someday but here on the east coast they seem to be scarce. Just my humble opinion and not meant as any criticism toward your project. Don Jr. |

Posted By: IBWD MIke

Date Posted: 04 Sep 2023 at 5:23am

|

Friend of mine has a D-17 with the 433 TI in it. Runs good! He also has a Farmall M with the same engine. |

Posted By: DrAllis

Date Posted: 04 Sep 2023 at 7:01am

| Finding any 170 or 175 seems to be a challenge these days, and for a reasonable price makes it even more difficult. This particular tractor badly needs an engine overhaul, so instead of spending $$$$ rebuilding the gas engine, why not resurrect it with a turbo-diesel transplant ? Also, to do an early 170/175 with the side hydraulic pump simply cannot be done, or if you got it done it wouldn't be nice. The power steering ram along the right front corner of the engine is in the way. The Perkins engine is shorter than the Allis engine making it possible. Also, the 175 tractors have 180/185 final drives, making it more rugged in the rear end if it gets used more heavily. Several reasons to use this tractor and the diesel engine install won't be a butcher job. It will look like it maybe could have been factory. The Harvey engine division had this 4 cylinder engine since 1964 (non-turbo) when they came out with the One-Ninety and in 1965 with the XT. Problem was, they never considered using a turbocharger on it until the late 1970's with the 78 model K2/F2 Gleaner combines. Without a turbo it was only 50 flywheel HP. Harvey needed to have 63 to 73 flywheel HP for a 170/175 tractor and without a turbo, that means 230 to 250 cubic inches instead of 200 cubes. They didn't allow for that many cubes in the engines design platform. |

Posted By: Tom59

Date Posted: 04 Sep 2023 at 8:12am

| Thanks for sharing your AC 175 tractor engine swap project. Look forward seeing it completed and pictures. Interesting story about the 433 engine and using a turbo on that engine to boost the horsepower, l really enjoy learning stuff like that, thanks for sharing. |

Posted By: IBWD MIke

Date Posted: 05 Sep 2023 at 7:39am

|

Doc, there seem to be a fair number that go through Colfax. Not too many 175 gas models but I see a diesel on the lot once in awhile and 170's seem more common. |

Posted By: captaindana

Date Posted: 05 Sep 2023 at 11:25am

|

Oh man this is going to be a thriller in the making !!! ------------- Blue Skies and Tail Winds Dana |

Posted By: coggonobrien

Date Posted: 11 Oct 2023 at 11:21am

|

Posted By: DrAllis

Date Posted: 11 Oct 2023 at 12:10pm

| Just some recent progress pictures. I'm using a maroon 7000 flywheel, pressure plate, and clutch disc assembly, which is 12 inches in diameter, instead of the original 11 inch clutch. To make this work, I have to space the engine forward, which requires a homemade spacer plate to go in between the engines backplate and the bell housing. The actual spacer dimension needed is 1.312" to 1.375" for the clutch shaft nose to connect to the pilot bearing. I have chosen to make my own relatively inexpensive spacer, by using two 1/2" thick engine backplates, sandwiching them together, and cutting them open in the center to slip over the flywheel and then attaching them to the backplate on the engine. To do this, I had to deepen the pilot bearing pocket into the flywheel .320", and move the throw out bearing and shifter rearward one full inch. This should work fine and won't cost much as compared to a custom made 1.375" thick plate with the center removed. Pics show all this I think except the T.O. bearing rework. In the lower right corner of the bellhousing is an alignment dowel hole that is never used on a gasoline powered D-17/170/175 tractor. I made a 1/2" diameter dowel pin to go in this hole and the engine backplates are already drilled to accept this dowel pin, which insures the engine and clutch shaft will be in perfect alignment. One 1/2" hole has to be drilled/tapped to clamp the engine to the bellhousing, but that was an easy job. Hope to have the engine and clutch assembled in a couple weeks. Picture of engine with 1 inch spacers to mock up what I wanted to do. Cardboard template shows how much has to be removed to fit over the flywheel. |

Posted By: AC7060IL

Date Posted: 11 Oct 2023 at 12:14pm

|

Thanks for sharing DrAllis & Coggonobrien. Nothing against the Perkins diesel, but IMO the AC 433 is how the One-Seventy & 175 diesels should have been built at Milwaukee's AC factory. |

Posted By: captaindana

Date Posted: 11 Oct 2023 at 2:16pm

|

Marvelous! ------------- Blue Skies and Tail Winds Dana |

Posted By: Jason n

Date Posted: 11 Oct 2023 at 8:34pm

| Is the original 175 radiator enough to cool the extra horsepower? I suppose so being that the new motor is less cubic inches |

Posted By: Ted J

Date Posted: 11 Oct 2023 at 11:11pm

|

Very interesting thread Doc. I'll be awaiting the next update. ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: DrAllis

Date Posted: 12 Oct 2023 at 5:51am

| As with any engine transplant that has more HP, the heat rejection capacity of the radiator could be challenged in some conditions. I intend on removing the intercooler on this engine to make things fit under the hood without modifications to the hood. This will help reduce the load on the radiator. I know in the 7000 tractor series days, the cooling systems were generally designed to maintain 100 degrees F over whatever the ambient temps of the day were. So, on a 100 degree F day, with the engine at 100% full rated load, one could expect to see 200 degrees F on the instrument panel temp gauge. I did actually dyno test my D-17 XT project tractor on an 80 to 85 degree summer day and at full load I saw 195 to 200 degrees temp at full load. That was with a clean radiator, tight fan belt and a properly positioned fan to move maximum air flow thru the radiator. I also had a Fall plow day with a 4 x 14's plow and the temps that day were in the low 40's when we started and probably near 50 degrees when we finished and had no issues whatsoever. So always remember the amibient temp makes the end result number. I'm not concerned about this 175 XTD cooling system keeping up for how the tractor should be used. I expect it to be just like the D-17 XT tractor with the same engine. |

Posted By: acken

Date Posted: 12 Oct 2023 at 8:40pm

| As usual your projects, and posts are very educational regardless of my own AC background. A few years back I spoke with an AGCO Service Tech about hydraulic oil temp concerns. He made the same comment about oil temp being acceptable at 100 degrees over ambient. |

Posted By: coggonobrien

Date Posted: 13 Nov 2023 at 8:04am

|

Posted By: DrAllis

Date Posted: 13 Nov 2023 at 8:15am

| Engine and clutch assembly are now installed. Trying to document this as I go, so anyone who might be thinking of doing the same thing can use this information. Using two OEM engine backplates made this a very inexpensive and accurately centered installation. I can't imagine what I would have spent having this 1 inch adapter made from scratch. I had to sink the pilot bearing into the flywheel a little deeper (.320" to .325") but that cost was minimal. The throwout bearing shifter was machined .900" farther back to move the throwout bearing away from the flywheel. Both of these procedures cost me less than $100 bucks. The lower right hand alignment dowel is just a 1/2" bolt shank driven in the existing hole. One 1/2" hole was drilled and tapped 1/2" x 13 NC into the bellhousing above the starter area, so there are four 1/2" bolts securing the engine to the tractor, plus the side frame bolts. The rearmost backplate is machined so if the tractor ever needs a foot clutch, a long dowel bolt can be used on each side to hold the back of the engine up while splitting it. Anyone could make this 1 inch adapter plate. I did have access to a plasma cutter, which allowed me (in about 3 minutes) to open up the centers of each adapter plate to go over the flywheel. All three plates are bolted and stitch welded together so they can't move. Now on to the injection pump OH and turbocharger reconfiguration !!! Then, a quick fire-up without a hydraulic pump or its drive and keep moving towards the finish line. I am going to have the fuel tank narrowed up about 2 inches front to back to get everything to fit with a 1000 CCA battery in the tray. |

Posted By: gleaner1

Date Posted: 13 Nov 2023 at 12:03pm

|

A gas 175 is way too rare to be butchered up. Heck most tractor books don’t even acknowledge there was even that model produced. ------------- ALLIS CHALMERS "The color is orange" |

Posted By: coggonobrien

Date Posted: 13 Nov 2023 at 12:20pm

| Outside of the fuel tank modification, there's been nothing done that can't be undone...... |

Posted By: DrAllis

Date Posted: 13 Nov 2023 at 12:34pm

| The gas engine in this tractor needs to be overhauled, as it uses oil badly. That would have cost me close to 3 grand when all finished, including the foot clutch. Each to his own, but 3K spent converting to this to an A-C turbo diesel is a very good upgrade. If you've never ran one of these engines, you don't know what you're missing. A couple of gallons less in the fuel tank (under the hood) is nothing with the fuel efficiency of the diesel powerplant. The gas engine is for sale if someone wants a running gas engine that uses oil. Make me an offer. |

Posted By: Pat the Plumber CIL

Date Posted: 13 Nov 2023 at 1:41pm

|

Thanks for posting this project Sometimes you have to dismantle, reconfigure something nice to make something even more special. I know there weren't a lot of these but I say carry on . Sounds like AC should have been using these engines in the 175s. Can't wait to see how it turns out. ------------- You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails 1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF. |

Posted By: DrAllis

Date Posted: 13 Nov 2023 at 2:06pm

| The only "butchering" might be a new hole in the hood for the exhaust pipe. And the only reason for that is there's a pre-cleaner stack on the right half of the hood and the OEM exhaust hole is on the left half. Makes sense to have the exhaust pipe in-line with the air cleaner stack for best visibility. I can make the exhaust come out the left side, but for now, don't think I'm going to do it that way. Nothing else is or will be butchered. The backplates to the engine are an engine part, not a chassis part. I've seen a real butcher job on a D-19 with one of these engines installed in it on the internet. It ain't pretty. |

Posted By: DSeries4

Date Posted: 13 Nov 2023 at 3:54pm

I would not be worried about ditching the gas engine for the 433. Yes,

175 gassers are rare, but that does not make them desirable. The 433

diesel is a beautiful engine to run and can generate far more power

while using much less fuel than the 226. The 226 is my favorite gas engine and they have their place in the WD45s and D17s. But in the mid 70s, diesel was the way to go. As others have said, Allis should have used the 433 in the 175 from the get go. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: AC7060IL

Date Posted: 13 Nov 2023 at 4:28pm

|

DrAllis, good thinking on the 3 engine plates. Thanks for sharing and please keep updating as it goes. How’s the song go? “Ya can’t always get what you want…….. But if ya try sometimes,,,, ya might just get what you need…….. Ooooh ooh oooh yeah!” |

Posted By: DrAllis

Date Posted: 13 Nov 2023 at 5:46pm

|

A little more info on grafting this engine into D-17's and D-19's for anyone contemplating doing so. If the donor chassis is any D-17 diesel, or any D-19, the flywheel from the D-262 or G-262 fits the 433-T or 433-TI engine crankshaft !! So, right off the bat, you are in business with flywheel and 11 inch clutch assemblies. When it comes to D-17 gassers and all 170/175 chassis (G or D), the clutch shaft is longer, approx 1 3/8" if I remember right. I was able to fudge this number down to an inch by moving the pilot bearing forward a little and using a different clutch disc on this 175 project. In my two engine swaps (D-17 III gas and now this 175) both had the long clutch shafts, but even they were different from each other !! The Pre series 4 gas clutch shaft has more spline length, allowing the clutch disc to slide on farther, which allows the engine to be made to fit flush to the bellhousing with no spacers, which in the end, helps you with the possibility of having hydrostatic power steering. A series-4 gas or early 170/175 chassis it will be impossible to do one of these 433 engine installs because of lack of room for the OEM power steering ram at the right front corner of the engine bay. If you're OK with manual steering, then have at it. The 175 I'm using is the later chassis with the front axle external steering ram cross-ways on the tie rod. A series 4 D-17 chassis and all 170/175 chassis use the larger diameter throwout bearing. This will then require the use of a maroon 7000 12 inch clutch disc and pressure plate and a 180 thru 7000 flywheel, like I'm doing on my 175. The trouble with any series 4 gas and all 170-175's is the 1 inch minimum spacer plate will be required to make this work. This is because the clutch shaft spline depth is shallow compared to pre series 4 models. On my series 3 gasser, I used a 180-200 flywheel and 12 inch clutch assembly which uses the smaller diameter throwout bearing and also required some grinding inside the bellhousing, but not a lot. Confused ?? That's why I've done this, to try and keep my mind straight on all the nuances between the different models. The power steering thing is a bugger on some of these. I cannot imagine manual steering with such a wonderful engine providing the power !!! |

Posted By: AC7060IL

Date Posted: 13 Nov 2023 at 6:06pm

| Good information. This thread should probably be transferred to the knowledge base section? |

Posted By: HudCo

Date Posted: 13 Nov 2023 at 6:22pm

| i am all for doing swaps , i am sure when its done it will look like it was meant to be there , also if the projects are done right you end up with somthing much better than when it was new |

Posted By: Michael V (NM)

Date Posted: 13 Nov 2023 at 7:33pm

|

I'm getting that the power steering is a big hold up on some of the older 17's, 170,175,,, so,, how about doing a steering setup similar to 7000-8000 series,, yea, more fab work,, but ya could rob the later gleaner combines of their orbit type steering and cylinder,,,,sooo.... maybe an option??

really like this project,, I'm watching and learning,

|

Posted By: DrAllis

Date Posted: 13 Nov 2023 at 9:57pm

| Power steering on D-17 III and older is not that bad to do. I've mounted a steering control orbitrol unit under the fuel tank (from a 170-200) and then connected it to an orbit motor that is connected to the manual worm steering gear in the front support. Works very well. The series 4 D-17 gas and older 170/175 won't let the engine sit flush to the bellhousing. So, that 1 inch spacer causes all kinds of power steering issues if you want to keep it looking relatively stock. On the later 170/175 they did have the power steering ram on the front axle tie rod, so there is no issue. The early/older 170/175's are not like that and have a steering cylinder that is horizontal to the engine at the right front corner of the engine, which there is no room for. Making a sideways steering cylinder connected to the tie rods would be a challenge the way the front axle is designed on the older 170/175's. |

Posted By: DSeries4

Date Posted: 15 Nov 2023 at 3:58pm

|

[QUOTE=Michael V (NM)]I'm getting that the power steering is a big hold up on some of the older 17's, 170,175,,, so,, how about doing a steering setup similar to 7000-8000 series,, yea, more fab work,, but ya could rob the later gleaner combines of their orbit type steering and cylinder,,,,sooo.... maybe an option??

really like this project,, I'm watching and learning, No steering issues on the 170/175. They are fully hydraulic, so there is no mechanical linkage to get in way of fitting another engine in the chassis. The D series are the problem children in that respect. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: JC-WI

Date Posted: 15 Nov 2023 at 6:22pm

|

D Series, That depends on which series your talking about, the earlier or the later... The later 170/175 had the cylinder on the tie rod which eliminated the cylinder along the frame. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: tbran

Date Posted: 15 Nov 2023 at 8:29pm

|

What about electric power steering add ons - started in Satun then many others. Now there are many universal power steering - or electrical assist kits on the market. https://www.summitracing.com/search/brand/epas-performance" rel="nofollow - https://www.summitracing.com/search/brand/epas-performance Saw one of there on a M Farmall I think years ago and it was neat and worked well - cept for the front end shimmy which didn't have anything to do with PS... Jus cut out a 4" section of steering rod and wa-la! ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: soggybottomboy

Date Posted: 15 Nov 2023 at 8:30pm

|

I have always wondered if the pto speed could be slowed down on the 175 tractor. The pto is turning 665 rpm at 2000 engine rpm and that is very fast. Could that be slowed down by putting in gears from a different AC tractor? The D19 also was rated at 2000 engine rpm and the pto was slower, 605 if i remember correctly. |

Posted By: DrAllis

Date Posted: 15 Nov 2023 at 8:45pm

| D-19 gearing will fit and work to slow the PTO about 10%. The negative is then, low side on the hand clutch is also 10% slower. |

Posted By: coggonobrien

Date Posted: 27 Nov 2023 at 10:51am

|

https://www.youtube.com/watch?v=ElYN5l1ocfg%20" rel="nofollow - https://www.youtube.com/watch?v=ElYN5l1ocfg

If somebody can remind me how to embed youtube videos I will update this. Thanks

|

Posted By: DSeries4

Date Posted: 27 Nov 2023 at 2:55pm

170/175s never had the steering cylinders along the frame. Early models had the cylinder built into the front casting. Later models had the external cylinder that runs parallel to the front axle. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: DrAllis

Date Posted: 27 Nov 2023 at 5:12pm

| All the One-Seventy's and 175's prior to 2053 (??) had a SIMILAR power steering cylinder (inside the right side frame) to a series IV D-17. It is smaller in diameter and moved forward as compared to the D-17 ( longer wheelbase). I'm guessing it butts up very close to the right front corner of the Perkins engine, but not past it. It does run alongside the oil pan on the G-226 gas engines. It is small enough in diameter and more forward to where you can pretty handily remove and replace the oil pan on a gas engine. D-17 moocho more difficult by comparison. It is this side mount cylinder that causes issues with the 433-TI swap, as the 433-TI engine is longer than a Perkins !! so I think there would be interference. Anyway, the later tractors do have the crossways ram on the tie rods making the engine swap to 433-TI easy. |

Posted By: HudCo

Date Posted: 27 Nov 2023 at 7:26pm

| dang that shop looks cold i am glad mine stays 62 |

Posted By: DrAllis

Date Posted: 27 Nov 2023 at 7:52pm

| It would have been 38 to 40 degrees that day, and if anyone knows how those little engines start, that was a pretty darn good first start with a fresh OH and bleed on the injection pump. Mine is 62 on SOME days !!! Out of the wind is huge for me. |

Posted By: injpumpEd

Date Posted: 28 Nov 2023 at 7:34am

|

Hey Dr, at least you aren't "homeless" anymore! lmfao!

Awesome project btw! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: orangeman

Date Posted: 29 Nov 2023 at 6:12pm

| Great Thread and Nice work! ~ Orangeman |

Posted By: DrAllis

Date Posted: 29 Nov 2023 at 8:26pm

| Got the valve cover off tonite, so I'll run the tappets and install a new valve cover gasket next. Hopefully by Saturday nite, I'll have the turbo mounted (backwards and raised one inch) and its oil lines fabbed up and the crossover air tube. I may be able to leave the intercooler after all, which would be kind of cool as long as I can squeak it under the hood lines. I'm also thinking the fuel tank will be OK fine as it is, but it will be a close fit with a 1000 CCA battery behind it. |

Posted By: captaindana

Date Posted: 29 Nov 2023 at 8:59pm

|

What a BEAST the Dr is forming in his laboratory! Incredible! ------------- Blue Skies and Tail Winds Dana |

Posted By: DrAllis

Date Posted: 03 Dec 2023 at 7:54am

|

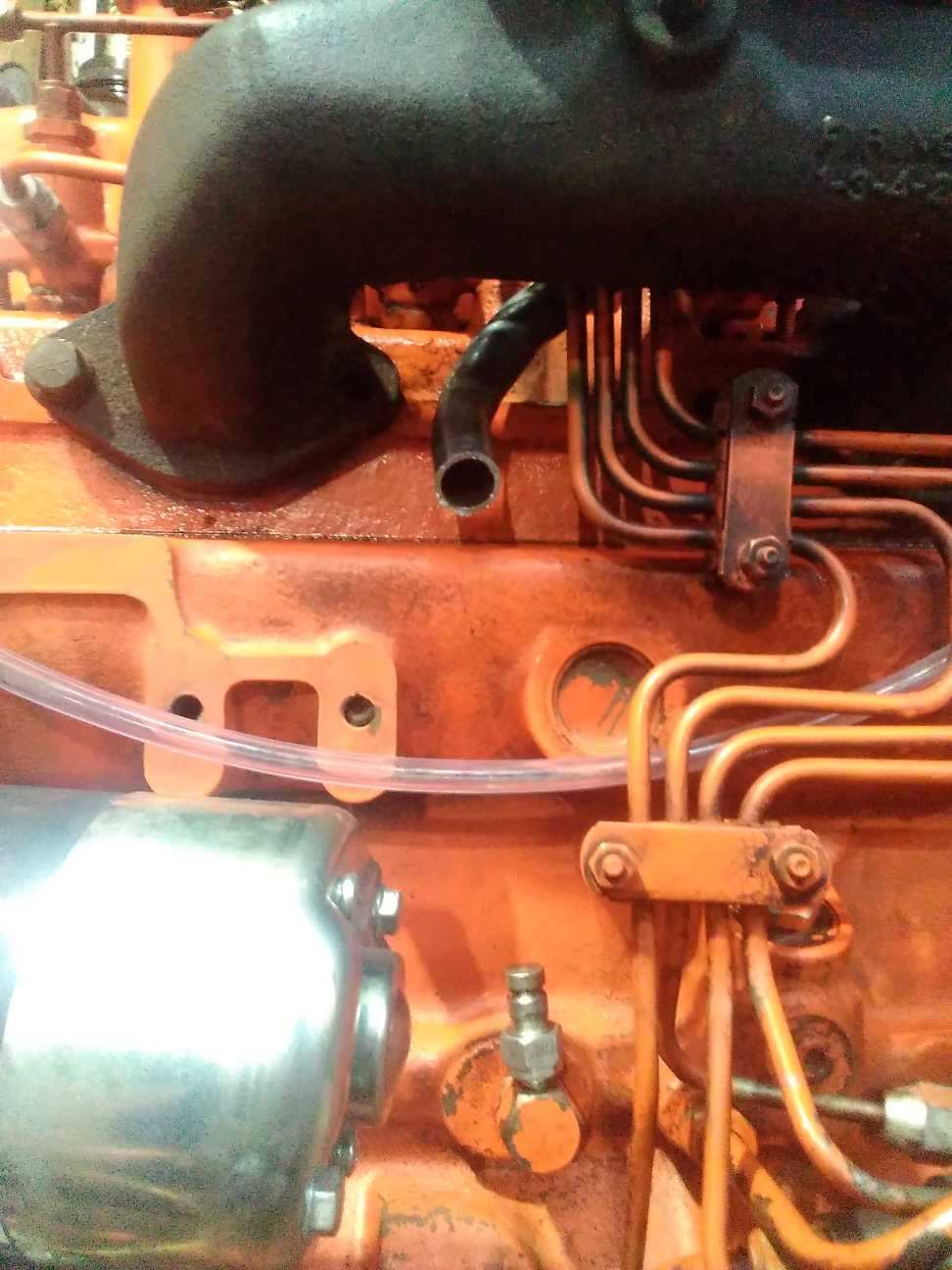

Posted By: DrAllis

Date Posted: 03 Dec 2023 at 8:25am

| Got a little more done yesterday. You can see the 3 inch offset in the turbo. Turning it around gets it inside the hood lines so no need to butcher the hood. Raising it up an inch is then needed to clear the injectors. The exhaust elbow I'll have to fabricate as this one comes out almost in the center of the hood, which is unacceptable. Intercooler gets to stay !! I can make room after all !! |

Posted By: captaindana

Date Posted: 03 Dec 2023 at 10:48am

|

Doc I can loan ya a couple shoehorns….. Awesome fitting! ------------- Blue Skies and Tail Winds Dana |

Posted By: SteveM C/IL

Date Posted: 03 Dec 2023 at 1:32pm

| would the later version manifold made the turbo fitting easier? It slopes away |

Posted By: DrAllis

Date Posted: 03 Dec 2023 at 1:53pm

| The 6000 series tractors are a different exhaust manifold that curl up and in towards the valve cover. Might work, but costs $$$$. Then, you have a perfectly good 45 year old 1978 turbo that you cannot, no way in he&& "clock" the center section to make it work with a different manifold. So, that would mean a different turbo to go with the different manifold. This works just as well and utilizes the parts that came on the engine with a little fabrication. |

Posted By: AC7060IL

Date Posted: 03 Dec 2023 at 3:55pm

|

Posted By: DrAllis

Date Posted: 03 Dec 2023 at 4:36pm

| Maybe, but it would be real close to the hood as it has a 2 1/4" offset to it the wrong way. 2 1/4" offset the other way would be near perfect !! I still like the idea of trying to align it with the pre-cleaner up ahead for best visibility. We'll see maybe the next trip to the farm when I make the turbo install permanent. |

Posted By: Ted J

Date Posted: 03 Dec 2023 at 4:59pm

|

Good Dr, this is a real learning experience for me! The pics are a big help, but I'd love to be there to watch you doing this. I've never had any Allis newer than a Series II D-17. ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: SteveM C/IL

Date Posted: 04 Dec 2023 at 9:10pm

| You are correct. I was thinking the other manifold leaned away. Black engine F2-3? had that manifold and turbo. |

Posted By: coggonobrien

Date Posted: 18 Dec 2023 at 8:50am

|

Posted By: DrAllis

Date Posted: 18 Dec 2023 at 9:08am

| Slowly coming around. Going to have to shorten the fuel tank a bit after all to make things fit correctly. |

Posted By: captaindana

Date Posted: 18 Dec 2023 at 9:59am

|

Well you got the exhaust snaked around nicely! ------------- Blue Skies and Tail Winds Dana |

Posted By: SLee(IA)

Date Posted: 18 Dec 2023 at 11:30am

|

DrAllis, I love watching your projects come together. It looks like the oil fill is on top of the valve cover. I'm not familiar with the 433 engines and i'm wondering if there is another place to add oil when the hood is on? The 301 has the filler on the side of the engine and I couldn't see another place to add oil in the pictures. Thanks Steve

|

Posted By: DrAllis

Date Posted: 18 Dec 2023 at 11:46am

| I'll have to change that to the side fill like a 185/200. The D-17 XT could remove the hood and use a small funnel, but this one I'll have to do differently, yes. |

Posted By: DrAllis

Date Posted: 16 May 2024 at 8:53pm

| If I have a good day this Saturday, the 175 XTD may go for a test drive. It's been a tough winter as I've had some health issues and am finally getting back on this project. Hope to drive it around this weekend !!! |

Posted By: captaindana

Date Posted: 17 May 2024 at 5:32am

|

🙏🙏🙏🙏🙏 ------------- Blue Skies and Tail Winds Dana |

Posted By: ACinSC

Date Posted: 17 May 2024 at 6:49am

| Hope Saturday is a very good day for you Dr Allis |

Posted By: plummerscarin

Date Posted: 17 May 2024 at 7:27am

| Good luck!! |

Posted By: coggonobrien

Date Posted: 21 May 2024 at 9:24am

| She's alive |

Posted By: coggonobrien

Date Posted: 03 Sep 2024 at 10:22am

|

The Dr. took the 175 xt to the tractor pull for an exhibition pull. 13:00minute mark https://youtu.be/TF2_E2syZpg?si=5N-Vd5uZPp-rrmUM" rel="nofollow - https://youtu.be/TF2_E2syZpg?si=5N-Vd5uZPp-rrmUM |

Posted By: DrAllis

Date Posted: 11 Sep 2024 at 7:49am

| Tractor now up for sale. Price is $7500 dollars. Look around the internet and you'll pay that much for many 175 diesels and some 170's. Hope to have this sale done by October 1st. Call or text 319-360-4788 or PM me here. New 1000 CCA battery..... near new brakes.....new 12 inch/100 HP foot clutch and everything related to the foot clutch.....new rear crank seal.....fresh OH injection pump.......new gear reduction starter........new water pump.....new fuel gauge sender...... new hydraulic oil and filter.....new transmission oil.......transmission and hand clutch all work fine and stay in gear going down hill......new custom made OEM looking seat cushions. No tire fluid. Rear rims are in excellent shape. This is a darn good tractor and will serve someone well for many years. Thanks for looking. |

Posted By: Mikez

Date Posted: 11 Sep 2024 at 8:03am

| Not to buy but wouldn’t mind seeing pictures |

Posted By: DrAllis

Date Posted: 11 Sep 2024 at 8:07am

| Have to see if my nephew can do that for us. The tractor pulling video is a good start. |

Posted By: coggonobrien

Date Posted: 11 Sep 2024 at 8:00pm

|

Final walk around https://youtu.be/DilMsUvrb18?si=R_3wZUIehG2LeahT" rel="nofollow - https://youtu.be/DilMsUvrb18?si=R_3wZUIehG2LeahT |

Posted By: DrAllis

Date Posted: 14 Sep 2024 at 5:04pm

| Went to another local tractor pull today and "courtesy hooked" in the 5500 lb farm stock class (weighing 5750 lbs) and drug the sled to a winning distance of 400+ feet, again with 16.9 x 28 rear tires !!! Will post a video as soon as I can. |

Posted By: victoryallis

Date Posted: 19 Sep 2024 at 5:18am

Had a 175 and have a 160 nothing wrong with the little Perkins. ------------- 8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760 |

Posted By: DrAllis

Date Posted: 01 Oct 2024 at 7:12pm

| Tractor is sold. Just trying up a few loose ends and maybe it will go to its new home this weekend. Thanks to all who took an interest in this project. I took it for spin down to the south farm last night and am so pleased with how it runs and drives. That little engine is really sweet !! |

Posted By: Jason n

Date Posted: 02 Oct 2024 at 8:28pm

| Now we're all wondering what your next project is going to be??? |

Posted By: DrAllis

Date Posted: 02 Oct 2024 at 10:41pm

| Good question. I've been thinking about grafting a 190/190XT complete "Console Control" onto a 180 or 185. I think that would be pretty cool to have the throttle and Power Director clutch levers located where your right hand would naturally fall on them. |

Posted By: injpumpEd

Date Posted: 03 Oct 2024 at 7:27am

|

That would be a cool project Dr, which there's plenty of 190's parted out. One other cool project I've always thought of doing is using a 7000 maroon chassis to build a live pto, 3 speed PS 190XT/200 style tractor. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: DrAllis

Date Posted: 03 Oct 2024 at 8:22am

| I've wanted to do one of those too, but that's probably not going to happen now. Someone (saw it on the internet) has already done that 190-200/7000 thing, but not quite the way I would have. I think it's been sold twice at auction. These "one of" projects are fun to do, but in the end, the profit is zero. And you give away 100 hrs (or more) of time to complete them it seems. |

Posted By: injpumpEd

Date Posted: 03 Oct 2024 at 12:00pm

|

another "project" I've dreamed about is a MM A4T1600 and put an AC 426, or 516 in it and put 220 sheet metal, would be a "what could have been" when AC was in talks with Moline about them supplying AC with the A4T for AC to market a 4wd. Big tractors are big problems though lol! I'll likely never do that one! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: 8070nc

Date Posted: 03 Oct 2024 at 2:29pm

|

Ive got a 25000 engine sitting on the floor in the shop. I thought about getting a 4w305 with a bad motor and putting it in it. What I need to do is quit thinking ------------- 1984 80780 1957 D14 DES 300 with 25000 engine 616 tractor |

Posted By: tbran

Date Posted: 03 Oct 2024 at 3:32pm

|

Basically the same - BUT this has been done before and the details of fabrication are time consuming. As long as one doesn't use all the lower RPM HP / torque it would be nice... go for it. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: tbran

Date Posted: 03 Oct 2024 at 3:51pm

|

I know what you mean Doc about detail time - I also ran into hundreds of issues when doing a swap like a L Gleaner 301 into a 190XT - got it down to the farm, hooked to a auger wagon and ran it - inline Simms was nice (had been turned up for a combine demo derby) . I checked the oil one day and , ruh ro, no side oil filler attachment. No problem, I said just put it in the valve cover - wrong - I had used the XT cover after adding initial oil.... trip to the salvage yard... ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: ToddnwIl

Date Posted: 03 Oct 2024 at 9:08pm

| I've always thought about sliding a 426 between the frame rails of a 200. Mostly for a light weight farm stock puller... but knowing us we would put it to work on the farm some! |

Posted By: injpumpEd

Date Posted: 04 Oct 2024 at 10:20am

|

Hey Todd, on the pulling section right now is an XT with a 426 for sale. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

gleaner1 wrote:

gleaner1 wrote: