185 pump removal Docs way

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=195995

Printed Date: 12 Nov 2025 at 3:13pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 185 pump removal Docs way

Posted By: captaindana

Subject: 185 pump removal Docs way

Date Posted: 03 Jul 2023 at 7:17pm

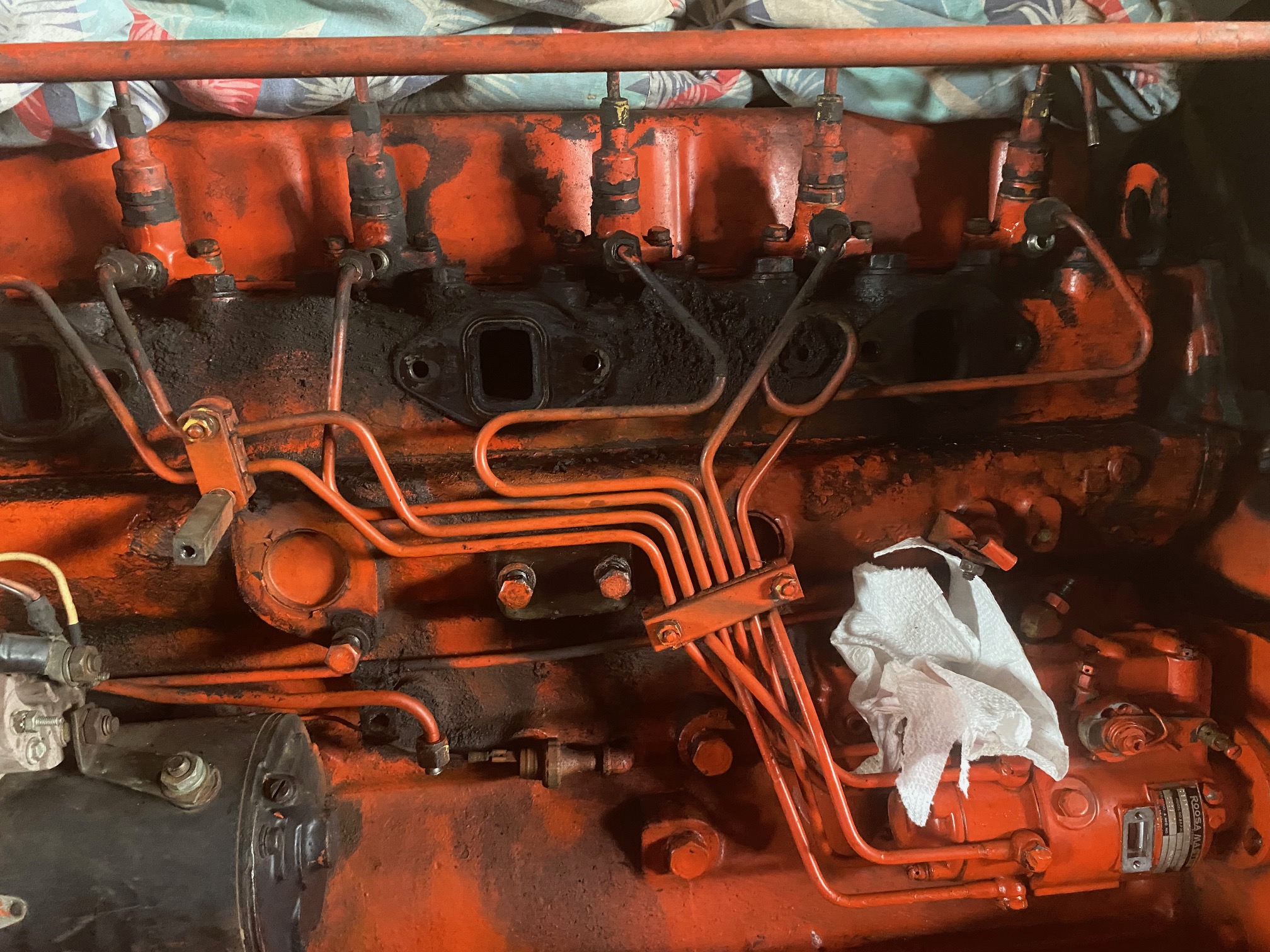

Thank the Lord for Dr Allis’ way for the 185’s injection pump removal! It’s a way better way Than tackling those banjo bolts. Plus…when I went to remove the exhaust manifold I was shocked that 5of the 6 anchor bolts were loose! I’ll have the lines in the window lined up perfectly when I pull the pump out in the morning. My question is….can I pull the pump with those lines lined up not knowing if I’m at #1 TDC??? Or do I need them lined up after proving I have #1 iat TDC? ?? Thanks. Dana   Gee maybe after a few more r&r’s I will be way more knowledgeable?    ------------- Blue Skies and Tail Winds Dana |

Replies:

Posted By: DrAllis

Date Posted: 03 Jul 2023 at 7:27pm

| You don't even need to align ANY timing marks. Scribe a line on the pump's mounting flange to the engine's front plate so you KNOW EXACTLY where the pump was positioned rotationally. Pull the pump back and off and make note of the driveshaft flat tang "DOT" and the "DOT" inside the pump's drive socket when you pull it off. Re-install the pump dot to dot and align your scribe mark and it is exactly timed where it was before. Leave all banjo bolts just snug and do the same to any line clamps. Get everything reconnected, leave one injector line started but loose and tighten everything else. Bleed and fire it up. Don't roll the first umbrella seal on the driveshaft!! Lots of light lube is your friend. Get the pump slid on and pull the pump back and forth a couple ot times, not letting the umbrella seal escape the tube. |

Posted By: captaindana

Date Posted: 03 Jul 2023 at 8:16pm

|

She’s scribed and thank you. I guess my confusion always starts here…the drive shaft is hooked to the gear drivers and can not be turned by fingers correct? So when my pump returns if the slot inside pump doesn’t exactly fit dot to dot I’d have to turn inside the pump so they’d fit together right? As usual my fear is if they are say 90* to each other which way I would turn the socket inside pump? I have r&r’d 3 pumps and it’s NEVER gone correctly. Those 3 turned into like 9!! Thanks for your expertise and patience. BTW Happy and SAFE 4th to you all. Dana ------------- Blue Skies and Tail Winds Dana |

Posted By: DrAllis

Date Posted: 03 Jul 2023 at 8:23pm

| Driveshaft on the engine cannot be turned. If the socket inside the pump isn't positioned correctly, stick a CLEAN large flat blade screwdriver carefully inside the hole and turn it where it needs to be. |

Posted By: captaindana

Date Posted: 04 Jul 2023 at 4:23am

|

Yaaaaayyy!!! I think I got it!!! Thanks Doc and safe holidays to all. ------------- Blue Skies and Tail Winds Dana |

Posted By: DougG

Date Posted: 04 Jul 2023 at 6:31am

| Capital Diesel in Holt Summit Mo can get you a tool to compress the umbrella seal to prevent rolling - comes in very handy - OR can get one off Ebay , Stanadyne Roosamaster injection pump shaft seal install tool kit 1337; little pricey on there @ 39 bucks , think i got mine for 13, but probably 12 years ago |

Posted By: captaindana

Date Posted: 04 Jul 2023 at 11:43am

|

Thanks Doug that’ll be handy! ------------- Blue Skies and Tail Winds Dana |

Posted By: DougG

Date Posted: 05 Jul 2023 at 5:14pm

| They are slick !! |