Dodge duellie?

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Shops, Barns, Varmints, and Trucks

Forum Description: anything you want to talk about except politics

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=194176

Printed Date: 21 Dec 2025 at 2:59am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Dodge duellie?

Posted By: Dave in PA

Subject: Dodge duellie?

Date Posted: 21 Mar 2023 at 3:48pm

|

Son has a 2009 or 2008 dodge dually with 4 door cab, 8' bed, etc. The question is here, before any repairs are done. He has a lug nut, between the rims, a inner wheel nut is rounded off, not good! I said to get a hole saw, no arbor, use garden hose, et. to shim it to the correct outer casting dia., drill the nut loose, chisel, and hope for the best???? I have not seen it, this just from what he told me. Any input will be appreciated. Thank You in advance! Opps forgot to say the does have a wheel spacer, not sure how wide. He did buy a new set of Bora ( sp. ) spacers just if neede.

|

Replies:

Posted By: DiyDave

Date Posted: 21 Mar 2023 at 5:51pm

|

Several types of goodies discussed and compared in this video: https://youtu.be/EWLxzuDMuhk" rel="nofollow - https://youtu.be/EWLxzuDMuhk Not discussed is what I used, a Torque multiplier, on my isuzu npr truck. And the nut wasn't rounded. And it's a big un, 40MM. Problem with duallie nuts is lack of space to work in, and its where 4-5 pieces of metal come together, so there is always corrosion there! https://youtu.be/ynyU2iJbg1o" rel="nofollow - https://youtu.be/ynyU2iJbg1o When you finally do get 'em free, never-seize is your friend! PS, Cremo's tools in York is where I got the TM...  ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: steve(ill)

Date Posted: 21 Mar 2023 at 6:43pm

|

I guess you are saying there is a SPACER block bolted to the ORIGINAL STUDS and then the duals bolt to the spacer block... The NUTS on the SPACER block are counter sunk and one is rounded off ?? I think i would center punch the nut between the stud and the outer flat.. then drill a 1/4 inch hole into the nut to make it thin on the threads and flat... then drive a punch into the hole and split the nut.. ------------- Like them all, but love the "B"s. |

Posted By: DMiller

Date Posted: 21 Mar 2023 at 6:48pm

|

WHY, just WHY would anyone of sound intelligence install spacers on a Dual Wheel Hub. Been a Mechanic since 75, Seen this More Than Once and every time is a Flaming Mess. Besides is excessively hard on Hub Bearings. Guys add spacers to install Wider Tires, just not good, Duals are fine as is OE Sizing.

|

Posted By: Ed (Ont)

Date Posted: 21 Mar 2023 at 7:43pm

| Stupidity reigns supreme in this country! Up here I see guys with their wheels offset 4-5 inches outside the body. Not sure what kind of stupidity that takes. Stress wheel bearings and have the whole entire vehicle covered with mud and road grit as well as all around you on a multi lane hi way. On a dually if you have anything other than stock configuration you are looking for major problems and a wheel off especially if carrying large loads. But who cares if you kill someone trying to look cool! |

Posted By: truckerfarmer

Date Posted: 21 Mar 2023 at 8:52pm

|

They make special sockets just for this. Most towing companies have them in their tool set for doing tire changes. Look like an inside out easy out. ------------- Looking at the past to see the future. '53 WD, '53 WD45, WD snap coupler field cultivator, #53 plow,'53 HD5B dozer Duct tape.... Can't fix stupidity. But will muffle the sound of it! |

Posted By: 200Tom1

Date Posted: 21 Mar 2023 at 11:38pm

| It sounds like has been a single rear wheel truck converted to a duallie. We did several while we owned the tire shop. Take the other 7 lug nuts off and everything may slide off. Good luck with it. |

Posted By: Tbone95

Date Posted: 22 Mar 2023 at 9:11am

And tires the size of o-rings on those chrome rims. Very useful on the farm.

|

Posted By: Dave in PA

Date Posted: 22 Mar 2023 at 1:46pm

| To clear the air here, yes, it is a factory dually. Dodge 4x4 or is that 2x4, 4x6? Front wheels can spin under power as well!!!! 4 door, 8' bed, diesel, with I believe the 6 speed manual tranny. The factory anti-stolen theft protection around here. No one can drive a standard tranny with a 3rd petal! He bought it with the wheel spacers installed, sorta the reason to get the wheel off!!!! And as far as stupidity, I am to believe it is everywhere, in every county. |

Posted By: steve(ill)

Date Posted: 22 Mar 2023 at 1:55pm

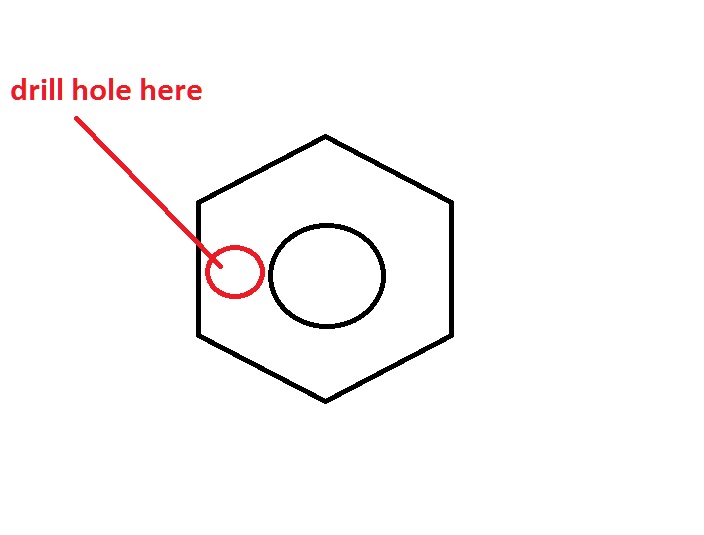

Dave, could you drill a hole in the nut between the stud and the flat .. and make it big enough to almost touch the thread and flat... then drive a punch or chisel in to spread it out ? ------------- Like them all, but love the "B"s. |

Posted By: Dirt Farmer

Date Posted: 23 Mar 2023 at 2:29am

| Could you get to it and beat a smaller metric socket on it if its SAE and using a long breaker bar get it loose that way. Worst case is if you decide to drill and you happen to hit the threads you need to replace the stud but might want to do that anyhow. Best of luck to ya. Just got to talk to it |

Posted By: jaybmiller

Date Posted: 23 Mar 2023 at 6:34am

|

? Is there any room to weld a nut onto the bolt, from the inside of the nut of course, let cool then 'burb' once, remove the *&%%&**** bolt ??? When removed, tie string to it and hang from rear view mirror with a note saying 'dad got this off for you' ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Ray54

Date Posted: 23 Mar 2023 at 10:44am

Jay your going the wrong  way as I understand way as I understand  it. But I have been wrong before. It is the nut they need off . You weld on the nut it expands like you want, but will cool quick, and be even tighter. So if the first try doesn't get it your now worse off. it. But I have been wrong before. It is the nut they need off . You weld on the nut it expands like you want, but will cool quick, and be even tighter. So if the first try doesn't get it your now worse off.Now broke off cap screws  I will weld flat washers and nuts on all day before drilling them anymore. Because each time you weld and heat the broken part it expands and then cooling contracts it breaking the rust bond. Thing like cast iron radiator tanks I have had to weld 6 or 8 nuts on the worst. BUT THEY ALL CAME OUT and the threads were still good. I will weld flat washers and nuts on all day before drilling them anymore. Because each time you weld and heat the broken part it expands and then cooling contracts it breaking the rust bond. Thing like cast iron radiator tanks I have had to weld 6 or 8 nuts on the worst. BUT THEY ALL CAME OUT and the threads were still good.And Steve were have you been my whole life. That sound good to drill and expand the hole. I have been involved with using a chisel to cut a nut. But why has no one I work with know of drilling to weaken the nut. Again never to old to learn. |

Posted By: jaybmiller

Date Posted: 23 Mar 2023 at 11:43am

|

hmm, maybe after it cools, you can reheat and then 'burp' it off ? a picture would be nice, just to SEE worst case ...'torch' the nut and stud,yank off spacer, replace stud ?? a good cold chisel will destroy the nut for sure, and mangle the stud.... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dakota Dave

Date Posted: 24 Mar 2023 at 8:47am

| Just go to the store and buy a locking lug nut removal tool. It looks like a socket the inside is a left handed cone shaped thread. Put it on the rounded nut and hit it with your impact it will screw its self down on the nut till it takes the nut off you must use an impact. To get the nut out you'll need to clamp it in the vise or put it on a stud in the vise and impact it back off they come in several sizes. Our Oriellys had them instock I think it was $20 makes taking a mangled nut off into a 20 sec job. It will mangle the nut. I've use mine a couple times and don't know how I got along without it. The first time I used it I had a rough time trying to take the nut out. The only way is hold it and impact in tighten moved and it'll screw it self off so fast. |

Posted By: jaybmiller

Date Posted: 24 Mar 2023 at 9:17am

|

I'm really wanting to see a picture of 'sucess'..... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: dawntreader74

Date Posted: 24 Mar 2023 at 10:37pm

| cut one side of nut off with a cut off wheel' will come wright off; did one the other day on a bad trailer stud. |

Posted By: jaybmiller

Date Posted: 25 Mar 2023 at 6:22am

|

I think the real PITA part is that the nut is recessed into the wheel spacer, limits what options one has to get the &^^$^%&(& nut off If (IF ) you've got good drill bits., could drill holes in 2 adjacent points of the nut, then use a sharp chisel to break off that section of nut, that should free up some space to chisel off 2 more 'flats' ? ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Ed (Ont) wrote:

Ed (Ont) wrote: