7010 - Steering Issue

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=193506

Printed Date: 18 Jan 2026 at 2:09pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 7010 - Steering Issue

Posted By: calico190xt68

Subject: 7010 - Steering Issue

Date Posted: 14 Feb 2023 at 10:46am

|

With the good weather over the weekend, I started doing all kinds of tractor stuff. I decided to fire up my 7010 and do some chores. The steering has become quite difficult. I looking for guidance on debugging the issue. The steering was fine when I parked it this past fall from what I remember so this is a mystery why sitting for several months would create this issue. I see Hydraulic fluid in the lower site glass on the back so it has fluid. It was almost 55 degrees so it wasn't that cold. I also worked it for about 30 minutes. Looking at the parts diagram, I have the Orbitrol, the hydraulic pump and the cylinder as culprits. I was able to lift my 3pt disc mower without issue and use the valves to hydraulically raise and lower the mower arm, so I conclude that my hydraulic pump is not the issue but could it be weak? I have to rev the engine all the way up though to get it to steer which might indicate a weak pump. I did not have to reve the engine to get the valve and rear lift to work. The wheels sometimes did not want to turn left or right, so it was hard to steer into intended direction. I did hear some squelching as I tried to turn the wheel sometimes. At this stage, it would not be safe in road gear or maybe any gear for that matter. I know that my 190XT had the orbitrol replaced at one point before my ownership but I do not know the symptoms of a bad orbitrol. I haven't changed the hydraulic filter yet this upcoming season and was going to do that as a first step. I would think a blocked hydro pump though would cause the valves to not work nor would it pickup the mower. Any ideas greatly appreciated! I also just realized there may be 2 pumps on the 7010. If so, that is why rear lift works. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Replies:

Posted By: tbran

Date Posted: 14 Feb 2023 at 5:23pm

|

The flow divider in the gear pump is stuck. 70265404 - look it up agcopartsbooks.com There is a plug on top and bottom - just remember how the spool, orfice, shims and spring comes out. https://na.epsilon1.agcocorp.com/p/agcoallis/79005649/l/258?keyfield=655c0ccb17f1355b3cb22340ffc7949e" rel="nofollow - https://na.epsilon1.agcocorp.com/p/agcoallis/79005649/l/258?keyfield=655c0ccb17f1355b3cb22340ffc7949e https://parts.agcocorp.com/en_US/apbsearch?q=agcoallis/79005649/l&name=7010+TRACTOR" rel="nofollow - https://parts.agcocorp.com/en_US/apbsearch?q=agcoallis/79005649/l&name=7010+TRACTOR ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: calico190xt68

Date Posted: 14 Feb 2023 at 5:52pm

|

tbran, thank you for getting me going in a direction. After original posting, I looked closer at the situation and realized that the middle part of the pump handled the steering, hence the name "dual" pump. This is the most likely cause based upon it's behavior. I looked at the parts diagram and I see the two plugs top and bottom and the various parts used. It also shows the order for the various parts. I need a clarification though. If I take it apart, don't I need new parts? Or are you saying that by taking it apart and putting it back together, it will become unstuck? Can I get the parts? I assume you have to take both plugs out on the top and bottom to get the parts out? Is there any trick to get the parts out if they are stuck. Can I leave it on the tractor or does it need to be de-installed. Sorry for all of the questions but this is new territory for me. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: CrestonM

Date Posted: 14 Feb 2023 at 5:53pm

| I’ve had this problem in my 7080 for several years, and I’m curious what you find the solution to be. I replaced all three pumps in my tractor with ones from a salvage unit. The issue I had with my remotes didn’t work. Swapping pumps fixed that, and steering improved slightly, but not enough to be a comfortable steering tractor. |

Posted By: MACK

Date Posted: 14 Feb 2023 at 8:36pm

| Can all be taken out from bottom plug. Keep track of how and order parts come out. Polish spool to where it slides free. Check for any foreign material. MACK |

Posted By: youngorange2000

Date Posted: 14 Feb 2023 at 9:37pm

| I have had to clean the flow devider on my 190xt once turns out it was a small piece of junk blocking a hole not much bigger then a pencil lead |

Posted By: victoryallis

Date Posted: 15 Feb 2023 at 5:07am

BTDT done my 8050 it’s not perfect but helped a lot. ------------- 8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760 |

Posted By: calico190xt68

Date Posted: 15 Feb 2023 at 7:50am

|

OK. This has become much clearer in what I have to do so thanks Mack and everyone else. Here are remaining questions from me before I start. Is it best to leave the pump on the tractor? Do I need to be ready for parts to drop out of the bottom when I remove the plug or can I take them out one at a time? Do I get a rush of hydraulic oil once the plug is removed pushing parts out at the same time? Once everything is removed, do I need to pump air into it to clean out foreign material or something else? Does this process create an air pocket that needs to be cleared? When I get the spool out, I may have some further questions on polishing. I have to finish my 500 loader cylinder rebuilds before I tackle this so it may be a few weeks before I can report back unless I prioritize this first. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: Lynn Marshall

Date Posted: 15 Feb 2023 at 8:41am

|

|

Posted By: victoryallis

Date Posted: 15 Feb 2023 at 9:15am

|

To polish mine I took a 3/8 or 1/2 wood dowel about 8 inches long and cut a slot in one end about as deep as a ribbon of Emory cloth is wide. Fed the Emory cloth threw the slot and put it in a drill and polished the barrel. ------------- 8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760 |

Posted By: calico190xt68

Date Posted: 15 Feb 2023 at 11:03am

Nice tip. So you were polishing only the inside of the barrel and not the outside of the barrel? ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 15 Feb 2023 at 11:05am

|

Thanks Lynn for the pic. I am wondering if the shim and one of the washers are optional from the parts diagram. Looks like the top portion of the parts did not come out of the pump. I only see the bottom portions of parts. Still curious if the pump stays on the tractor or not when this is done. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: victoryallis

Date Posted: 15 Feb 2023 at 11:59am

Polish the surface that the left most piece in Lynn’s picture travels against. ------------- 8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760 |

Posted By: calico190xt68

Date Posted: 15 Feb 2023 at 1:13pm

|

Isn't that the inside of the pump housing then? ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: Lynn Marshall

Date Posted: 15 Feb 2023 at 1:19pm

| Leave the pump on the tractor. No need to remove the top cap. The orifice disc with the small hole can get restricted and cause problems. The spool should slide in and out of the bore easily. Polish both surfaces the best you can and flush the bore before reassembly. You may have to devise something to pull the spool out if it is stuck. I would also be checking the left hand filter and screen to be sure that they're good. |

Posted By: calico190xt68

Date Posted: 15 Feb 2023 at 1:28pm

Thanks Lynn for that detailed explanation. It sounds like my problem should be obvious once I disassemble. I might tackle it this weekend since it may not take that much time to do. I will report back my findings. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: victoryallis

Date Posted: 15 Feb 2023 at 1:29pm

|

I never got lucky enough to be able to leave the top cap on. For me that spool was firmly stuck. ------------- 8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760 |

Posted By: Play Farmer

Date Posted: 15 Feb 2023 at 1:49pm

| For the cost of a seal kit I'd be looking at the steering cylinder too. Much of what you described is what my 7000 was doing. Although that is a different hydraulic pump fixing the cylinder fixed my issue. |

Posted By: youngorange2000

Date Posted: 15 Feb 2023 at 2:40pm

| +1 on resealing cylinder. Brought mine to a highly regarded hydraulic shop and the owner was too rude to me to earn my buissniss instead bought the agco seal kit for $80 and did it myself in a half an hour so far it's been 3 years with no leaks |

Posted By: calico190xt68

Date Posted: 15 Feb 2023 at 3:14pm

|

I think there is a bit of leak on the cylinder and I am getting ready to do my 500 loader cylinders myself so I might be warmed up to do that cylinder too. I bet it comes apart differently though since it is a bit more modern. I would like to do one at a time though to see what my issue really is. I am anticipating finding two things: either a clogged washer or a stuck spool. We will see when I dig into it. Thanks guys for the input! ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: MACK

Date Posted: 15 Feb 2023 at 8:42pm

| I use a big easyout to get spool out if it is stuck. MACK |

Posted By: calico190xt68

Date Posted: 16 Feb 2023 at 8:41am

I was thinking I could take the top cap off and use a punch to drive it out of the bottom if it was stuck but your idea is a little less obtrusive. This all has me wondering why does the spool get stuck? Are parts disintegrating that causes a build up? Do I need to change the hydraulic filter more often? Do I need to get an Agco filter as it might be better? ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: plummerscarin

Date Posted: 16 Feb 2023 at 9:23am

| A change to a AGCO filter fixed my steering issues on the 7040 |

Posted By: calico190xt68

Date Posted: 16 Feb 2023 at 12:43pm

After I get done fixing this, I think I will get an Agco filter as a safety precaution. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: bigal121892

Date Posted: 16 Feb 2023 at 4:10pm

|

Polish it up, it should slide very freely. If it acts up again, within the next 100 hours, then you want to be concerned, and start looking else where for the problem, because at that point the flow divider is now the symptom. |

Posted By: calico190xt68

Date Posted: 17 Feb 2023 at 9:25am

|

Nevermind - I found my manuals. I hate to ask this but could anyone post the section in the service manual on replacing the hydraulic filters? I believe a 7010, 7020 and 7045 are the same. I have misplaced my $160 service manual and don't want to buy another one until I have exhausted all of the places left to look. Seems there are specific steps on replacing that I need to take. I also wonder if there is a section about the spool replacement that might be handy. Thanks in advance. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: SteveM C/IL

Date Posted: 17 Feb 2023 at 8:33pm

| AGCO filters I put in 8070 had papers with drawings of what went where. Not too complex. |

Posted By: plummerscarin

Date Posted: 17 Feb 2023 at 8:44pm

| Ditto what Steve said. Instructions came with the filters I put in 7040 |

Posted By: CrestonM

Date Posted: 28 Feb 2023 at 10:11am

| Did you end up getting a chance to work on this yet? Curious what you found. |

Posted By: calico190xt68

Date Posted: 28 Feb 2023 at 11:33am

|

Not yet. I was working on my 190xt this past weekend. I hope to tackle it this weekend though and will definitely report back on what I find. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 05 Mar 2023 at 9:18am

|

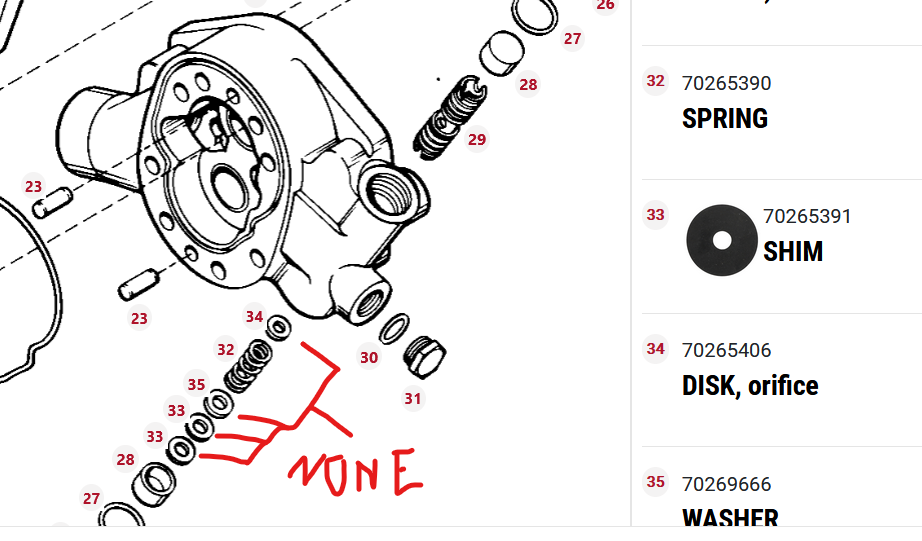

I took the skid plate off and then got a 1 1/4 inch socket on the

lower plug. I don't see how you would get to the upper plug with the

pump still on the tractor. After removing the plug the lower cap and

the spring fell out. The spool did not fall out but it didn't take a

lot of twisting via the the two slots at the end of the spool to get it

to come out. There was no resistance which makes me think it wasn't

really stuck. The spring does not appear to be broken. However, I went back and looked at parts diagram and the

shims and washer have not fallen out. I took a picture after the spool

came out. I don't see anything left in there. I dug around and found nothing. I

show the parts diagram and the parts I haven't found yet however I did find the disk orifice but I can't tell the difference from a shim or a washer? Since it fell out, I am not sure of it's order, but I think it was on the bottom so it may be a shim. If so, where is the disk orifiice? Shims may be optional? I thought I would

hesitate to get comments as well before proceeding. All I can do is put it back together again unless the washer and shims are necessary. The spool certainly

doesn't seem to have burrs and baby butt smooth. I haven't dealt with

the inside yet to see if it needs smoothing. My current guess is that

maybe the washer or shims have gotten stuck up inside there. The long side of the spool appeared to be pointing down in case that matters. But, someone would have to have installed it wrong a long time ago. Here are pictures in case anyone can shed some light on what I am seeing now. Any insight is appreciated: After spool is out:  Parts that came out so far plus the disk orifice. I found it in the pan later:  Here is the parts diagram. and the parts I haven't found yet but may still be in there.  ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 05 Mar 2023 at 9:54am

|

I felt like I needed to add more clarity and identify if this is a shim or a disk orifice. It fits perfectly inside the spool so I think it is a disk orifice. That means I am missing shim and washer potentially. I can call Agco and see if they have these parts. Not sure about availability though. Here it is:  ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: Lynn Marshall

Date Posted: 05 Mar 2023 at 12:18pm

| I think that you have everything. Reassemble it like my picture from earlier shows. Short side of spool up and long side down. Orifice disc goes in the long side followed by the spring. Then the cap and nut. I think that your shims are still stuck in the cap, I can see the hole in the shim stack. |

Posted By: calico190xt68

Date Posted: 05 Mar 2023 at 2:33pm

Lynn, you were right. A single washer was in the cap. No shims though as in your picture. I reassembled, long side down and put it all back and tractor steers just great now! While I didn't see anything in the orifice when it dropped out into the bucket, it might have been in there. I think the blockage has been there for awhile because I think in the fall it got a little harder to steer but not like it got after sitting over the winter. Regardless, it is nice to have a fix and buy no parts! Thanks for everyone's assistance and help. Now, I have to get that skid plate back on. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: CrestonM

Date Posted: 24 Mar 2023 at 8:02pm

| I’m doing the same thing to my tractor, I finally got the spool out, after removing the top plug and punching it out from the bottom. A whole bunch of metal chips came out when I pulled the bottom plug and some more came out with the spool. The spool itself doesn’t look like it’s in bad shape, I think these metal chips where what was making a stick. Are these chips most likely gear pump teeth? |

Posted By: calico190xt68

Date Posted: 25 Mar 2023 at 10:43am

|

I am a newbie on working on Allis equipment but metal chips don't sound good. I saw none of that when I took mine apart. I also didn't have to take the top plug out and do any punching. After removing the bottom plug everything fell out. That orifice hole isn't very big so I imagine the chips were obstructing it. I don't know about fixing just the gear pump. Probably depends how bad. I know a rebuilt replacement hydraulic pump was about $1,800 when I priced it last month. There isn't a lot of room at the top to get that punch in there so not sure how you did that without removing the pump. My guess is that I had something other than metal in mine. Do you have a washer or two as well? Those didn't get chewed up by any chance? I don't think there is any harm in putting it back together and see if the steering is better or good enough to avoid a replacement pump for awhile. If you put the spool back in and you can't push it up and down without much resistance, you still have something wrong. It slid up and down easy for me. I wish you luck and hope you don't have to replace it. ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: CrestonM

Date Posted: 27 Mar 2023 at 9:26pm

|

Yes, I have those two spacer washers in the bottom plug. I will clean it up and put it back together and see how it steers, I hope it’s an improvement, but I’m really concerned about the gear teeth. I can’t figure out how they would get so chewed up, I don’t think that is a very typical failure. The way I got the top plug out, was using a wrench to get it loose, then carefully using my fingers to get to it, and unscrew it. Getting it started back in might be another story… I just used the punch from the bottom side to knock the spool out through the top. That’s when some more metal chunks came out with it. |

Posted By: CrestonM

Date Posted: 27 Mar 2023 at 9:27pm

|

Posted By: Lynn Marshall

Date Posted: 27 Mar 2023 at 10:04pm

| I don't see your orifice disc in that picture. I would also be pulling the left hand hydraulic filter to see what it looks like. |

Posted By: CrestonM

Date Posted: 29 Mar 2023 at 9:47pm

| Been busy the last couple days, but hopefully soon I will have time to get back on this. I will double check everything that fell out in the pan for the orifice disc, and after making sure the spool slides freely, I’ll put it back together and see if that makes a difference. Hopefully it does. Then I may look into a gear pump rebuild, because those chunks scare me. |

Posted By: DrAllis

Date Posted: 30 Mar 2023 at 7:24am

| If the steering works reasonably well after cleaning up that spool, I don't know why you would want to tear that pump apart. I doubt there are hardly ANY PARTS available for it internally. Leave it alone. |

Posted By: CrestonM

Date Posted: 30 Mar 2023 at 10:36pm

| I checked today and the orifice disc is not accounted for. Anyone have one to part with? |

Posted By: calico190xt68

Date Posted: 30 Mar 2023 at 11:24pm

|

You might try agco. Wonder where it went? ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: calico190xt68

Date Posted: 05 Apr 2023 at 8:21am

Curious if you ever found an orifice? ------------- 80 7010, 80 7020, 68 190XTD, 67 190XTD, 500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC |

Posted By: CrestonM

Date Posted: 05 Apr 2023 at 9:15pm

|

I looked back through all the parts double checking I didn’t miss anything, and it wasn’t there. But it was also missing one of the shim disks. So maybe whoever pulled the shim also lost the orifice disk? I then remembered I had a “parts” pump assembly from one of these tractors, and it had the orifice disk and 3 shim disks. So I’ll clean the spool and put this orifice in. How do I determine how many shims are needed? Thanks! |

Posted By: CrestonM

Date Posted: 11 Apr 2023 at 8:07pm

|

Got some time to work on this again this afternoon, cleaned everything up, tried to put the spool in, and it was really sticking. Took the inspiration from an earlier post and used a piece of emery cloth on a wooden dowel in a drill chuck to clean the bore out. Perfect. Spool slides freely. Reassembled in the right order, started the tractor. Had steering but was just a tough as before. At about 1,400 rpm I could turn the wheels fully but the steering wheel was still very slow and stiff. Shut the tractor off and did something else, came back about 5 minutes later and tried again. Bumped the steering wheel and it bounced back and forth a few times. Never has done that before. Started engine. This time no steering at all. Wheel turned a little bit easier but no response. Noticed a drip coming out of the hand pump under the dash. Oil is seeping out at the top of the hand pump. Ignoring the chunks of metal that originally came out with the spool, could it possibly be the hand pump that’s the issue? I wish I had a flow meter, but those are pretty expensive for something so seldom needed, so it’s not in the budget. I’m not seasoned like some on here, but those chunks of iron that came out with spool really concern me as to the condition of the pump. Thanks PS- I might should add…last spring the entire trio of pumps was swapped out for a set of pumps from a donor tractor (the donor set being what’s installed currently). The original problem was the same steering issue, but also the remote hydraulics did not work. Swapping in this replacement pump fixed the remote operation, but the steering is only slightly better than with the original pump. |

Posted By: DrAllis

Date Posted: 11 Apr 2023 at 9:41pm

| Start by rechecking the spool to see if it is stuck again !! Steering did work, now it doesn't. Stuck again might mean you are missing the screen in the left hand hydraulic filter...and if the screen is missing, there isn't any filtering going on. More shims should improve steering effort if the pump is good at all and IF THE SPOOL IS FREE. The top sight glass is full of oil ??? |

Posted By: CrestonM

Date Posted: 11 Apr 2023 at 9:46pm

|

I’ll check the spool again tomorrow. Hopefully there aren’t more chunks coming through. When I reassembled, I used 2 shims as it had before but I’ll add the third one and see what happens. Oil is in the bottom sight glass but not the top. Hydraulic fluid and filters were changed last spring with only about 10 hrs put on them since. The screen is present because I had to order one for it since the PO didn’t put it back in. Oops |

Posted By: CrestonM

Date Posted: 12 Apr 2023 at 5:50pm

| Checked it out. Spool fell out, so it’s not sticking. No metal chunks. Added another couple shims. The shim stack is now about 1/16” below the top edge of the cap they fit into. Started tractor, steering worked but was just as hard and slow as before. Once the engine got up to 2,300 RPM, I could almost spin it with the palm of my hand going to the right, it was easier going to the left. Guess that’s an effect of the regenerative steering. |

Posted By: DrAllis

Date Posted: 12 Apr 2023 at 9:13pm

| Dead-head a pressure gauge on the end of one steering hose and see what you have for pressure when you're turning the wheel hard against the gauge. I think the power steering relief is built into the orbitrol on those tractors and should be 1800 to 2,000 psi at 2300 RPM. Shims go in the bottom cap/cup. Spring seats against the shims. Orifice goes on top of the spring. Spool sits on top of the orifice. Priority circuit flow is to be 5 to 6 GPM at 2300 RPM. |

Posted By: CrestonM

Date Posted: 12 Apr 2023 at 10:46pm

| I’ll try to round up a gauge and test that. Sounds like everything is assembled in the right order. I may also call a dealer and see if I can get someone to bring a flow meter out. |

MACK wrote:

MACK wrote: