Rod bolt/main bearing thread stretch?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=190858

Printed Date: 29 Jan 2026 at 10:08pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Rod bolt/main bearing thread stretch?

Posted By: Hunt4Allis

Subject: Rod bolt/main bearing thread stretch?

Date Posted: 23 Sep 2022 at 8:54pm

|

When reassembling an engine can I reuse the rod bolts and nuts and main bearing cap bolts and also the head bolts? I've been watching some rebuild videos and they're talking about thread stretch so in other words only using them or torquing them once and not reusing them when rebuilding? I guess now that I've watched the video again it sounds like it's only talking about when it's a bolt and nut which would only be the rod bolts, but I'm just trying to get people's thoughts here before I put it back together... It's on a 1972 60 horsepower diesel 4 cylinder that I'm rebuilding in frame. Thanks Matt |

Replies:

Posted By: steve(ill)

Date Posted: 23 Sep 2022 at 9:33pm

|

I think most of that " stretch to yield " bolt spec happened in the last 20 years.. I dont remember any ( off hand) for the 1950-70 era that recommended changing out the bolts.

i think most of that had to do with new aluminum heads on engines.... not rod bolts. ------------- Like them all, but love the "B"s. |

Posted By: wjohn

Date Posted: 23 Sep 2022 at 11:01pm

|

What's the service manual for your engine say? ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: DMiller

Date Posted: 24 Sep 2022 at 5:23am

|

All fasteners do stretch, some acceptance criteria was established as to bolt shank thickness or thread departure from concentric or depression at Detroit Diesel and Cummins engines when I was first learning engines. As little as .002 in thread region as to that was the max allowable for rod or smaller fasteners on engines. Head Bolts, Main Cap Screws, Stud systems were all inspected similarly, where those were based on Shank Length. Cummins allowed .015 stretch on Main Bolts, Detroit allowed .012 according to what I had in some old class room notes I found on Head Studs. Would require engineering dimensions of which not many still remain for Allis machines. For a long time simple departures from normal were as detectable pitting or hairline crack development on non threaded shanks, any damage to threads as galled or missing thread portions in the fastener torque regions. Many of the older Factory Service manuals simply stated Discard Old Fasteners/Replace All as was too labor intensive to inspect them all or to put any level of value of reuse. Caterpillar still notes in their manuals as to which fasteners are ONE TIME USE, once torqued are thrown out. Head Bolts, Rocker Arm bolts and Studs, even gear train fasteners.

|

Posted By: B26240

Date Posted: 24 Sep 2022 at 6:05am

| When I was a young guy in the 70's I worked for a road contractor that had a crusher ran by a Murphy diesel. One spring they overhauled it mechanic and shop forman argued about changing rod bolts as repair mannual said " use new rod bolts " shop forman won mechanic reused old bolts. Engine came back to shop with big hole in side of block after less than one shift. That was my first lesson about bolt stretch and reading repaire manual carefully. Side note company replaced engine with a Detroit then several months later welded hole in the Murphy and used it on annother application |

Posted By: Les Kerf

Date Posted: 24 Sep 2022 at 7:24am

Modern high performance engine builders (think NASCAR, etc.) don't use torque wrenches on rod bolts, they use a special tool that measures the actual stretch of each (always brand new) bolt as it is tightened. Your 1972 60 horsepower diesel 4 cylinder engine 'may' fit that criterion  |

Posted By: Hunt4Allis

Date Posted: 24 Sep 2022 at 7:28am

| I don't remember reading in the manual if it calls out for replacement of rod bolts but I'll have to check |

Posted By: Hunt4Allis

Date Posted: 24 Sep 2022 at 7:44am

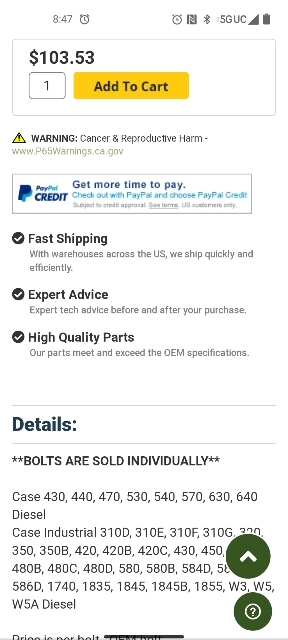

| These connecting rod bolts may not be available, unless I'm just that terrible at searching for them? |

Posted By: Hunt4Allis

Date Posted: 24 Sep 2022 at 7:48am

I cannot believe these are over $100 per bolt? That seems a bit insane, I could see if it were a NASCAR rod bolt or something... |

Posted By: AaronSEIA

Date Posted: 24 Sep 2022 at 7:53am

Thats gotta be a typo. AaronSEIA

|

Posted By: injpumpEd

Date Posted: 24 Sep 2022 at 10:28am

|

you'll need to use the paypal credit to pay for those lmao! Old low rpm engines don't need the rod bolts, main bolts or head bolts replaced unless there's something wrong with them. You'll know when torqueing them if they are good, as mentioned above, all bolts are designed to stretch a small amount and torqueing them is a simple universal method of achieving that stretch. If a bolt "goes plastic" while torqueing it, in other words, just keeps stretching, it's junk, unless it's designed as a stretch bolt, like the old VW head bolts. The old Case is not like that though. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Hunt4Allis

Date Posted: 24 Sep 2022 at 11:25am

| I've read to use blue medium loctite on these bolts when reassembling? I'm assuming they should be completely dry and free of oil when I do that correct? |

Posted By: steve(ill)

Date Posted: 24 Sep 2022 at 4:00pm

|

yes... loctite will only work on clean, dry steel........ i think the blue is a low / medium strength... in place of lock washers..

if thats what the book says, OK... some use sealastic type nuts, some use lock washers, some use lock wire, some use steel tab washers..

------------- Like them all, but love the "B"s. |

Posted By: Hunt4Allis

Date Posted: 24 Sep 2022 at 4:40pm

|

Okay when I removed them there was no lock washers or any type of mechanical fasteners on the rod bolts.(other than the nuts which I'm unsure of their type, I think some had slits cut in them about halfway) Using blue loctite is something someone told me to do, I will look in the manual |

Posted By: injpumpEd

Date Posted: 24 Sep 2022 at 4:47pm

|

normally rod, main and head bolts need oiled so they torque properly. No loctite, unless specified. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: steve(ill)

Date Posted: 24 Sep 2022 at 4:48pm

|

yes, there are various ways to make a nut LOCK onto the bolt.... the book should say to replace the nuts after use... or add loctite to OLD nuts, etc... ...Cutting slots and distorting the end thread is one way ...putting a DIMPLE in the center of the flat on each side to distort the thread is another ...adding a star washer to the bottom to dig into the metal ...external lockwasher ...locktite ... lock wire ------------- Like them all, but love the "B"s. |

Posted By: MACK

Date Posted: 24 Sep 2022 at 8:58pm

| If a rod or main bolt is properly torqued, it won't come loose unless bolt stretches or brakes. MACK |

Posted By: Hunt4Allis

Date Posted: 24 Sep 2022 at 9:06pm

| Gotcha |

Posted By: Calvin Schmidt

Date Posted: 26 Sep 2022 at 7:20am

|

When we rebuilt my D21 engine, the new rod bolts came from AGCO. They were actually ARP bolts. Instructions were to torque to yield and do not reuse. ------------- Nothing is impossible if it is properly financed |

Posted By: injpumpEd

Date Posted: 26 Sep 2022 at 7:30am

|

Those ARP bolts are not torque to yield. They are simply torqued to a certain stretch, of .008" and 80ft lbs is what it takes to make them stretch that much. In my puller, I've reused those AGCO/ARP bolts numerous times. I also check the bolt stretch with my stretch gauge. Torque to yield bolts would have you torque to say 50 ft lbs, then turn them a half round stretching the bolt in the process. Special bolts made to work that way, and are one and done. People tend to mix up torque/turn method, and torque to yield, which is stretch bolts. You can definitely feel the stretch bolts stretching while turning them the half turn. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Hunt4Allis

Date Posted: 26 Sep 2022 at 7:37am

|

My manual just says torque to 45-50ft/lbs.so I'd say as long as there looking ok I can re-use them as they not torque to yield before. It doesn't say to add oil before torquing so is that just a standard to do as opposed to being dry and using locktight? |

Posted By: Boss Man

Date Posted: 26 Sep 2022 at 3:32pm

| Problem with loctite is unless the blocks been boiled theres still oil in the main cap holes. A drop of oil on the threads and under the bolt head is all you need. This ensures the torque is true. I've never took an older engine apart that had loctite on mains or rods. Timing gears yes, never bottom end. The disposable bolts have a narrowed shank. That enegine shouldn't and that why they're expensive. Dont sell enough. |

Hunt4Allis wrote:

Hunt4Allis wrote: