WD45 Shift Tower

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=190689

Printed Date: 24 Dec 2024 at 1:04pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD45 Shift Tower

Posted By: KenBWisc

Subject: WD45 Shift Tower

Date Posted: 15 Sep 2022 at 4:28pm

|

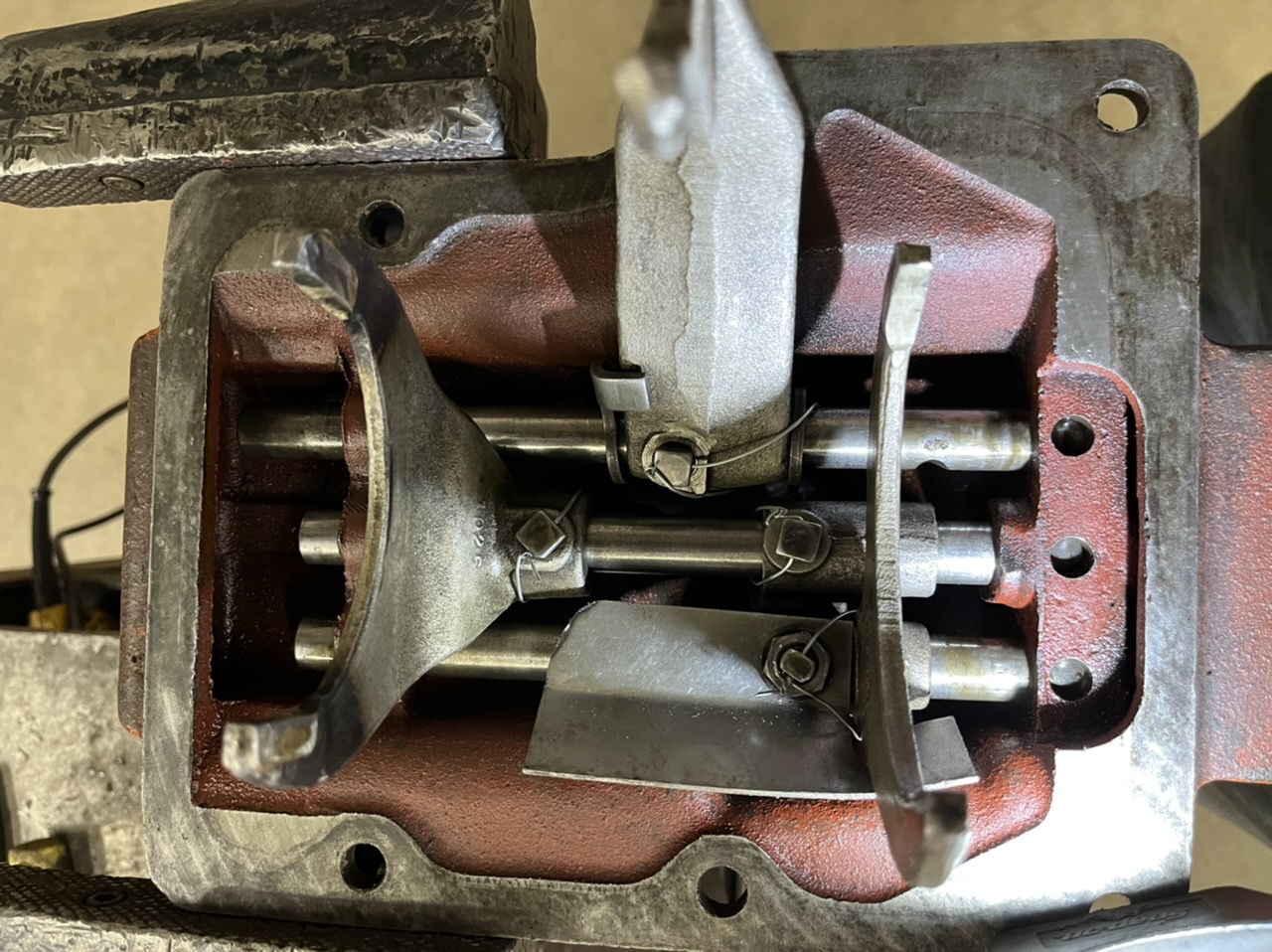

I’m have trouble uploading photos so will proceed in writing. During operation the tractor wouldn’t come out of second gear. It would go into reverse but remained in second. I pulled the tower and overhauled the shifter rod end, replaced one of the two tower bolts that fit into the shifter ball, rebuilt the reverse lockout lever and installed the horizontal lockout rod according to archived postings. I am not able to install the top on the transmission. I have the shifter top in reverse but it doesn’t stay in gear during installation. I have locked the shifter in reverse with vise grips but then there doesn’t seem to be enough slack to get the fork to engage. What am I doing wrong?  ------------- '34 WC #629, '49 G, '49 B, '49 WD, '62 D-19, '38 All Crop 60 and still hunting! |

Replies:

Posted By: MACK

Date Posted: 15 Sep 2022 at 8:48pm

| Put it in 2nd or natural. MACK |

Posted By: SteveM C/IL

Date Posted: 15 Sep 2022 at 10:19pm

| 2nd works best |

Posted By: KenBWisc

Date Posted: 17 Sep 2022 at 5:06pm

|

I agree that 2nd worked best in my situation. However, even though I was successful in engaging each of the shifter forks and the shifter felt good when I shifted out of second, the end of the shifter rod then refused to engage with any gear lugs. So now my question is “is the problem at the bottom of the rod or is it too much slack at the upper ball?” When I took the thing apart it had an added coil spring setting on the cupped washer which was covered by a flat washer then the snap ring. I did not put the spring and flat washer back in when I installed new, correct washer and snap ring. The upper ball, rebuilt bottom ball and lugs mic out near recommendations. Further guidance is appreciated! ------------- '34 WC #629, '49 G, '49 B, '49 WD, '62 D-19, '38 All Crop 60 and still hunting! |

Posted By: MACK

Date Posted: 17 Sep 2022 at 8:51pm

| I would say there is ware in every thing in top. Lower parts could have ware but most accrues in top. MACK |

Posted By: JC-WI

Date Posted: 17 Sep 2022 at 9:56pm

|

Did you get the interlocks in correctly? Did you try shifting while tractor was off? Maybe need to roll gears a little bit for lugs to line up. Maybe you built up shifter end to much and won't fit through the gates? ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Rltool

Date Posted: 18 Sep 2022 at 5:40am

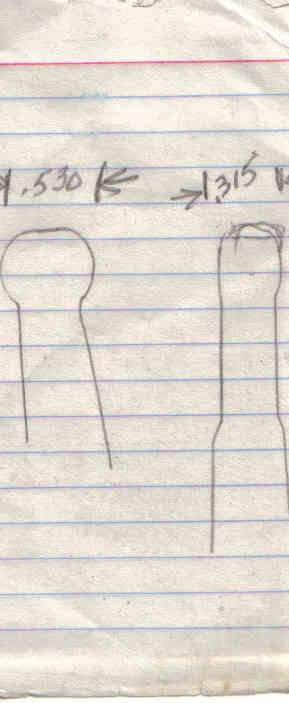

I have found that I can go up to .340 wide on the width of the lower ball. Ray W. |

Posted By: IBWD MIke

Date Posted: 18 Sep 2022 at 7:38am

|

Here's a link to Sugarmaker's thread on this; https://www.allischalmers.com/forum/wd45-shift-tower-details-picture-heavy_topic169724_page1.html?KW=shifter" rel="nofollow - https://www.allischalmers.com/forum/wd45-shift-tower-details-picture-heavy_topic169724_page1.html?KW=shifter I added a few pics of my own shifter rebuild, not as involved as Chris's.

|

Posted By: KenBWisc

Date Posted: 18 Sep 2022 at 8:08am

|

Thanks for the input. Yes, I did as indicated. I’m thinking Mack has a point concerning the upper part of the shifter. ------------- '34 WC #629, '49 G, '49 B, '49 WD, '62 D-19, '38 All Crop 60 and still hunting! |

Posted By: garden_guy

Date Posted: 18 Sep 2022 at 1:23pm

|

With the shifter in the tower and the snap ring and washer on, is there much vertical play? Perhaps wear in the either the ball portion that goes in the socket, or wear of the socket itself that the shifter sits in (in the area just below where the two side pins are in the tower). |

Posted By: KenBWisc

Date Posted: 18 Sep 2022 at 5:04pm

|

When I took the tower apart it contained two “extra special” parts in the top. The original washer was turned upside down with a coil spring placed in the cup. The spring was covered with a badly worn flat washer, all not so perfectly held in place with a snap ring. My parts man and shop manual says the extra parts are not original. I removed them and put in the their place a new washer and snap ring. Too much slop so today I made a new cover washer and replaced the upside down washer and coil spring. Mounted the cover and successfully shifted through all gears twice. The third time however the bottom of the shifter came out of the lugs. I’m looking for a replacement trans top! ------------- '34 WC #629, '49 G, '49 B, '49 WD, '62 D-19, '38 All Crop 60 and still hunting! |

Posted By: MACK

Date Posted: 18 Sep 2022 at 8:26pm

| Finding a better top is like finding hens teeth. I would guess your worst ware problem is the rotation of gear shift, slipping between notches In rails. AGCO has over size pins. Drill housing for new pins, at same time, drill on through other side for two pins. Machine gear shift for two pins to fit over size pins. Last I knew you could buy a new gear shift. MACK |

Posted By: KenBWisc

Date Posted: 28 Sep 2022 at 11:19am

Well, that didn’t work well! The new shifter broke off in my hand on the second shift. The vendor was very good about it and is sending another. Of the 360 degrees that needed welding only 10-12 degrees was. ------------- '34 WC #629, '49 G, '49 B, '49 WD, '62 D-19, '38 All Crop 60 and still hunting! |

Posted By: dawntreader74

Date Posted: 28 Sep 2022 at 7:55pm

| bet the ball is wore out' may need to be welded up some to fat it up a little' won't work good if the ball is to small. |