HD9B ALLIS CHALMERS DOZER 1953/1954

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=190080

Printed Date: 04 Feb 2026 at 11:47am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: HD9B ALLIS CHALMERS DOZER 1953/1954

Posted By: danny1954

Subject: HD9B ALLIS CHALMERS DOZER 1953/1954

Date Posted: 15 Aug 2022 at 12:42pm

| HELP PLEASE!! i have a allis chalmers hd9b dozer that broke the u joint for the hydraulic pump at the crank shaft pulley. Cant find any information on hd9b with front mounted hydraulic pump. Need help finding manual and parts. Part # on tag HD-9B-3443 |

Replies:

Posted By: gemdozer

Date Posted: 15 Aug 2022 at 5:27pm

| I dismantled 2 HD9 for parts and should still have 1 or 2 u-joint on racking if you could have a picture |

Posted By: AC Mel

Date Posted: 15 Aug 2022 at 5:45pm

| Do you know who the blade manufacturer is? CARCO? GARWOOD? . At that time all of the blades and hydraulics were aftermarket. I might have a manual....but the numbers probably won't be to helpful...pictures would be good. |

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:06am

| absolutely i just took some pictures and will post them shortly. thank you for the reply |

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:07am

| i do not know the manufacture of the blade i cannot find anything on it. I did take some pictures of the dozer and blade along with the parts i am needing. Will post those shortly |

Posted By: CAL(KS)

Date Posted: 16 Aug 2022 at 9:26am

|

i think a majority of hydraulic equipment at that time was hydreco but you can measure the yokes to find the correct u joint. thats how i got u joints for my TL-12 loader. no part #s used ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:28am

|

Posted By: CAL(KS)

Date Posted: 16 Aug 2022 at 9:48am

|

thats a Garwood blade, but they didnt make hydraulic systems. Could be a baker hard nose and cylinders, either added on or the blade was swapped. I dont have my book here to double check. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:51am

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:55am

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:55am

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:56am

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:57am

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 9:58am

|

Posted By: CAL(KS)

Date Posted: 16 Aug 2022 at 10:01am

|

I would take those pieces to a truck shop like Inland truck parts. I see they have locations in texas. They can make drive shafts. You will never find a new one and salvage is going to take time and money to find and it could be near failure also. We have inland rebuild our CV joints on our large 4wd AC tractors and build shafts when worn. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: danny1954

Date Posted: 16 Aug 2022 at 11:39am

| I know that i can get the driveshaft built. But i need the end that connects to the crankshaft. Also i cannot figure out how to get the broken piece off the crankshaft. Any tips would be appreciated. Would be happy to give yall my phone # if you think you can help me. Thanks Danny |

Posted By: CAL(KS)

Date Posted: 16 Aug 2022 at 12:08pm

|

surely the short yoke on the crank is splined and slips in because the pulley is retained by a nut so it has to come off. could be packed tight with dirt or possibly the pully is multipiece, hard to see from picture. none of our detroits have crank drives. did some more looking that is a garwood hardnose as well, so they did have hydraulic setups not just cable, but definitely not as common ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: gemdozer

Date Posted: 16 Aug 2022 at 1:42pm

| My joint yoke to the pump have 14 narrow teethsand spider is 3 1/2 inchs outside but have 2 more on racking and recheck tomorrow. |

Posted By: danny1954

Date Posted: 16 Aug 2022 at 2:39pm

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 2:40pm

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 2:41pm

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 2:42pm

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 2:42pm

|

Posted By: Codger

Date Posted: 16 Aug 2022 at 3:24pm

|

That coupler should be splined to the crankshaft snout. Take two sections of hardwood cut at a taper and drive between the crankshaft pulley, (sheave) and back of the coupler. drive these wedges till they are tight. Use either a 2lb hammer, or better yet an air hammer with mushroom bit and impact directly in the center of the coupler from the front of the tractor. Pound your wedges in tightly again and repeat as needed. It will let go with a "pop" but the force must be kept heavy on the wedges. You could use heat but that would chance damaging the engine front oil seal.

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 3:25pm

|

Posted By: danny1954

Date Posted: 16 Aug 2022 at 3:25pm

|

Posted By: Ray54

Date Posted: 16 Aug 2022 at 5:49pm

My experience of someone hammering on a crank shafted ended very badly. Was a Ford 460 in a New Holland bale wagon if a gas engine may have a weaker crank. But the pully needed to come of crank to replace hydraulic drive belts. It had places to use pusher bolts but threads where stripped owner elected to use chisels as a wedge as suggested here. It came off and new belts installed. A mile down the road the crank broke. And that is a literal mile ran 10 minutes at most. As a interesting fact the bale wagon owner also had 4 or 5 HD 9 crawlers for tillage.

|

Posted By: Codger

Date Posted: 16 Aug 2022 at 7:47pm

|

I can see that happening with a nodular iron crankshaft of a Ford 460 engine. I've seen the crank snout snapped off on those engines from using belt driven hydraulic clutch pumps. High engine rpm and the all or nothing engagement these offer is brutal via shock loading. One shouldn't need to hit this very hard at all. The trick is to set up high frequency vibrations through the parts with mechanical leverage in your favor. An air hammer does a great job for this. It is possible that front yoke is bolted to the front plate on the backside also. This plate and yoke assembly is then bolted to the sheave. If so, and with the four capscrews removed as shown, side force via hammer to the remaining yoke ear would break it loose.

|

Posted By: AC Mel

Date Posted: 16 Aug 2022 at 9:53pm

|

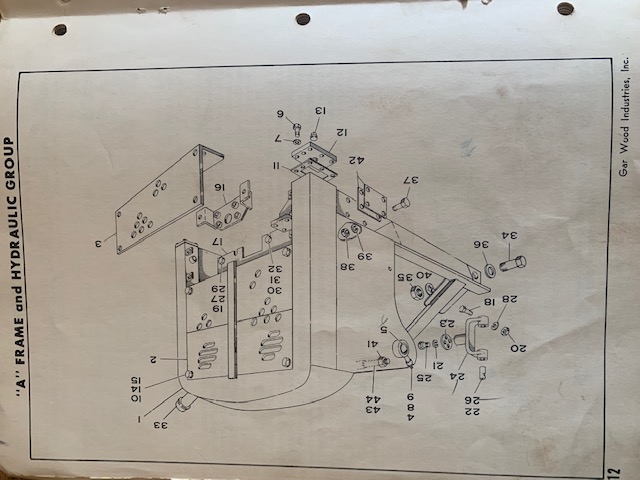

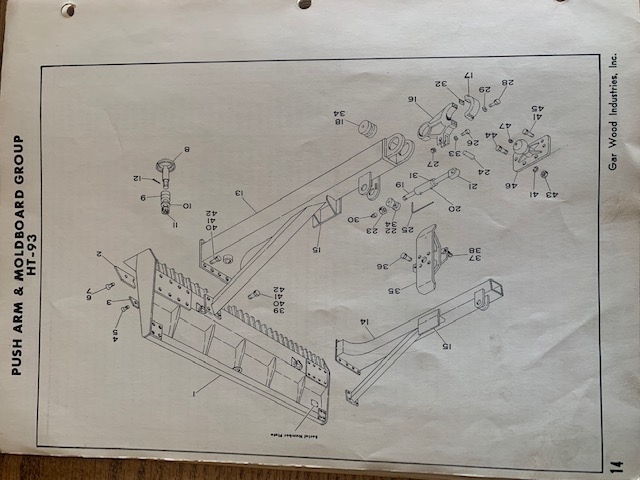

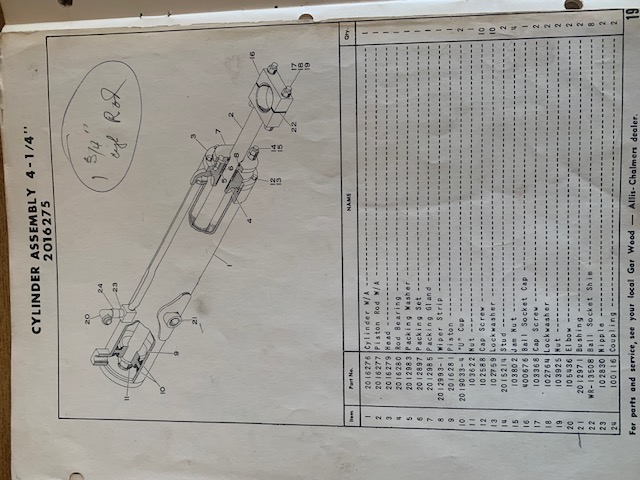

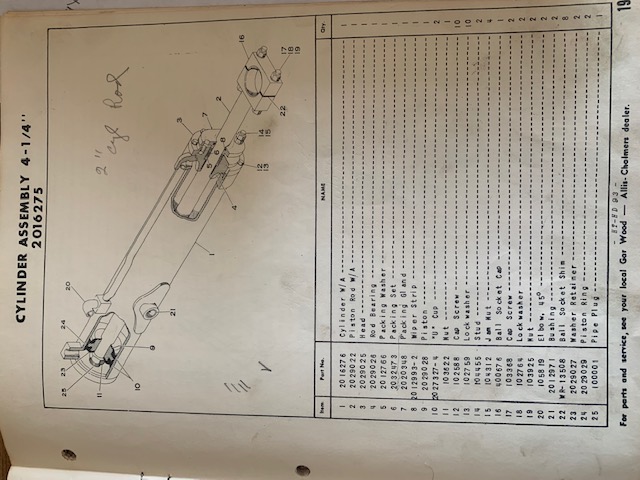

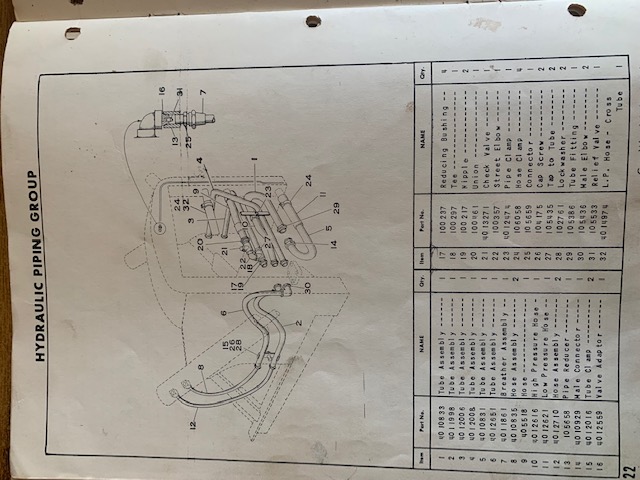

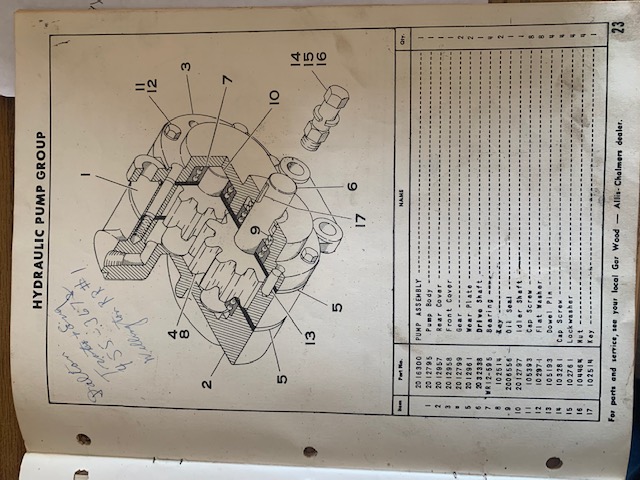

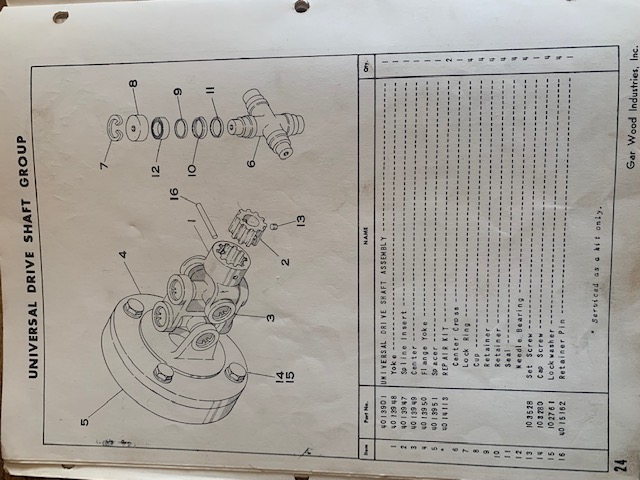

Ok.....Man you guys are making me work hard here!!!...Dug through our archives and library and did find this Garwood book. They did make a hydraulic blade set up for all the dozers at the time. Cal's right that the cable blades and units seem to be more popular then. Also as he says...the HYDRECO pump was the main player then.....the pump in your picture I'm sure is a HYDRECO. I'm also sure the whole hardnose assembly is Garwood with maybe some modifications. The parts book of course does not mention HYDRECO by name. If I get them posted right the last picture....albeit disappointing...does not show getting the yoke of the pulley. I'll look at a HD 9 tractor tomorrow that might give us some help. Don't break anything ....cause yes..you should be able to build one.         |

Posted By: CAL(KS)

Date Posted: 17 Aug 2022 at 7:28am

|

Mel to the rescue. Those are the books that are indispensable because unlike the tractor books, most can not be found online @ minnpar, and who knows how longs those will last. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: gemdozer

Date Posted: 17 Aug 2022 at 7:36am

| How manay spleene on pump shaft |

Posted By: Ray54

Date Posted: 17 Aug 2022 at 10:17am

|

Thanks for explaining farther Codger. I just wanted to make sure the problem did not get bigger. Mel you have it, but even more you found it and got pictures over her too.

|

Posted By: AC Mel

Date Posted: 17 Aug 2022 at 11:10am

|

Yes...I was going to mention to Cal...we started buying those books probably 20 years ago on ebay....they were cheap to almost free....we bought everything we could get our hands on if we thought we didn't have it.....brochures..flyers...service bulletins...parts ...service...Garwood..Caro...Baker. People were cleaning there shelves and we filled ours up. It's all gone now..seems like...occasionally some will show up...and of course there's lots of the common stuff that's helpful...but sellers appear to be emotionally attached to it...probably not having a clue what it's for. Don't know if I'll ever get it all sorted...but it's fun to look through it if I think It will help someone. Hector...not sure about the pump splines...looking at the book of the picture I posted...it appears the pump shaft is plain and keyed to match a splined insert (2) to the drive shaft yoke. Looks like the splined insert might be 10 splines.....but we don't know if that's what he has...can't tell by the pictures he has posted

|

Posted By: danny1954

Date Posted: 17 Aug 2022 at 11:13am

| thank you for the help. is there a picture i could take that would give you a better idea of what we are looking at?? i greatly appreciate all of the help |

Posted By: AC Mel

Date Posted: 17 Aug 2022 at 2:59pm

|

Danny...I think Hector (GEMDOZER) was thinking he might have some parts that would help you...was interested in how many splines on the pump? Can you get the yoke of the end of the pump and take pictures of the pump or those parts maybe? Here are pictures of an HD9 crankshaft pulley...it should be the same as yours....all the HD9s should have come to there dealers with no blades...so all of these were the same. 1 picture is straight on....one a little from the side hoping to show some depth...as per Cal...it covers the bolt that holds the pulley on.....and of course someone might have modified something in the last 60 years....that would of course void the warranty...LOL    |

Posted By: danny1954

Date Posted: 18 Aug 2022 at 8:03am

so mine does not have the bolt on the front of the crankshaft like your picture. mine has the u joint that is broken off and i do not know how to remove it. that is the problem

|

Posted By: Codger

Date Posted: 18 Aug 2022 at 8:09am

| I think you do have the setup Mel shows but it is behind the plate the broken part is attached to. From the side smack the broken u joint flange on both sides and that front plate should start to break free. Rust is holding it fast in place. |

Posted By: Lee Bradley

Date Posted: 18 Aug 2022 at 10:06am

| Welded to the bolt? Maybe try unsrcewing it. Didn't think 'B's were that early. |

Posted By: danny1954

Date Posted: 18 Aug 2022 at 2:02pm

|

by george we got it!!!!! thank you thank you thank you for the tips. Codger it broke loose just like you said it would |

Posted By: danny1954

Date Posted: 18 Aug 2022 at 2:03pm

|

Posted By: danny1954

Date Posted: 18 Aug 2022 at 2:04pm

|

Posted By: danny1954

Date Posted: 18 Aug 2022 at 2:04pm

|

Posted By: danny1954

Date Posted: 18 Aug 2022 at 2:06pm

| anybody have this whole driveshaft with the fittings on both ends they are looking to get rid of. Need the shaft, 2 ujoints, and both ends! see pics |

Posted By: Codger

Date Posted: 18 Aug 2022 at 2:39pm

| Thank you to AC Mel for tipping me off and thanks to you for the follow up. |

Posted By: AC Mel

Date Posted: 18 Aug 2022 at 8:48pm

| Danny....were getting close....I'm still curious about the end of the yoke that goes into the pump? Can you get that off...lets see how that looks...splines...straight shaft with keyway? If we can see that then everyone knows what you need. Hector (Gemdozer) said he might have some parts...and if not....I know Codger and I would concur with Cal that all of that could be fabricated up pretty easy. |

Posted By: Lee Bradley

Date Posted: 18 Aug 2022 at 9:20pm

| You can see the grease fitting on the housing to grease the shaft going through that housing. Pull those six bolts and split the house off the pump. |

Posted By: danny1954

Date Posted: 19 Aug 2022 at 10:56am

|

Posted By: danny1954

Date Posted: 19 Aug 2022 at 10:57am

|

Posted By: danny1954

Date Posted: 19 Aug 2022 at 10:58am

|

Posted By: danny1954

Date Posted: 19 Aug 2022 at 10:59am

|

Posted By: danny1954

Date Posted: 19 Aug 2022 at 10:59am

|

Posted By: Codger

Date Posted: 19 Aug 2022 at 11:02am

| If'n it were me, and looking at those splines, I'd replace the pump also as it's splines are also beaten upon. The original pump may have parts available and could be rebuilt; this is possibility also. |

Posted By: gemdozer

Date Posted: 19 Aug 2022 at 2:56pm

| I recheck tomorrow for a 6 spleene yoke |

Posted By: gemdozer

Date Posted: 20 Aug 2022 at 8:49am

| you could gogul yoke and joint the should have new parts and in 3701 holmes road in houston +713-731-0030 |

Posted By: doctorcorey

Date Posted: 10 Sep 2022 at 10:38pm

|

What other AC crawlers used this driveshaft setup? ------------- Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel |

Codger wrote:

Codger wrote: