Need Advice on Left Brake Roll Pin for D17 IV

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=187853

Printed Date: 29 Oct 2025 at 2:28am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Need Advice on Left Brake Roll Pin for D17 IV

Posted By: Oldwrench

Subject: Need Advice on Left Brake Roll Pin for D17 IV

Date Posted: 24 Apr 2022 at 4:57pm

|

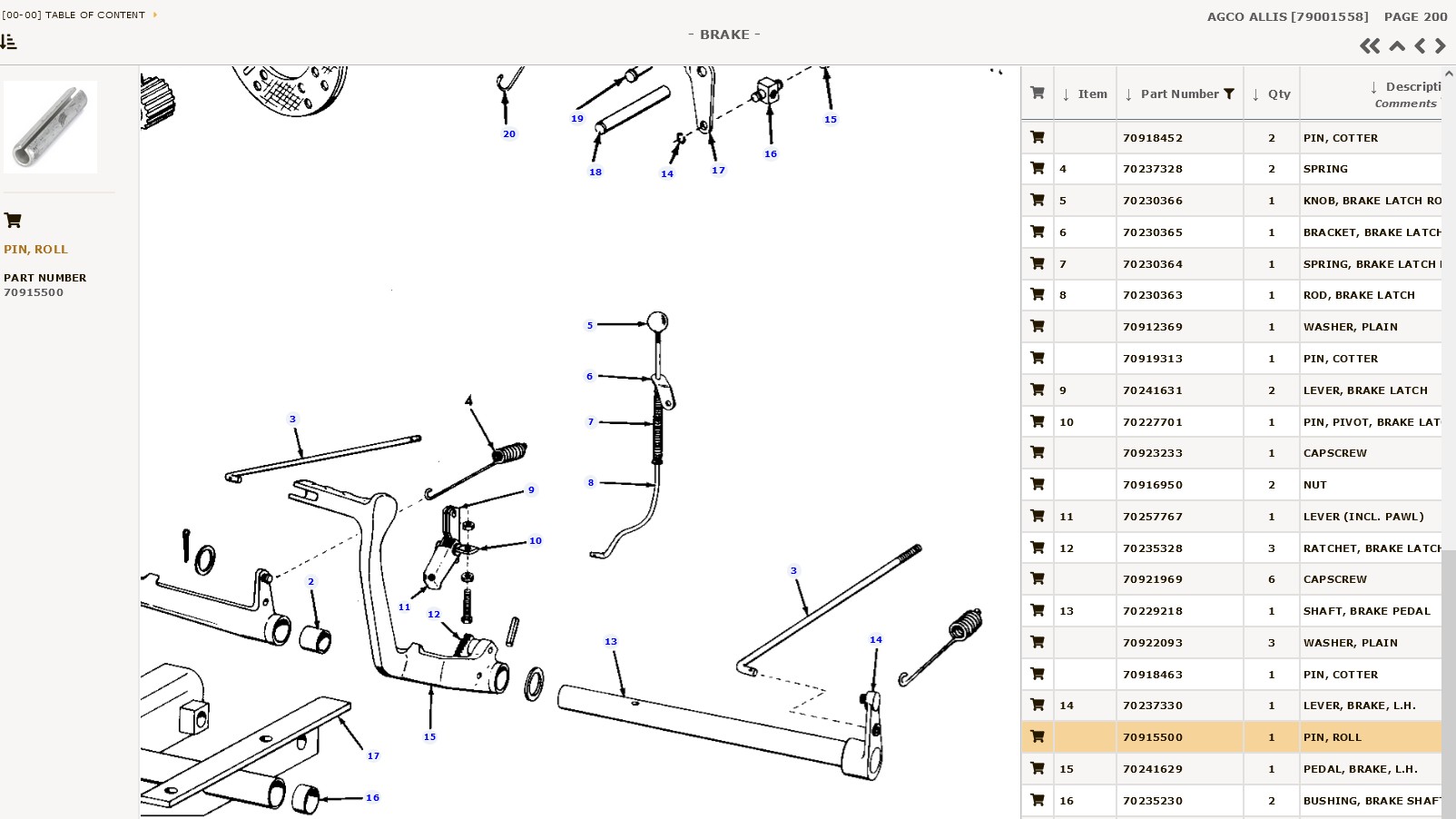

So the left brake started not returning back to its stop. Studying it, the spring on the left is intact and seems to be returning the actuating lever and rod back to its rest position. There appears to be slop in the pedal to the shaft. The Agco parts book shows a roll pin or something similar securing the left brake pedal to the shaft. It looks like I need to replace the roll pin in the left brake pedal to the cross shaft. Can I just drive out the old, bent pin and replace it with new, or should I plan to pull both pedals off and kind of rework everything? Is there room for the old pin to be driven out leaving everything intact, which would sure make things simple. Also, is there an "upgrade" in that I should replace the pin with a hardened bolt, assuming I have enough clearance? Thanks in advance for anyone who has done this before.

|

Replies:

Posted By: Gatz in NE

Date Posted: 24 Apr 2022 at 5:24pm

|

You're on the right track. Before driving the old pin out, make sure the mating holes in the brake pedal and the shaft are still aligned as the pin may have been crushed. LH brake pedal back; LH brake shaft retracted by spring. Should be room to drive it up. I'm not sure what size the 70915599 roll pin is (might be 5/16 ") but should be easily obtained locally. If not, check with AGCO dealer.  |

Posted By: DSeries4

Date Posted: 24 Apr 2022 at 7:38pm

|

Before anything, I would apply some penetrating oil to the shaft to make sure it is not rust and crud preventing things from moving properly. I have had good luck with that before. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Oldwrench

Date Posted: 25 Apr 2022 at 12:33pm

| Thanks to both of you for the help. I'll find the right sized drift and see what happens. A roll pin doesn't seem like the strongest type of pin for this situation, but it did hold up for 50+ years so maybe that's good enough. |

Posted By: Gatz in NE

Date Posted: 25 Apr 2022 at 4:41pm

|

Agree with lubing up the shaft/bracket to make sure it isn't bound up. I had something similar happen to a JD lawn tractor a couple years ago. Took some time to find where the problem was. The

picture shows a "standard" roll pin. There's also "Coiled Spring Pins"

if the hole has out-of-roundness or the standard pin is too loose. http://www.mcmaster.com/pins/pin-type~spring/heavy-duty-coiled-spring-pins/" rel="nofollow - http://www.mcmaster.com/pins/pin-type~spring/heavy-duty-coiled-spring-pins/ If those won't work because the hole is wore out, you could go with a 8mm (nominal Ø.315) roll pin which would definitely fill the gap, but it may require drilling it out first.

|