D15 Torque Tube and Hydraulic Pump

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=184257

Printed Date: 03 Feb 2025 at 12:54am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D15 Torque Tube and Hydraulic Pump

Posted By: WeisAC2

Subject: D15 Torque Tube and Hydraulic Pump

Date Posted: 29 Oct 2021 at 3:13pm

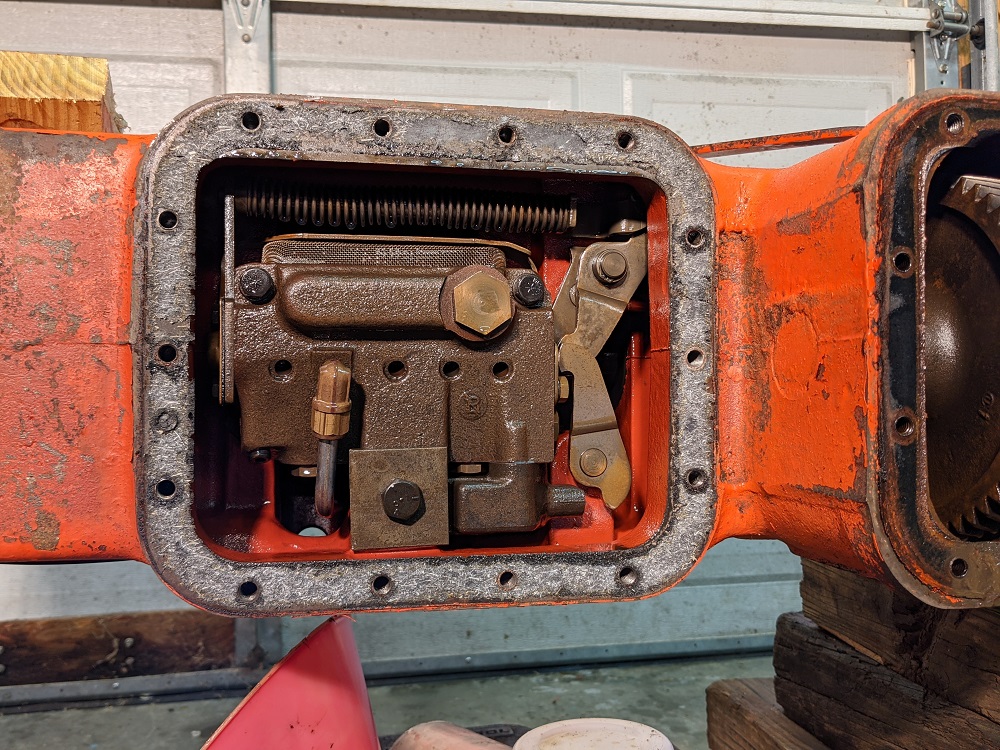

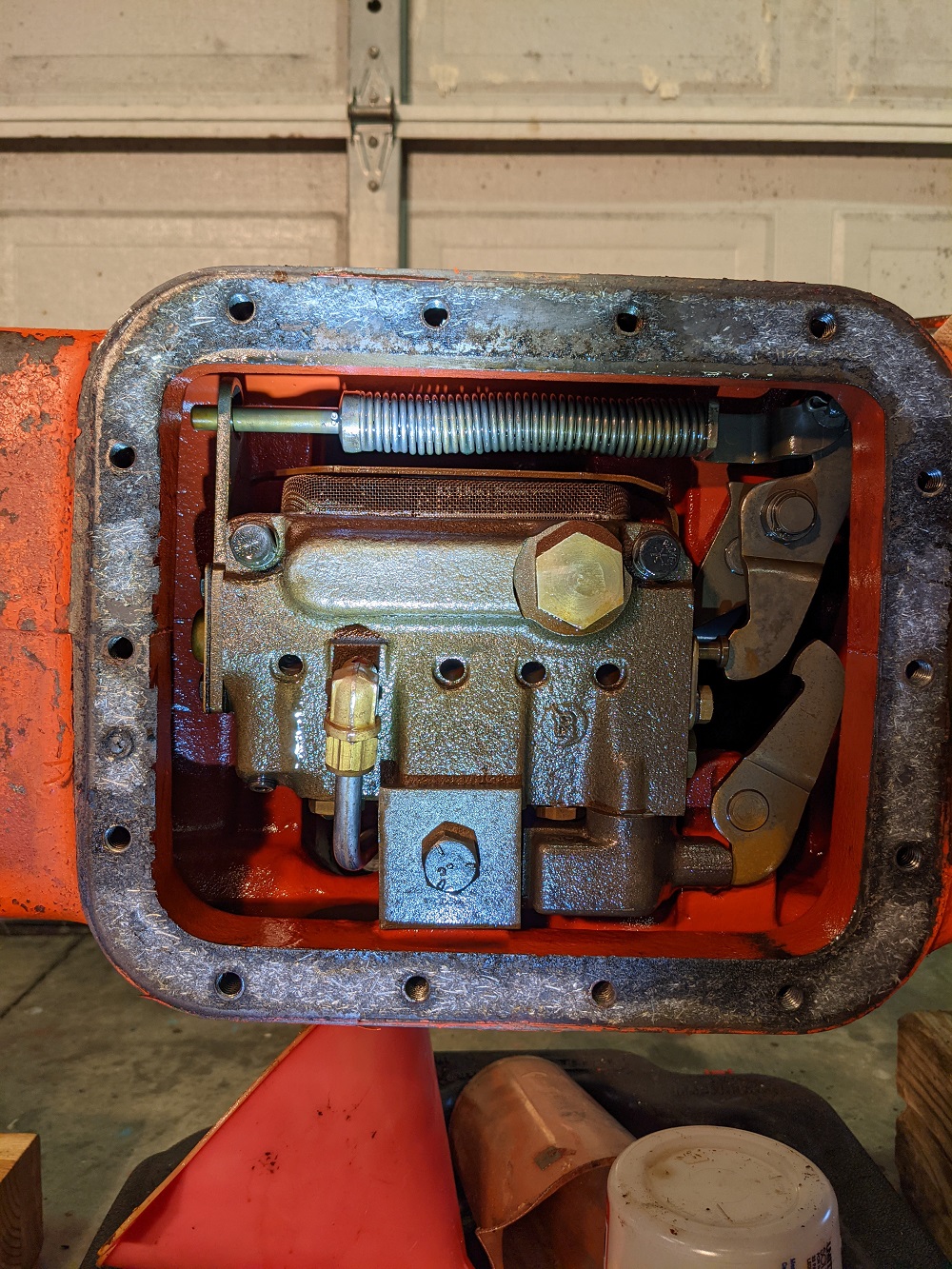

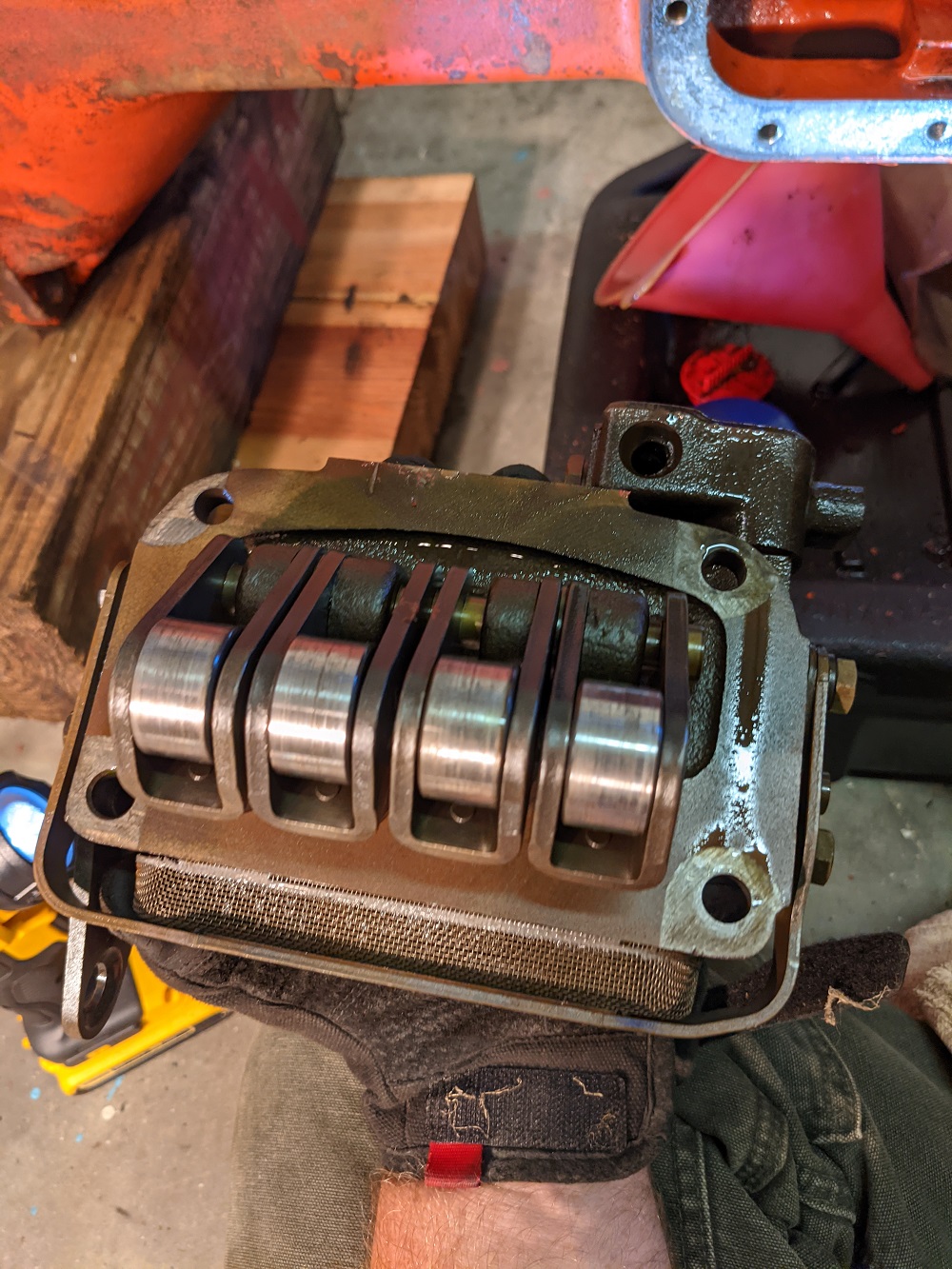

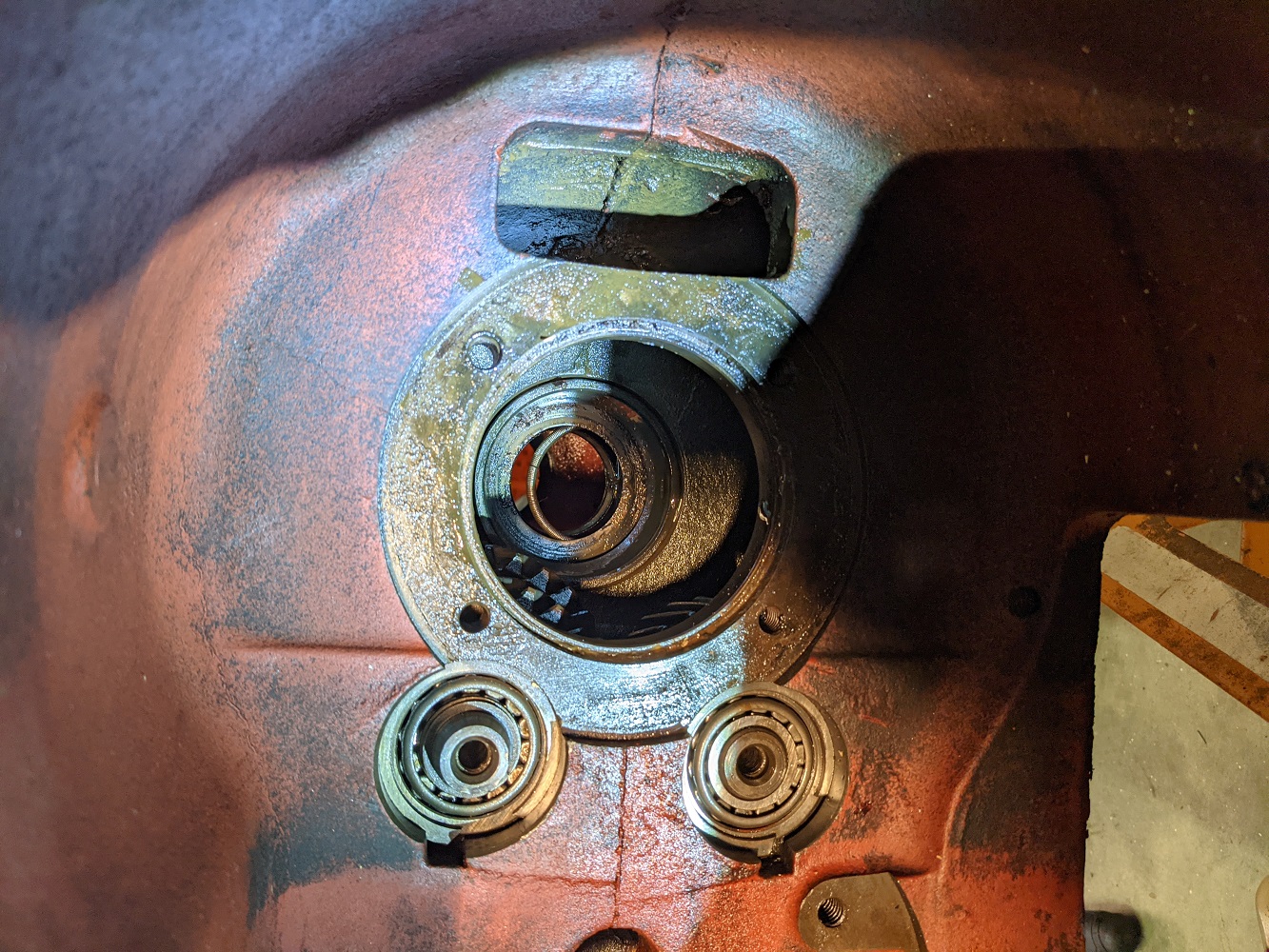

While waiting on parts for PTO and for the power director I've started disassembling the rest of the torque tube. As stated in earlier thread this tractor had a rattle when in neutral at low idle. It could have just been the broken power director, but I figure there's no better time to replace all of these bearings and seals on the engine clutch shaft, idler shaft, and intermediate shaft. Probably get the hydraulic pump rebuilt... Seems like a never ending list ... Below are some pics from today.          |

Replies:

Posted By: John m

Date Posted: 30 Oct 2021 at 7:26am

| Nice pictures. My winter job is replacing the the torque tube housing and rebuilding the power director on my 190xt. Hydraulic pump ate some of the ground up gears while brush hogging this summer. Keep us updated, I'm learning as I go. John |

Posted By: jaybmiller

Date Posted: 30 Oct 2021 at 7:34am

|

sigh, my back hurts just LOOKING at that 'project'. seems like a lot of rust in it..or is that just my aging eyes ?? I do admire the ambition you guys have !! ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: SteveM C/IL

Date Posted: 30 Oct 2021 at 6:12pm

| It's old rust Jay. It'll be fine...just add new hy-tran type oil and it will live longer than the rest of us. |

Posted By: WeisAC2

Date Posted: 31 Oct 2021 at 9:31am

|

Jay, there's some rust in the PTO gear compartment. This compartment communicates with the power director compartment which also had some rust. I'm going to get everything cleaned up as best I can then fill with universal hydraulic fluid. The hydraulic pump compartment doesn't have much rust and to me looks pretty good. I'm kinda hoping to find a bad bearing on the engine clutch shaft to justify me completely disassembling this torque tube. Seems warranted either way tho...

|

Posted By: John m

Date Posted: 31 Oct 2021 at 1:26pm

| Just my opinion but, sometimes ya just gotta take em apart and fix them. Haven't figured out exactly what the issues were to necisitate doing it but I'm sure it's warranted. I personally enjoy keeping up with his progress seems I have a similar job to do this winter. Thumbs up fer me. |

Posted By: John m

Date Posted: 31 Oct 2021 at 1:29pm

| By the way that clacking and noise he's hearing is what I was hearing from my 190 before the gears let go in the tube. |

Posted By: jaybmiller

Date Posted: 31 Oct 2021 at 3:11pm

|

yeah, I know about rust..... rearend diff gear of Troy was rusty from resting for 25 years. I'm just not dedicated or 'focussed' enough to replace that silly PTO O-ring.... I do admire you guys that DO though... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: DrAllis

Date Posted: 31 Oct 2021 at 5:25pm

| Generally, all of those Power Director tractors have a certain kind of rumbling noise (gear backlash rattle) when they idle and you can make it go away by leaving the hand clutch in neutral or throttle the engine up a bit. Cold oil, maybe not so much. Hot oil more noticeable. |

Posted By: MACK

Date Posted: 31 Oct 2021 at 7:34pm

| splines and gear wears on torque tube shaft causing gear to jump up and down on shaft will make a noise plus brake plates in hi side of PD. MACK |

Posted By: WeisAC2

Date Posted: 05 Nov 2021 at 3:24pm

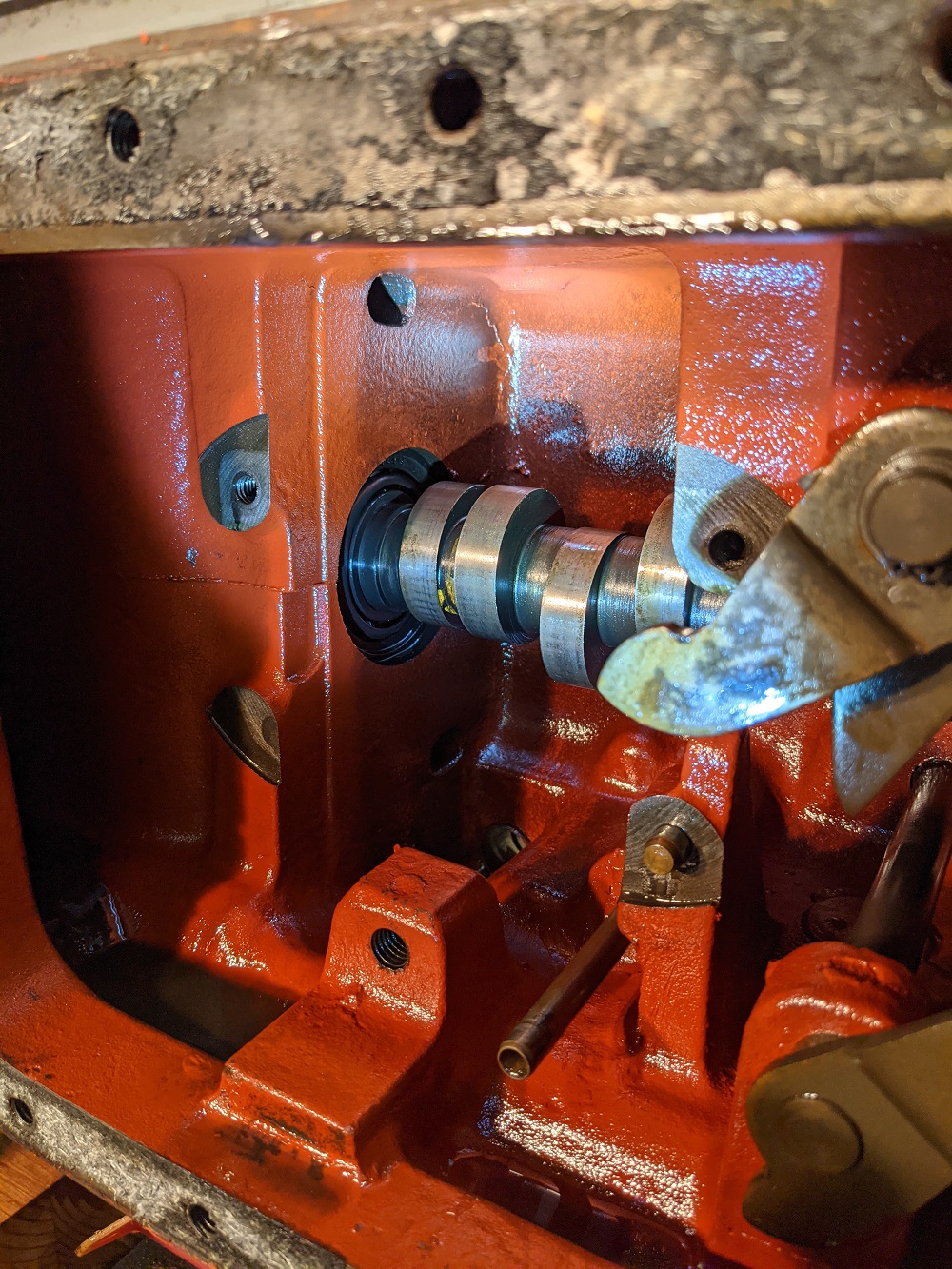

Made a little more progress today. Used a slide hammer to get the front PTO shaft out. That worked very well! Once the PTO shaft and gear were out I was able to remove the engine clutch shaft. I should get parts in next week and will start replacing all of these seals and bearings. Once done with these two shafts I'll then do the idler and intermediate shafts.   Front PTO shaft removed  View of idler shaft and intermediate shaft gears    Belt pulley pinion gear      |

Posted By: John m

Date Posted: 05 Nov 2021 at 5:34pm

| Looking good. Nice pictures and updates. Your gonna get er done yet. |

Posted By: WeisAC2

Date Posted: 06 Nov 2021 at 11:03am

|

Thanks John! I'm thinking that the pictures may help someone in the future thinking about doing this project. I know I've appreciated pictures and videos that other's have posted on their projects. Gotta start getting everything cleaned up for reassembly.

|