wd pistons with 45 crank compression?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=184158

Printed Date: 04 Feb 2026 at 2:00pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: wd pistons with 45 crank compression?

Posted By: JamesP

Subject: wd pistons with 45 crank compression?

Date Posted: 25 Oct 2021 at 6:51pm

| What would the compression be on a wd45 engine with new overbore wd pistons? Anybody ever dyno one? Thanks |

Replies:

Posted By: DrAllis

Date Posted: 25 Oct 2021 at 7:11pm

| There are probably a half-a-dozen WD pistons, all with differing compression heights. What is the exact distance between the top (flat top I hope) of the piston at TDC to the top of the block ?? |

Posted By: JamesP

Date Posted: 25 Oct 2021 at 7:35pm

|

Not sure Doctor, I am looking at piston kits on ytparts. They have a flat top for a 175-wd45 kit might be higher than the wd ? I am looking to get 65 hp, hoping a set of overbores and longer rods for 12-1 will be enough. Maybe murphy rockers. Any advice? Using calculators they say should make 69. I can bore the block and get some more cubes, but if I can do simpler I am all for it. Thanks

|

Posted By: Jtaylor

Date Posted: 25 Oct 2021 at 7:38pm

| Tuning in for the latest and greatest. intrigued myself |

Posted By: MACK

Date Posted: 25 Oct 2021 at 8:38pm

| 12-1 will take some more work. Better rods, better fuel, better ignition, and something to hold main webbing in block. MACK |

Posted By: DrAllis

Date Posted: 26 Oct 2021 at 6:34am

| Anything over 8 or 8.25 to 1 compression ratio will require higher octane fuel. You didn't post this is the Tractor pulling section, so I have to assume you think you're going to use this to "farm" with ??? The last 114 octane fuel I bought was $10 bucks a gallon. I think you could be looking at a "kit" that is in the 8 to 1 range on YT, and that could use regular 87 octane gas if the timing is set right. A larger carburetor will easily add HP and torque without changing the internals of the engine. Or, buy a regular Power Crater bowl 4 1/8" kit and have Murphy actually make you a set of rods to get that 12 to 1 compression utilizing the bowl design piston top. As Mack said, the center main bearing cap will be the weak link on a W-226 engine as will be the crankshaft, where a G-226 would be stronger. Either one I usually build a center main cap brace for to help the strength. |

Posted By: DrAllis

Date Posted: 26 Oct 2021 at 8:55am

| An old M & W overbore piston and sleeve chart had the D-17 at 57 PTO HP @ 1650 RPM with their 4 1/8" bore/7.5 to 1 compression ratio bowled pistons. If you removed the power steering pump, you'd gain 2 to 3 HP putting you at 60 ish HP at 1650 RPM. Compression ratio of 8 or 8.25 to 1 should add another 3 to 4 HP. Your roller rocker arms with more lift should get you to the 65 number and a correct larger carb would hit 69. Again, all of this is at 1650 full load RPM, not 1400 RPM like a WD45 is. |

Posted By: TramwayGuy

Date Posted: 26 Oct 2021 at 9:02am

| A 175 piston set would not be any higher compression than WD pistons, because the stroke on a 175 is the same 4-1/2” as a WD-45. WD piston can be way higher, depending on which one. |

Posted By: Alvin M

Date Posted: 26 Oct 2021 at 9:40am

| WD45 crankshaft with wd over bore flat top pistons 10to1 i built 4 like that about 65 hp |

Posted By: JamesP

Date Posted: 26 Oct 2021 at 4:07pm

|

Thanks for your input guys At what hp. does the block fail? I would think, and could be wrong, that high hp output would shove the crank out the bottom, but, low hp and high compression would do the same? I dont know. If so, would I be better off building a 302 with 9-1 and run on pump fuel? I am pulling div. 2 , 3 mph. on 15.5-38s, 4000-5000 lbs. Another well known allis builder advised me 65 hp would be enough and to much is not an advantage. As an alternative, I can get a diesel rear end and just rebuild with a kit. My club has a 2000 rpm rule on 4 cylinders, that would put me just at 3 mph. But I would think without the extra wheel speed I will be at a big disadvantage. |

Posted By: DrAllis

Date Posted: 26 Oct 2021 at 7:40pm

| You're better off with the WD45 gas ring and pinion for a faster low gear IF the engine can handle it. Depends on the sled and soil types of tracks. Your tires aren't cut (I assume) so that will help the HP requirements a little. Now that we actually know how you're going to use the tractor, high compression with 4 1/8" bore is probably good enough. Roller rockers will take place of a cam regrind. I doubt I'd worry about a center main cap girdle for what you're trying to do. 175 carb venturi is larger than the OEM venturi if it is still available. Ignition timing MUST be retarded as the compression goes UP. 12 to 1 with 110 octane fuel I'd probably have the timing at 20 degrees BTDC at full throttle to start with. Dyno tuning is the best but 20 degrees will be close. Mark your flywheel accordingly. |

Posted By: JamesP

Date Posted: 26 Oct 2021 at 7:55pm

|

Thanks Doc, appreciate the advice. I think that is the plan, I let you guys know how it goes, thanks again

|

Posted By: Bill_MN

Date Posted: 28 Oct 2021 at 6:48pm

|

I have overbore WD flat top pistons on a 45 crank, .53" to top of sleeve and 8.86:1 calculated static CR with a stock thickness compressed head gasket, don't remember how thick. Pistons were identical measurements to original except for bore. Doesn't mean much but will give you an idea. Never dynoed or did compression test but I do have to run 30-50% ethanol to keep it happy.  ------------- 1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow |

Posted By: JamesP

Date Posted: 28 Oct 2021 at 7:34pm

|

Thanks Bill, that helps. Do you pull?

|

Posted By: JamesP

Date Posted: 28 Oct 2021 at 7:35pm

| I was thinking of opening the carb jets and running e85 as a cheap alt to racing gas. |

Posted By: DrAllis

Date Posted: 28 Oct 2021 at 8:01pm

| Bill, I would encourage you to run a compression test with throttle wide open, a battery charger connected and all plugs removed. I'm thinking 200 psi. |

Posted By: PaulB

Date Posted: 29 Oct 2021 at 6:49am

I highly recommend it: E85 is supposed to be 105 octane. I would not even consider running a spark ignition pulling tractor on anything else unless the winey club rules wouldn't allow it, Then just find an open minded place to pull. E85 has the advantage of cooling the intake charge to get more air/fuel into the engine. Way back when I fist put the turbo on the CA I was running ice water through the waterjacket of the turbo to help with the detonation problem with 110 octane racing gas. When the E85 became available, I switched to engine water from the waterpump bypass to keep the intake side from freezing. On the naturally aspirated engine I made up a heat shield like for a Kerosene tractor would have, otherwise the intake would freeze and stall the engine. Install an EGT gauge and try to get about 800-1000 degrees under full load. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: Charlie175

Date Posted: 29 Oct 2021 at 9:47am

I get 210 psi with HC Flatops in a M code motor. ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: DrAllis

Date Posted: 29 Oct 2021 at 10:18am

| Whose motor kit is that ?? A p/n please... |

Posted By: LouSWPA

Date Posted: 29 Oct 2021 at 10:49am

------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: Charlie175

Date Posted: 29 Oct 2021 at 11:29am

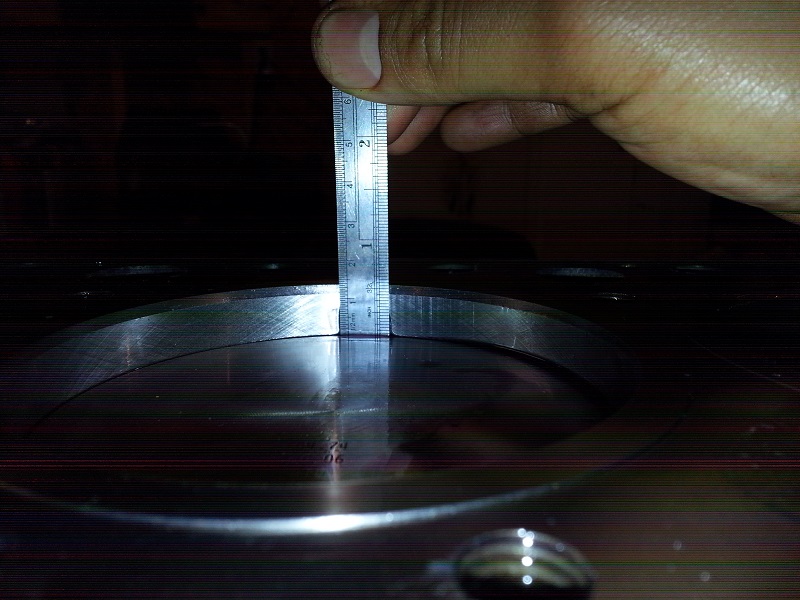

SK-156 Wrist pin lined up, the D17 piston is higher on the edges. It requires 93 octane with the flat top  ------------- Charlie '48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD |

Posted By: Bill_MN

Date Posted: 29 Oct 2021 at 4:14pm

------------- 1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow |

Posted By: DrAllis

Date Posted: 29 Oct 2021 at 5:31pm

| 170 and 175 compression check usually shows 175 to 180 psi, so 210 psi is a noticeable increase. |

Posted By: DrAllis

Date Posted: 09 Oct 2025 at 8:28pm

| BACK TO THE TOP PLEASE. LOOKS LIKE AN SK 156 piston/sleeve kit is more than 8 to 1 for sure. With 210 psi cranking compression it might be 10 to 1, too high to farm with because it would require better octane gas. |

JamesP wrote:

JamesP wrote: