My C project

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=173123

Printed Date: 23 Oct 2025 at 2:22pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: My C project

Posted By: kelso

Subject: My C project

Date Posted: 27 Jul 2020 at 6:08am

|

Another AC story:) I have been working on restoring a family 1949 model C that lived on Lopez Island in the San Juan islands of Washington State. In the late 60's it was moved to Port Townsend, Washington on the mainland and became non-operable. In the 1980's is was given away and the family lost track of it assuming it was scraped. When I became part of the family I wanted to find it and restore it but figured it had indeed been scraped. Well a few years ago a picture was found of it being loaded on a tow truck. We contacted the guy who got it and low in behold he remembered the tractor. Of course our first question was what did he do with it???? He stated that he had sold it to a farmer only a few miles away from him. With that news I made a mad dash over to the farmer who had brought it and well yes he still had the tractor:) The sad news was that he never got the tractor operating. He had broken the engine open to work on it but after years in the barn he pulled it out into the pasture and it became a poesy bed of junk and briers. It has been sitting out for about 30 years with the engine block open to the elements. Needless to say I brought it off his hands very quickly:) This tractor has had many stories told about it by the children who grew up with it so I wanted to find it and do a complete restoration back into operating condition (big eye syndrome). Below is a picture of the C as I found it on the farm. A close-up before starting work |

Replies:

Posted By: IBWD MIke

Date Posted: 27 Jul 2020 at 7:54am

|

That's going to take some love! |

Posted By: Boss Man

Date Posted: 27 Jul 2020 at 8:24am

| Good luck on your adventure. Hope it isn't as bad as it looks. |

Posted By: kelso

Date Posted: 27 Jul 2020 at 11:30am

|

Here are pictures at the start of the process. First removing the sickle mower.  As I start to break it apart  Yes it is a rusty bucket. I have used a lot of elbow grease, heat, and BK blaster to get it apart:)

|

Posted By: Dick L

Date Posted: 27 Jul 2020 at 11:46am

|

Not an impossible task! I have started with less. The C I used in tractor pulls was in such condition. It is like they tell you how to eat an elephant. (one bite at a time) There is not a bolt or part I have not removed or replaced on the B's and C's. I bought 7 of each all in non running condition over the past. I have many pictures in fotki that you are welcome to look at for reference if you have a need. http://public.fotki.com/DickL/" rel="nofollow - http://public.fotki.com/DickL/  |

Posted By: Steve in NJ

Date Posted: 28 Jul 2020 at 12:46pm

|

Great story so far! I've seen worst than that, but it does take big love (and a little extra wide wallet) to bring this ole' girl back to lookin' better than new! My first B that I did (which I still have yet) was out in the Adirondack woods rustin' away for years till yours truly came along to rescue it. My wife at the time thought I was nuts, but that was over 20 years ago already! My B still runs nice, but its time to do her over again pretty soon. She's been sitting outside under a tarp for quite a few years cause she gave up her space in the pole barn for some Antique cars. She still works around the property yet. Keep at it, before ya know it, she'll been lookin' dandy!! Steve@B&B BTW, when your ready for a wiring harness, or any electrical, stop by to see us via the internet. We can fix ya up with lottsa' cool stuff....! ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: Boss Man

Date Posted: 28 Jul 2020 at 1:14pm

Read that as the wife you had at the time needed a do over because she was under the tarp......lol

|

Posted By: garden_guy

Date Posted: 28 Jul 2020 at 1:35pm

|

Oh man, make sure to take lots of pics as you go -- I love these restoration threads!! |

Posted By: Dave(inMA)

Date Posted: 28 Jul 2020 at 9:39pm

|

Should be a great project! Looking forward to your pictures and stories along the way. ------------- WC, CA, D14, WD45 |

Posted By: Jacob (WI,ND)

Date Posted: 28 Jul 2020 at 10:16pm

|

I'm a sucker for projects, and bringing things back from the dead. Keep us posted, keep up the good work! ------------- Jacob Swanson 1920 6-12; 1925,1926 20-35 longfenders; 1925,1926 15-25's; 1927,1929 20-35 shortfenders; C; B's; IB; WC's; WD; WD45 |

Posted By: Sugarmaker

Date Posted: 28 Jul 2020 at 10:59pm

|

kelso, Welcome! As one guys says on another tractor forum: if it casts a shadow it can be restored. This tractor is close to that. Good news is there are lots on donor tractor/s and parts out there. Nice project! I will be watching too. Makes me want to check on that CA near by too! Good documentation/ pictures! Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: kelso

Date Posted: 29 Jul 2020 at 3:59pm

|

Thank everyone for your support! Yes Dick these are slow but fun projects. I now have 3 C's and 1 B models to work with:) I have been using your pictures a lot what a good resource. The hardest part to work on has been the final drives. Getting the brake pins out and then the brake drums off took a long time. They were some of the most rusted and seized parts to get off. I was very surprised how good of a condition the bearing and cups, and gears are. There is some gunk but they were not dry and rusted out. I am replacing all the seals but the bearings are in great shape after a good cleaning. Tim |

Posted By: Dick L

Date Posted: 30 Jul 2020 at 6:46am

|

The brake pins are easy the way my pictures show. I had one fellow wanted to trade a final drive he couldn't get the pins out. He had already put holes in the final drive. I took my air chisel with a long punch I had made up out to his trailer. I pushed out his pins in a puff of rust dust. He took his own final drive back home. The pictures are from before I started using the air chisel. My moto has always been (don't force it, get a bigger hammer) My bigger hammer !  |

Posted By: steve(ill)

Date Posted: 30 Jul 2020 at 9:25am

I bought a CASE backhoe that looked like that, setting in the field........... I can still remember the kids saying "pour some gas in it dad and lets pull start it "...  ------------- Like them all, but love the "B"s. |

Posted By: kelso

Date Posted: 17 Aug 2020 at 11:21pm

|

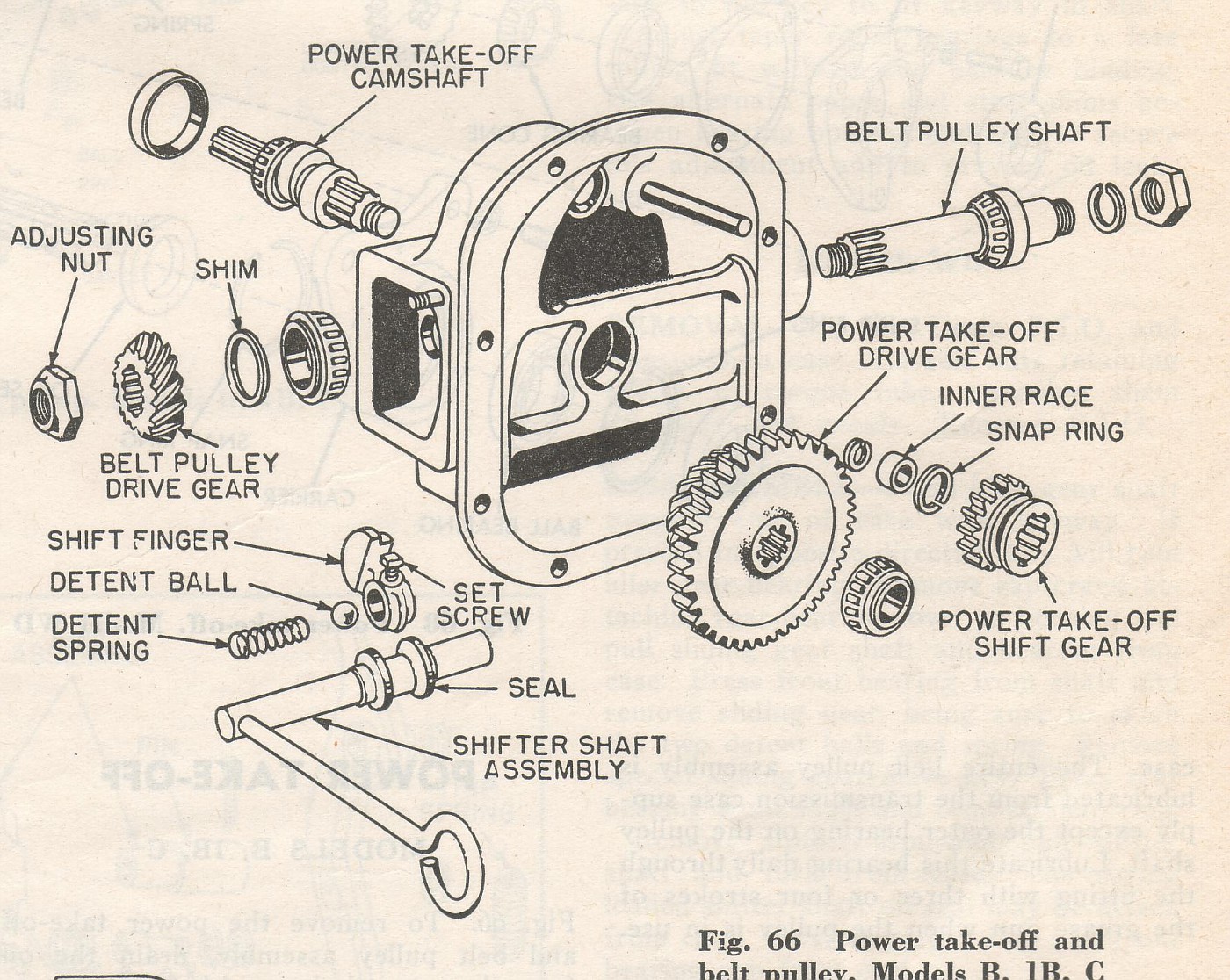

I am making progress but I have several questions. I have been trying to get the axles out of the final drives to replace the axle seals. I have gotten the retaining nut loosen on the axle by the bull gear and have been trying to drive them out but have had no luck so far. I do not have any kind of puller (like shown in the service manual) that could pull the axle out from the hub end of the final drive. Does anyone have suggestions on getting the axle out. The other problem is getting the PTO shaft out so I can replace its seal and then remove the Belt pulley shaft so I can replace that seal also. I have wedged the gear and have tried to press the PTO shaft out with a 12 ton press but no luck so far. I even had the press bend with the press force. Again any suggestions with the PTO shaft? Thanks, Tim

|

Posted By: Sugarmaker

Date Posted: 18 Aug 2020 at 5:44am

|

Tim, I have never been into a C. So cant help much. But two things. There will be a bunch of folks on here that will help you. And second when I am in doubt I call Bill at Sandy Lake Implement. He is a good recourse for these AC tractors. We need more pictures too! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dick L

Date Posted: 18 Aug 2020 at 7:25am

The final drive axle is a press fit. Most of the time trying to beat them out will damage the threads on the end. As they are pressed out the inner nut will have to be loosened a littlie at a time as the axle moves.  Most likely you have not removed the snap ring.  |

Posted By: kelso

Date Posted: 31 Mar 2021 at 3:42pm

|

hello folks sorry for the long time in getting back to ya'll on my model c work. I owe ya'll a lot of picture but right now I need a quick bit of info. I am rebuilding the oil pump and am trying to get the blades/vanes in the right direction. The shop book saids to install the tapered edge of the blades/vanes leading in a anti/counter clockwise direction from the drive end! What is considered the drive end for this purpose? I currently have them installed with the tapered edge leading to the right as looked from the oil pump cover end toward the engine block. I have several books and forum post but my brain is not getting this right. Thanks for your help. Tim

|

Posted By: kelso

Date Posted: 31 Mar 2021 at 4:15pm

|

below are two pictures of my oil pump. the second one shows the blades/vanes as I have them installed. The first shows the inside of the cover cap with a little wear. Is this two much wear? I have a rebuild kit that I am using.   |

Posted By: steve(ill)

Date Posted: 31 Mar 2021 at 5:46pm

|

The blades as installed should be about FLUSH with the side of the case ?? If your cover plate has .020 inch clearance and you install it, you will have that area as LEAK BY inside the pump.. The blades should be FLUSH and you should sand or machine the cover FLAT... Then you add a very thin gasket to get Minimum clearance ( maybe .003 ?)

------------- Like them all, but love the "B"s. |

Posted By: kelso

Date Posted: 31 Mar 2021 at 6:38pm

|

Steve, Thanks, I have cleaned (removed the old gasket) and sanded the cover and have it petty smooth. What do you think about the direction of the blades? I only got a little oil pressure with them this direction. To me this is backwards to what the paper saids about the taper of the blade facing the counter clockwise direction of travel. I am taking the drive view means from the driver seat looking toward the engine which would make the rotation counter clockwise. Tim

|

Posted By: steve(ill)

Date Posted: 31 Mar 2021 at 6:53pm

|

the DRIVE they are talking about is the DRIVE END of the PUMP... it plugs into the cam shaft. ........... and yes, the book is confusing.

its been a while since i read the book.. but i think i installed the blades as in your photo.... end clearance on the pump cover is CRITICAL. for pressure, are you testing on the bench or in the motor ? Cam shaft is hollow and there is a spring / piston at the front end that must be in position to maintain pressure.

------------- Like them all, but love the "B"s. |

Posted By: C in Concord

Date Posted: 31 Mar 2021 at 7:01pm

|

Manual says the vanes must be installed with tapered side towards direction of rotation. Rotation is clockwise when viewed with cover removed, as the image above shows. Looks like you have it right. Ben ------------- Leave things better than you found them. 1941 Model C (restored 2020) |

Posted By: kelso

Date Posted: 02 Apr 2021 at 4:38pm

|

Thanks everybody for the oil pump replies. I got the oil pump rebuild kit and new check ball in oil pump and tractor back together. Tractor starts up but still not priming so I stop and prime oil pump the way Dick L. has stated (rubber hose on oil filter filler tub and fill with oil) I laid the rubber hose over in the head. Start tractor and oil pressure come up to the 'N' of normal on the oi gauge and oil is pumping out of hose. Stop tractor and 15 minutes later start tractor and no oil pressure:( Re-prime oil pump and get oil pressure to 'N' of normal. Every time I let tractor sit it losses oil pump prime. Checked all fittings I could and everything is tight. Any suggestions????? Tim

|

Posted By: steve(ill)

Date Posted: 02 Apr 2021 at 6:42pm

|

check ball not seating ? clean up the seat... maybe touch with a drill bit if it looks real bad.. if not too bad, smack the ball with a hammer and punch and deform the seat to fit the ball.

------------- Like them all, but love the "B"s. |

Posted By: AC720Man

Date Posted: 02 Apr 2021 at 7:48pm

|

You do have the pump vanes installed correctly, we just rebuilt our D15II. We bought a rebuild kit which includes the springs, new blades,ball and new pump. We have great oil pressure. There is a lot of wear on the end plate as it appears extremely worn especially on one side which would mean a lot of wear where the pump shaft slides into the housing. The kit is well worth the money it cost, it will provide the engine with the blood it needs to survive. There are certain parts I will not reuse, our vanes, pump, springs, and ball looked good. But we choose to replace them since it was 53 years old. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: kelso

Date Posted: 04 Apr 2021 at 6:52am

|

Steve, That is what I was afraid of:( I have a completely new pump insides...rotor, new ball and spring, vanes and springs. The new ball seamed to seat fine into the rotor but I did not tap it in to make a hard seat. The new spring is tight holding the check ball. Is there a way to bench test the pump operation before installing in motor? I used both thin gaskets under cover which is what was on the pump before I rebuilt it. There was some play but not much could this cause lost of oil prime? I am getting a 0-30psi oil gauge so I can see what actual pressure I am getting. Tim |

Posted By: kelso

Date Posted: 04 Apr 2021 at 3:35pm

|

another question I have is when did the model C's switch from a non-pressurized radiator to a pressurized radiator. Mine is a 1949 C and seems to have had a pressure radiator cap, from old photos, but the book shows a cap like the gas cap. If it is pressurized what cap is right? I have a 7lb cap but I also see a 4lb cap used. What Little I have run my C so far I had the radiator over flow at about 110 degrees with a a 7lb cap. I have a rebuilt thermostat on the tractor. Is this normal?? Tim

|

Posted By: steve(ill)

Date Posted: 04 Apr 2021 at 9:16pm

|

You could probably test the pump on the bench spinning it with an electric drill.. I have never bothered to do that.......You should not notice any SIDE TO SIDE shake on the pump. The internal clearance is only 2-3 thousands i think ? If you have too much , you need a paper thin gasket . The blades should be the same width as the pump case. The only clearance you get is putting a 1-2 thousandths paper gasket on each end... The cover can not have excess wear / more clearance.... The only time i have heard of oil LEAKING BACK was when the ball did not seat in the pump. If your radiator is over flowing at 110 degrees, it could be the thermostat is stuck, not opening, or in backward... It is spring loaded, right ? I have several tractors and they have 4 or 7 psi caps.. None are "no pressure" caps. Since there is no overflow tank, you can not fill the radiator to the top.. I have the top tank about 1/2 full. Keep level down an inch and give room for things to breath / expand. ------------- Like them all, but love the "B"s. |

Posted By: kelso

Date Posted: 05 Apr 2021 at 2:39pm

|

Does anyone know of a source for rebuilt or rebuilding and checking these oil pumps? I am now looking for a completely rebuilt oil pump for a AC 1949 model C. Thanks, Tim

|

Posted By: Ted in NE-OH

Date Posted: 05 Apr 2021 at 5:29pm

|

Sandy Lake Implement has them, see advertisers ------------- CA, WD, C, 3 Bs, 2 Gs, WC, I-400, 914 |

Posted By: steve(ill)

Date Posted: 05 Apr 2021 at 5:40pm

Tim, i know your rebuilt or heavily repaired the motor... at the FRONT of the hollow cam shaft is a small spring loaded plug that helps maintain pressure in the system... You remember seeing that ? ........... I new good pump is always a benefit !!!  ------------- Like them all, but love the "B"s. |

Posted By: kelso

Date Posted: 05 Apr 2021 at 7:02pm

|

I contacted Sand Lake today and they can check out my pump. I also found a pump off a 1940 B block that I may try. Steve I did place the spring and thrust plunger back in the front of the cam shaft - spring first and then plunger toward the gear cover. Both looked good so I cleaned and replaced them. I may take the gear cover off to double check and rule out the thrust plunger and spring as a problem. Tim |

Posted By: steve(ill)

Date Posted: 05 Apr 2021 at 7:44pm

|

Pump repair might fix it... Maybe wait on the front end inspection ? ------------- Like them all, but love the "B"s. |

Posted By: kelso

Date Posted: 14 Apr 2021 at 11:00am

|

here is a picture of the C as I have been fine tuning her:)  |

Posted By: kelso

Date Posted: 14 Apr 2021 at 11:48am

|

Well guys I have been making some progress:) I now have good oil pressure and prime (most of the time)!! What I did is take the tractor apart again and replaced the C oil pump housing with a B oil pump housing. I put the new rebuild kit I had put in the C into the B housing. The B housing looked a little better than the C. I rechecked the new check ball. spring and its fit into the rotor and they were good. The main difference is I only used one gasket under the cover instead of two as on the C. I had found an old 0-80 psi oil gauge off of a C tractor and tried it so I could see an actual pressure number. After I reconnected the tractor and tried the oil pump it would not pick up prime so I primed the oil pump and had some pressure on the old gauge. The gauge measured about 2/3 way between 0-20 psi markers so this was much better:) On Monday my new 0-30 psi oil gauge came in and I put it on the tractor to see what I got. I did not re-prime the oil pump and tried it with the new gauge. Well amazingly it picked up prime from sitting over night and the new gauge registered oil pressure and it kept climbing to 20psi:)  It has settled being between about 15psi and 20psi depending on rpm and running temp it seams. It has keep prime all but one time when after running it 5-6 times it would not re-prime on its own. It has settled being between about 15psi and 20psi depending on rpm and running temp it seams. It has keep prime all but one time when after running it 5-6 times it would not re-prime on its own.Yesterday it had prime from the start and did not lose it  Below are a few pictures of the gauge and the rocker arm getting oiled   On the rocker arm you can see the oil being pumped and moved along like it is supposed to be soooo I got oil everywhere   |

Posted By: kelso

Date Posted: 14 Apr 2021 at 12:18pm

|

What I have now run into after getting oil pressure is the tractor dying. While working on the oil pressure issue I have run the engine a short amount of time i.e. 10-60 sec are so. The engine starts up just fine and runs smooth with no signs of sputter and cutting out. After I got oil pressure and ran the engine longer it has started cutting out and going dead. I have gotten the temperature up to 170 degrees but the cutting out has happened at different temps. I have a rebuilt mag. new plugs and wires and timing has been good. The engine will be running smoothly and then just cuts out with very little signs of lugging down. The most it has run before cutting out is just under 2 minutes. I have re-checked the fuel system and it all looks good. Any ideals???? Tim |

Posted By: steve(ill)

Date Posted: 14 Apr 2021 at 12:31pm

|

If it starts back up within a couple minutes, it probably is NOT electrical.. your running out of gas.. Sounds like it runs on what is in the bowl, then dies out... bowl refills slowly, then you can run another 2 minutes.. Restriction in gas tank, sendiment bowl, line or carb inlet... or bad float level.. Pull the line off at the carb and put into a bucket.. see if you get a constant flow from the tank / bowl, line... that will narrow down where to look. ------------- Like them all, but love the "B"s. |

Posted By: Luke114

Date Posted: 14 Apr 2021 at 1:35pm

|

That looks like pretty solid oil pressure for a C. What does the tube that goes up inside your oil filter look like? Is it sort of rounded off with a small hole? Or just a straight hollow tube? And by the way....WOW!! Your photos went from rust bucket to shiny! That thing is really looking good. Were you able to save the original gas tank, radiator, tool box?

|

Posted By: Steve in NJ

Date Posted: 14 Apr 2021 at 2:20pm

|

Man, you've been hammerin' on that baby! From junk pile to a shiny gem that runs! Great job so far. I'm wit' Steve. Sounds like a fuel delivery problem...... Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: kelso

Date Posted: 14 Apr 2021 at 3:19pm

|

Thank guys...I will recheck the gas system all the way through. I had the carburetor rebuilt by Sandy Lake and have not done any adjustment to it other than the fuel mixture screw. When I turn the screw there is not any noticeable change in the running. Is there any other adjustment on the carburetor??? Here is a picture before I got the valves adjusted and started the engine the first time. I was dry fitting everything to see how they fit but getting the radiator and cowling to fit was time consuming. I have a lot of pictures on the rebuild and video of it starting and running but they are two much for this site to store. I am working on getting them on my Dropbox account so everyone can view them.  |

Posted By: steve(ill)

Date Posted: 14 Apr 2021 at 3:21pm

|

how about a little story about the PREP , PRIMER, PAINT... what brand ? Looks VERY NICE ! ------------- Like them all, but love the "B"s. |

Posted By: kelso

Date Posted: 14 Apr 2021 at 3:41pm

|

Luke114 ... the oil tube in the oil filter is hollow with two side holes at the top along with a hole at the very top. The top of the tube is rounded. Below is a picture of the tube and you can just see the side holes and the top hole and rounded tub. You should be able to zoom in to see the holes better.  Luke114....The new parts are the battery box, door to tool box, water pump, and seat. The fenders, instrument box, gas tank, front rims and one rear rim are off a C parts tractor as original ones were two far gone. The tires are off a C and B parts tractor. The radiator core is new but housing is original. The cowling, hood, tool box, one rear rim, and all main parts are original but cleaned and rebuilt as needed. Tim

|

Posted By: kelso

Date Posted: 15 Apr 2021 at 11:42am

|

I have gotten some of the videos I have taken of the engine starting, running and oil pressure gauge on my Dropbox so you can look at them. This is the link to my folder with pictures and videos of the AC model C restoration. I will be adding move pictures and videos as I can. http://www.dropbox.com/sh/uq9xvwmaq741zow/AADXvSGoXa_Tyt9PyL5-7kkPa?dl=0" rel="nofollow - https://www.dropbox.com/sh/uq9xvwmaq741zow/AADXvSGoXa_Tyt9PyL5-7kkPa?dl=0 Below are the first two times that the tractor engine has been cranked in 40+ years. http://www.dropbox.com/s/1ij09ry6xe6ii7i/First%20cranking%20in%2040%2B%20years-IMG_5708.mov?dl=0" rel="nofollow - https://www.dropbox.com/s/1ij09ry6xe6ii7i/First%20cranking%20in%2040%2B%20years-IMG_5708.mov?dl=0 http://www.dropbox.com/s/rkiqcot3nwb7yf5/Second%20cranking%20in%2040%2B%20years%20-%20IMG_5709.mov?dl=0" rel="nofollow - https://www.dropbox.com/s/rkiqcot3nwb7yf5/Second%20cranking%20in%2040%2B%20years%20-%20IMG_5709.mov?dl=0 We had no oil pressure at first and had to prime the oil pump if engine set 10+ minutes but it runs and sounds good  http://www.dropbox.com/s/du2nqp5i3f60i51/Priming%20oil%20pump%20and%20oil%20gauge%20reading%20to%20the%20N%20-%20IMG_5760.mov?dl=0" rel="nofollow - https://www.dropbox.com/s/du2nqp5i3f60i51/Priming%20oil%20pump%20and%20oil%20gauge%20reading%20to%20the%20%22N%22%20-%20IMG_5760.mov?dl=0 After we got good oil pressure the engine ran nicely but would just die. You can hear it running and then die....trying to figure out what the cause is. http://www.dropbox.com/s/cafyftlxhi4f9ku/Longer%20run%20before%20engine%20just%20dies%20-%20IMG_5805.mov?dl=0" rel="nofollow - https://www.dropbox.com/s/cafyftlxhi4f9ku/Longer%20run%20before%20engine%20just%20dies%20-%20IMG_5805.mov?dl=0 This is a video of the rocker arm being oiled. Oil pressure is running between 15-20 psi. http://www.dropbox.com/s/d3suh5wve9yqpz8/Oiling%20rocker%20arm%20with%20good%20oil%20pressure%20-%20IMG_5802.mov?dl=0" rel="nofollow - https://www.dropbox.com/s/d3suh5wve9yqpz8/Oiling%20rocker%20arm%20with%20good%20oil%20pressure%20-%20IMG_5802.mov?dl=0 More to follow  Tim |

Posted By: Luke114

Date Posted: 15 Apr 2021 at 2:27pm

|

6 volt sure makes them grunt a little on a tight rebuild. Looks like first rate work all around. And what's that project car in the back? Is that a Toyota? |

Posted By: Wispitfiremike

Date Posted: 15 Apr 2021 at 8:23pm

| Guessing GM product in background of one, Caprice or maybe a Riviera, the other I think maybe Peugot? |

Posted By: plummerscarin

Date Posted: 15 Apr 2021 at 8:37pm

| Riviera for sure. I see boattail glass in the rear. Don't know the imports that well |

Posted By: Alberta Phil

Date Posted: 16 Apr 2021 at 10:30am

|

Blue car is a Rover. Can't tell if it's a 2000 (4 cyl) or a 3500 (V8) |

Posted By: Luke114

Date Posted: 16 Apr 2021 at 10:54am

| A rover!! Ok that makes sense now. Thought it was one of the early Japanese models. They both had that styling that looks like a big American car, then you realize they are pint sized. |

Posted By: kelso

Date Posted: 16 Apr 2021 at 3:20pm

And Albert Phil wins the prize It is a 1969 Rover 3500S and the other car in the background is a 1971 Buick Riviera. It is a 1969 Rover 3500S and the other car in the background is a 1971 Buick Riviera. |

Posted By: kelso

Date Posted: 16 Apr 2021 at 8:45pm

|

Well guys I think I may have found the source of my engine dying problem. I have taken the carburetor and fuel line system apart several time and everything looked good as it was all new or newly re-built. Today I noticed that the float valve was not dropping when the floats dropped down. This is all new but I took it apart and worked on this making sure the float valve dropped every time the floats dropped. The rubber tip of the new float valve must have been sticking and not letting fuel into the carburetor. I put the carburetor back on the tractor and it cranked like normal and ran good for a little longer but still died. Without doing anything different I cranked the engine and it ran for ~5 minutes and then for ~10 minutes before dying. These are the longest times the engine has run before dying  Let's see what tomorrow brings  Tim |

Posted By: kelso

Date Posted: 17 Apr 2021 at 8:02pm

|

Out in the Sun!   http://www.dropbox.com/s/lp9sq7ypwgc985v/Out%20into%20the%20sunlight%20-%20IMG_5839.mov?dl=0" rel="nofollow - https://www.dropbox.com/s/lp9sq7ypwgc985v/Out%20into%20the%20sunlight%20-%20IMG_5839.mov?dl=0 Tim |

Posted By: kelso

Date Posted: 20 Apr 2021 at 3:28pm

|

Does anyone have a source for the lever spring (207883) used on the throttle control lever on a C? I have one I got at a hardware store to fit the shaft size of the lever control bolt but it's not strong enough. Tim |

Posted By: Luke114

Date Posted: 20 Apr 2021 at 3:52pm

|

Very cool video! Sounds like you've whipped the fuel problem. Float needles can really be a pain sometimes. For oddball hardware I've always liked McMaster Carr. Big spring selection that you can spec both by size and spring rate, and one of the best online catalogs out there.

|

Posted By: kelso

Date Posted: 22 Apr 2021 at 3:13pm

|

luke114 good ideal. I use MacMaster-Carr for bolts but have not through about them as a source for springs. I have found an old throttle control lever spring so I have a sample to use to find a proper new spring.

|

Posted By: Steve in NJ

Date Posted: 22 Apr 2021 at 7:14pm

|

If you are looking for a new throttle surge spring, we carry them in stock. Our P/N 1601-07C on our website if interested... Steve@B&B bb-customcircuits.com ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Steve in NJ wrote:

Steve in NJ wrote: