A/C HD5G #9552

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=167112

Printed Date: 03 Mar 2026 at 11:53pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: A/C HD5G #9552

Posted By: WaltDevore

Subject: A/C HD5G #9552

Date Posted: 03 Jan 2020 at 6:19pm

|

Hello Gentlemen, So look forward to gaining some important advice. My tractor over the years with me out of the country accumulated water in the muffler through countless freeze thaw cycles. I cleaned everything up and tried to start it. It sounded fine turning over but even with starting fluid gave no hint of kicking in. No doubt the rings are toast. There is half life on the tracks and sprockets. Is the engine rebuildable? I was told it's a 2-72 engine but don't know about that. I'm in Colorado in the mountains just west of Denver. Any value in the tractor? It has both a blade and bucket. One idler is like new, the other completely worn. I have an excellent replacement for it, but not skilled enough to install it. There is also a cracked water jacket visible through the muffler side inspection cover. I have three layers of JB Weld on it. Don't know if that will do any good. I sure love the beast. It made my life for me. I have many pictures on a facebook page: https://www.facebook.com/Allis-Chalmers-HD5G-109124077151035/?modal=media_composer" rel="nofollow - https://www.facebook.com/Allis-Chalmers-HD5G-109124077151035/?modal=media_composer Thanks for whatever you can offer!

|

Replies:

Posted By: DMiller

Date Posted: 03 Jan 2020 at 6:35pm

|

Is a 2/71 Detroit Diesel, likely the Governor control rack is stuck in OFF or No Fuel. Possibly one of the unit injectors is frozen in the off position and the rack will not allow the other to move. Are covers on the side of the engine opposite the blower, pull those and can see in the cylinders as bar the engine over, can see if really rusted or not. Simple engines, dry sleeved but is a fitting process to rebuild them replacing sleeves. Pistons have wrist pin seals and MUST be vacuum checked when assembling, no head gasket just seal rings block to head is machined fit, liner height must be within spec or will leak and or blow the liner fire rings. If intent to do this older tools available on fleabay and other sites, a Detroit 71 series engine manual is a MUST Have. |

Posted By: NomoreJohnDeere

Date Posted: 03 Jan 2020 at 6:38pm

|

Is it getting fuel? ------------- HD3 |

Posted By: WaltDevore

Date Posted: 03 Jan 2020 at 8:18pm

|

I forgot to add that. I unhooked the line from the fuel pump and could not get any fuel to come out. I filled the tank with compressed air to try to push and still nothing. Mystery as to why the pump isn't pumping. I back tracked to first filter and fuel was getting that far. Possibly a plugged line? I don't quite remember, it's been a few months. |

Posted By: WaltDevore

Date Posted: 03 Jan 2020 at 8:24pm

|

I do have the service manual. |

Posted By: DMiller

Date Posted: 04 Jan 2020 at 6:30am

| Fuel should flow gravity to the lift pump thru the filters, pull and blow air thru the lines, pull the air box intake off the blower and hand turn the engine see if the blower is rotating. Detroit's are known on older engines with enough set time corrosion to seize a blower and shear the drive splines, that in turn drives the lift pump. |

Posted By: Lee Bradley

Date Posted: 04 Jan 2020 at 7:59am

| That would also explain it no firing on starting fluid. No air through the engine. |

Posted By: WaltDevore

Date Posted: 04 Jan 2020 at 10:48am

|

Thank you for the invaluable suggestion. Would that situation be repairable? |

Posted By: Coke-in-MN

Date Posted: 04 Jan 2020 at 10:52am

|

One 2-71 in a 5B I bought was locked up - seems someone plugged the drain hole in bottom of blower box - water froze andsheared one lobe off one rotor . have rebuilt 2 engines complete with just the only special tool needed was height gauge to set injectors . Shimming the liners was a little tedious Engine is easily rebuildable - you can check the compression by removing injectors and using a compression gauge with rubber tip into injector tube . Parts are interchangeable with all inline 71 series engines , the V 71 uses a different piston. check the air shutoff and governor linkage work and rack is moving when throttle is moved also that air filter is not overfilled so air can't pass through element ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: WaltDevore

Date Posted: 04 Jan 2020 at 10:53am

|

I'm not where my tractor is right now. Can't wait to consult the manual and see how to do it. |

Posted By: WaltDevore

Date Posted: 04 Jan 2020 at 12:41pm

|

I appreciate the encouragement. How miraculous to resurrect. Back to my idler, is it possible to replace the front idler without splitting the track? The track comes off so easily running it. I can't quite get it off so far with the side jacked up. I'd hope to put the new idler on with the adjuster all the way back and use a chain hooked to the track and forward tilt to pull track over new idler. Is that too optimistic? |

Posted By: DMiller

Date Posted: 04 Jan 2020 at 12:44pm

| If rails worn enough have rolled my own off and back on, PITA but better than pounding pins. |

Posted By: dadsdozerhd5b

Date Posted: 04 Jan 2020 at 8:49pm

|

Looked at your Facebook posts. Engine interior does not look too bad. I double the blower is bad as would have to get water through motor to intake if just the muffler was uncovered. Definitely looks like no fuel getting to it. Get fuel to it, then pull off the intake and put ether there directly. See if you get smoke or an attempt to fire. Drain a small amount of oil out of the pan to be sure none got into the lower end. I have had Detroit’s sit 20 years and can ge them to fire. Easy engine to work on also but may be cheaper to get a complete and swap. Rails on the undercarriage look in good shape, definitely worth the idler swap if you get it running. It is an early one by the serial number. Good luck, ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: WaltDevore

Date Posted: 05 Jan 2020 at 11:22am

|

Is it likely that the blower is reparable, maybe a shear pin, or will a replacement need to be scrounged? |

Posted By: DMiller

Date Posted: 05 Jan 2020 at 3:13pm

| Blower drives are splined, if locked up the splines shear away in the drive coupler, easy enough to tell if not rotating will need to come off. IF sheared will have to change the Drive coupler(Flat Splined Plate) and shaft. Any decent Detroit Diesel repair parts shop can ID by Engine s/n. Blower is rebuildable and many times are exchange units available. Blower also drives governor. |

Posted By: WaltDevore

Date Posted: 05 Jan 2020 at 3:31pm

|

Thanks everyone for lighting the darkness for me!! |

Posted By: WaltDevore

Date Posted: 08 Jan 2020 at 12:37pm

|

I have removed the governor and air pipe, ready to extricate blower. I don't know where or if to split it at the central assembly or does it all get removed to the front of the engine. I better not screw this up. What do you think? Thanks |

Posted By: dadsdozerhd5b

Date Posted: 08 Jan 2020 at 1:14pm

|

Once the intake pipe is removed look at the blower lobes when cranking and see if they are spinning. If so it is not the blower. If not then you have some kind of issue. I have not personally had a blower off but I believe it comes off as an assembly. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: WaltDevore

Date Posted: 08 Jan 2020 at 5:17pm

Looks like solid pieces in there. Do they rotate? I have no jumper cables right now so can't turn the engine over. If this rear shaft rotates, will that indicate the blower is good? |

Posted By: WaltDevore

Date Posted: 08 Jan 2020 at 5:19pm

If this shaft is rotating, will that indicate the blower is functional? |

Posted By: DiyDave

Date Posted: 08 Jan 2020 at 5:27pm

Looks like you have busted splines or some other foreign material, laying against the bearing. Maybe its an oil reflection, IDK... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: WaltDevore

Date Posted: 08 Jan 2020 at 5:29pm

|

It's the wire retainer for the ball bearings I think and a little puddle of oil. If this shaft doesn't turn, is that a bad blower? |

Posted By: NomoreJohnDeere

Date Posted: 08 Jan 2020 at 7:59pm

|

If you can't turn the splined shaft something is not right ------------- HD3 |

Posted By: DMiller

Date Posted: 09 Jan 2020 at 5:59am

| Blower sitting on the ground, no governor and nothing else attached should roll with some resistance. Hanging on the engine is still connected to drive coupling. Either corrosion or metal displacement or bad bearing will lock one up, is only .0015 clearance when new lobe to lobe and I did not misplace a 0. |

Posted By: WaltDevore

Date Posted: 09 Jan 2020 at 1:25pm

|

Well, the shaft rotates with the engine turning over. I sprayed ether into the air pipe opening and the engine air heater opening. Zero response. I guess a compression test is next without the injectors?? |

Posted By: DMiller

Date Posted: 09 Jan 2020 at 1:39pm

| Valve cover is off? Check the valves, only has Exhaust valve where if stuck open head will need come off. |

Posted By: WaltDevore

Date Posted: 09 Jan 2020 at 1:47pm

|

It seems the piston rings and valves are next. My guess. Can the piston rings be replaced without pulling the engine? My old 240Z was so easy, drop the pan and remove the head. These real life mysteries keep the feeling of being alive fresh. |

Posted By: CAL(KS)

Date Posted: 09 Jan 2020 at 1:53pm

|

detroit pistons go in from the bottom. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: WaltDevore

Date Posted: 09 Jan 2020 at 3:32pm

|

The action seems to be normal, at least the springs are being compressed and extended. Seems regardless now, after verifying no compression, to take head off, inspect the cylinders, pull pistons from bottom of engine, replace rings, and new machine? |

Posted By: DMiller

Date Posted: 09 Jan 2020 at 6:46pm

| Cannot pull pistons from bottom, pulled as a Set with sleeves and installed same manner. Sleeves are loaded from bottom outside engine. |

Posted By: CAL(KS)

Date Posted: 10 Jan 2020 at 7:13am

yes thank you for clarifying, i should have elaborated ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: DMiller

Date Posted: 10 Jan 2020 at 7:19am

| Dependent on if Trunk type or Cross Head pistons as to parts lists. |

Posted By: gemdozer

Date Posted: 10 Jan 2020 at 8:32am

| Did you removed the fuel pump if the coupling or the shaft is't brooked. |

Posted By: WaltDevore

Date Posted: 17 Jan 2020 at 8:59pm

|

I'm ready to pull the head. Is there any trick to get it loose? It doesn't seem too big and heavy to manage it manually. I can't find any point of purchase to work a long crowbar. Recommendations? Thanks |

Posted By: DMiller

Date Posted: 18 Jan 2020 at 6:01am

| Try NOT to pry Under the head, just get it loose then lift it off the studs with a small hoist or a tractor using bolt holes on the top. These have no true Head Gasket, the block and head are a machined fit up with seal rings. The studs will need to be in place to reset the head so as not to shift it across these seal rings. |

Posted By: gemdozer

Date Posted: 18 Jan 2020 at 6:02am

| I am't sure if the water pump have to be removed with speacer plate to pull the head off and not sure too if the 2 long bolts from blower are bolted in block or in head |

Posted By: WaltDevore

Date Posted: 25 Jan 2020 at 5:01pm

It may be above freezing for the first time in a while tomorrow. With my limited resources, I've devised this rig to pull the head off. Do you see any obvious absurditi es I'm missing? es I'm missing? |

Posted By: WaltDevore

Date Posted: 25 Jan 2020 at 5:03pm

|

I'll put the chain on the back of the lift circle closest to the handle. The pull won't be perfectly vertical. Just hope to break loose without breaking anything. |

Posted By: DiyDave

Date Posted: 25 Jan 2020 at 6:05pm

If you have everything on the head that holds it to the block removed, take #2 piston, and re-assemble it, with a piece of something like carpet, or a circle of wood, on top. Put the old bearing halves in, around the crank, and turn the crank, to pop the head off...

------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: DiyDave

Date Posted: 25 Jan 2020 at 6:12pm

[QUOTE=DiyDave]If you have everything on the head that holds it to the block removed, take #2 piston, and re-assemble it, with a piece of something like carpet, or a circle of wood, on top. Put the old bearing halves in, around the crank, and turn the crank, to pop the head off... [QUOTE] [QUOTE]Whoops, didn't remember that you don't have the pistons out. Do you have an injector out? If so, feed a length of rope, down the injector hole, to do the same thing as I said earlier, above!  ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: WaltDevore

Date Posted: 25 Jan 2020 at 7:21pm

|

I do have the injectors out. That is an amazing idea. Thanks!! |

Posted By: Coke-in-MN

Date Posted: 25 Jan 2020 at 10:16pm

|

Head should come off easily without all this monkey business . Injector tube is copper and flared at end into head - the hole through is not large enough to pass much through . IF all the bolts are removed head should be able to be lifted - looks like you have the lift rings on head secured to your lifting device , next get a soft blow hammer and tap on head . Now pistons and liners come out from top , pistons can be removed with liners intact yet in block - liners are shimmed into block to get a proud dimension from top of block face of about .005 . With all the crusty crud in the bottom of the blower housing - evidently the drain hole on bottom of housing is closed off - it's a 1/4" threaded hole in bottom of the housing and it MUST be open to allow drainage . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: WaltDevore

Date Posted: 26 Jan 2020 at 12:13pm

|

Thanks for that. I'm off to see what happens. I sure appreciate the tips as I go. I pray the beast will rise again. |

Posted By: gemdozer

Date Posted: 26 Jan 2020 at 12:23pm

| I am not sure but you need to removed the water pump and oil cooler for removed the head |

Posted By: WaltDevore

Date Posted: 26 Jan 2020 at 3:16pm

|

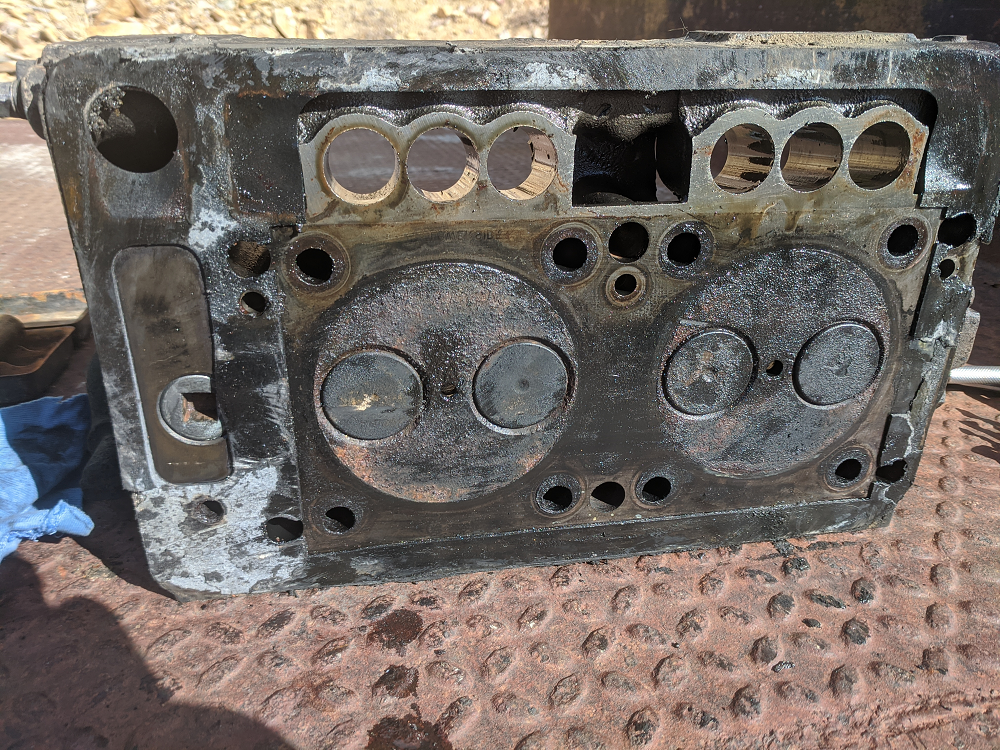

Rust  |

Posted By: WaltDevore

Date Posted: 26 Jan 2020 at 3:17pm

|

Cylinder1  |

Posted By: WaltDevore

Date Posted: 26 Jan 2020 at 3:20pm

|

Is this worth saving? |

Posted By: NomoreJohnDeere

Date Posted: 26 Jan 2020 at 3:32pm

|

tolerances determine that Hows the crosshatch? ------------- HD3 |

Posted By: DMiller

Date Posted: 26 Jan 2020 at 3:36pm

| Cannot see it for the Red Rust!! Rings will be stuck if not scrubbed raw. |

Posted By: WaltDevore

Date Posted: 26 Jan 2020 at 3:38pm

|

Is cross hatch the hone on the cylinder wall? I guess I should get each piston to its bottom and see what it looks like. I should clean it up with some oil and check it then? The exhaust stems as seen through the ports are rusted. I'll try to do this now. Need to charge up my battery. |

Posted By: WaltDevore

Date Posted: 26 Jan 2020 at 4:39pm

|

The liners feel pitted in areas. At this moment it seems a valve job, liners, and rings. Any guess as to the bucks that involves? Thanks |

Posted By: DMiller

Date Posted: 26 Jan 2020 at 6:17pm

| Google Detroit 71 Series Cylinder Kits. Gonna be in the $200 Each hole range. |

Posted By: WaltDevore

Date Posted: 29 Jan 2020 at 11:37am

|

I have not tended to the fuel pump yet. I'm unclear as to its operation. Seems it operates down in the block. Will it disassemble straight forward and reveal its condition? Can't see how anything could have happened to it but for some reason it's not pumping. I will check that next. Thanks! |

Posted By: DMiller

Date Posted: 29 Jan 2020 at 12:35pm

| They are a pretty simple PDP Gear Pump with check valves to keep flowing forward. Feed thru to a restrictor fitting at end of head on the back to tank line. |

Posted By: Ray54

Date Posted: 30 Jan 2020 at 11:22am

| If there is question about the pump replace it. It has been 20 years but I think $35. Went through much hasle because it was not the experts idea to replace. It is out in the open 2 fuel lines and 2 bolts. |

Posted By: jerbob

Date Posted: 31 Jan 2020 at 8:57am

Good luck on your project Walt and welcome to the forum. These folks have the advice and answers. AS to your track idler, I was able to pull my track adjuster, yoke and then idler assembly on my HD16. I used a 20 ton porta power to push the idler and yoke as far forward as possible and they allowed me just enough room to pull the adjuster rod out at the rear of the assembly. Once that was out, I pulled the yoke and was able to jack up the tractor enough to free up the idler. Was a hot mess of a project as I was learning as I was going but I did not have to split the track. Also the comment as to the wear on the rails is very valid. Mine are adjusted almost to the very front of the rails so I had enough stretch to be make it all work. ------------- HD16DC, Bobcat 863 Turbo, Oliver 1855, John Deere 855, |

Posted By: jerbob

Date Posted: 31 Jan 2020 at 9:03am

You can see the slack on my tracks when I purchased my baby. Pushing on the track adjuster all the way forward with the porta power allowed me to pull the adjuster rod and then everything freed up. ------------- HD16DC, Bobcat 863 Turbo, Oliver 1855, John Deere 855, |

DMiller wrote:

DMiller wrote: