Electric Motor Question

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Shops, Barns, Varmints, and Trucks

Forum Description: anything you want to talk about except politics

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=166686

Printed Date: 16 Oct 2025 at 7:09pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Electric Motor Question

Posted By: CrestonM

Subject: Electric Motor Question

Date Posted: 16 Dec 2019 at 10:16am

|

Recently inherited an old Wards circular saw in mint condition. In the original metal carrying box, no scratches, complete with manual. Saw and cord both look great. I plugged it in, pulled the trigger, and it started turning, but maybe only a couple hundred RPM, then slowed down a little, smoked some, and tripped the breaker in the shop. Any electrical gurus have any advice? Think it could be saved or is it ruined since the smoke got out? Thanks

|

Replies:

Posted By: Coke-in-MN

Date Posted: 16 Dec 2019 at 10:33am

|

Probably brushes stuck or birty communtator - if it smoked it might be done for especially as it tripped a breaker - which would mean a 15 Amp dead short somewhere inside . Depending on what age and who made it - never know might be parts out there to fix it - but at what cost is next - setting for long time varnish on armature or field winding probably broke down from moisture ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: tadams(OH)

Date Posted: 16 Dec 2019 at 2:00pm

| I would take it apart and check the brushes and the bearing, a bearing might be the cause of the problem |

Posted By: steve(ill)

Date Posted: 16 Dec 2019 at 4:52pm

|

yea, you got nothing to loose now.. pull the brushes out and rub some very very very fine cloth or steel wool over the commutator... make sure the brushes SLIDE easy in the holder and the springs hold tension .......... and as tadams said, rotate it to see how the bearings feel. ------------- Like them all, but love the "B"s. |

Posted By: DiyDave

Date Posted: 16 Dec 2019 at 5:22pm

As others have said, brushes stuck or gone is most likely. Coulda been dropped real hard, too, to break insulation, or make something rub... ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: HD6GTOM

Date Posted: 16 Dec 2019 at 6:58pm

|

My air compressor motor went up in smoke last fall, actually had flames shooting out of it. I took it to a rebuild shop IT works great now. Motor was made many years ago. |

Posted By: Tbone95

Date Posted: 17 Dec 2019 at 9:46am

|

Posted By: JC-WI

Date Posted: 17 Dec 2019 at 10:25am

|

"Think it could be saved or is it ruined since the smoke got out? " Creston... It sounds like it was old enough to have a smoke... an maybe you triggered the smoke switch? or did you turn a smoke screw on it? I would take it apart and look and see if the brushes are loose and the armature is clean and to check for burnt wires in the windings on bothe the armeture and the outer field windings.. If they are burnt it is toast. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: shameless dude

Date Posted: 18 Dec 2019 at 8:41pm

| I thought maybe you were going to re-power one of your ferd tractors! prolly get more HP! (poke,poke) |

Posted By: Ted J

Date Posted: 19 Dec 2019 at 4:29pm

|

I disagree with JC. It CAN be fixed no matter what...... Yes, tear into it and see what is what. It's already broke, so you can't hurt it anymore. Just be mindful of how you take it apart. Ever had one apart?? If no, take pics with your phone as you go along. I'm guessing brushes also. Unless you got a ton of spiders in there building nests, I don't know what else could stop the armature from turning. But, could be a bearing. Good luck!! I have a Monkey Wards one that I bought back in the 60s. It's a 3/4 horse 7-1/2" and it still runs GREAT. Beats all the new 3/4 ones hands down. If worse comes to worse, bring it along to Hutch. I've got an old guy (yep, older than ME) and he's STILL got his shop. His daughter (she's about my age) does all the work now, but he's always there, sittin by the potbelly and drinking HIS coffee. You can CUT it..... ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: CrestonM

Date Posted: 20 Dec 2019 at 12:51pm

| Thanks guys, I'll dig in and see what I can find! |

Posted By: LouSWPA

Date Posted: 21 Dec 2019 at 11:15am

|

UH...before we get ahead of ourselves, first question is how does it turn by hand? if it tight, turning by hand, I would suspect dryed out sticking bearings/bushings. I doubt it is a dead short, a dead short would trip the breaker pretty darn fast. It is drawing too much current from too high a load, it was running near stall by your description. I suspect old sawdust wadded up in it and or bushing/bearings ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: CrestonM

Date Posted: 21 Dec 2019 at 6:51pm

| Haven't worked on it yet, but it does turn quite freely by hand. Bearings/bushings don't feel bad, but I'll learn more on disassembly. |

Posted By: CrestonM

Date Posted: 22 Dec 2019 at 8:23pm

|

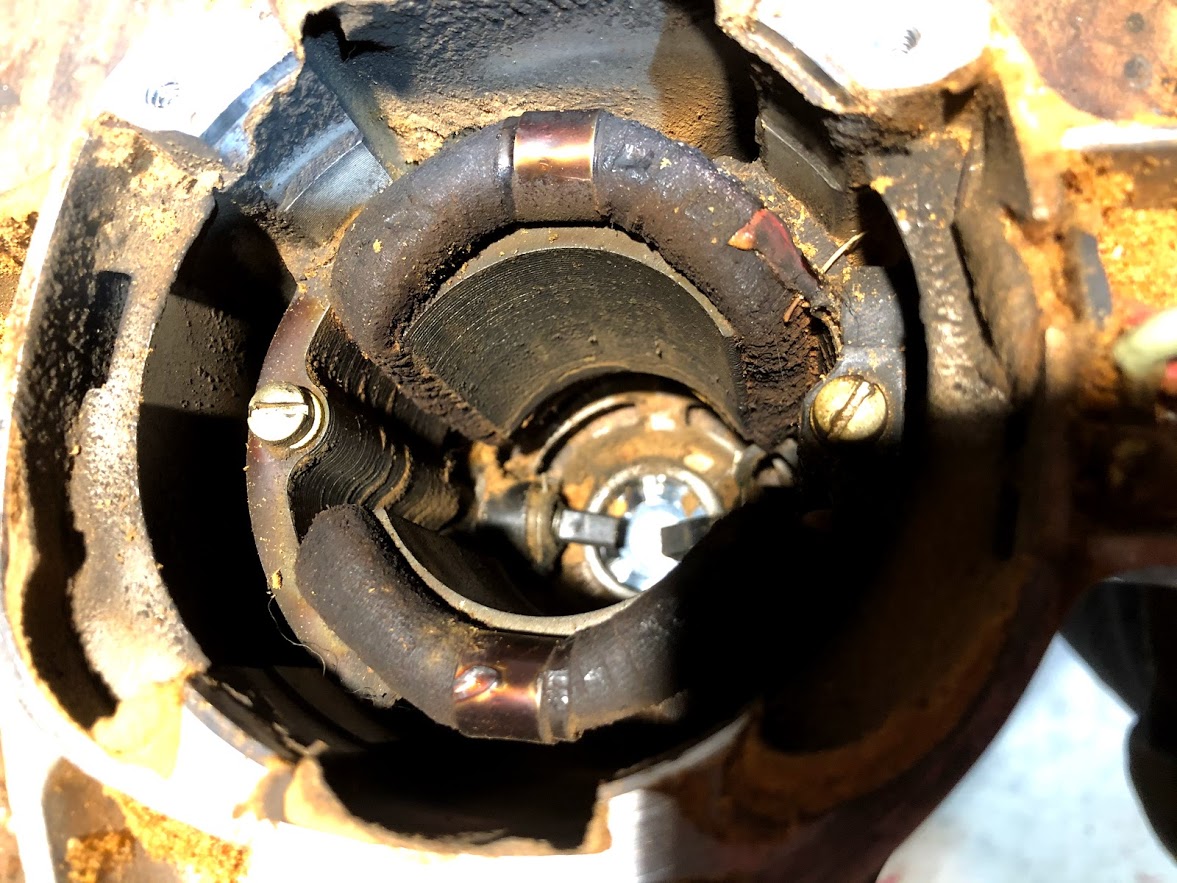

Got it disassembled today. The blade turned a little harder by hand than I remembered. I did find a lot of old saw dust and hard dried grease around the reduction gears (if that's what you call them). The bearing on the commutator end turns smooth, but there is a brass bushing on the other end that looks kinda dry. Brushes weren't stuck, but the commutator does have a glaze on it that will need cleaned off. I'm thinking a good cleaning may get it back in service. Here's a couple photos.   |

Posted By: tadams(OH)

Date Posted: 23 Dec 2019 at 3:06pm

| Yes, looks like it needs a good cleaning and that saw dust drawed moister |

Posted By: CrestonM

Date Posted: 31 Dec 2019 at 12:53pm

| What grease do y’all recommend putting in the gear reduction assembly? All the old grease was pretty hard, so I cleaned it all out. |

Posted By: steve(ill)

Date Posted: 31 Dec 2019 at 12:55pm

|

any grease is fine, as long as it is not too thick.......... If you have some lithium wheel bearing grease around, that would be GREAT. ------------- Like them all, but love the "B"s. |

Posted By: CrestonM

Date Posted: 31 Dec 2019 at 5:25pm

| Hey, I actually do! I’ll use that |

Posted By: CrestonM

Date Posted: 31 Dec 2019 at 5:56pm

| Got everything put back together, and same exact symptoms. Turns slow and trips breaker after a few seconds of running, and light smoke. It’s not in the gear reducer, as it does it whether it’s installed or not. The reduction gear turns smooth, and the motor turns smooth. I’m not an electrician, so any ideas welcome. Thanks |

Posted By: shameless dude

Date Posted: 31 Dec 2019 at 11:04pm

| you didn't feel a buzz on yer fingers did you? |

Posted By: LouSWPA

Date Posted: 31 Dec 2019 at 11:09pm

|

Then I would suspect one or more windings have opened up on the field, or stator. That is assuming you have checked out the brushes and commutator ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: CrestonM

Date Posted: 01 Jan 2020 at 9:12am

Haha, no I didn’t. I was a little leery of that. |

Posted By: CrestonM

Date Posted: 01 Jan 2020 at 9:20am

I had it all apart for cleaning, and the brushes looked ok to me. The commutator had a lot of glaze on it, but it shined up nice with steel wool. I’ll be honest when I say I don’t know what the field or stator is. |

Posted By: steve(ill)

Date Posted: 01 Jan 2020 at 9:25am

|

When too much of the SMOKE leaks out, the motor is no longer usable........ I would guess that is the case. Internal damage of the windings.

all them bare wires in the WINDINGS are coated with a clear (shellac) so they don't touch each other.. IF some of the clear melts or gets rubbed off and two wires touch, then you loose the capacity of some of the windings.... that is what Lou is saying.

------------- Like them all, but love the "B"s. |

Posted By: CrestonM

Date Posted: 01 Jan 2020 at 9:30am

| Would that be the windings around the armature area? Would a new (if could be found) shaft with another armature, commutator, etc. fix the problem maybe? |

Posted By: steve(ill)

Date Posted: 01 Jan 2020 at 9:30am

field rotates, then the rotor will follow and rotate with the magnetic field of the stator.  As shown in Figure 9, the stator has six magnetic poles and the rotor has two poles. At time 1, stator poles A-1 and C-2 are north poles and the opposite poles, A-2 and C-1, are south poles. The S-pole of the rotor is attracted by the two N-poles of the stator and the two south poles of the stator attract the N-pole of the rotor. At time 2, the polarity of the stator poles is changed so that now C-2 and B-1 and N-poles and C-1 and B-2 are S-poles. The rotor then is forced to rotate 60 degrees to line up with the stator poles as shown. At time 3, B-1 and A-2 are N. At time 4, A-2 and C-1 are N. As each change is made, the opposite poles on the stator attract the poles of the rotor. Thus, as the magnetic field of the stator rotates, the rotor is forced to rotate with it. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 01 Jan 2020 at 9:35am

|

you would have to have the stator and rotor meggared to see which is the problem.. A motor shop can test and tell you the problem... and rewind, but I doubt it would be economical unless you REALLY want that motor !

this is basically the same thing that happens to tractor STARTERS when they go bad. I would shine it up real good and hang it on the shop wall as a decoration !!

------------- Like them all, but love the "B"s. |

Posted By: CrestonM

Date Posted: 01 Jan 2020 at 4:17pm

| Well, as much as I hate to junk something as well built as this (and built in America), I may end up doing that, or save it for wall decor like you say. |

Posted By: Ted J

Date Posted: 03 Jan 2020 at 11:00pm

|

Sometimes a man has to do what a man must do......at least it's not Orange, or I'd be all over you....mine still works and I've had it for almost 50 years!! ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

HD6GTOM wrote:

HD6GTOM wrote: