HD5 clutch yoke question

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=165063

Printed Date: 11 Jan 2026 at 9:52pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: HD5 clutch yoke question

Posted By: heron

Subject: HD5 clutch yoke question

Date Posted: 15 Oct 2019 at 6:28pm

|

Haven't had the time to work on my grandfather's HD5 for too long but decided today to tackle the first of a few things needing to be done but of course it's more complicated than I first thought. For too many years my dad thought the vibration was a Ujoint under the pedals. The vibration annoyed me to the point before givin her a run around today I figured I would get that UJ fixed. But, after pulling it apart it seems the wobble is either the yoke or clutch shaft...So, how does one figure this out and what kind of work would it be to change out the clutch shaft? The keys look perfect, no obvious "wallowing" out of the notches but when I inserted just the yoke back on the shaft it was way too loose. I thought at first maybe it was the bearing in there but the clutch shaft is tight and the Uj's on the driveshaft are all tight. How the wobble got there I haven't a clue. Maybe back in the 60's the machine was run too long with a bad Uj and that's what caused it. Over the last 50 years there probably hasn't been more than 100 hours total put on the dozer. I think it must have been there but my dad never liked wrenching on machines much. I personally cannot stand for things not to be "right". My first thought is to try to find a yoke and try that, if it doesn't tighten things up then I must go with the clutch shaft..maybe, if I can find one. Open to any and all suggestions. Once I get this done, I've got to get the shifting linkage tightened up, the blade valve gasket repaired and then she'll be good to go. On another note if anyone is in the market for an HD5 I think I may have to let this sentimental piece go soon. I have no time to tinker and 3 kids to go to college so putting more money into something I don't even use is not going to go over with the boss. I hate the thought but I have to be practical.

|

Replies:

Posted By: heron

Date Posted: 21 Oct 2019 at 12:22pm

| Does anyone have any yokes or clutch shafts they would sell? Also, I've attached pictures. I would call these tapered but I'm not certain as this machine should only have the straight splines...? uploads/8354/clutch_shaft_1.jpg" rel="nofollow - uploads/835 uploads/8354/clutch_shaft_3.jpg" rel="nofollow - uploads/8354/clutch_shaft_3.jpg uploads/8354/yoke_2.jpg" rel="nofollow - uploads/8354/yoke_2.jpg 4/clutch_shaft_1.jpg |

Posted By: gemdozer

Date Posted: 21 Oct 2019 at 6:08pm

| I check tomorrow if am still have the yoke and shaft for HD5 |

Posted By: Ray54

Date Posted: 21 Oct 2019 at 7:48pm

|

Those are straight cut, there is bit of bevel at the ends to help them get started . All Cat parts that I have incounterd that are tapered,you need a puller or press to take them apart. Many of which don't have slines,just a woodruff key.

|

Posted By: heron

Date Posted: 21 Oct 2019 at 8:09pm

|

The angle starts at the top and slopes consistently down.. not tapered..weird. In the book it shows the earlier 5xxxx serial numbers had tapered and the later models had straight cut. The serial number on mine is 27528 so it should be straight but the sides of the splines definitely have an angle. But if that's considered straight then that's what I need. Poor machine has vibrated there since I can remember, my dad always said it was the Ujoints. Ujoints are perfect, can tell they are original and have been greased well. Not sure what they did back then but is the shaft harder than the yoke? Not sure which to look for or do you just replace them both after adding a grease zirk to the yoke....? If there was a way to mic them out I would.... Thanks for the enlightenment!

|

Posted By: heron

Date Posted: 21 Oct 2019 at 8:11pm

I'd really appreciate it. If not I may have to rig it somehow...not sure how but cannot let it keep wobbling there. Maybe drill it, pin it and put a zirk in the yoke...?

|

Posted By: NomoreJohnDeere

Date Posted: 21 Oct 2019 at 11:08pm

|

straight cut as in long ways from front to back as yours are not straight cut as in the sides of the splines 90 degree tapered would be from front to back long ways are the ujoints free? or bound up? ------------- HD3 |

Posted By: heron

Date Posted: 22 Oct 2019 at 8:39am

| Ok, got it. The ujoints are perfect. |

Posted By: Coke-in-MN

Date Posted: 23 Oct 2019 at 1:17pm

|

Another thing could be the brass sleve in the culuth throw out bearing housing being worn out from not being greased , or leaving machine idle without the transmission being in neutral and clutch engaged . Many do not realize the clutch drive shaft is supported in the clutch by this brass bearing , as it only contacts the shaft when clutch is released and turns with shaft when clutch in engaged . Mine was worn badly after 50 years and I machined a new one from brass stock I picked up . The throw out bearing housing has grease fittings on the collar to grease this part . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 23 Oct 2019 at 2:04pm

|

Coke, my first thought was the bearing but as soon as I fitted the yoke(removed from Ujoint) on to the shaft it wobbled. At that point I wrapped the end of the clutch shaft with a rubber sleeve, threw some big channel locks on to see if I could move the shaft and it was tight. Greasing was always done(probably in excess) as my grandfather and my dad having owned and managed many pieces of equipment knew the cost because it came right out of their pockets. First thing my dad said to me about this issue was, "haven't you greased the driveshaft...?" when he thought the vibration was the Ujoint. Once I told him it was the Yoke/jack shaft he was surprised. If that yoke had a zirk it would have been greased. If I can get one I'll be putting one in it. You had given me advice on how to do some things on this machine 6 years ago. I'm just now getting to it. It may end up being sold as I don't have the time or place to give it the attention it needs.

|

Posted By: Leop

Date Posted: 23 Oct 2019 at 8:07pm

|

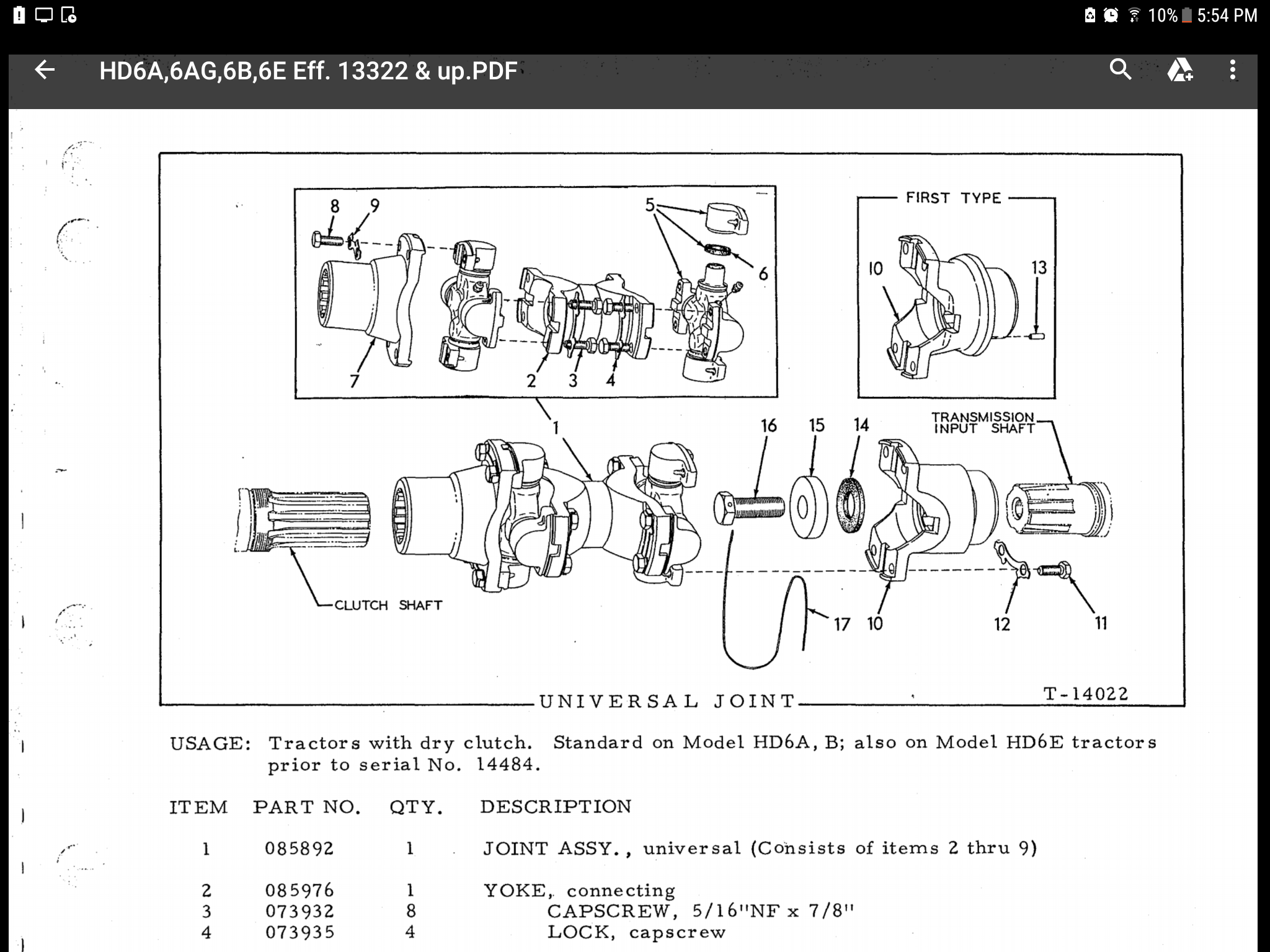

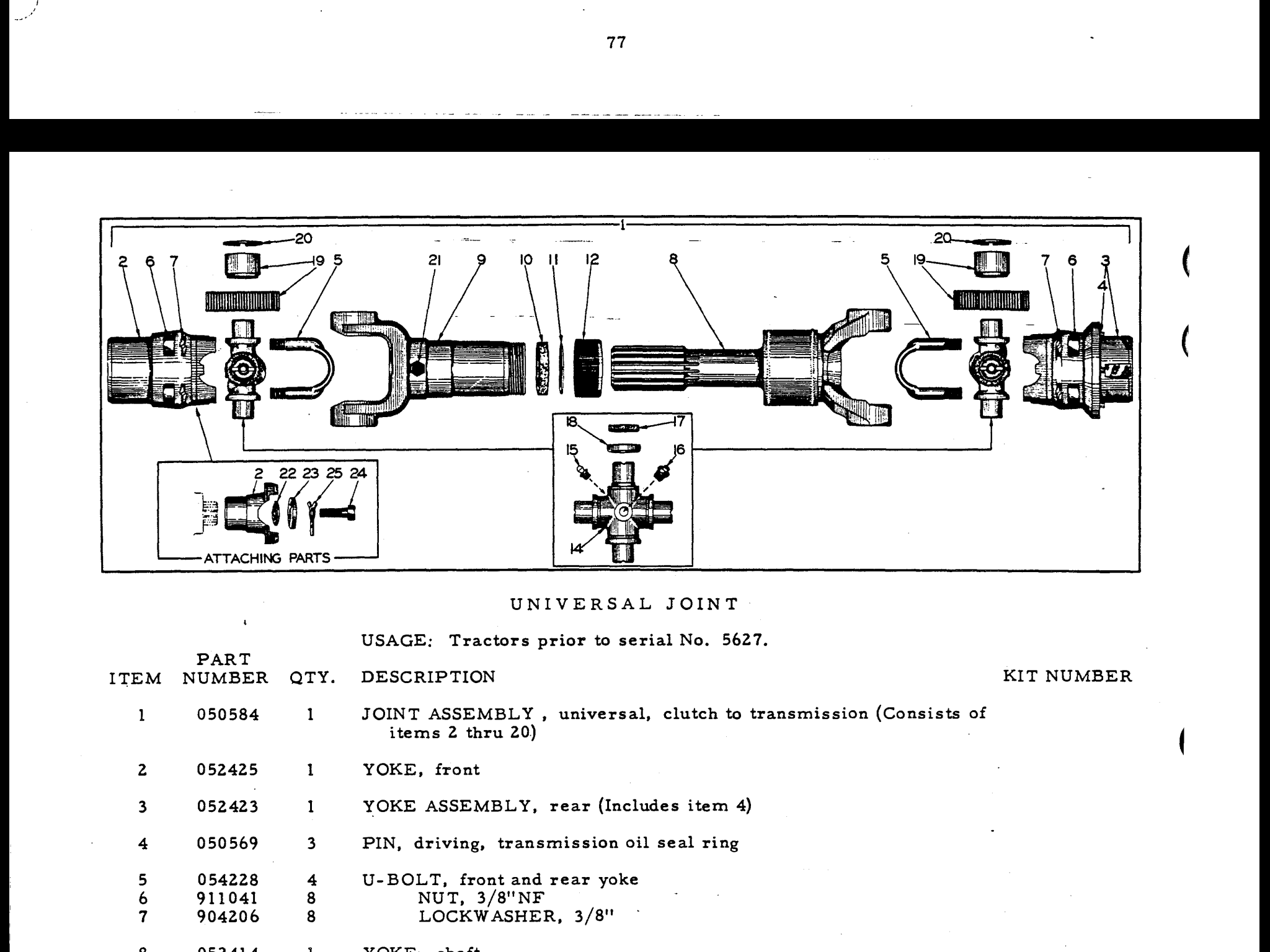

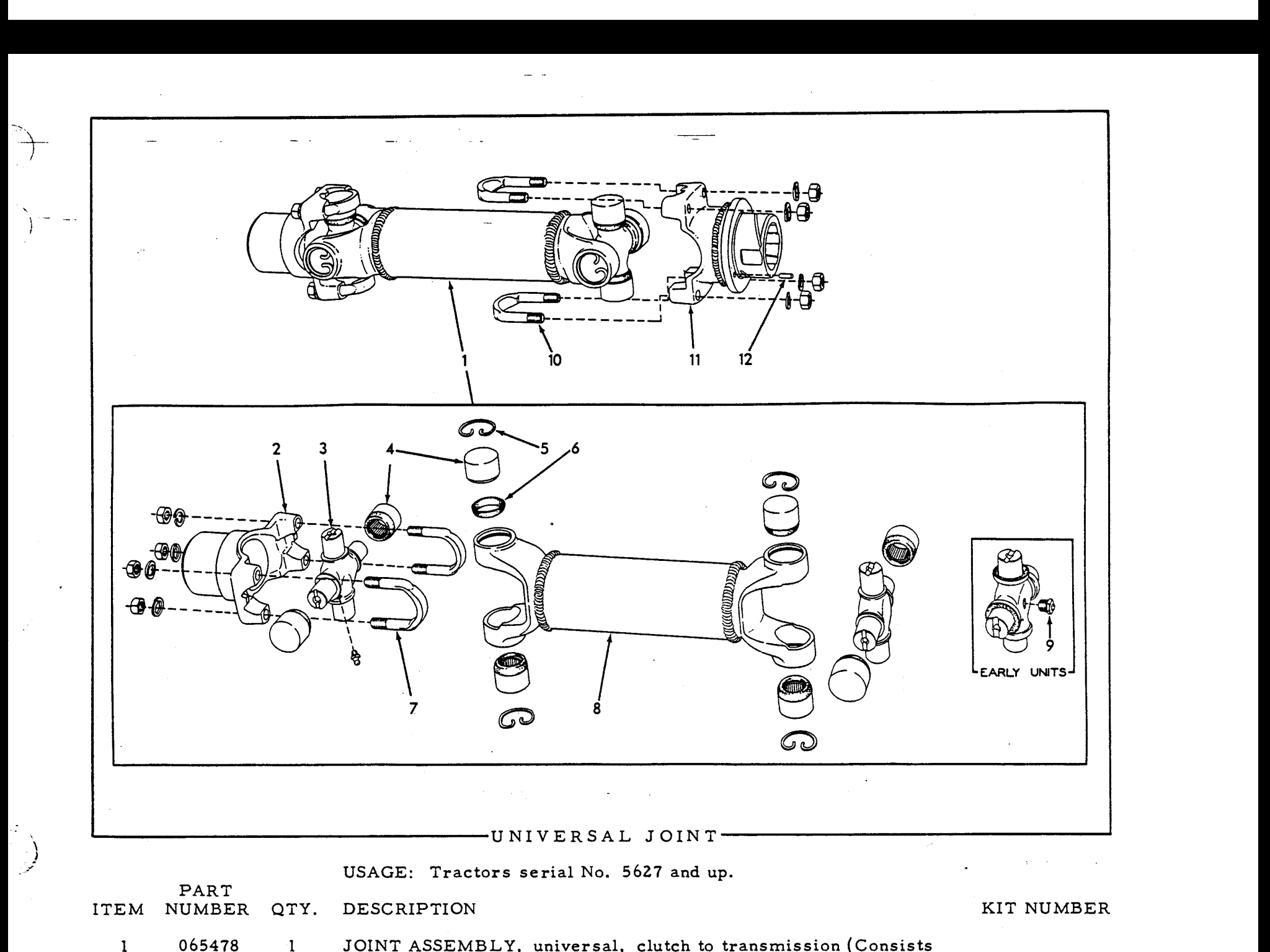

Hi Heron, Please reffer to the attached parts diagram. Do I understand you correctly that the flange of the yoke labled #7 is not running true to the clutch shaft which is shown on the left side? You also seam at some point to imply that the yoke has tapered splines, and that the clutch shaft splines are straight. Do I understand that correctly? If assume that both my assumption as stated above are true then I might have an explanation for your troubles. Note in the drawing that the transmission input shaft appears to be tapered. If that is the case then I would assume that the yoke labled #10 has a tapered & splined female hole to accept the shaft. Also note that a bolt through the center on yoke #10 holds the yoke onto the shaft, therefore not requiring a press fit as was mention was the case on CAT equipment. Given all the above observations might I suggest that it could be possible that your dad got yokes #7 and #10 mixed up by accident? If he did then your observations would maybe make sense. In the case of a mix up the #10 tapered yoke would not slide onto the clutch output shaft far enough to line up true with it's plane of rotation and that might be why you see the wobble you do. Also, the straight splined yoke #7 would be loose and sloppy on the transmission input shaft side and that could also be inducing a wobble. I have some other ideas, and I might also have a yoke I can sell you if it turns out that you need one, but check out the above theory first and let me know what you find. Sincerely, Leo Beginner HD6G Mechanic Leo

|

Posted By: Coke-in-MN

Date Posted: 23 Oct 2019 at 9:07pm

|

That diagram isn't for a HD5 as the part with #1 is about 18" of tube - single joint on front and single joint at transmission . == ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: Leop

Date Posted: 23 Oct 2019 at 10:33pm

|

Thats 100% true Coke, and I should have made that clear. That drawing is for an HD6. I assumed that they were similar. I apologize for any confusion. Does anyone have the proper diagram for the HD5. My brain has been turning over this question over and over and It would be great to examin the problem using the correct diagram. Cheers, Leo |

Posted By: Leop

Date Posted: 23 Oct 2019 at 10:38pm

|

Coke it sounds like a typical 4 wheel drive front driveshaft setup. Is the tube there so that it can slide back and forth over the clutch shaft? On a truck that is nessesary because the length of the drive shaft side changes as the axel sweeps across it's arc when the suspension flexes. Does the HD five have such an issue? |

Posted By: Ray54

Date Posted: 24 Oct 2019 at 3:05pm

|

Just thinking here and could be going in the worry direction. Could one of the cam assemblies on the clutch come off ? And the vibration is from clutch being way out of balance. I am thinking at least 3 of the cam linkages maybe more,and have no idea why one would come loose. Just fishing for could be things. Another thought how loose is the yoke on the spline, could that be the cause. Again no idea why it would get so loose.

|

Posted By: Coke-in-MN

Date Posted: 24 Oct 2019 at 8:04pm

|

It's a alip fit into the shaft from clutch housing and a bolt on U joint to the transmission yoke ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 25 Oct 2019 at 10:37am

|

As a previous poster said they are straight according to Allils. To me since the top is narrower than the bottom it should be called a tapered but it doesn't matter. I have other yokes where the straight splines are boxed completely but they also have grease fittings on them. Also, when I removed the yoke from the Ujoint and slipped it on the shaft it definitely wobbles and has too much play and as I said in an earlier post I wrapped the end of the clutch shaft and put a large pair of channel locks on it and couldn't budge it. When the machine is running at high idle you can see the wobble right there but as the rpms increase the vibration lessens. Not sure if it's the yoke or the shaft that is worn. I'd hoped the yoke was softer than the shaft but I don't know so I'm assuming I need to get another yoke and put it on and see what happens. I'd like to find one that someone could place on a clutch shaft, see if it's tight, if it is on their's but not on mine I know its the shaft...No way to mic it out properly, at least with the tools I have. I also talked to someone who told me the 5 and 6 shared the same yoke and shaft but the 5 had a longer driveshaft than the 6...? So, maybe someone that has parts for a 6 might have a yoke and shaft that's good. Thanks for all the replies fellas.

|

Posted By: Coke-in-MN

Date Posted: 25 Oct 2019 at 1:45pm

|

Like I mentioned the yoke is a slip fit onto rear of clutch housing . But also with clutch disengaged seeif there is wobble of the shaft in the throw out bearing inner housing where the brass sleve holds the shaft . i got a different drive shaft off a parts machine I had and replaced mine as it was real lose on the clutch shaft . Never noticed a vibration in old one . Check your shaft to make sure it's not dented or bent to cause a imbalance or flexing in the joints . According to the diagram above 5 and 6 are completely different units. To fit the bigger engine up against the HD6 they moved everything back - the HD5 and HD6 share the same rear housing but being the Budda was longer than a 2-71 things were changed in the power train ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 25 Oct 2019 at 1:52pm

Just to clarifyl; you are saying I still may see the wobble in that area yet it could be that bearing...? When you fit your yoke on to your clutch shaft it still had a lot of play...right? If you are correct I'm not sure if this would be better news or worse news.. So, I wouldn't feel any movement(with my large channel locks on the end of the clutch shaft)in the clutch shaft if that bearing was bad? Is it straightforward in the manual of how to check it? Thx Coke So, I wouldn't feel any movement(with my large channel locks on the end of the clutch shaft)in the clutch shaft if that bearing was bad? Is it straightforward in the manual of how to check it? Thx Coke

|

Posted By: Leop

Date Posted: 25 Oct 2019 at 3:37pm

|

Go to harbor freight tools and get yourself an indicator. Check the shaft coming off the clutch side first. Then just keep checking parts as you work your way back towards the transmission side untill find where your runout is comming from. Once you know which part is worn or bent pull it out and find an independent machinist in your area. An old cranky guy is usualy best. Explain the problem and he will fix you right up. These guys are a gold mine to America and keep old stuff working for a resonable cost. Look up a guy on Youtube named Keith Fenner. He has many videos on finding and fixing slop and vibration on shafts. Here are some economical indicators up to the task. https://www.harborfreight.com/search?q=Indicator" rel="nofollow - https://www.harborfreight.com/search?q=Indicator |

Posted By: heron

Date Posted: 25 Oct 2019 at 5:07pm

| I'll look him up. I do agree with you as far as finding a "backyard" machinist. Does not seem to be very many in my area as I have been asking around. I'm not sure how any of those indicators would work to find discrepencies in the splines. I'll see if I can find some videos of how to measure out the shaft splines and the yoke splines. I know for a fact I cannot get to the back of the yoke to measure anything as the back is sealed. |

Posted By: DiyDave

Date Posted: 25 Oct 2019 at 5:57pm

Coke's post brought another thought to mind. along with shaft dents and bends, check the u-joint phasing. Simply put if the u joints are +'s they should look like this ++, in a straight line, not +x, out of phase...  Dial indicator , in use: [TUBE]r8VXU-lZnXQ[/TUBE] ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: gemdozer

Date Posted: 25 Oct 2019 at 6:04pm

| The shaft picture I can see oil in cover and this cluch should be dry and you could have a broken block sliding shifting yoke |

Posted By: Leop

Date Posted: 25 Oct 2019 at 11:17pm

|

I have measured the splines for fit two ways. Fist way is to steel some of my sons playdogh and push it into the splines. Then take it off and carfully unroll it on a table. Then use calipers and eye ball it. The other way is to use drill bits. Identify the spline by taking rough measurments and then looking on line, or ask in one of the machinists forums if someone can look it up for you. Then with the true dimensions use a drill bit that touches all three sides of the spline. That and some advice on which size to use will confirm if the splines are worn. That said, I have never seen splines so worn as to cause a wobble like you describe without also seeing obviouse signs of wear on the splines themselves. They are surface hardened, and they prety much wear only after you break through that surface hardened metal. When that happens it's obviouse. Phasing as mention above or some other issue seams more likely to me. You could try cutting up some shims from an aluminium can. Make sure you use at least four at 0, 90, 180 and then tap the yoke on with a mallet. If it goes on easy then you have a problem. If not at all then you are good. If hard but on then see if the wobble is gone. |

Posted By: Leop

Date Posted: 25 Oct 2019 at 11:51pm

|

How to measure splines http://www.tandwiel.info/en/gears/internal-and-external-spline-teeth/" rel="nofollow - http://www.tandwiel.info/en/gears/internal-and-external-spline-teeth/ |

Posted By: heron

Date Posted: 26 Oct 2019 at 10:36am

|

So there would be no wobble in the shaft with the clutch engaged...? The reason I say this is because since this machine has been in the Southern humidity the flywheel clutch will seize up after sitting. I start it up in gear and it breaks free. As far as the fit what you are saying is its normal to have the yoke not fit right in the shaft but that inner bearing is exacerbating the wobble. But, when I grabbed the installed driveshaft up by the yoke I could move it quite a bit and that was with the clutch "engaged" or stuck in my case. So maybe the bearing could be bad which started this issue. I'll dig into the manual to see how to check that bearing. |

Posted By: heron

Date Posted: 26 Oct 2019 at 10:41am

| The oil is residual grease that's been pumped into that zirk for that bearing over the years. This machine has had the grease put to it. Probably too much. I'll know more once I open it up. |

Posted By: heron

Date Posted: 26 Oct 2019 at 10:44am

|

Leop, Great idea with the play doh. I'll look into the dial indicator but without baselines I'm not sure how it will work. I'll make a video of the play although I'm not sure I can upload it. Also, the joints are in phase. |

Posted By: Ray54

Date Posted: 26 Oct 2019 at 11:56am

|

Some maintiances for long term,as you are real close. I was adviced by a independent mechanic that had been rebuilding a number of HD 5 transmissions at the time to replace the top bearing in the front. If that bearing fails the balls go down into the gears,in most cases breaking the case. I was asking about linkage at the used parts place and they put me in touch with the mechanic,as had taken all the AC transmissions they had just to get cases. I was working on the shifter linkage, and I remember it being a easy thing to get out. But

that means nothing. that means nothing. This vibration you have put extra ware on the bearing in my opinion, This vibration you have put extra ware on the bearing in my opinion, but I don't claim to know much. but I don't claim to know much. But Coke is saying brass bushing so I could be way But Coke is saying brass bushing so I could be way  off again. off again. |

Posted By: Leop

Date Posted: 26 Oct 2019 at 3:36pm

|

Heron you dont have a runout spec, but the 8ndicator will still tell you a lot. You can tell which part of the conection is the worse (more slop) and then you can focus your efforts there. I also remember seeing runout speccs for the clutch output shaft and transmission input shaft somewhere in the service manual, so if you have one then you could check that out. |

Posted By: heron

Date Posted: 26 Oct 2019 at 9:02pm

|

Here are some more pics and hopefully a video link. Bearing in the plate seems tight, not sure on on the brass bearing Cokes referring to but if it's the lining pressed into the outer plate it doesn't look worn to me. I did wiggle the plate back in forth and the bearing had no excessive play what so ever. When I pulled the larger plate with the clutch shaft and inch or so backward everything looked clean down behind it, actually looks kind of new. What kind of job is it to remove the clutch shaft because I'm thinking that may have to be done. http://photos.app.goo.gl/sR9NCbyuRGudp4Ya8" rel="nofollow - http://photos.app.goo.gl/sR9NCbyuRGudp4Ya8 uploads/8354/IMG_20191026_142435571.jpg" rel="nofollow - uploads/8354/IMG_20191026_142435571.jpg

|

Posted By: heron

Date Posted: 26 Oct 2019 at 9:05pm

|

I guess I exceeded how much I could put on one post so here is one more, not sure why it won't upload more. uploads/8354/IMG_20191026_142505896_2019-10-26_21-05-04.jpg" rel="nofollow - uploads/8354/IMG_20191026_142505896_2019-10-26_21-05-04.jpg

Also, there are no issues with Ujoints, transmission or anything from the rear that could have caused this, the joint going into the tranny feels tight and Ujoints are great and in phase. I'm at a loss...

|

Posted By: Leop

Date Posted: 26 Oct 2019 at 10:18pm

|

Those don't look bad at all. Much better than mine in fact. Could it be that it seams like the vibration is comming from that area when it is really coming from some place totaly different. Vice grips on the output shaft isnt much of a load. I was taught to check deflection with a crowbar. But other than that it seams like you have done a thorough job. Have you tried running just the motor and clutch with nothing at all connected to the output shaft? No video. But one would help. Honestly though im totaly baffled. |

Posted By: heron

Date Posted: 26 Oct 2019 at 11:49pm

| Did the video link not work? Yes, perhaps the vibration could be coming from somewhere else but I haven't a clue. I'll recheck why my video is not working tomorrow. Thanks for taking your time. |

Posted By: Ray54

Date Posted: 27 Oct 2019 at 6:44pm

| I think Leop is on to something by trying the engine if you can, and then with the clutch installed but the drive line off yet. |

Posted By: Leop

Date Posted: 27 Oct 2019 at 7:25pm

|

Heron, Are you sure that you have the hardware numbered 22, 23, 24, and 25? Are you also sure that #24 is tight. Im thinking that #24 might be missing, or perhaps it loosened itself over the years, especialy if no locktight was used. Leo

|

Posted By: Leop

Date Posted: 27 Oct 2019 at 7:28pm

This is the other relevant diagram.

|

Posted By: heron

Date Posted: 27 Oct 2019 at 8:14pm

|

I tried it today without the driveshaft attached and there was still a vibration but I don't think it's as bad. I did get the shaft back in but ran out of time to start it up. BTW: The clutch shaft was spinning because the flywheel clutch is stuck again. I'll have to start it in gear then see how the vibration feels once the clutch is broke free. I'm wondering if maybe the clutch assembly has so much rust maybe it's creating a vibration. Then again maybe it's just this 271 as it's not going to be smooth, I would think. We had this same motor in a Marco screening plant back in the 70's and I remember it vibrating quite a bit also. If you guys say the wobble and play is normal than so be it. I'll keep you guys posted as my next priority is to figure out a way to make the shifter work better as it has too much play. The good news is the steering clutches are like new, undercarriage is also like new and motor runs like a top with no oil burning and no smoke.

|

Posted By: heron

Date Posted: 28 Oct 2019 at 9:07am

| Oh yes, all the hardware is in place. Fortunately, this machine was purchased directly by my grandfather so my father has given me the history plus this machine was in my backyard when I was born. It was retired from the company in 1964. It was ran very little as most of their work was large scale. The only thing that was done was the flywheel clutch assembly in early 1960. My father said there was some kind of updated or better clutch and that it came as an entire assembly. He remembers putting it in with his dad in one afternoon. |

Posted By: Leop

Date Posted: 28 Oct 2019 at 10:36am

|

Well if that machine has been in your family for that long then we got to get it fixed! You mentioned in your first post that the yoke was way too loose on the clutch shaft. Can you tell us how you determined that? I have been assuming that you pulled the entire driveshaft out, separated the clutch side yoke from the ujoint, and then hand fitted just the yoke on to the clutch shaft and then noticed at that point that it slipped on loose and wobbled? But is that what you actualy did? |

Posted By: heron

Date Posted: 28 Oct 2019 at 12:00pm

| Yes, I took it off the ujoint and put it on the end of the clutch shaft. It wobbled unlike any yoke I've ever fitted on a shaft. But, seems from what I've read it will not be tight. Yet when the shaft is connected the front of the driveshaft moves quite a bit...hence why my dad always thought it was a bad ujoint. The wobble has been there for many decades but again the machine was not used much and my dad always said once you increase rpms the the vibration goes away. It's only at a lower idle you feel it but I still felt it with no shaft connected and the machine running. I've never sat on another HD5 running so I have nothing to compare it to. Bird in a cage analogy as I've never known another HD5 outside of this one. We had lots of other larger detroits but I don't remember any vibration in our loaders(michigans) or other AC dozers. |

Posted By: Leop

Date Posted: 28 Oct 2019 at 1:24pm

|

So to clarify: From the first drawing above (on page 2) the only thing connected on the engine side (clutch shaft) was #2 the yoke, and the hardware that holds the yoke onto the clutch shaft which is numbered #22, #23,#24 and #25? And the #24 bolt was tightened down? And even after all that you could wobble the #2 yoke around the clutch shaft by hand? And by wobble I mean that the yoke can turn an elipse around the shaft. I would expect it to slide on loose, and maybe chatter when turned clockwise and counter clockwise around the clutch shaft due to cleance or wear between the yoke splines and shaft splines. But to me wobble of any huge amount that can be caused by hand even when the yoke and shaft are bolted together through thier centerlines (by bolt #24) indicates some kind of seriouse problem in that area. If the above is true then something must be wrong. Im no Allis Chalmers expert but like you I have never seen a yoke wobble on it's shaft to any great degree. And even if it did, you would think that after bolt #24 was tightened down tight that it would be hard to get it to wobble just by hand. All I can think of is that if they got bolt #24 mixed up with some other longer bolt that maybe when they tightened it the bolt hit the bottom of it's hole before it was able to cinched down the yoke to the shaft? Maybe that let the yoke move around enough that it wobbled itself out and then that wobble ruined the ujoint, or allowed something to bend? A video of you wobbling the yoke on the shaft by hand would help. I would think it would let the real experts on these machines tell us if it looks like an acceptable amount. My advice would be to get this wobble question figured out first and then move on to the ujoint next to see if it is also damaged. Cheers, Leo |

Posted By: Coke-in-MN

Date Posted: 28 Oct 2019 at 7:48pm

|

To tighten up tha shifter - check that cross tube that is held into shift tower by the 2 bolts through the sides of the tower , the pin in the yoke could be work or the ends of the bolts could be worn and allowing slop , also the end of the shift lever can be worn and sliding past shifting rails - might require welding it up someand grinding down to size . I made new bolts and machined ends to fit into a new tube I made - then used a larger pin with cuts where end of bolts index into pin to hold it secure - adjusted tension by using spacer washers under the bolts to get proper play needed to work smooth . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: Leop

Date Posted: 28 Oct 2019 at 10:22pm

|

Coke, The shifter in my HD6G also has lots of slop in it. Will this advice to heron also apply to an HD6G? |

Posted By: Coke-in-MN

Date Posted: 29 Oct 2019 at 1:38pm

|

Yes - the forward and back movement depends on the right tension on all parts involved so if the tube is worn or the bolts there will be slop and the internal shift yoke will be out of allignment - Next that pin sontrols left and right movement and if yoke and pin are worn allows the end of yoke to be out of allingment with shifting rails creating wear on the end of the yoke that fits into rails . Getting it tightened up in both directions allows smooth movement and positive contact in the right place in the 3 internal rails that select gearing . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dadsdozerhd5b

Date Posted: 03 Nov 2019 at 7:11pm

|

INSTALL A GREASE FITTING IN THE YOLK AND GREASE IT OCCASIONALLY. MINE HAS ALOT OF SLOP AND THAT TAKES CARE OF THE WORST OF IT. OLD, LOUD, VIBRATING MACHINE, AREN'T THEY GREAT! I LOVE BOTH OF MINE! ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: heron

Date Posted: 20 Nov 2019 at 8:21am

|

No bolts are sized wrong. I spoke to a retired mechanic who worked on these machines a lot at the time. He said the yoke wear was a "common" issue. Most often he had to replace the shaft and the yoke. I did install a zirk and greased it up but the wobble is still present and yes you can definitely can move it around in an oblong fashion easily by hand. As I had said in an earlier post my dad has known about it for probably 40 years but assumed it was a worn ujoint. He never really worked the machine since the 60's so he simply greased up the Ujoints and called it a day. If he had to "work" it I'm certain he would have fixed it properly at the time. For me I do think at this point I'm going to be getting rid of the dozer. I simply don't have the time nor can I justify putting money in to the machine just to have it sit. I'd rather get it to someone that can work on it and use it.

|

Posted By: heron

Date Posted: 20 Nov 2019 at 8:22am

| Did the grease fitting, still wobbles but at this point I'll run it the way it is and has been for many decades...Thanks for the suggestion! |

Coke-in-MN wrote:

Coke-in-MN wrote: