Calling all welders here,,,,,,

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Shops, Barns, Varmints, and Trucks

Forum Description: anything you want to talk about except politics

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=162710

Printed Date: 05 Oct 2025 at 9:25am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Calling all welders here,,,,,,

Posted By: desertjoe

Subject: Calling all welders here,,,,,,

Date Posted: 11 Jul 2019 at 10:47am

|

Here lately the Campbell Hausfeld 140 mig welder I have has been steadedly going south on me. I called CH and they suggested I switch polarity on the leads,,CHIT that didn't work,,just made things worse. The machine just spits all the time anymore and I am tired of fookin with it. I see lots of "new" style migs using "Inverter technology" and are less than half of the weight of a regular machine but that don't concern me. I would rather get a 115 machine as the 220 volt machines, while they do produce more power,,,are limited by length of the power cord. I want to be able to mig weld under my favorite tree out back which is bout 30' from the 220 outlet,!! I've about decided getting a Miller, Hobart or a Lincoln to be more trouble free but ,,,,??? There are an AWFUL lot of new chinese brands out there,,,so what are ya'll having good luck with? I would be using the mig on 3/8" or less as I have ole Brutus 200 amp lincoln arc welder to take care of the big jobs. Anybody???

|

Replies:

Posted By: ac fleet

Date Posted: 11 Jul 2019 at 11:41am

|

A 30' 220 power cord is doable!---I use one all the time and its 50'. use 10 gauge wires inside the cable. As for the new welders, they are made cheep and I will never buy one of them. I have an old century 200 wire welder and my fav., a Linc. 225 stick unit.---these will last me for the rest of my life. ------------- http://machinebuildersnetwork.com/ |

Posted By: DougG

Date Posted: 11 Jul 2019 at 11:52am

| I've used them all and Lincoln seems the best |

Posted By: Tbone95

Date Posted: 11 Jul 2019 at 12:46pm

| Joe, you said it, AWFUL. I know yer, er, um, frugal. But there sure is a difference in welders. |

Posted By: Thad in AR.

Date Posted: 11 Jul 2019 at 1:04pm

|

Miller and Hobart are built in the same factory with the same stuff. Miller might have an extra bell or whistle. I’ve been around lots of Lincoln 120’s and had no luck. The best 120 I ever used was a Marquette. I’ll also add my vote for a 220 and 50’ extension cord. When it comes to 220 Wire welders Miller is king. Find a used MillerMatic 200 and live happily ever after. |

Posted By: Ray54

Date Posted: 11 Jul 2019 at 8:19pm

Joe were you not crowing about a cheap welder deal a year or 2 ago.........poke poke.(Shameless go easy on O'l Joe I just got him). Joe were you not crowing about a cheap welder deal a year or 2 ago.........poke poke.(Shameless go easy on O'l Joe I just got him).     I just use the old portable Lincoln 200 DC for best results.

|

Posted By: desertjoe

Date Posted: 11 Jul 2019 at 8:43pm

|

RAY,,,,!!!! RAY,,,,!!!!! RAY,,,,!!!!! chit,,,,, I was hopin nobody would remember thet little number,,,,,and,,,and I AM gonna own up to thinkin I HAD cut a fat hog on that welder,,,but RAY,,,mayhaps it WAS a good deal as it didn't cost me a red cent,,,,,remember??  Chit,,,,I been dreadin that dang Shameless and HIS poker'er all day but,,,I'm ready to take my poison,,I am,,,,,  I'm really thinkin it mabe some little ole something with it but I ain't gonna mess with it no more. I'm puttin it on the Marketplace this weekend and price it kinda cheep at $537.00,,,so it sells quickly,,,,,   Hey Thad,,,,,chit fire them millermatic 200 is EXPENSIVE,,ain't they,,?? Lowest price one I seen on ebay was $1523.63 and,,,and,,they wouldn't even throw in a few rolls of wire and some gloves,,,,  But I'll keep lookin,,,,they's lots of the overseas products that are of good usable quality but GOOD quality welders is something that needs to be Made in the USA,,I'm thinkin. Say,,,I just thought of something,,,I'll bet ole Shameless maybe gots one of them Millers or a one of them red ones in one of his many barns,,,,,

Gotta get back on his good side anyway,,,,,, Gotta get back on his good side anyway,,,,,, |

Posted By: JC-WI

Date Posted: 11 Jul 2019 at 8:49pm

|

Ray, that still was an awful sharp pointy stick ye used on our ol' Desert Fox... Ye notice he hasn't figured out his picture taken phone yet...  ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: steve(ill)

Date Posted: 11 Jul 2019 at 9:22pm

|

SPITTING on a wire feed is normally low GAS pressure... Are you using CORE wire or Purge Gas to weld ?..If GAS, try turning up the flow.... I have a small Lincoln 140 amp 120 v wire feed that I use .025 solid wire with CO2 gas for all welds 3/16 inch and smaller... Anything over 1/4 inch gets the Miller 200 amp DC stick unit running 7018... 3/32 rod. ------------- Like them all, but love the "B"s. |

Posted By: LeonR2013

Date Posted: 11 Jul 2019 at 9:58pm

| Probably can't beat a Miller, Joe. |

Posted By: desertjoe

Date Posted: 11 Jul 2019 at 9:59pm

|

Hey Steve,,,the tech with CH told me wire speed was too fast, so I cut it back to .5,,any slower and it would stop rolling out,,,still spitting, Then I increased the shielding gas rate,,still spitting. Took the gun apart and removed the liner and blew it out but it was nice and clean as I had cleaned it bout 2 months ago when issues started. Yeah,,,JC,,,ole Ray,,he been talkin to ole Shameless on the sly and sharin them poker'er jabs,,,I can tell,,,,but,,,,but,,,I'm still gonna worry bout him after the next earthquake,,I am,,,,,,,

Chit,,,,I'm outa here,,,,,, Chit,,,,I'm outa here,,,,,, |

Posted By: desertjoe

Date Posted: 11 Jul 2019 at 10:03pm

|

Oh ,,I totally agree with you Leon and all the other Miller lovers,,,but gosh dang are them things expensive,,,!!! maybe I can pawn thet last half acre down below and get me one of them nice Millermatic 200's like ole Thad is sayin bout,,,,

sigh,,, sigh,,, |

Posted By: truckerfarmer

Date Posted: 11 Jul 2019 at 10:28pm

|

Check your feed rollers. If they are getting worn, could be part of your problem. Another problem could be your wire. I used to use KT wire from local farm supply store, and had some of the same problems. Bought last spool from welding supply store and it's a world of difference. Cheap wire has bigger tolerance in thickness, and if you run your fingers over it you may notice burrs on it. Another thing is how old is your wire. If it has been through a couple seasonal changes, such as summer to winter and back to summer in an unheated shop, might be a light rust on it due to condensation. Make sure spool is turning freely on spindle and make sure wire it is feeding off spool smoothly. Sometimes you just have to open up the door and trigger out a couple feet an watch what's going on inside to see what's causing the problem. ------------- Looking at the past to see the future. '53 WD, '53 WD45, WD snap coupler field cultivator, #53 plow,'53 HD5B dozer Duct tape.... Can't fix stupidity. But will muffle the sound of it! |

Posted By: shameless dude

Date Posted: 11 Jul 2019 at 11:15pm

| GOOD JOB RAY! yeppers...ya'll know if that ole Joe wasn't so chea…! he'd go to the dump and grab him one outta the pile! if'n he sells that ferd, he still won't have nuff to buy a good welder. if he sells one or 2 of them green mowers, that might get him nuff for sales taxes. (poke,poke,did I forget anything?) |

Posted By: JohnCO

Date Posted: 11 Jul 2019 at 11:51pm

|

Can't help you with the problem on that welder, Joe. I have a Miller 210 wire feed which makes me a halfway decent welder. I was told that the difference between a Miller and Hobart is that Miller has copper windings and the Hobart aluminum, never took one apart to see. ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: Leop

Date Posted: 12 Jul 2019 at 12:45am

|

I recommend that you watch a few videos from Jody who runs a channel called "Welding Tips and Tricks" on YouTube. I like Jody because he is a pro. I like learning welding via video because it is a very physical and audible art. For example we all hear that a proper Mig feed should sound like bacon frying. Actually hearing it made my welding improve a lot. He and others also include debugging videos for equipment, welder technique, consumables. But by far the best videos up there are a variation of "How to make the best welds you can with consumer level equipment". One guy shows how to get excellent results on a Harbor Freight Tools low end welder. By low end I mean the lowest end of thier already low end welders.  Check out a channel by Ave about the new orange welders from HFT. They actualy turned out to be pretty good machines. At least those are the resources that have helped me the most. |

Posted By: Leop

Date Posted: 12 Jul 2019 at 1:39am

|

BTW I have the following welders: Miller 330 - old huge beast, impossible to blow up, welds great. Con - super heavy. Cost me $350 used on Craigslist not including bottle or torch. Miller econotig. Welds great, cant blow it up neither. Paid $900 on Craigslist for welder, torch, consumables, bottle. Hold thier value excellent. Miller synchrowave 300. Impossible to blow up. Coveted welder by pros. Paid $900 off Craigslist, cart, cooler, and bottle included. My best by far. Snap On MIG. Paid $1,200 off Craigslist . Trouble now and then but mostly due to poor welder, lack of feed mechanism maintenance, use of cheap wire. My wife says I need one tig and one mig and get rid of the rest. I should have married a welder i guess. Tig was harder to learn but I like it cause i add the wire myself. Mig is always shoving it in. I am an electrical engineer and have designed many switching power supplies. Nothing wrong with them. They are light, efficient and easy to controll so that tricky power curves can be created that make a crappy welder look like a good welder. If you buy a well designed inverter/switcher welder then they should do you good. The issue to watch for though is cost. Initial, and maintenance. This is the primary reason i have gone old school. In theory the switchers should be cheaper to build and maintain. In practice they are not. The huge transformers in any of my welders cost more to build than an entire switcher. However, that transformer will last longer than most of the electronic components in a switcher. Remember, welding is basically a short to ground! If you could fix a board in your switcher when something went bad then the above wouldn't matter. Most components are in the 25 cent range, and even the expensive IGBT and Mosfet transistors are at the most $30 each. But you can't fix those boards or have them fixed inexpensively because neither you, nor even authorized service centers are allowed to get schematics. Debugging these days is for the most part a board swap excersie and they are allowed to put test boards back into stock. Ypu are not allowed to return a board that was not needed after you confirmed that the new board did not fix the problem. Oh, and some companies really bend you over for new boards, often because they dont bother to repair bad boards that they get back. Even if they do, the average cost to send the board to China or the board house is $10~$15 dollars. Even if you persisted and debugged a board without schematics you are often still stuck because the larged chips are marked with a special part number for the customer. The generic part is 100% identical to the specialy marked one, but no one will tell you what it is. I can fix my old school welders with an ohm meter. Everything is generic. Short of a short in the main transformer's windings the welder will never die. Often the price of copper makes fixing a transformer uneconomical, but i have still done it using wire from another damaged transformer if i have one lying about. All the above listed welders are great machines. A lot of the machines designed and built Australia (ESAB) are great. Many of the newest models from china are also dang well designed; I used to fix Lotus plasma cutters part time and they were not rhe worst design i had ever seen! What I recomend is that you pick the features you like, then the model from each vendor that fits those requirments, including used welders. Once thats done do a quick online parts search for each of the welders you are considering. A random 10 min search per welder for similar parts across all the welders in your list is plenty; mother board, power board, etc. After that you will know which welder you want to buy if you only want to buy one more welder in this lifetime. That's what I did. Often the cheaper welders are easiest to fix and weld almost as good. I did however just turn 51, and my back does look at those little light weight switcher jobbers with envy, so there is that to consider too. Hope this helps. Leo |

Posted By: desertjoe

Date Posted: 12 Jul 2019 at 3:37am

Naw,,,"Good Buddy",,,,,I think you and ole Ray pretty much covered everything,,,,still havin some issues sittin down for too long,,,,,  But,,,,but,,,I will survive,,, But,,,,but,,,I will survive,,, OH Chit,,you plumb forgot to even give me credit for the CHEVROLET Silverado I just stol,,er, bought,,,,,  in case you missed my post,,I'll refresh your memory. I just bought the nicest Silverado I have seen in a long, long time,,!! ALL Black inside and out,,,I think has every option they had back then even includin the Blair type 5 lights across the top of the cab (You'ld like them) (1st poke) in case you missed my post,,I'll refresh your memory. I just bought the nicest Silverado I have seen in a long, long time,,!! ALL Black inside and out,,,I think has every option they had back then even includin the Blair type 5 lights across the top of the cab (You'ld like them) (1st poke) I bought this CHEVROLET just KNOWIN you was gonna brag on ole Joe but NNNNOOOoooo,,,sheeesh,,,just can't win for losin,,,,,,  Anyway,,Body as straight as can be and inside is gonna clean up real nice and even has a "felt" type headliner that is in perfect shape (it black too),,,,I'll tell you what ,,if you like Black,,this sob is for YOU,,!! Not sure if odometer is kosher or not but only showin 77,523  Has factory AC, cruise control, PB that all work, The little 305 has a miss that don't bother me to awful much. Has factory AC, cruise control, PB that all work, The little 305 has a miss that don't bother me to awful much. The only'ist thing is the steering column is a friggin mess,,,PO said they tried to steal the trk and tore up the column is why he decided to sell. I got the whole column out and even the tilt mechanism is broken,! I want to keep and repair this column, if possible as it ,,,,caiuse it black toooooooooo  AND,,,,AND,,,I ain't gots no green mowers,,!!!! well,,,lemme back up a bit,,,I do gots just one little ole JD push mower,,,but I ain't used it in a year,,,,does that count,,??  By the way,,,if I could get my friggin phone transfer fixed,,,I did happen to pick up another rider that is now ready for re-sale,,,,,it black too,,,!!!

I gotta go,,,, I gotta go,,,, |

Posted By: desertjoe

Date Posted: 12 Jul 2019 at 3:57am

|

Hey Leo,,,many thanks for thet great post,,,I feel much better now,,,,  Well,,I'm not an EE but,,but I wish I had studied more,,,, Yeah, I been readin lots bout the new inverter type welders with the IGBT technology and that is where my concerns lay. I've talked to a few rig welders that complain bout issues with some of the "boards" constantly giving them issues and like you say,,,you buy it and it yours if fixes your problem or not. I would rather have an old school wire machine, as I'm not a bells and whistles kind of guy,,,just give me a good heavy machine that will fry lots of bacon and i be very happy guy. Well,,I'm not an EE but,,but I wish I had studied more,,,, Yeah, I been readin lots bout the new inverter type welders with the IGBT technology and that is where my concerns lay. I've talked to a few rig welders that complain bout issues with some of the "boards" constantly giving them issues and like you say,,,you buy it and it yours if fixes your problem or not. I would rather have an old school wire machine, as I'm not a bells and whistles kind of guy,,,just give me a good heavy machine that will fry lots of bacon and i be very happy guy. I DO agree with your wife,,,,you gots TOoooooo many welders,,,you want I should send you my mailin address,,,,????  I promise I'll take good care of whichever one you send,,,,, I promise I'll take good care of whichever one you send,,,,, Many THANKS for the help, Leo,!! OH,,,and welcome to this group of misfits,,,I NEED all the help I can get what with some of these guys (ain't callin out any names just yet) always wantin to pile on,,,,,

Chit,,I'm outa here 'fore they wake up,,,,, Chit,,I'm outa here 'fore they wake up,,,,, |

Posted By: desertjoe

Date Posted: 12 Jul 2019 at 4:09am

|

Hey Trucker,,I'm thinkin you may be onto something as I do get the bacon fryin sound now and then but more of the "then",,,,and,, your suggestion of maybe all them cheep rolls of wire ole Shameless sent me ain't too swift and only agravatin the problem,,,because it do come and go all the time from spittin to fryin,,,,I'ma goin to weldin shop first thing and see if they got a part of a roll they want to bargain for ,,,,,,,,      Naw,,,,seriously,,I'ma gonna get me a roll of the best'est solid wire they gots and also check the feed rollers real close and,,,and,,Trucker,,,since I don't know what you looks like,,,I'ma hold off on the "kiss on da cheek" this time,,OK,,??

|

Posted By: Leop

Date Posted: 12 Jul 2019 at 5:06am

|

If you like the way the welder used to weld, and you are cheap like me, you might want to reconsider fixing it. The two components that are most likely causing you problems are $6.00 and $18.00. And the parts at those prices are the same or better as the original ones! Yes, cheap welders are in some ways total rip offs, but you allready own it so why worry about that now. When Mig welders sputter it means that the wire-speed/voltage/mass-of-base-metal ratio is not correct. This can be due to improper settings or a problem with the welder. Since the OP said it used to weld well then we can assume he knows how to weld and that the problem is with the welder not the weldor. Sputtering is caused by the weld circuit being broken. This is due to using too much power, or feeding the wire into the weld puddle too slowly. It is rare for the welder to break such that it feeds more power than the weldor called for. The more likely issue is therfore that the wire is feeding too slow or feeding erraticaly. We can nonetheless check the welder for an overpower problem by using a volt meter to check the voltage from the tip to the work clamp. It should vary when the voltage knob is turned up to down. Specs should be in the welder's manual. Next Make sure the wire passes through the torch without much force. If it does not it might mean the tip is melted and a bit tight, or the inner liner of the torch lead is worn through and the wire is encountering lots of friction. Often a sticky torch lead only manifests itself when it lays a certain way, and this often fools people into thinking the torch lead is okay when it is not. This torch is equivalent to rhe factory torch, and yes campbell hausfeld probably paid around $4.00 for your torch. https://www.ebay.com/itm/Mig-Welding-Gun-Torch-Parts-Fit-CAMPBELL-HAUSFELD-WF2150-WF2000-Wire-Feed-Welder/183619720867?hash=item2ac09696a3:m:mhSVgBW7FXFhWHkRDUQj_vA&redirect=mobile" rel="nofollow - https://www.ebay.com/itm/Mig-Welding-Gun-Torch-Parts-Fit-CAMPBELL-HAUSFELD-WF2150-WF2000-Wire-Feed-Welder/183619720867?hash=item2ac09696a3:m:mhSVgBW7FXFhWHkRDUQj_vA&redirect=mobile If the tip and feed rollers are stamped with the same wire size that you are actually using then you may need to tighten the feed roller pressure, loosen the spool resistance, or both. If that doesnt fix the problem a new feed mechanism like this one will work: https://www.ebay.com/i/172135828462?chn=ps&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=172135828462&targetid=484681047731&device=t&mktype=pla&googleloc=9032143&poi=&campaignid=1497793372&mkgroupid=60383707640&rlsatarget=pla-484681047731&abcId=1139456&merchantid=101706952&gclid=CjwKCAjw36DpBRAYEiwAmVVDMHBYZ6-A-by0XxwZ4ESsKSHcqK741YW-kLmzCogwPAR0KBGS9IWr2hoCzWwQAvD_BwE" rel="nofollow - https://www.ebay.com/i/172135828462?chn=ps&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=172135828462&targetid=484681047731&device=t&mktype=pla&googleloc=9032143&poi=&campaignid=1497793372&mkgroupid=60383707640&rlsatarget=pla-484681047731&abcId=1139456&merchantid=101706952&gclid=CjwKCAjw36DpBRAYEiwAmVVDMHBYZ6-A-by0XxwZ4ESsKSHcqK741YW-kLmzCogwPAR0KBGS9IWr2hoCzWwQAvD_BwE Here are okay instructions on how to measure voltage and wirespeed: https://www.google.com/url?sa=t&source=web&rct=j&url=%23&ved=2ahUKEwi_n_m0jq_jAhWsB50JHUYzCPgQwqsBMAB6BAgLEAU&usg=AOvVaw0VTJzWxrN8ZFOD4xbU2nov" rel="nofollow - https://www.google.com/url?sa=t&source=web&rct=j&url=%23&ved=2ahUKEwi_n_m0jq_jAhWsB50JHUYzCPgQwqsBMAB6BAgLEAU&usg=AOvVaw0VTJzWxrN8ZFOD4xbU2nov To make sure its not operator error both of these short videos are helpfull https://www.google.com/url?sa=t&source=web&rct=j&url=%23&ved=2ahUKEwi_n_m0jq_jAhWsB50JHUYzCPgQwqsBMAF6BAgLEAg&usg=AOvVaw0VTJzWxrN8ZFOD4xbU2nov" rel="nofollow - https://www.google.com/url?sa=t&source=web&rct=j&url=%23&ved=2ahUKEwi_n_m0jq_jAhWsB50JHUYzCPgQwqsBMAF6BAgLEAg&usg=AOvVaw0VTJzWxrN8ZFOD4xbU2nov https://www.google.com/url?sa=t&source=web&rct=j&url=%23&ved=2ahUKEwi_n_m0jq_jAhWsB50JHUYzCPgQwqsBMAJ6BAgLEAs&usg=AOvVaw0VTJzWxrN8ZFOD4xbU2nov" rel="nofollow - https://www.google.com/url?sa=t&source=web&rct=j&url=%23&ved=2ahUKEwi_n_m0jq_jAhWsB50JHUYzCPgQwqsBMAJ6BAgLEAs&usg=AOvVaw0VTJzWxrN8ZFOD4xbU2nov TO LEARN THE DETAILS Of HOW MIG WELDERS WORK, AND WHY THEY SPUTTER READ THE NEXT OPTIONAL SECTION. Ever drop a wrench across a car's battery terminals? The wrench melts in half right! When it melts clean through the circuit is broken and the shower of sparks and molten metal stops. If we wanted to weld we could use the metal from the melted wrench; I have done exactly this to weld a cracked component on my 4x4 in the back country so that i could get home. But if we wanted to keep welding after the wrench melted in half then we would have to keep throwing wrenches on after the previouse one melted in half. This on off on pattern is the sputtering mentioned in the post. A welder gets its power from the wall socket instead of a battery. It reduces the 115 volt current down to about 50 ~ 70 volts. A stick welder uses ac current and a mig welder uses DC current. However you can mig and stick weld with either AC or DC. In stick welding the equivent of throwing a wrench across the terminals of the power supply is a weldor feeding welding sticks into the weld puddle. In a mig welder the welder pushes welding wire into the weld. When stick welding the weld will sputter if the welder does not feed the stick into the weld puddle fast enough. In mig welding the same thing will happen if the mig wire is not fed in fast enough (assuming all other settings are correct) How fast is fast enough? It depends, but with regard to sputtering: The bigger the metal the more voltage you need. A higher voltage makes a hotter arc and a hotter arc melts thicker metal than a cooler arc. Arc temperatures vary based on how big the welder is and its voltage setting, but they range from around 3000 to 20,000 °C. The mig wire is thiner then the metal you are welding, so it melts faster. We therfore need to feed it into the weld faster to keep the arc going then we would at a lower voltage setting. A table came with the welder to get you in the ball park. Put in your wire size and thickness of what you want to weld and it will tell you what voltage and speed to use; then tweak the speed to eliminate sputtering, but not so fast as to freeze the wire into the weld puddle. If you follow the table and the welder still sputters then somthing is wrong with the welder, and whatever it is is slowing the wire feed speed too much, or delivering more voltage than it should to the torch head. |

Posted By: Thad in AR.

Date Posted: 12 Jul 2019 at 5:21am

|

Joe I went through a rough spell with my MM a while back. I thought I had a bad capacitor. I replaced the liner, cleaned the rollers polished up the axle the roll spins on and changed wire. All good to go. I believe the Arkansas humidity got to my wire. I keep two of those wire cleaners ahead of my rollers. The first one gets a squirt of WD on occasion. I have blown liners out with air and squirted WD and air until it comes out clean. Check the ground cable connections. Oh and keep an eye on alien city Craig’s list. Time for a 220 wire feed.👍 I see them for $500 to $750 quite often. |

Posted By: Leop

Date Posted: 12 Jul 2019 at 5:23am

|

Thanks for kind words Desert Joe. Im no professional weldor, and I don't design welders, but a lot of this is just common sense and an understanding of how companies make money these days. Check out my last post. Yes, your torch head cost Campbell $4.00 or less. Feed roller mechanism - maybe $9.00. Entire welder in the box and shipped to Home Depot, $65 max! Those are cheap prices, and longevity will reflect them. Sad but true. Good luck on finding a boat anchor if you go that way. And if you pick a switcher that aint so bad neither. Just more cash short term and long term. Cheers to you. |

Posted By: Leop

Date Posted: 12 Jul 2019 at 5:32am

My wire got a touch rusty once and caused havoc. The clearance through the tip is tight, and the rust just made the wire too fat. I had to throw the entire roll away. Now i buy small spools in case it happens again. |

Posted By: DMiller

Date Posted: 12 Jul 2019 at 6:19am

|

Hey joe, increase that wire speed and turn UP the heat, that sputter is from losing contact or continuity and may be from too LOW a voltage setting. In that consideration you get a shield effect from the wire you just put down. Get some scrap 1/8" sheet stock and keep ramping UP the heat until you get a burn thru then back down. Seen it all too often and I use a Miller 210 that was performing similarly until a buddy of mine came over and did what I just explained. Zig Zag stitch, start at one side of seam, cross to other and pause JUST MOMENTARILY then sweep back, try it you will like it. I still use stick for strength welds, 7018 rod. As for pretty and limited spatter/sl*g, MIG. |

Posted By: Thad in AR.

Date Posted: 12 Jul 2019 at 6:20am

II’m lucky if I use 1 or 2 small rolls a year. I agree small rolls now. Joe also make sure your tips will slide over the wire easily. I check mine and use a tip cleaner as necessary. I once had problems similar to what you describe. Wire would get tight in tip in spots. |

Posted By: shameless dude

Date Posted: 12 Jul 2019 at 7:50am

| the wire I sent Joe was baling wire...now ain't that funny that he would even try? I told ya'll he was CHEAP! LOL (poke,poke) |

Posted By: DMiller

Date Posted: 12 Jul 2019 at 7:55am

| MIG gun tips and cones are considered Consumables, as they age they also corrode or develop burn markings internally as externally as that is where the wire receives its energy, I replace mine roughly twice a year low use, sometimes in hard use twice a week. I use a good quality Spatter Shield on the cones comes in a dip tub just poke the gun in it to minimize spatter build up collection. |

Posted By: shameless dude

Date Posted: 12 Jul 2019 at 8:16am

| I always used an old refridgerator to store wire and sticks in when between welds of anything. worked great keeping moisture out/off items stored inside. |

Posted By: Dusty MI

Date Posted: 12 Jul 2019 at 8:35am

|

Many years ago I bought a new Lincoln 140. Which is 120 volt, because I figured it would be easier to use an extension cord. Well that don't work, the wilder pulls a little over 20 amps when turned full up. I had used #10 romex and 20 amp outlets with 20 amp breakers, when I built my new shop. Because of this weldor I had to go to a 25 amp breaker. Never have used an extension cord with the welder. What seems strange to me is the welder came with a 15 amp cord cap. This set-up does work well. Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: desertjoe

Date Posted: 12 Jul 2019 at 8:37am

CHIT,,,Shameless,,,,Ya got me on thet one,,,,,    BALING WIRE,,,????,,what the heck I gonna do with all them rolls of baling wire you sold me as mig wire,,,???

|

Posted By: JC-WI

Date Posted: 12 Jul 2019 at 10:21am

|

"

the wire I sent Joe was baling wire...now ain't that funny that he would even try? I told ya'll he was CHEAP! LOL (poke,poke)

" Joe, did ye measure Shameless's balin wire he sents you??? if he sent the good stuff it would measure about 14 1/2 gauge, or... .076 ' an your little sputter prolly takes .030" ... What did ye do to get shameless's wire through that little tip on your welder? An if he sent ye some really cheap 16 gauge baling wire, it's still .0675" ... meaning you had to drill that tip out. LOL Say Joe, didn't you get Shameless's double platinum guarentee that if it didn't work, he would refund your money for twice what you paid for it? Worked in a peat processing plant where the dust would get into the welder contactors on the circuit board and after a few replacements of the little switch modules on the board of the 220v Lincoln wire feed, I started taking them apart and cleaning the points and then taping the seams shut to keep the dust out. You would not have believed how that dust could somehow get in there, but it did. One of the contactors would not even allow the spool to feed, another one messed with the wire feed and have poor splatter sounds... also the tips would wear out fast up there and had to change them out every couple days, we even used the dip to try and keep the sl*g from sticking. The dust probably came from getting on the wire at the feed rollers. We also had to lay the shielded cable out as straight as possible too. A new whip helped for awhile and still had to blow that out too. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Leop

Date Posted: 12 Jul 2019 at 12:12pm

Thats a great idea. I am going to start storing my wire in an 9ld fridge first thing after work today. I am thinking that I might add a light bulb like the gun safes do. Not needed for mig wire, but might help with the coating on my sticks not getting soggy? Thabks for sharing. |

Posted By: TDF

Date Posted: 12 Jul 2019 at 6:23pm

Amen to that. Look for them on local auctions, and local classifieds. They regularly turn up in my area for under 1k. I got mine on a farm sale. Not much use. Full bottle of gas and full spool of wire for $750, a year and a half ago. And it is one fine welding S.O.B. capable of small welds up to very thick stuff. We haven't used the old arc since I bought the 200, and I built a fork attachment for a loader tractor that I've since used to pick up cars with and haven't broken a weld yet. TDF |

Posted By: DMiller

Date Posted: 12 Jul 2019 at 8:22pm

| For my stick rods I actually bought two old heated rod totes, fill one with what I intend to use, plug it in overnight and nice and dry by morning. Otherwise they lay in the tin I buy them in inside the shop. |

Posted By: desertjoe

Date Posted: 13 Jul 2019 at 4:31am

|

Yeah,,JC,,10-4 on keeping the flyin stuff away from them welders,,,I use up a lot of grinder wheels for most of my work and will NOT grind any metal around the mig,, I ought to have a canvas cover or something but usually either move the work or the welder away from the other to save the welder. I have one of those white plastic "trays" out of an old fridge that I use to cover the welder with when it stays out that works pretty good. I've bout decided I'm gonna have to get me a good 220 mig with a 50' power cord since I use a welder so much any more. I just remembered something when this all started with the CH mig,,,that I had rebuilt a miller arc welder with a Onan engine on a nice trailer sometime back and it been in the boat shed all this time,,,I should bring it out, dust it off and try to trade it for something I can use,,, I cannot remember which model it was,,but I bet ole Thad remembers,,,he helped me so much on it,

I'ma go look when sun-up.... I'ma go look when sun-up.... |

Posted By: Thad in AR.

Date Posted: 13 Jul 2019 at 5:49am

|

Miller Aead 200 LE and apparently you use it as much as I use mine. I have used it for a generator but that’s been a few years back. |

Posted By: desertjoe

Date Posted: 13 Jul 2019 at 8:13am

|

Dang,,but you gots you a dang good memory,,THad,,I kept thinkin on thet welder so I had to go take a look see and you are exactly right it an AEA 200LE and still looks like i left it,,,what,,2-3 years,,??

I'ma gonna move a bunch of chit to get it out,,check the engine and get it runnin. One of the ta'ars is blown so got to fix that and put it on the MarketPlace for sale or trade for a 220 volt Miller mig. What you think a good sellin price for this "vintage" welder,,,,,, I'ma gonna move a bunch of chit to get it out,,check the engine and get it runnin. One of the ta'ars is blown so got to fix that and put it on the MarketPlace for sale or trade for a 220 volt Miller mig. What you think a good sellin price for this "vintage" welder,,,,,, Ordinarily,,,,I dislike that word when I'm buyin,,,,,but,,,,?? Ordinarily,,,,I dislike that word when I'm buyin,,,,,but,,,,?? I did find a brand new faceplate,,,looks nice,,,huh? I did find a brand new faceplate,,,looks nice,,,huh? |

Posted By: Thad in AR.

Date Posted: 13 Jul 2019 at 8:48am

|

I don’t know on the value but I traded a Lincoln weldonpower 200 Rope start AC only for a $ 750.00 Ruger. It wasn’t near the welder you have. I’d really search out a Mm 200. They quit making them and soon the welders all started complaining so they made the MillerMatic Vintage which is what I have. It’s awesome but still not the welder the original 200 is. If you can test a capacitor or change out an electric motor you can make a MM 200 last forever. No boards or BS to mess with and the most crisp arm of all Migs |

Posted By: desertjoe

Date Posted: 14 Jul 2019 at 7:15am

|

Well, Gents,,I gots a bit of an update as I did take all the comments to heart,,,,  I had been buying the solid wire from Harbor Freight thinkin it was chea,,,,err,,, more economical,,so I went to the weldin supply and asked for their best (almost choked on thet word) wire they had and he handed me a roll that was ,,gulp,,priced less than a five spot,,told him again I wanted the best and he tells me that one is made by a company that only sells welding supplies and they have been carryin this brand for over 10 years with NO Complaints from any of the welders. I had been buying the solid wire from Harbor Freight thinkin it was chea,,,,err,,, more economical,,so I went to the weldin supply and asked for their best (almost choked on thet word) wire they had and he handed me a roll that was ,,gulp,,priced less than a five spot,,told him again I wanted the best and he tells me that one is made by a company that only sells welding supplies and they have been carryin this brand for over 10 years with NO Complaints from any of the welders. Run home and took the gun apart again and cleaned it all out, blew the new liner out good,,reassembled it all and give it a go,,,,,Same friggin thing,,!! Messed with the wire speed a bunch and finally remember that CH tech had got me to reverse the leads (?) back couple of months ago, so I reverse them like manual says they should be and ,,,,,,,PRESTO,,,the sound of fryin bacon starts comin outa thet thing,,,!! It still erratic but I keep messin with the wire speed and finally get to where it will weld good bout a 1 1/2" long weld,,spit a little and then take off again fryin bacon, Lots more better if you just go for 1" welds,,, stop for an instant,,,then give her another inch,,,,,  It hard to believe the changing to a different (better) wire has done the trick on this machine but I have still made up my mind to get me a 220 volt Miller soon as I find one worth the money. I don't want to mess with this CH so I can sell it while it still weldin good soon as I can. I cannot remember the brand of the wire I think,,Weld Cote,,?? but had a strip of brown paper coverin the wire with a tag "Qualified",,,??? qualified for what??  What other "GOOD" brands of wire are there out there?

|

Posted By: steve(ill)

Date Posted: 14 Jul 2019 at 9:41pm

|

If it welds for a little bit, then SKIPS, it is probably in the roller adjustment ( tension) or the liner is getting OLD and grabbing the wire........... either way, not SMOOTH TRAVEL. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 14 Jul 2019 at 9:43pm

|

If you have CERTIFIED Welders welding up a boiler or pipe line, you have to keep RECORDS, and the ROD has to have a paper trail of where it came from, what and who made it, and what % metals are included in the rod ( wire)... that is its CERTIFICATION. ------------- Like them all, but love the "B"s. |

Posted By: desertjoe

Date Posted: 15 Jul 2019 at 4:42am

Hey Steve,,,,you know,,I've been told two different things on setting wire tension,,,,The CH tech told me to tighten the agjustin knob down to where it will NOT slip,,,,then a half more turn,,,?? Then a dude on YouTube had a long winded video that says to hold the torch end against a solid something, hit the trigger and adjust the knob to where it will slip when held up to something solid,,,,,UMMmm,,,which is which,,,???

|

Posted By: desertjoe

Date Posted: 15 Jul 2019 at 5:19am

|

One other thing,,,,,  I did notice that when weldin on the galvanized tubing,,the welds will NOT be nice and smooth and tend to require too much grindin to make em look purdy,,,,I remember way back when,,reading bout weldin on galvanized pipe releases some gas that is hazardous if you are standin right over the fumes,,, I'm wonderin if this release of fumes are what are makin the weld look crappy,,?? This CH mig NOW lays a real purdy bead on carbon steel but looks like Chit on the galvanized pipe,,,,???

|

Posted By: Alberta Phil

Date Posted: 15 Jul 2019 at 9:29am

|

Your weld metal is being contaminated by picking up zinc from the galvanized pipe and you won't get a nice bead with the contamination. |

Posted By: HudCo

Date Posted: 17 Jul 2019 at 10:13pm

| i did not read many post but i would stay with lincoln or miller because repair parts consumables and acessorys are readly avalable |

Posted By: Coke-in-MN

Date Posted: 17 Jul 2019 at 11:04pm

|

I bought a POW-CON inverter welder about 1990 - it's DC / reverse polarity for Stick , Wire Feed , and can TIG with it but scratch start . A high low setting and dial in amp adjustable , stitch weld , spray arc or ? Wish it had high frequency but seems only thing lacking . (Thermal Arc bought them out) son has 2 Thero Arc welders - I also have a Miller 304 that will do SMAW, TIG, MIG - that unit I bought from shop I worked for when it closed - was close to $5,000 new with water cooled TIG torch . Bought it for $1 when I was clearing out building Problems with sputtering can also be bad liner or bad gun - the Pow-Con when i bought it had a 130 Amp rating on the gun and seems I overheated it enough that i had to replace liners regularly - finally bought a 200 A gun - not as flexible but no more problems with bad liners . Also check your feed rollers as they can be worn and skipping on wire , also a wiper on wire where it enters the liner keeps both wire and liner as well as tips in good working order . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: JC-WI

Date Posted: 18 Jul 2019 at 12:05am

|

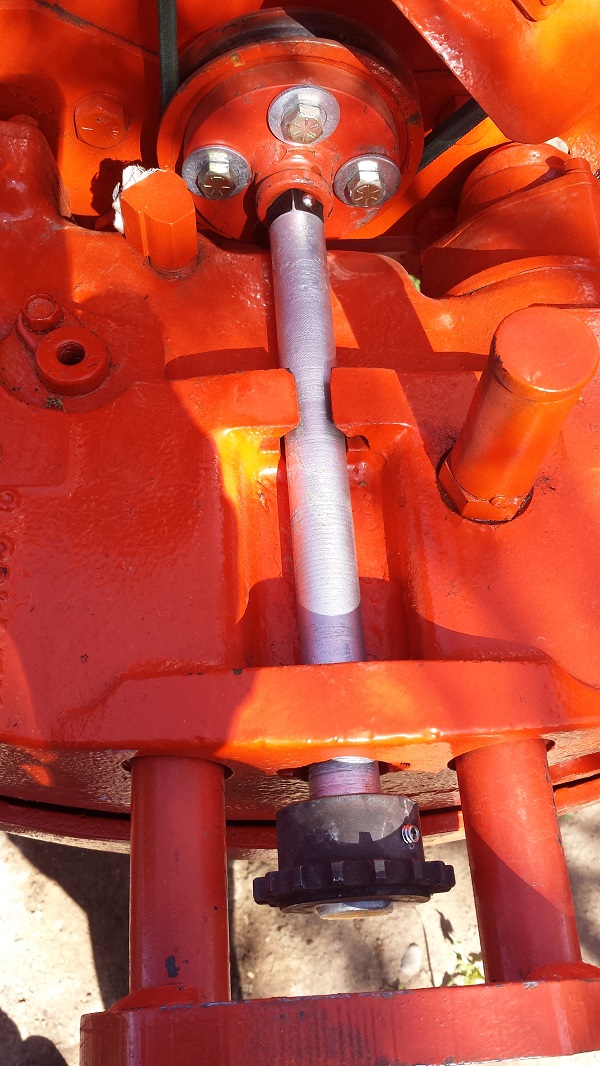

Ol' Desert Joe with all the free advice here will be such a pro that he will be able to weld juss about everything... I gots some parts that need welding on my old 1327 discbine. Here's a picture of the drive assembly to the discbine's cutter bar...  The drive hubs, there are three and this one pictured is the worse with worn splines... $90 bucks each... then the drive shaft, some worn splines, JD price on it is $136 bucks... and then there's the hexagon drive pucks with the 6 holes in them, They are $146 dollars and 4 cents... 4 cents? Yup, thats what the feller said, JD's that proud of them rubber pucks. Well anyways, with all the good advice on how to weld things, ole Joe will be an xpurt in welding these rubber hexagon pucks... I 'll get them in the mail to you a couple dayz after tomorrow Joe... an when your finished with them, I expect them to look like brand spankin new...   Say, does anyone know what size of a hockey puck disc BMW uses? ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: desertjoe

Date Posted: 18 Jul 2019 at 2:56am

|

Hey JC,,,I woluld tend to say,,you gots you some pretty good service outa them tractor parts,,,,,but,,,but,, they can ALL be fixed. AND was I to have me a great reliable welder,,,,,I could,,,,,,,UMMmmmm Don't know if you remember,, way back when I was in the rebuilding of the D14 Industrial, I had a similar dilema of high priced parts with low amount of dollars. The splines of drive shaft and the hub for the front pump had wore each other out and cost of the shaft and hub was gonna be lots of dollars,,,so my engineerin mind went to work and I come up on a fix that still looks and operates like the day I done it,,,,,  What I done was while in O'relly's,,I seen what was a 1" drive impact socket and a i" drive impact extension,,,,, The both pieces were only $20 and the socket was almost an exact fit in the center of the hub where the wore out splines were,,,,,

SO, I machined the center of the hub out to where the female part of the impact socket would fit in there just so,,,and put one of my "special" super duper welds on it to last forever,,!! I had a piece of 1" reciprocating pump shaft that was just the length of the needed shaft,,so I welded the male end of the impact extension to the driveshaft and PRESTO a drive shaft and hub arrangement that will outlive me and two-three others. The impact socket and extension are work hardened to outlive all that pounding back and forth so I feel sure they will work out just fine. SO, I machined the center of the hub out to where the female part of the impact socket would fit in there just so,,,and put one of my "special" super duper welds on it to last forever,,!! I had a piece of 1" reciprocating pump shaft that was just the length of the needed shaft,,so I welded the male end of the impact extension to the driveshaft and PRESTO a drive shaft and hub arrangement that will outlive me and two-three others. The impact socket and extension are work hardened to outlive all that pounding back and forth so I feel sure they will work out just fine. |

Posted By: jaybmiller

Date Posted: 18 Jul 2019 at 6:06am

|

Hay DJ Is that a factory or 'DJ special' fill/vent cap for the steering bolster? yeesh, Grade 8 bolts to attach the adapter ! Kinda 'overkill'.......lol Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: desertjoe

Date Posted: 18 Jul 2019 at 8:42am

|

Well,,,Jay,,put it this way,,,that one was on the tractor when I drug it out the weeds to get it home,,,, I did add a tack weld as the top part kept wantin to fall off. When I build something,,I build it to last,,,ME,

|

Posted By: DMiller

Date Posted: 18 Jul 2019 at 2:41pm

| One other IMPORTANT point of Wire Welding, is it HAS to be PRISTINE Clean, no Mill finish, no rust, no coatings or paint, SHINY, CLEAN and NO OIL. Every one of those mentioned will cause a cut out sputter and inclusion in the weld. |

shameless dude wrote:

shameless dude wrote: