B cold vale clearence

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=159081

Printed Date: 27 Jul 2025 at 11:02am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: B cold vale clearence

Posted By: 2011dandd

Subject: B cold vale clearence

Date Posted: 16 Mar 2019 at 5:07am

|

Hi I want to check the valve gap/clearence next week on the b. Does anyone have a cold gap that’s correct? Also will the rule of nine work for this engine? Cheers |

Replies:

Posted By: Jim.ME

Date Posted: 16 Mar 2019 at 5:20am

|

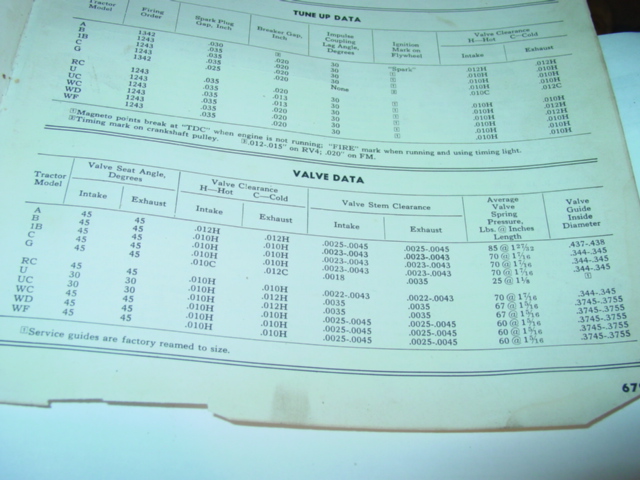

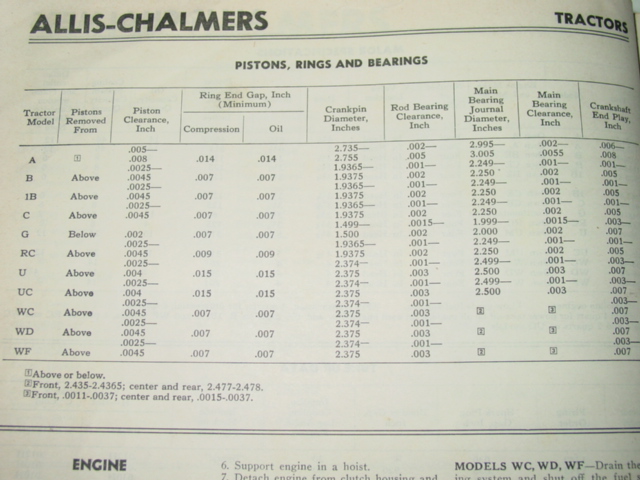

Tappet clearance .010" Hot from manual Gerald posted. .012" to .013" cold will be a good starting point. Rule of nine should work. http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf |

Posted By: brkfldj

Date Posted: 16 Mar 2019 at 6:30am

|

Educate me, please. What is the rule of 9? Thanks. Jim ------------- Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin |

Posted By: Dick L

Date Posted: 16 Mar 2019 at 7:04am

|

This covers the older Allis Chalmers data. If you have to ask questions on how to set the valve gap you would be well served to do one cylinder at a time. Short cuts followed will get you there but will not help you learn all the details in how to trouble shoot some problems. One cylinder at a time both rocker arms on the cylinder will be all the way up and to be exact the flywheel will have the TDC mark in the center of the inspection hole. It is not necessary to check the exact top dead center on these slow rpm engines but is a way for a person to double check. I learned to set the valve gap in the 1950,s with the engine running at idle. A few oil spots on the face and shirt sleeves was part of being a mechanic. I set these engines at .012 both hot or cold. What happens with having them a little wider within reason is a noisy valve train. Setting them tighter than the .010 can result in burnt valves or a miss firing.

|

Posted By: Jim.ME

Date Posted: 16 Mar 2019 at 7:34am

|

I had to look it up when he asked. Apparently it is commonly used with 4 cylinder sports cars. It maybe slightly more accurate than using the rock method. Like Dick L, I learned to check and set valve lash with the engine running, other than for the initial setting during a rebuild or head/valve work, which I usually did using the rock method. uploads/16335/Valves_Rule_of_Nines.pdf" rel="nofollow - Valves_Rule_of_Nines.pdf |

Posted By: 2011dandd

Date Posted: 19 Mar 2019 at 6:10am

|

Thanks for the help. Watched a few videos on how to do it whilst the engine is running. Is that an accurate way of doing it? Please correct me if I’m wrong but is that a case of Backing the nut of slowly until it starts to make a taping noise Then tighten but up just enough for the obvious tapping noise to stop Then 1/2 to 3/4 further turn on the nut. Job done?? |

Posted By: Dick L

Date Posted: 19 Mar 2019 at 7:41am

|

The nut is a lock nut not an adjustment nut. You put a 5/8" box end wrench on the nut and a screw driver in the center. You unlock the screw and adjust with the screw driver. When running at idle I tighten the screw on a .012 feeler gauge until I hear a miss and then loosen it until the miss is gone. That is the way I did it until about 20 years ago. I then started setting them at TDC on each cylinder. It is less messy and just as good. On these small low rpm engines a couple a thousands wide will not make a difference in performance. Tight can though. Double checking is not a weakness. It is called being prudent! |

Posted By: Jim.ME

Date Posted: 19 Mar 2019 at 10:03am

|

2011dandd, It sounds like you watched a video(s) of adjusting hydraulic tappets (lifters) in an automobile. Your engine has solid tappets and that procedure does not apply. Here is the instruction section on adjusting the valve tappets from the Allis Chalmers D14 Operator's manual that may help you. Use the clearance spec for your engine in place of the one in this document. As Dick L said use a wrench to unlock the nut, turn the screw with a screwdriver to adjust, then set the locknut to hold it. You will likely need to hold the screw with the screwdriver while you set the nut to keep it from turning and changing the adjustment. Check it again after you have the wrench and screwdriver off it to see that it stayed where you set it. uploads/16335/Valve_tappet_adjustment.pdf" rel="nofollow - Valve_tappet_adjustment.pdf |

Posted By: chaskaduo

Date Posted: 19 Mar 2019 at 11:53am

Thank you Dick L and Mr. Bonney.  ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: HoughMade

Date Posted: 19 Mar 2019 at 12:10pm

Just do this and call it good. ------------- 1951 B |

Posted By: Gerald J.

Date Posted: 19 Mar 2019 at 9:56pm

|

Valve clearance in an overhead valve engine can be a bit critical. Needs to be enough clearance that the valve closes completely when the engine is hot and the heat has stretched the length of the valve stem, bent the rocker, stretched the length of the push rod, and expanded the length of the block and the height of the cylinder head. All those pieces changing dimensions due to heat makes forecasting a suitable cold clearance likely to be wrong. If the valve doesn't close all the way it will burn the valve and the seat. If the clearance is excessive, the valve won't open as much and will restrict the air flow in the intake valve and the exhaust flow out the exhaust valve hurting engine performance. Gerald J. |

Posted By: 2011dandd

Date Posted: 20 Mar 2019 at 5:44am

|

As always thanks for the advice and all the know how. Invaluable Cheers |

Jim.ME wrote:

Jim.ME wrote: