WD45 Loader Cylinder Help

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=151890

Printed Date: 23 Jan 2025 at 7:50pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD45 Loader Cylinder Help

Posted By: AJ

Subject: WD45 Loader Cylinder Help

Date Posted: 07 Jul 2018 at 10:35am

|

Is there new seals available for these? Can a couple wrenches and elbow grease rebuild these or do I need to take them to a shop? Anyone have a part number for the seals or know where to get them? These drool and slobber like 12 month old baby.   ------------- Can't fix stupid |

Replies:

Posted By: TramwayGuy

Date Posted: 07 Jul 2018 at 10:46am

| They are Freeman (part of Allied farm equipment) parts, if that helps.... |

Posted By: DougS

Date Posted: 07 Jul 2018 at 11:16am

|

I'd take those to a hydraulic shop and get them polished anyway. Let them fix it all. |

Posted By: Jim Hancock

Date Posted: 07 Jul 2018 at 11:22am

|

Mine is a Freeman of another style and I pulled the rod to take to the seal business to get an exact fit here in OKC. If you have the funds available, I'm with Doug.

------------- How blessed we are by HIS GRACE! |

Posted By: AJ

Date Posted: 07 Jul 2018 at 11:55am

Loader does have a WD9 tag on it if that make any difference. ------------- Can't fix stupid |

Posted By: AJ

Date Posted: 07 Jul 2018 at 11:57am

|

Anyone have any idea what having them done by a shop might cost as to me buying the seals and doing it myself? ------------- Can't fix stupid |

Posted By: Tom IA

Date Posted: 07 Jul 2018 at 12:05pm

| I got a set from Agco couple years ago |

Posted By: jaybmiller

Date Posted: 07 Jul 2018 at 3:20pm

|

Uup shop wanted $400 to refurb 2 cylinders, I did it for $30 worth of parts. That was 8 years ago,worked real nice. 4 days ago I hauled them to the scrap yard with the rest of the loader. I had ZERO interest in them for 90 days.Nada,zip,zilch..I'd have given them away to any tractor guy. Also took a whack of cylinders from a car carrier and a section of 1.25 bar stock 10' long with a bunch of #80 sprockets and bearings on it. Only 10 cents a pound but made some room and filled the truck with $5.50 /gal gas. Sorry guys but I can't keep everything forever and shipping 'south of the 49th' is $$$ . ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dakota Dave

Date Posted: 07 Jul 2018 at 6:11pm

| I rebuilt both mine with$24 for two seal kits from AGCO. Took pictures and put part numbers in post you should be able to find it. Unless the cylinder has b en laying in the dirt 10 minutes with some fine Emory cloth and transmition fluid will polish them right up. It only takes a large pipe wrench a wrench for the bolts and a screwdriver to get the stop ring off the end. The second tractor I did it took me 30 minutes from start to finish. Use a pipe wrench and loosten the end cap before taking the cylinder off the tractor |

Posted By: Ray54

Date Posted: 07 Jul 2018 at 6:20pm

|

How smooth are the shafts? If pitted check out what Surpus Center has. Could be cheaper to replace the whole cylinder.

Just worked on my JD 1250 and JD sold seals in kit form $60 a cylinder. But didn't look right in the plastic so visited the local bearing and hydraulic shop $30 bucks for everything but the piston seals as they didn't have that. No oil pouring out but now settles much faster than before. So one of those work on it twice things. But I tried the ordering parts before taking it apart way with no luck besides having to pay a restocking few to get rid of the wrong parts. I know Shameless poke away. So with time and helpful store you should be able to find parts.

|

Posted By: CTuckerNWIL

Date Posted: 07 Jul 2018 at 6:22pm

|

The last cylinder I rebuilt was a remote for the WD45. The packing cost me about $8 The rod was bad on it so it cost me another $20 for some chrome shaft and a couple hours in the shop to cut me a new rod out of the shaft. https://www.garlock.com/en/products/chevron-v-ring-packing" rel="nofollow - https://www.garlock.com/en/products/chevron-v-ring-packing

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: AJ

Date Posted: 07 Jul 2018 at 6:33pm

|

Dave do you happen to have the part number for the kits. My local deal wants to sell me individual pieces at $7.50 each. I figured surely there's a kits for these things. ------------- Can't fix stupid |

Posted By: CTuckerNWIL

Date Posted: 07 Jul 2018 at 10:33pm

|

I wouldn't have a clue about part numbers. Find a Motion Industries near you and bring the old packing with or measure the rod and the bore of the packing gland. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Gary

Date Posted: 08 Jul 2018 at 4:59am

|

this link may help Gary http://s577.photobucket.com/user/dannyraddatz/library/Rebuilding%20Allis%20Chalmers%20Loader%20Cylinders?sort=3&page=1" rel="nofollow - http://s577.photobucket.com/user/dannyraddatz/library/Rebuilding%20Allis%20Chalmers%20Loader%20Cylinders?sort=3&page=1 |

Posted By: Gary Burnett

Date Posted: 08 Jul 2018 at 5:47am

|

On a one way cylinder it doesn't matter if the shaft is smooth or not as it doesn't hold oil back,if there is oil coming by the shaft it means the packing on the cylinder rod is bad. |

Posted By: TramwayGuy

Date Posted: 08 Jul 2018 at 7:53am

| Wrong. On this cylinder, there is no piston on the bottom of the rod. The rod itself is the piston, so smoothness of the rod is important. All there is at the bottom is a snap ring that keeps the rod from pushing itself right out the top. |

Posted By: Alvin M

Date Posted: 08 Jul 2018 at 7:54am

| the rod has to be smooth there is no piston. go to hyd shop for packing that is what I do the price is better |

Posted By: Gary Burnett

Date Posted: 08 Jul 2018 at 8:54am

|

I can't see how the fluid can come past the base of the cylinder and still be able to push the cylinder rod forward.Where does the fluid go when the cylinder comes up and the rod pushes out? No holes or return on that end of the rod base. And what pushes the rod out in the first place? If the fluid can get between the base of the rod and the barrel the rod isn't going anywhere. |

Posted By: Don(MO)

Date Posted: 08 Jul 2018 at 9:21am

|

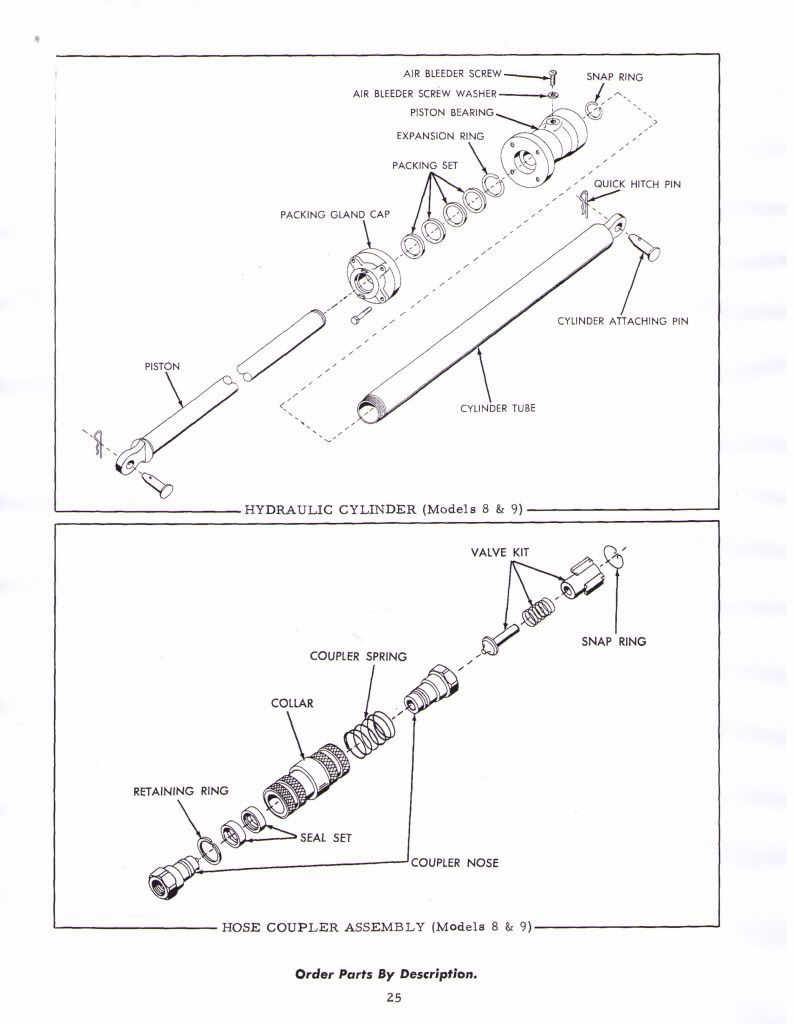

If you look at the pic showing the breakdown of the loader's cylinders, the WD-9 loader cyl's are about the same as WD tractor used. http://s577.photobucket.com/user/dannyraddatz/slideshow/Rebuilding%20Allis%20Chalmers%20Loader%20Cylinders?sort=3" rel="nofollow - http://s577.photobucket.com/user/dannyraddatz/slideshow/Rebuilding%20Allis%20Chalmers%20Loader%20Cylinders?sort=3 ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Don(MO)

Date Posted: 08 Jul 2018 at 9:26am

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: CTuckerNWIL

Date Posted: 08 Jul 2018 at 9:41am

Fluid does not compress. When you put fluid, under pressure, into a single acting cylinder, something has to give. The rod is the only thing free to move.  ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Alvin M

Date Posted: 08 Jul 2018 at 12:18pm

| all the lift cylinders on allis from about 1940 until d17 s 4 where that way on the lift arms |

Posted By: AJ

Date Posted: 08 Jul 2018 at 1:08pm

|

I was able to get one apart last night guys. It was actually pretty easy with the biggest pipe wrench I have and my chain binder cheater bar. Have completely disassembled the ram assembly and plan to clean things up to rebuild it. I will post pics soon. ------------- Can't fix stupid |

Posted By: AJ

Date Posted: 08 Jul 2018 at 1:09pm

|

If anyone has the kit part number for AGCO that would be helpful. ------------- Can't fix stupid |

Posted By: Alvin M

Date Posted: 08 Jul 2018 at 1:49pm

| 72000064 was kit now agco sells 72000650 seals only takes 4 |

Posted By: LouSWPA

Date Posted: 08 Jul 2018 at 2:49pm

|

For what it is worth, I "rebuilt" mine on the tractor. I packet it with some sort of rope packing my neighbor gave me for the purpose. Probably not AC, but generic instead, I'd check around with hydraulic shops. I do not know where he got it, but I will ask when I get a chance. cut the rope seal a bit longer than the circumference, cut the ends for a nice scarf joint. Cleaned up the shaft a bit with emery cloth (and mine was worse than yours!). Just make sure you 'walk' the seal flange down evenly, stuffing the rope in with a blunt screwdriver as you go. I never had a problem with leaking afterwards, even as bad as mine were. I doubt both cylinders took me more than 45mins to an hour ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: LouSWPA

Date Posted: 08 Jul 2018 at 2:52pm

|

BTW, I have repacked two sets, one set had the 'W' seals in them, the other had the rope packing as I described above ------------- I am still confident of this; I will see the goodness of the Lord in the land of the living. Wait for the Lord; be strong and take heart and wait for the Lord. Ps 27 |

Posted By: Dakota Dave

Date Posted: 08 Jul 2018 at 2:58pm

|

http://allischalmers.com/forum/freeman-w9-loader-cylinder-overhaul_topic149366_post1241269.html?KW=Dakota+Dave#1241269" rel="nofollow - http://allischalmers.com/forum/freeman-w9-loader-cylinder-overhaul_topic149366_post1241269.html?KW=Dakota+Dave#1241269 Seal package is in pictures. The AGCO seals are leather chevron packings . They will seal on less than perfect rods. Just oil the rod and rub with some fine emery cloth. |

Posted By: corbinstein

Date Posted: 09 Jul 2018 at 7:41am

| I bought my seals from a place that advertises here. Sandy Lake Implement. Takes 4 per cyl. I've done 2 sets now. One thing. Polish those rods till they shine like a mirror. Otherwise you're seals will go bad after a while. |

Posted By: Steve Zidlicky

Date Posted: 09 Jul 2018 at 10:38pm

| yarbrough industries Springfield mo 417 869 5344 will have your seals. do not go by loader model just measure shaft size. I would polish those shafts real well before ordering parts from anywhere. they will not have the air cleaner hose |

Posted By: AJ

Date Posted: 10 Jul 2018 at 8:48am

|

I have bought the seals from a local hydraulic supplies store. Cost a little more than I wanted but they were local and in my hand on site. I cleaned up the rams as best as I could last night. There is some pitting but not much can be done about that. If these seals last me 10 years I'm happy. Things seem to have went back together decent. Is there a specific process to tightening down those four bolts with the new seals? I snugged down the first one pretty much all the way but evenly. Cant get the ram to come out by hand but then again it does have new seals in it so hoping it will work correctly once I hook it back up for fluid. ------------- Can't fix stupid |

Posted By: Dakota Dave

Date Posted: 10 Jul 2018 at 9:16am

| Did you soak the leather packings in oil before installing. If not your seal life will be very short. In every tighten them until live run them out without a load and compress them back again. After that snug but don't use gorilla torque. You can always tighten some more. Once the leathers are soaked they will swell slightly and slide smoothly. If you can't at least twist the ram with hand pressure it's to tight. |

Posted By: CTuckerNWIL

Date Posted: 10 Jul 2018 at 9:26am

|

I agree with Dave. Those packings HAVE to weep a bit of oil to keep lubed. Not leak oil , but you should be able to wipe a bit off with your finger after an up and down cycle. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: AJ

Date Posted: 10 Jul 2018 at 10:50am

|

Yes I did let them sit on fluid for a while before assembly. The ones I tightened more, can that be loosened to allow the seals to do their thing yet or should I plan to replace those seals? ------------- Can't fix stupid |

Posted By: Dakota Dave

Date Posted: 10 Jul 2018 at 11:27am

| As long as you haven't forced them just loosten real loose and push the rod out and in by hand before snugging back down again. |

Posted By: AJ

Date Posted: 12 Jul 2018 at 3:37pm

Well her she is. Works great! Probably raised and lowered it a couple 100 times now and no issue. Very little seepage but that will only get better the more the seals swell up. She ain't no beauty queen but will save my back a lot of work.   ------------- Can't fix stupid |

Posted By: chaskaduo

Date Posted: 12 Jul 2018 at 4:05pm

|

Yep, chrome may shine but chrome don't get ya home. ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Gary Burnett wrote:

Gary Burnett wrote: