D-10 Final Drive - seeking help advice

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=149209

Printed Date: 08 Sep 2025 at 6:40am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D-10 Final Drive - seeking help advice

Posted By: snowman(MI)

Subject: D-10 Final Drive - seeking help advice

Date Posted: 06 Apr 2018 at 1:01pm

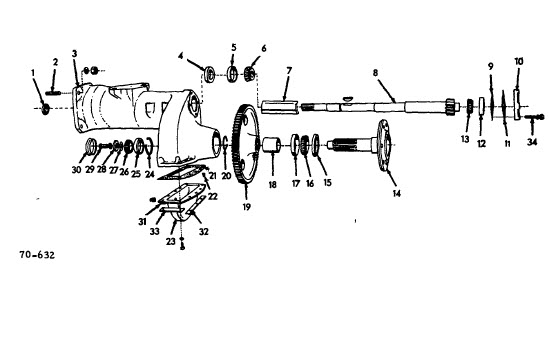

Was going after replacing the axle seal (#15) pictured above. Have been following the instructions in the service manual for trying to remove the axle (#14). We know you need to remove and have the snap ring (#20). We have removed the bolt, cap washer and shims (parts #27 - 30) and put the fine thread bolt back in the end of the axle to apply some hammer blows to take the axle out. Ain't moving nothing. Before going into stupid mode of potentially doing something that leads to my next post of looking for a large casting, I thought I would put this out there as to what have other wise minds have tried when you run into the stubborn things like this. Currently appears to be a small bit of surface rust between the shaft (#14) and bearing (#26) that I currently have the two rear out drives in a vertical position with a good soaking of PB Blaster hopefully seeping in between the bearing and shaft. This is like "phone a friend" on the old Millionaire tv show. Don't be afraid to say retreat. snowman(MI) ------------- 1950 WD, 1966 D-10 III, 1961 D-10 II, 1966 D-15 II Gas, A-C Minibike, 917 Hydro Mower, 917 Hydro Blower w/cab, West Michigan "Allis Express" |

Replies:

Posted By: CAL(KS)

Date Posted: 06 Apr 2018 at 2:06pm

|

everything is just stuck there from all those years. did this on a wd45. if the snapring is out the only thing holding it is the bearing on the shaft and the seal. take the bolt out and give it some good whacks with a good piece of hardwood or a piece of soft shaft like aluminum or brass. it might take some good smacks to get the bearing to move but you don't want to bugger the shaft. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: DrAllis

Date Posted: 06 Apr 2018 at 4:08pm

| You may have to get a bottle jack in there sideways and press it out if there is something to get it up against. There are two threaded holes in the final drive straddling the inner bearing bore that could be used to get 2 threaded rods and a plate to push against the axle end. A big hammer is hard to swing in that area. |

Posted By: wigtrain

Date Posted: 06 Apr 2018 at 4:59pm

|

Just did this same process on a D-14 yesterday. They are made the same. Doubt that a hammer will do the trick. Use the two threaded holes on the inside and fabricate something to push it out with. I used threaded rods and a flat plate so that I could push with a small bottle jack. The axle outer bearing and seal will come out as a unit. When reassembling place the bearing and then install the seal. Freeze the axle and if all goes well it will slide into the bearing. If things do not go well then you will need to fabricate a way to pull the axle through. I needed to pull so another piece of threaded screwed into the axle and a very large washer will allow you to pull the whole assembly into place. Too many pieces to do it all with a hammer. You are correct that after the inner screw is removed the only thing other than time that is holding things in place is the inner snap ring. You may need to spend some extra time locating a threaded rod to pull with since it is a fine thread. The rods to hold the bottle jack in place are coarse thread that can be purchased almost anywhere. Good luck ------------- Jim Wiggin |

Posted By: DiyDave

Date Posted: 06 Apr 2018 at 6:24pm

You can get FT all thread at McMaster-Carr, or other suppliers. Just don't forget the anti-seize, when re-assembling...

|

Posted By: MACK

Date Posted: 06 Apr 2018 at 8:23pm

| Put a junk bolt in end of axel, get your big sledge hammer and beat it out. MACK |

Posted By: Ted in NE-OH

Date Posted: 06 Apr 2018 at 9:12pm

|

What is the trick to get the snap ring out? ------------- CA, WD, C, 3 Bs, 2 Gs, WC, I-400, 914 |

Posted By: MACK

Date Posted: 07 Apr 2018 at 6:56am

| A pair of snap ring plires and screw driver. MACK |

Posted By: snowman(MI)

Date Posted: 07 Apr 2018 at 5:31pm

|

After a night of soaking with PB Blaster, the information shared, I purchased a longer 5/8"-18 UNF bolt which allowed me to use the full charge of the sledge. About 6 blows and both drive axles came out. Thanks for the advice and wisdom this site provides. snowman(MI)  ------------- 1950 WD, 1966 D-10 III, 1961 D-10 II, 1966 D-15 II Gas, A-C Minibike, 917 Hydro Mower, 917 Hydro Blower w/cab, West Michigan "Allis Express" |

Posted By: SteveM C/IL

Date Posted: 07 Apr 2018 at 9:00pm

| YAAAAAH !!! |