WD45 with 433I runs rough smokes bad cold???

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=148956

Printed Date: 12 Sep 2025 at 9:29am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD45 with 433I runs rough smokes bad cold???

Posted By: pirlbeck

Subject: WD45 with 433I runs rough smokes bad cold???

Date Posted: 30 Mar 2018 at 8:53am

|

I have a WD45 in the shop that we helped the owner install a F2 433I in it a number of years ago. At that time we helped get the flywheel and clutch put together and got everything aligned with the input shaft so the clutch would work properly. Once we got the engine bolted in and doweled pin in the proper location the owner took it and finished it up, so until now I had never heard it run. I have never been around one of these engines ( been around plenty of 301's) so I don't know if this is the nature of them or not. When first started in my heated shop it smokes bad and runs pretty rough. It takes several minutes before it smooths out. I believe the owner just had the pump and injector rebuilt, but I don't know the reason for that. The owner does not seem too concerned about the way it runs, but I thought if I could make it run better he would appreciate it. The pump timing is presently set at 21 degrees BTDC. I am not sure how they checked/set the timing when they had the pump off because I had to clean the paint off of the damper pulley before I could see any marks. Anyone have the timing spec for this engine? Do these engines tend to run poor until warmed up? Thanks!

|

Replies:

Posted By: DrAllis

Date Posted: 30 Mar 2018 at 9:06am

| Not at home where my books are, but 16 or 18 degrees is more like it. They are lower compression in pre-1983 ? models so a little sputtering is normal. 21 degrees will make it worse. |

Posted By: SteveM C/IL

Date Posted: 30 Mar 2018 at 9:46am

| "smokes bad and runs rough"...Yep that's a normal F2 starting up. Can take 10 seconds or so of sputtering to get em all firing and fog up the place. |

Posted By: AC7060IL

Date Posted: 30 Mar 2018 at 11:13am

Diddo

|

Posted By: fastallis

Date Posted: 30 Mar 2018 at 1:15pm

| Post some pictures of it. |

Posted By: injpumpEd

Date Posted: 30 Mar 2018 at 2:26pm

|

spec is 18* ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: pirlbeck

Date Posted: 30 Mar 2018 at 3:28pm

| OK, thanks for the help and info. I will have to check with the owner to see if he is OK with me posting pictures of it. It will also depend on if I can figure out how picture posting works on this site. |

Posted By: JoeO(CMO)

Date Posted: 30 Mar 2018 at 3:35pm

------------- |

Posted By: DrAllis

Date Posted: 30 Mar 2018 at 3:56pm

| That engine was used in the F-2 combine from 1978 until 1982. In the beginning, they were only 14 to 1 compression ratio. I know that it was raised to 15 to 1 later on, but not until the F-3 models in 1983 ?? |

Posted By: cwhit

Date Posted: 31 Mar 2018 at 12:25am

| We had an F3 years ago and It started just like that . Was an 84-85 model. Was told that they all sounded like was mentioned. A cousin had a 6080 with the same engine and was day and night different. Never knew why but I can still remember what that F3 sounded like starting up first time each day. |

Posted By: FREEDGUY

Date Posted: 31 Mar 2018 at 7:17am

That makes me feel ALOT better on how ours starts !!

|

Posted By: DrAllis

Date Posted: 31 Mar 2018 at 7:41am

| The engines used in combines have the low idle set at 1100-1200 RPM, which makes all the blubbering worse than the tractor engine that starts at 750 RPM. I usually slowed down the combine engine speed to help with this issue. |

Posted By: pirlbeck

Date Posted: 31 Mar 2018 at 3:59pm

|

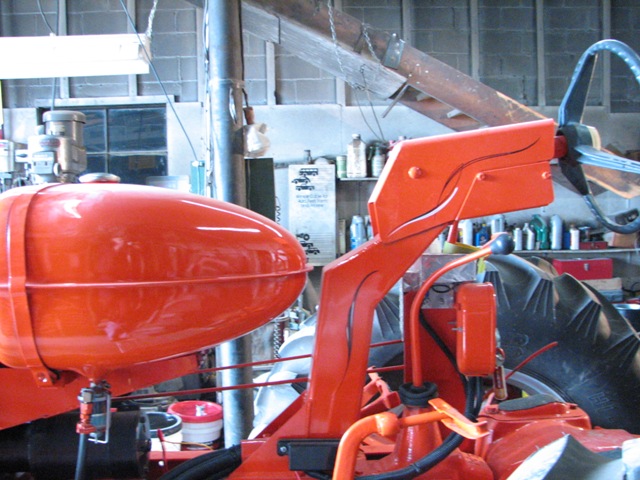

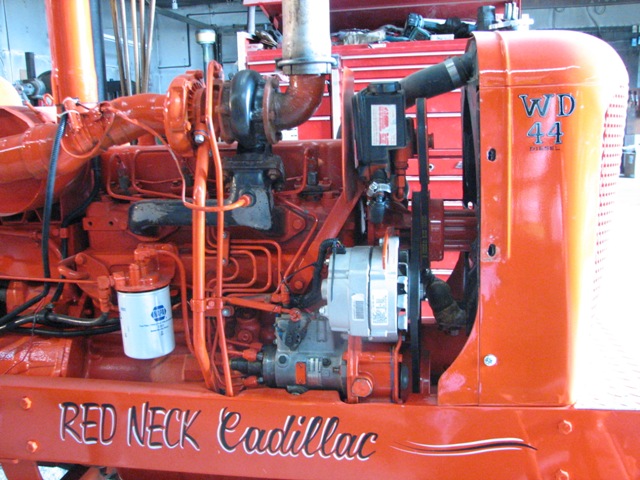

I have received permission from the owner to post some pictures. I have sent them in a PM to JoeO. The hood, fenders and other parts were removed before he brought it to my shop. The final drives are not painted because they were recently replaced. He has very nice 4 gauge panel that has been relocated while working on it and is not shown in the pictures. Thanks for all the help and info.

|

Posted By: SteveM C/IL

Date Posted: 31 Mar 2018 at 6:29pm

| I would like to have the 8010 kits in my F2 but it doesn't use oil and would be about so much work and expense just to have nicer starting. I thought it needed pump work when I bought it but I learned from this forum that it's "normal".....For 35hrs a year,it seems foolish. |

Posted By: JoeO(CMO)

Date Posted: 31 Mar 2018 at 9:23pm

Resized and loaded! ------------- |

Posted By: pirlbeck

Date Posted: 31 Mar 2018 at 10:56pm

Thanks for your help!

|

Posted By: CrestonM

Date Posted: 31 Mar 2018 at 11:23pm

|

Wow, that's a cool build! Someday I want to get a SP-100 All-Crop combine and put a 433 in it. That'll turn it into a "true" Super 100! |

Posted By: orangeman69

Date Posted: 31 Mar 2018 at 11:39pm

|

I think its awesome!!!! its not all butchered up.. I would love to see that pull... ------------- d17,d17nfpuller,d-17IVdiesel,d19gas,d19diesel nf,d21seriesII,180,190xtseries III,200,210,7020,7060,7080w/8.3cummins,8070fwa w/8.3cummins,8550 185 w/322 original hrs. |

Posted By: steve fischer

Date Posted: 01 Apr 2018 at 7:07am

| wow and I have 8- f2 with 433ts on and I was trying to find a place for them , I have one in a 175 , I did over haul a 6080 for customer and put the 15 to 1's in starts get |

Posted By: pirlbeck

Date Posted: 01 Apr 2018 at 9:50am

| Yes the owner did a really nice job of finishing the install. I think the front end was from a 180 and the steering setup may of been from the same combine that the engine came from. |

Posted By: Larry B

Date Posted: 01 Apr 2018 at 12:43pm

| is that tractor in the Manning area? |

Posted By: pirlbeck

Date Posted: 01 Apr 2018 at 1:09pm

Yes

|

Posted By: pirlbeck

Date Posted: 03 Apr 2018 at 6:44am

|

OK, I adjusted the pump timing to 18 degrees and this thing may run worse, certainly no better. After warming up for several minutes it will run pretty decent at idle and wide open, but at part throttle, maybe around 1200-1300 RPM it misses, slobbers and smokes terrible. It acts to me like it does not have enough timing advance at this RPM. I know these engines are not known for running smooth when cold, but this just does not seem right. Anyone have any thoughts on this? Thanks!

|

Posted By: corbinstein

Date Posted: 03 Apr 2018 at 6:52am

|

What did the 433i come in originally? What did it take to cram it in there?

|

Posted By: pirlbeck

Date Posted: 03 Apr 2018 at 7:00am

| I think the engine came out of an F2 combine. Read my first post, that explains a little bit about the part I was involved with as far as getting it in the tractor. |

Posted By: Amos

Date Posted: 03 Apr 2018 at 7:05am

| My 6060, which I have had since new, started acting just like you describe. I had the pump rebuilt and the injectors as well. Didn't change anything, so I tore it down and found the head was cracked. Inframed it while the head was being repaired and six years later it is runing the same as it when it was new...maybe do a compression test an it? |

Posted By: pirlbeck

Date Posted: 04 Apr 2018 at 7:34am

|

OK, I played around with this some more yesterday. I reset the timing to 21 degrees which is where it had been set at when it came in. At 21 it ran better then at 18 but still smoked and fluttered at part throttle. Putting a little load on it would smooth it out, so I was pretty sure we needed more timing advance. I set it at 23 degrees and it runs pretty decent. I don't want to advance it any more then this so I am going to see how it starts this morning and unless it really starts bad I am going to leave it. Thanks!

|

Posted By: DrAllis

Date Posted: 04 Apr 2018 at 7:41am

| Sounds to me like your pumps timing advance isn't working as it should. They will always start quicker with somewhat retarded timing, but need to advance when running to smooth things out. |

Posted By: injpumpEd

Date Posted: 04 Apr 2018 at 7:59am

|

You'd be surprised how many pump timing marks I've seen put in the wrong place. If this pump has been turned up much above stock, that will affect the timing of the Roosa pump also. What I tell my customers, ask the engine what it wants for timing. If it runs and starts better at 23, or even 24 or 25, then that's where I'd put it. The engine will run best at the proper timing, just setting to a spec isn't always the best spot. Like I said above, the timing mark in the pump could be off several degrees. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: pirlbeck

Date Posted: 04 Apr 2018 at 8:52am

I tried turning the advance trimmer screw out some (2 turns just to see if it made a difference) to give it more part throttle advance and it made no difference. This was with the static timing at 18 degrees. I turned it back in after it made no difference. You may be correct that the advance is not working correctly. The pump and injectors were rebuilt by a shop that I have never used. The tractor owner took them to this shop. If the pump was a little easier to get off I would send it to my regular pump guy to have him at least put it on his test bench, but removing the pump is going to require removal of the side frame and I don't want to mess up his nice paint job. I do have to fix a couple of injectors that have leaked since they were worked on. I have not pulled them yet, but it looks like they are leaking between the nozzle valve and the nozzle body.

|

Posted By: pirlbeck

Date Posted: 04 Apr 2018 at 8:53am

I have had other engines that I have had to deviate from the factory spec to get to run correctly. I am always a little hesitant to advance pump timing very much from the stock setting as I have seen piston failure as a result of too much static timing advance.

|

Posted By: injpumpEd

Date Posted: 04 Apr 2018 at 11:17am

|

This pump should have a "push-pull" advance trimmer screw, so that means you'd need to run it IN to get more advance movement earlier. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: pirlbeck

Date Posted: 04 Apr 2018 at 12:41pm

Ops......I thought you needed to turn them out for quicker advance. I will play with it again when I get the injectors back in it as I don't think it starts as well set at 23 degrees. Thanks for the help!

|

Posted By: SteveM C/IL

Date Posted: 04 Apr 2018 at 1:49pm

| does the 433 have the rubber ring in balancer? Ya know a lot were slipped on 301's throwing timing marks off. |

Posted By: pirlbeck

Date Posted: 04 Apr 2018 at 2:25pm

From looking at it I am pretty sure it is solid......no rubber at all that I can see.

|

Posted By: tbran

Date Posted: 04 Apr 2018 at 2:26pm

|

guys as stated before - the spitting and slobbering when cold is the nature of the beast and made even worse w/o a muffler as in a 6080. Ruff idle is or probably is the elastocast rubber ring on the weight retaining bracket. Almost every engine with 1000 hours or more does this that I have seen - the 6080's down to the 2200 in fork lifts. . Now this issue should go away after a minute or two after the throttle is cracked and boost is obtained a couple of times. If it still idles rough it is the rubber washer afore mentioned. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: pirlbeck

Date Posted: 05 Apr 2018 at 7:23am

Injection pump was recently rebuild so I don't think that is the problem. As far as being the "nature of the beast" the way this thing runs when the static timing is set to the factory spec of 18 degress is not normal. At part throttle it misses, slobbers and smokes bad and it runs like this regardless of how long it has been running.

|

Posted By: Lonn

Date Posted: 05 Apr 2018 at 3:34pm

|

Post a video ------------- -- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... - Wink I am a Russian Bot |

Posted By: SteveM C/IL

Date Posted: 05 Apr 2018 at 4:03pm

| just because the pump was "recently rebuit",I wouldn't rule it out especially if you don't know the reputation of the rebuilder. |

Posted By: tbran

Date Posted: 06 Apr 2018 at 3:38pm

|

The only thing that will cause that is erratic timing assuming the engine is ok (valves, setting, injectors and air filters). Also I would never touch the advance trimmer w/o a timing needle inserted. The other thing to check is the turbo - check the intake manifold and intercooler for oil contamination. Droplets of oil will not burn well at low rpm. As the boost increases so does the temp and the back pressure on the turbine shaft on the compressor sided. Also, an injector nozzle dribble will also complicate matters. As stated previously, always verify TDC on the crank pulley and the timing mark on the fuel pump . Trust but verify.

------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

SteveM C/IL wrote:

SteveM C/IL wrote: