H3 dozer update

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=114660

Printed Date: 09 Feb 2026 at 11:57pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: H3 dozer update

Posted By: OldSchoolRecovery

Subject: H3 dozer update

Date Posted: 13 Nov 2015 at 10:08pm

|

Had a chance to dig into the H3 I picked up at an auction. Engine stuck, I put a battery in it, replaced ground cable, anyway, turn to start, fan moves about a quarter of an inch, and then back. Soaked 24 hours with PB Blaster and Carb cleaner (contains acetone) so far. Hoping it may free up without pulling head, etc. Will give a couple more days. Me thinks its number two as spark plug had rust on it. FWIW, the plugs where new, never run. Second, the left steering clutch lever is (was) stuck forward position. I looked into the brake adjuster holes and the left box was half full of water, right was dry. Looked under machine, right plug was out. Took left plug out and drained out about 4 gallons of water, no oil, which is good. Anyway, gave the left steering clutch lever a yank (harder than before) and it freed up. Probably take the cover off the box and give it a shot of blaster. The tag (if believeable) said stored insice for many years, not run since put away. It did however sit outside at the auction site for at least a month and we did have a couple torensial rainfalls during that time. Still can not believe that much water found its way inside there, but no cracks from freezing, so I think it should be all right. For future reference, is it ok to run with out he plugs?? For now, wait out the frooze cylinder.. cb1

|

Replies:

Posted By: OldSchoolRecovery

Date Posted: 13 Nov 2015 at 10:10pm

|

That would be "froze" not frooze..... cb1

|

Posted By: DiyDave

Date Posted: 14 Nov 2015 at 4:50am

Ya never knoow it might be frooze real good...

|

Posted By: Randaleky

Date Posted: 14 Nov 2015 at 8:39am

|

leave plugs out unless you are working in water area ie creek, swamp etc. left clutch will probably be ok once water is drained and unit is worked a little. |

Posted By: OldSchoolRecovery

Date Posted: 14 Nov 2015 at 4:21pm

|

Thanks, will do. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 14 Nov 2015 at 4:22pm

|

So, day three. No movement yet. Got called into work tonight, so now probablly Wednesday if no movement will pull head.. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 15 Nov 2015 at 10:27pm

| Took the motor apart today. |

Posted By: OldSchoolRecovery

Date Posted: 15 Nov 2015 at 10:29pm

| Trying to load picture.. |

Posted By: OldSchoolRecovery

Date Posted: 15 Nov 2015 at 10:33pm

|

Well, not very successful. Anyway, two and three pistons stuck to sleeves. You can see the sleeves move up and down when toggling the start switch. Rocker arms and shaft look the worst from condensation rust. Probably replace all four piston sleeve assemblies and rod bearings.. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 15 Nov 2015 at 10:34pm

|

And send the head out to get freshened up, etc.. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 12:59am

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 1:00am

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 1:01am

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 1:02am

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 1:03am

|

Hit or miss on the pictures, but here are some. cb1

|

Posted By: Eric B

Date Posted: 16 Nov 2015 at 3:55pm

|

That head looks good...freshen up is a good thing. Depending on how much you want to play around...you could probably get the engine nicely loosened up for good running but if you're looking for perfection - only new parts will do. If the "stuck position" is high up in the liner you'll be able to clean it up nicely. With bolts and flat bar you can lock down the liners that want to come up. I had this same thing on a 201 cu. in. The piston stuck position was a little too low on the liner. After getting freed up and started that piston/cylinder had too tight of a clearance on engine warm up resulting in a bearing knock. Other engines came back to life ...no issues or oil consumption. ------------- Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal! |

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 4:43pm

|

I see where I can get single piston sleeve kit for less than a set of 4. And I can get all of the parts individually cheaper than a complete set, so I may just replace whats needed, etc. There is absolutly no ridge on one and four, two and three have enough pitting, that I would not want to use again, so I may just change out two and three. Neighbor is a machinist, may have him measure one and four and go from there. cb1

|

Posted By: Ages Cat

Date Posted: 16 Nov 2015 at 4:52pm

|

We recently removed a stuck engine from a D grader. The cam lobes were rusted, the lifter faces had rust, the cam gear, several pistons were stuck in the sleeves and the crankshaft was cracked about 150 degrees of the circumference. When you tear down a stuck engine, it is a pandoras box. The H3 may have been parked due to low oil pressure and if that is the case, then it is cam bearings, mains, rods , etc. Unless you completely dis assemble it, you won't know what you have. Our HD-3 is my favorite tractor and since these are so much fun to own and operate, you want it to be dependable. The engine is the heartbeat of any tractor. You want it to be beating on all four. ------------- Curt Anderson HD3, HD5B, HD6AG,HD6B dozer, I-400,615, 616,620,720,ACP25 lift truck, 1956 D Grader, AC 540 loader, AC #84 plow, Simplicity tractors, Agco MT225, Agco 2025, |

Posted By: DiyDave

Date Posted: 16 Nov 2015 at 5:53pm

| Kinda looks like it was sitting out in the weather, with no rain cap on the muffler... |

Posted By: Coke-in-MN

Date Posted: 16 Nov 2015 at 8:20pm

|

Depending on the plug size of the rear case (HD4 was 2") If these are the same I would find some 2" barrel bung plugs and install - drill several 1/4" holes for drainage but small enough to exclude mice ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 10:23pm

|

I like that, sounds good. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 10:26pm

It had a muffler and rain cap, however, and automotive oval muffler with rolled end cap that actually held water, etc. So, Im thinking some of that water found its way into two and three. The stock muffler has a molded end as you know. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 16 Nov 2015 at 10:34pm

I understand your post, however, that could be a endless $$$$ rathole. I in the past have allready stuck 7G's into a 3G machine if you know what I mean. I would like to know what else is wrong or weak with the machine besides the motor. For the limited use it will provide (its a hobby for me) I will probably put two piston liner sets (90 bucks each), couple gaskets and a carb kit and see what happens. Three hundred bucks onto the 1000 original price wont put me too far in the hole, just to see what I have. cb1 |

Posted By: JC-WI

Date Posted: 16 Nov 2015 at 11:14pm

|

Old school, Looking at the pics, it doesn't look that bad., just might take a little more soaking as in filling those stuck cylinders and then wait a few day, them come back and tap on them with a wooden block on top... might come loose easier than you think.... and maybe harder than I thought. but it might surprise you how good the pistons are... and as for the liners, maybe just polish them up a bit and blow them out and use them.... if pitted severely, than forget that idea.

Ages cat made a comment..."The H3 may have been parked due to low oil pressure and if that is the case, then it is cam bearings, mains, rods , etc. " If that motor had low oil pressure, check the intake screen in the sump, check the bypass valve, and oil pressure springs and the biggest one is the little oil pump that is bolted to the back of the engine, it has 2 scrawny little springs that hold the vane blades apart, and had to replace those springs one time because they were next to disintegrated .

I just broke loose a D7 that the coffee can on the exhaust had holes in it and those holes were directly down the pipe... Old Cat had been there so long that the tree growing up in the frame was 15 years worth of rings on it at 3 ft up.

Broke it loose, fired it up and drove her out to where we loaded it. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: OldSchoolRecovery

Date Posted: 18 Nov 2015 at 10:40pm

|

Am going to make a plate and push down (with screws) on both piston at the same time as they are both stuck and they both travel together. I previously thought one would be coming up and the other down. If I can break them free and push them down I will evaluate the sleeve finish and go from there. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 18 Nov 2015 at 10:40pm

| I will lathe up some pucks to push against the piston tops etc.. |

Posted By: OldSchoolRecovery

Date Posted: 18 Nov 2015 at 10:42pm

|

Maybe even some pictures if I remember as I go.. Deerhunting starts Saturday, so this may be a week or two.. cb1

|

Posted By: Eric B

Date Posted: 19 Nov 2015 at 12:30am

What I found very effective in loosening the pistons was using the air-chisel on top of one of those "pucks". Using a 50/50 mix of acetone and automatic trans. fluid is awesome for loosening the pistons...just let it sit on top for a few days before you "harass" the pistons :-) ------------- Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal! |

Posted By: JC-WI

Date Posted: 19 Nov 2015 at 11:55pm

|

Yup, deer huntin starts saturday... but you got a few minutes at noon and then a few minutes after dark... unless ye gets lucky and bag some of them big bucks out your way. An then you shoulda had the H3 cat runnin to drag em out of the woods or swamps. LOL ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: michale34

Date Posted: 20 Nov 2015 at 7:49am

| I had a old john deere 400 backhoe that was stuck like that water ran down the exhaust I used brake fluid to brake them loose |

Posted By: OldSchoolRecovery

Date Posted: 20 Nov 2015 at 8:04pm

|

Posted By: OldSchoolRecovery

Date Posted: 20 Nov 2015 at 8:05pm

|

Posted By: OldSchoolRecovery

Date Posted: 20 Nov 2015 at 8:05pm

|

Posted By: OldSchoolRecovery

Date Posted: 20 Nov 2015 at 8:06pm

|

Posted By: OldSchoolRecovery

Date Posted: 20 Nov 2015 at 8:10pm

|

Contraption I built to move two stuck pistons. Well the bar stock wasnt strong enough, but did put a little tension on the slugs. Couple raps with a hammer moved both pistons about a half an inch down. I locked the sleeves down with bolts and washers. But the starter wont move them yet, so I am soaking them some 50/50 acetone/transmission fluid. cb1 |

Posted By: Eric B

Date Posted: 21 Nov 2015 at 12:24am

|

You are well on your way. You do have the advantage of the pistons being high up in the sleeves...will be easy to hone out the deposits of crud once you're down a bit more. We'll look forward to your next report. ------------- Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal! |

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:09pm

|

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:09pm

|

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:10pm

|

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:16pm

|

Ok, Arhggg, had to pull the sleeve as I could not get the piston to move freely enought, i.e. with the starter, etc. Glad I did as it looks like the rod bearing(s) are wiped out. Looks like a complete now. Pressed the piston out of the sleeve, yuk.. Oh, and I think I solved the riddle. They (???) left the skid pan off and put a whopper of a dent in the oil pan, which in turn lifted the oil pickup out of the oil and walla, no oil, wiped bearings. Then left out in the rain. The good news is I really like this machine and how its put together. Simple enough for even me. And it doesnt look as bad as the pictures. Now, pull the motor and put on a stand and the dozer on trailer back outside until the motor is dun. cb1 |

Posted By: JC-WI

Date Posted: 23 Nov 2015 at 9:21pm

|

Well, I didn't count on pistons running dry before the bearings got wiped out... and then the rust formed on that dry steel...

you are right, your in for a full overhaul... and get that block cooked. Check the oil pump too, see if theres rust in it and make sure the little springs that hold the vanes apart are good. Hope the pistons are salvageable. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:27pm

|

New pistons, rings and sleeves are $90 a pop, so not too terrible... cb1 |

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:30pm

|

Where the crank stopped I can read M020, R030 and another number. So shes been rebuild before. Rods at 030 is a concern as Im not too sure if they (Allis) surface hardened thier cranks and to what thickness. I see they have new cranks out there for $400. A little pricey but may have too... cb1

|

Posted By: OldSchoolRecovery

Date Posted: 23 Nov 2015 at 9:42pm

Yep, cb1

|

Posted By: Tracy Martin TN

Date Posted: 23 Nov 2015 at 9:56pm

Grinding your crank will be a hundred plus dollars. Buy a new one, you will save money on it and the bearings. Check the block,oil pump and galleys. A very stout engine if running correctly. Good Luck. ------------- No greater gift than healthy grandkids! |

Posted By: OldSchoolRecovery

Date Posted: 24 Nov 2015 at 11:58am

|

I see rod bearing for sale at .040 over. Seams like a lot to me. Any thoughts? cb1

|

Posted By: JohnCO

Date Posted: 24 Nov 2015 at 1:35pm

|

Seems like getting a new crank is the way to go, expensive but in the big picture, the engine will be just like brand new. 040 over is a lot and a potential problem down the road, imho.

------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: JC-WI

Date Posted: 24 Nov 2015 at 5:48pm

|

Old school, did you delete pictures off the Allis storage site? All your first pics are showing up as a boxed X. ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: OldSchoolRecovery

Date Posted: 24 Nov 2015 at 5:54pm

|

I did. Didnt want too many on there and I did not know that they would be gone. Not sure if I put them back in there that they will show, but will try.. cb1

|

Posted By: OldSchoolRecovery

Date Posted: 24 Nov 2015 at 5:58pm

|

Pictures are back, cb1

|

Posted By: JC-WI

Date Posted: 24 Nov 2015 at 7:45pm

|

There is 20 megs of space... I have over 160 pics in there.... I need to delete some since I am getting close to maxed out. ... but that has been since sept. 2009. Guess its time for a cleaning. LOL ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: OldSchoolRecovery

Date Posted: 25 Nov 2015 at 2:32am

|

Posted By: OldSchoolRecovery

Date Posted: 25 Nov 2015 at 2:33am

|

Posted By: OldSchoolRecovery

Date Posted: 25 Nov 2015 at 2:33am

|

Posted By: OldSchoolRecovery

Date Posted: 25 Nov 2015 at 2:34am

| Got the motor out. Took all of about an hour. |

Posted By: OldSchoolRecovery

Date Posted: 25 Nov 2015 at 2:34am

|

Posted By: OldSchoolRecovery

Date Posted: 25 Nov 2015 at 2:39am

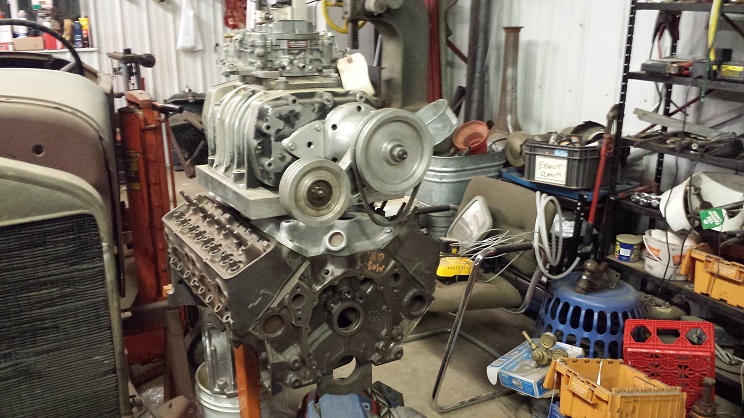

| New motor getting ready to go in!! |

Posted By: Sugarmaker

Date Posted: 25 Nov 2015 at 8:11am

|

Looks like a little more power!? good shots! Maybe this will get me going on some of my projects:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: JC-WI

Date Posted: 25 Nov 2015 at 9:09am

|

Sugarmaker, It looks like he's yanking that old model A motor out to put in his crawler. OSR, yur makin progress... ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Eric B

Date Posted: 25 Nov 2015 at 12:12pm

You are really good with the wrenches!! You have the virtue of being able to stay focussed. My Dad, soon 82, is the same, once he tears into a tractor he stays on it 'til it's finished making very good use of time. I wish for more of the same for myself You have the virtue of being able to stay focussed. My Dad, soon 82, is the same, once he tears into a tractor he stays on it 'til it's finished making very good use of time. I wish for more of the same for myself ------------- Currently- WD,WC,3WF's,2 D14's B. Previously- I 600,TL745,200,FL9,FR12,H3,816 LBH. Earth has no sorrow that Heaven cannot heal! |

Posted By: HudCo

Date Posted: 25 Nov 2015 at 12:34pm

| glad to see you got those pistons out when we rebiult the wd45 when we got it back i let those same two cyliners soak in atf and acitone for a whole summer, then still had to chain the tractor to the shop floor and jack the piston and sleaves out in one piece could not believe it did not break the block but we still did send the block to the machine shop and the mains line bored got rid of the shims and had cam brgs installed pressed one assy apart in the press to see how far the stuff had penitrated it was only about a 1/4 inch all summer long |

Posted By: orangeman

Date Posted: 26 Nov 2015 at 11:16am

|

OldSchool: Might check to see if someone is parting a G-138 or G-149 Power Unit for a useable crank. Orangeman

|

Posted By: OldSchoolRecovery

Date Posted: 14 Dec 2015 at 1:11am

|

Got the motor on the motor stand and stripped of all parts. However, under the oil filter mount, there is a hole with a ball bearing (about 3/8" diameter) in it. Anyone tell me what it is and or how to remove to clean. Or if you just leave it in. Anyway, the block will be going in to be shot blasted (cleaned) and magnafluxed for cracks, this week. Thanks, cb1

|

Posted By: SteveM C/IL

Date Posted: 26 Dec 2015 at 10:49pm

| How's this project coming? |

Posted By: OldSchoolRecovery

Date Posted: 26 Dec 2015 at 10:52pm

|

Waiting until after the holidays to send in the block and get it checked for cracks. And for some mad money to pop up!! Still debating on the crankshaft, grind for 040 on the rods or get a new one for $400...

cb1 |

DiyDave wrote:

DiyDave wrote: