| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(3) Thanks(3)

Quote Quote  Reply Reply

Topic: ONE-EIGHTY 4 cyl gas: The first and the last !!! Topic: ONE-EIGHTY 4 cyl gas: The first and the last !!!

Posted: 04 Sep 2023 at 4:08pm |

|

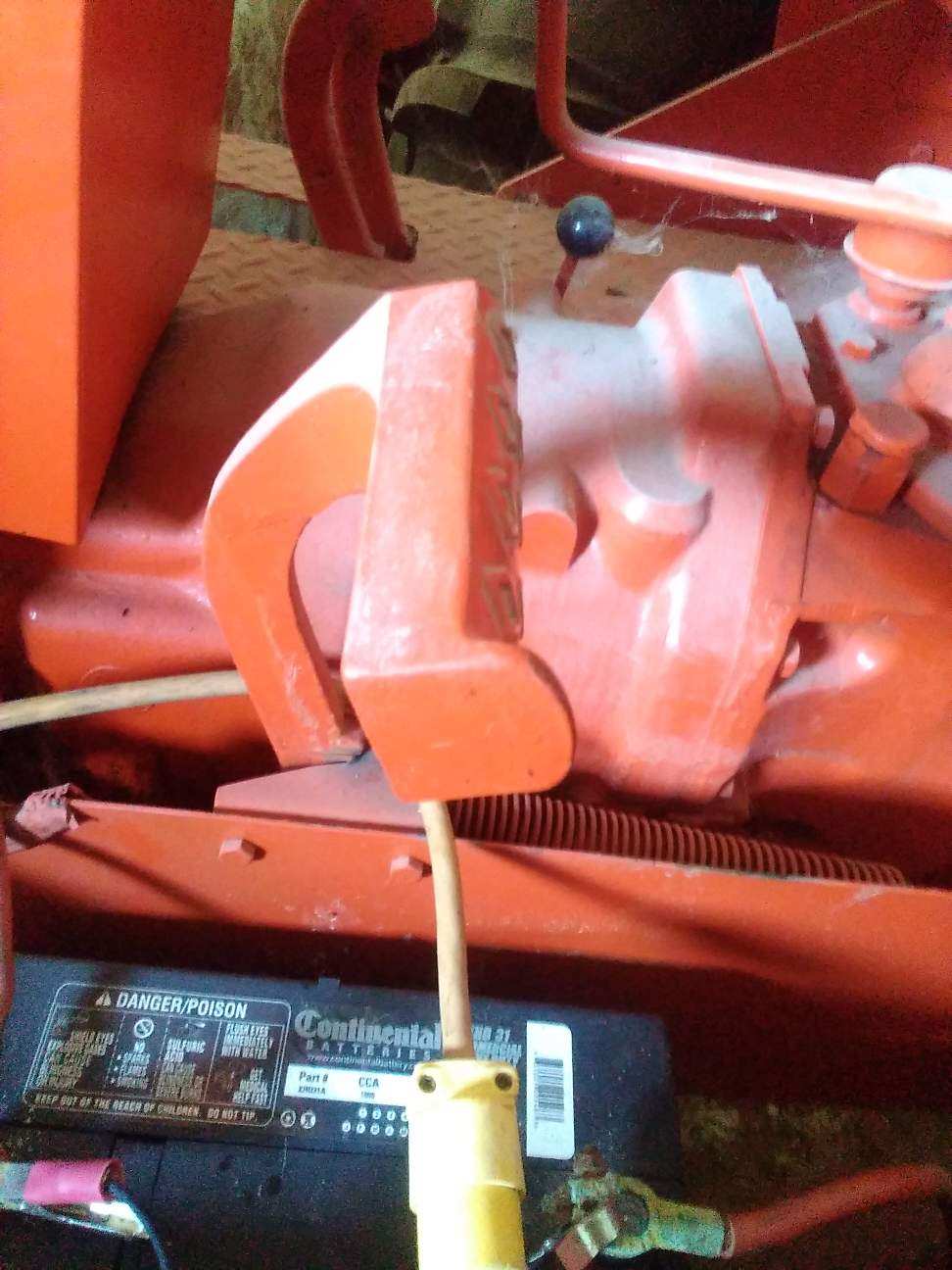

I've had a very nice Labor Day holiday !! I was able to see and test drive the one and only surviving A-C One-Eighty 4-cylinder gas tractor, out of about 100 or so ever built. It also just happens to be the prototype model with an interesting chassis serial number of : WP V d17 T2 . The "V" is actually the symbol for Roman numeral 5, which I can't make with my keyboard. I wonder now if the T2 was meant to be 1/2 because the "T" was on its side !! I have 14 or so things that I was able to verify in the design and build of this One-Eighty prototype tractor from the beginning in December of 1965. #1. The chassis serial number is clearly unique. The engine s/n is 17-104951. Nothing really noteworthy about that. #2. Carburetor is a Marvel Schebler brand, quite similar to what the 175 gas tractor wound up with. Larger air inlet and probably venturi size as well, compared to the D-17 engine. I know the compression was increased and can only assume the camshaft was also the same grind as a 175 tractor to arrive at the desired 64-65 PTO HP @ 2,000 rated load RPM's with a no-load high idle of 2,200 RPM. This would calculate out correctly, as the 175 tractor had 61 (60.88) HP at 1800 RPM and an extra 200 RPM increase would be 4 more HP to bring it in at 65-ish HP @ 2,000 RPM. #3. Flywheel and clutch size appear to be 11 inch, same as a D-17. Pressure plate bolts are 3/8" diameter and flywheel looks small inside that 190 bellhousing. So, I think it's safe to say that the gas tractor got an 11 inch clutch and diesels got the 12 inch clutch. #4. There is a camshaft operated fuel pump under the full-flow engine oil filter, just like a Gleaner "E" combine engine would have had. #5. Muffler and manifold appear to be regular stock items as the muffler inlet/manifold outlet pipe is the same diameter as a D-17. So, the only change in this area would have been the muffler which would have been the same for the new One-Seventy and One-Eighty gas engines, with the inlet being the same as the D-17 III and IV and the outlet pipe being slightly larger in diameter and taller than the late D-17 series. #6. Engine rear adapter plate is the same as a D-17 with the same D-17 starter too. #7. Engine front mount plate also the same as a D-17 with 3/4" spacers added on each end so it fits between the wider side frames of the 180/190 tractor chassis. #8. Cooling fan is the 5-blade D-17 design with a very deep metal radiator shroud that comes back about 4 inches to meet the fan properly. This shroud actually extends rearward enough it is exposed on the bottom as you can easily see it standing from the side. #9. The triple section hydraulic pump is (I assume) the exact same pump they eventually used on the later 170/175 tractors. It is located under the radiator and air cleaner area. The interesting thing is they used a U-joint at the crankshaft pulley end and possibly one on the pumps drive shaft end too. I'm wondering if the pump maybe does not sit in a perfectly straight line with the crankshaft, like most front pumps do. It would take some disassembly to verify that, but not worth the hassle. #10. The hydraulic pump suction tube is routed like the diesel tractor, up and over the bellhousing and then along a centerline inside of the left side frame. Then, they added an extension to go thru the front engine mount plate where the steering shaft would normally be on a D-17. #11. The front steering support/bolster is clearly unique to this tractor chassis. First, it is not the traditional 190 zipper style front end with dual internal pistons. It is more like an early One-Seventy housing as it has an external steering ram inside of the right side frame, up tight to the engine at the right front corner. But, it is different than a One-Seventy, because they have hogged out the area underneath the radiator for the triple hydraulic pump to mount. This area is clearly a different design than any other A-C tractor of any time frame. Even the steering ram appears to be larger in diameter than a One-Seventy. #12. The fenders were clearly prototype as all the bends and kinks are much sharper than production. The platform pieces appear to be production like, as do the brake pedals, but the clutch pedal pad is clearly different (thicker) and I was told made of brass not cast steel. All seat suspension parts and brackets appeared to be production. I didn't have a tape measure, but I swear the battery box was 2 inches shallower than production. It just looked not nearly as deep. #13. Three point top link anchor bracket wasn't one piece cast....it was 2-piece mild steel, just like tractors ten years later would have. #14. Lastly, the gear ratios of the driveline appear to be production. By this I mean the shift progression is 1-2...3-4...5-6...7-8 with 20% spread in Power Director ranges. When this tractor was originally built in Dec 1965, (according to Norm Swinford book) the gear ratios should have been the same as a One-Ninety 1-2..3-5..4-6..7-8 with 30% spread in Power Director ranges. The "up-graded" and improved "XT" parts hadn't even been built yet, so I have to assume it was originally built with 30% spread and then it too was updated to the 20% spread parts. I know what's in it. I just don't know what it was built with for certain. Anyway, it has the newer production parts. OK. I think I'm done. Pictures will be coming. Thank you to the Kelly, Sandra, and Trigbee Lien family from NE Iowa. The tractor came from the A-C test farm south of Milwaukee to Richard and Nancy Sleichter, Sandra's parents. Also thanks to Dean Byerly for his help in making this informational meeting happen. My brother and I were warmly welcomed and they really went out of their way to make our trip worthwhile. Hope you A-C people enjoy this bit of digging into the past.

|

|

|

Sponsored Links

|

|

|

Leon B MO

Orange Level

Joined: 12 Sep 2009

Location: Old Monroe, Mo

Points: 2200

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 4:58pm Posted: 04 Sep 2023 at 4:58pm |

This is the tractor that had vibration problems and AC brought most of them back in for a retro fit right?

Glad to hear it's going to a good home. Congrats Leon B MO

|

|

Uncle always said "Fill the back of the shovel and the front will take care of itself".

|

|

Ed (Ont)

Orange Level

Joined: 08 Nov 2009

Location: New Lowell, Ont

Points: 1510

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 5:23pm Posted: 04 Sep 2023 at 5:23pm |

What an interesting story! Thanks for sharing the info.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 5:43pm Posted: 04 Sep 2023 at 5:43pm |

|

This is the tractor that DIDN'T have a vibration issue. The other 99 or so did and I believe they were all changed out to a diesel engine or waited until the 6-cylinder G-2500 engine was made available.

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 8371

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 6:20pm Posted: 04 Sep 2023 at 6:20pm |

|

Very nice and interesting! Thanks,,

|

|

Leon B MO

Orange Level

Joined: 12 Sep 2009

Location: Old Monroe, Mo

Points: 2200

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 6:31pm Posted: 04 Sep 2023 at 6:31pm |

Soooo...Doc, In your opinion, what changed from the proto-type to the production model that brought on the vibration? If AC sent this proto-type to a test farm, why not go back out to the proto-type tractor and say, "OK, What the hell changed here"? Was it because in the few short years of development of the gas 180, the new farm tractor wave was to switch to diesel? Making the gas 180 kinda of an outdated unit as it came into the market? Looking forward to the 180 perkins results. Leon B Mo

|

|

Uncle always said "Fill the back of the shovel and the front will take care of itself".

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 7:20pm Posted: 04 Sep 2023 at 7:20pm |

|

I've got several thoughts on this vibration problem. Remember, I have a One-Seventy gasser that I have configured to have a 180 platform ( a really nice tractor to operate by the way). I too had some vibration issues at high idle or near high idle. My problems were dancing clutch and brake pedals. I fixed those with rubber stops for each pedal. Then, the battery box cover (left platform) was shaking. I took some rubber edging and placed it around the top of the battery box lips, so the lid/platform was then suspended by rubber. All problems were solved. Sooooo, I have no bonafied engineering degree, but it wasn't too hard to solve my vibration issues. Why did they bail out ?? All four cylinder engines, to a degree, have an inherent problem with this. A spinning balancer in the crankcase area is one (expensive) way to solve it. Well, instead of the D-17 flywheel, why didn't they make a special heavy/larger diameter flywheel that would accept a 12 inch clutch, similar to the diesel engine ?? I guarantee if it was perfectly balanced, it would certainly have helped dampen the problem they had, but no, I doubt they even tried that. They didn't come up with any rubber pedal stops or batt box cover rubber isolation either. I think it could have been dealt with. But, that's my opinion. I do feel the fenders on this one tractor may have played a role in why this tractor was smoother than the others. The fenders on any 180-185 are bolted to the right platform and left battery box. Engine vibrations travel thru sheet metal. Those fabbed up non-standard fenders are quite a bit lighter and are shaped differently than a production fender. I think that could be one reason things were different. The other possibility would be the spinning balance of the crankshaft and flywheel. All of these engine parts have a tolerance spec to fall into. Plus or minus something. I'm sure this hand built engine may have had some "special" attention given to the specs and was held to a tighter standard. Combine this with the lighter weight and slightly different shaped fenders and that could have been thee difference in this case. Again, just opinion and from my own One-Seventy vibration experience.

Edited by DrAllis - 04 Sep 2023 at 7:39pm

|

|

captaindana

Orange Level

Joined: 14 Sep 2009

Location: Fort Plain, NY

Points: 2573

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 8:03pm Posted: 04 Sep 2023 at 8:03pm |

|

Very interesting!!

|

|

Blue Skies and Tail Winds

Dana

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 8:54pm Posted: 04 Sep 2023 at 8:54pm |

|

Interesting story, were you allowed to take any pictures?

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Kenny L.

Orange Level Access

Joined: 12 Sep 2009

Location: NEIOWA

Points: 1363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Sep 2023 at 9:20pm Posted: 04 Sep 2023 at 9:20pm |

|

I've seen that tractor when we done one of are winter tours I think it was 10 or so years ago, did you get to go thru the dealer display or did they sell alot of that stuff off.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 12:04am Posted: 05 Sep 2023 at 12:04am |

|

A few pics coming. Yes, we went into the display area.

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 7:57am Posted: 05 Sep 2023 at 7:57am |

|

Thank you for taking the time to give this info. I really respect your mechanical ability and your memory. No one could ever put a price on what you, Mack, Tbran and a few others offer every day free of charge. Thanks again. The drive line for the hydraulic pump would have soured a sale foe me.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1394

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 9:22am Posted: 05 Sep 2023 at 9:22am |

|

Inline four-cylinder engines have an inherent vibration problem due to having two pistons stopping/starting in the down position while two pistons are stopping/starting in the up position; this results in a 'rocking couple' that twists and bends the crankshaft to and fro, and when this rocking couple coincides with the wrong harmonic frequency it can become quite noticeable.

Big inline fours are worse. Big, heavy flywheels help, big heavy crankshafts help, counterweighted crankshafts help, reverse rotating counterbalance shafts help but the inherent dynamics are always there.

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1864

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 9:39am Posted: 05 Sep 2023 at 9:39am |

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 10:18am Posted: 05 Sep 2023 at 10:18am |

|

I've come to accept the fact that the West Allis Engineers never went more than a 4.500" stroke just because of that. They were able to keep those vibrations in check up to 2,000 RPM without issue the way they were doing it. They kept raising compression ratios and using different carburetors and in the end a higher lift camshaft to attain the HP levels they desired. A 5 inch stroke would have just added to these vibrations and maybe even forced the RPM's downward to keep them at an acceptable level. Also, if you read between the lines in Swinford's book, the original plan was to replace the D-17 IV with a new looking "60" HP tractor. I imagine when some of the larger dealerships and Blockmen heard about that, that's when the D-17 IV was to be replaced with a same size 53-54 HP new styling tractor (170) and the 60 HP future tractor became 64-65 HP. So, in the beginning the G-226 was only going to be 60 HP (like the 175 gas eventually was) but was then forced into becoming something it maybe shouldn't have been (64-65 HP). I know the overhaul hours would have been shortened at 2,200 RPM/64-65 HP. Probably down to 2500-3000 hrs instead of 3500-4000 hrs of the series 4 engine.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 12:26pm Posted: 05 Sep 2023 at 12:26pm |

|

I remember an advertising story in the Fall of 1967 in Successful Farming or Farm Journal magazine. There was always one page dedicated each month to "What's New in Machinery", and that particular month the new A-C One-Seventy and One-Eighty tractors were mentioned. There was a picture of this tractor with a 4-bottom plow featured, with the G-226 engine at 64-65 HP and the narrow front end. I was 13 at the time and remember thinking that it compared to a 3020 John Deere gasser with 227 cubic inches while IH and Oliver's were six-cylinders with more cubes. Fast forward to late August of 1980 when I was 26, my new wife and I were on our "honey-mood' and West Allis and the proving grounds/test farm south of Milwaukee was on our list of many things to do that particular week. Well, low and behold there was that same tractor with a street sweeper broom on the front of it. It was now 13 years old and had been retired to the test farm for menial duties. I didn't pay much attention to it at the time, not realizing it was a piece of history I should have been looking over really good. Anyway, yesterday, 43 years later, I get to see it again. So, this time I did look it over really good and took some notes to boot !!!

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 6:06pm Posted: 05 Sep 2023 at 6:06pm |

|

Neat piece of history and thanks so much for the pictures. Curious how many hours are on it?

Edited by AC720Man - 05 Sep 2023 at 6:07pm

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 6:34pm Posted: 05 Sep 2023 at 6:34pm |

|

Can't tell you that. Didn't pay attention to the hrs when I was driving it.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2263

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 8:42pm Posted: 05 Sep 2023 at 8:42pm |

It's always neat when a prototype tractor survives, especially since there don't seem to be as many AC prototypes out there.

My guess would also be that the stars aligned with this tractor and the tolerances lined up to make it not quite vibrate like the others. Would be interesting to see inside the engine too though... Maybe there was some extra attention given to it like you said.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

TramwayGuy

Orange Level Access

Joined: 19 Jan 2010

Location: Northern NY

Points: 11784

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Sep 2023 at 11:27pm Posted: 05 Sep 2023 at 11:27pm |

|

The John Deere 3020 with the 227 engine had a Lanchester balancer inside the crankcase. My brother owned one and it ran pretty smoothly even at 2500 RPM.

|

|

JPG AUSTRALIA

Orange Level

Joined: 13 Sep 2009

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Sep 2023 at 12:04am Posted: 06 Sep 2023 at 12:04am |

|

Great post! Thanks for sharing 👍

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3580

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 7:32am Posted: 23 Apr 2025 at 7:32am |

|

Back to the top

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3102

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 7:44am Posted: 23 Apr 2025 at 7:44am |

|

Old post but the spinning balancer was interesting to me.The 4 cylinder Fiat motors in my Oliver 1365 tractors have a balancer on the crank as they call it.They have zero vibration and run smooth but at low idle have sort of a 'lope' that can't be felt but able to hear it.Supposedly the there is a firing gap between some cylinders different from others.The balancer is inside the block BTW

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 8:21am Posted: 23 Apr 2025 at 8:21am |

|

Pretty sure those Fiat 4-bangers used the "Lanchester" design balancer box. It just bolts up to the bottom of the block inside the oil pan and gets powered by the front crankshaft gear OR a special gear made on the crank somewhere near the middle of the engine. Some balancers are similar to camshafts with weights on them, located down low in the block, one on each side of the crankshaft.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1857

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 9:15am Posted: 23 Apr 2025 at 9:15am |

Excellent post Dr. Allis - bookworthy certainly! At this point, am wondering why AC didn't pursue some sort of balancer for the gas motor similar to that equipped by Perkins in the 4-236 which was the option of the 170 diesel tractor. AC was taking delivery of the venerable Perkins 4-236 engine at the time and one could assume AC had the Perkins engine apart at some point to have a look at the internals and evaluate it operational characteristics within the design RPM range.

My understanding through discussion with Perkins design staff, is that Perkins had an office in Detroit Michigan that worked with non MF vendors that needed a diesel or gas power plant and that those engines had a unique reference spec. build to the engines sold to AC and others.

In close, who needs an engineering degree when the best teacher is listening, learning and applying real world experience - your talent in this area and your ability to transform and improve on existing AC designs has proven this. Keep up the good work and importantly your insightful articles on what possibly could have been!

Respectfully ~ Orangeman |

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22166

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 9:45am Posted: 23 Apr 2025 at 9:45am |

|

The reasons (in my thinking) for there even being a Perkins diesel engine in the 170 and 175 was this: Allis-Chalmers/Harvey Engine division didn't have an diesel engine that would work. Perkins did and they were for sale. They needed a 4 cylinder engine to fit into the provided space, not a 6-cylinder, as it was too long. The D-2200 Harvey engine was only about 48 PTO HP at 1800 RPM, nowhere near the 54 and 62 HP they needed. If the D-2200 had been 235-250 cubic inches, they could have made it work, but sadly it was only 200 cubes and nothing was ever done about that all the years they built it. A balancer designed into the A-C G-226 engine would have made its cost too high, to where they could have purchased the Perkins 200-236 gas engine for less money. In the farm tractor world, having an in-house engine was expected. In the case of Perkins, Massey Ferguson owned them, so they were "in-house". A-C was trying to get the cheapest cost gas engine into the new One-Eighty but the G-226 just didn't meet the desired results, so they were forced into buying the more expensive G-2500 with a smaller carburetor on it, than a One-Ninety had and slow down the RPM's. Excellent choice, just expensive.

|

|

DanielW

Silver Level

Joined: 19 Sep 2022

Location: Ontario

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 9:47am Posted: 23 Apr 2025 at 9:47am |

orangeman wrote: orangeman wrote:

At this point, am wondering why AC didn't pursue some sort of balancer for the gas motor similar to that equipped by Perkins in the 4-236 which was the option of the 170 diesel tractor.

|

I know we're beating an old post here, but from the Doc's initial description it sounds like this 180 prototype had many differences to the 180 Diesel - more than the later 180 gasser with the G2500 had. So maybe they just decided the extra cost of a 6 cylinder was still worth it, to save all the other mods and the rotating balancer. Keep in mind, Inline 4's are inherently unbalanced by nature, and most require some sort of balancing to be vibration free - especially at higher speeds. Most of the time it's just a correctly-weighted crank, but for higher-torque industrial 4-cyl's (especially those that work hard over a larger RPM range) sometimes more balancing tricks are required. The 45+ HP Mannheim-series 4-cylinder Deeres had balancing shafts, because the first few models they produced had the same vibration issues. Similarly with the large I4 Continentals like the 382's in the Massey 55's & 555's: Very unbalanced with lots of vibration at higher RPM's. I'm unfortunate enough to own a 555 with the I4 diesel 382 in it. Bad vibration and an unhappy-sounding engine when you get up near rated PTO speed. Continental later put rotating balancer shafts in the 382's that Case & Terratrac used in their crawlers. Similarly with the I4's in the Ford 5000, 6600, the X84 series IH's, etc. They had the Lanchester-style balancers in them. That's just the nature of long-stroke, high-torque I4's. The longer the stoke, the greater the journal throw, and it's that sideways throw of the rod that causes the imbalance (at least, that's what I was told).

For my part, I'm glad they switched to the G2500 gasser. Inline 6's are (more or less) balanced by nature. My 180 gasser might be the best running tractor I have. Incredibly smooth at all RPM's, very quiet, loads of torque (for a gasser), idles right down to a few hundred rpm, starts easily in all weather, and is pretty decent on fuel (for a 60 HP gasser, that is).

Edited by DanielW - 23 Apr 2025 at 10:17am

|

|

Ron Eggen

Orange Level

Joined: 15 Sep 2009

Location: Lohman, Missour

Points: 550

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 7:40pm Posted: 23 Apr 2025 at 7:40pm |

|

Very interesting post on Richard & some of his tractors . He was a friend of the # 3 man at A-C farm equipment at the time. My Dad & I visited him one night when he had the 80 in his front yard. We looked at it but if I would have had a cell phone like I do now, I would have taken 100 pictures. A-C was also instrumental in Richard acquiring his 10-18 which his family still own. They paid to have it hauled to a lot of farm shows one year. He told me that he also had the 6-12 duplex in his yard at one time , but he didn't get to keep it. I have no idea where it went to . it wasn't the one Dave & Deb Harrison have in Nebraska. Richard was very much involved in the start of the Aliis Connection organization and the Old Allis News. His wife's family owned an Allis dealership around Riverside Iowa . He used a lot of their trade in equipment at his farm ,not all Allis, and some people complained that he wasn't a true A-C fan. I thought he did a lot getting everything we now have off the ground. Those were the good old days.

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6089

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Apr 2025 at 9:36pm Posted: 23 Apr 2025 at 9:36pm |

Gary Burnett wrote: Gary Burnett wrote:

Old post but the spinning balancer was interesting to me.The 4 cylinder Fiat motors in my Oliver 1365 tractors have a balancer on the crank as they call it.They have zero vibration and run smooth but at low idle have sort of a 'lope' that can't be felt but able to hear it.Supposedly the there is a firing gap between some cylinders different from others.The balancer is inside the block BTW |

The 'lope' you hear, is a result of the firing order and intake/exhaust runner design.

Most of the time, four-cylinder engines with one carbeurator have the carb in center of the block, with runner pair going forward, and another pair going back... so cylinders 1 and 2 are close, 3 and 4 are close.

In a 4 cylinder 'even fire' inline four, you have a single-plane crankshaft where the two center throws are down, when the 1 and 4 throws are UP... this puts the primary oscillation of pistons in opposite of eachother... the mass of two moving up, is equated by the mass of 2 going down, and they're centered on eachother. The crankshaft flexes, but the block doesn't jump up and down. You still get secondary imbalance because the rods and throws are spinning, and the reaction of balance of the rods is going in a sinusoidal pattern, not strictly vertical, right?

So with 1 and 4 up, 2 and 3 down, you have 1 firing while 4 is on the intake exhaust stroke. A four-stroke engine goes through 720 degrees for a full four... so 1 fires, one full rotation later, 4 fires. Midway through, you've got 3, alternating with 4...

So depending on how you have the camshaft lobes placed, you either get a firing order of 1, 2, 4, 3...,or you get 1,3,4,2.

Consider the intake runner flow patterns of each.

1243 means you have airflow to the forward ports in short succession, then port flow turns to rear two, again in short succession.

Regardless of HOW the firing order IS, the result is the same- you get two cylinders pulling through the front branch, then two through the back.

This means the airflow through the runner of the FIRST two to fire is getting started for the FIRST cylinder, and when the SECOND cylinder's intake is opening, the inertia of airflow from the first cylinder's intake draw pressurizes the intake toward the SECOND in the firing order... then the intake slams shut, airflow has mass, and can compress, so doesn't stop instant, but now the demand to the THIRD cylinder in the order pulls intake flow to the back pair... the third cylinder is under a fair vacuum, after it's intake slams shut, pressure builds, then that last cylinder's intake valve opens.

The result of this, is that mixtures and charges between the cylinders will NOT be symmetrical... they'll have a 'pattern', where two cylinders are a little leaner than the others.

And THIS is the 'lope' you hear... mixture variations and airflow alteration from rear to front, and back again.

Making equal length runners REDUCES, but won't 'fix' this, because the prior cylinder's intake pressure will ALWAYS affect airflow to the NEXT.

Running four carbs, individual matched runners. and having same in the exhaust would help smooth out this inconsistency... but it'll add significant complexity.

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3102

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2025 at 3:15am Posted: 24 Apr 2025 at 3:15am |

DaveKamp wrote: DaveKamp wrote:

Gary Burnett wrote: Gary Burnett wrote:

Old post but the spinning balancer was interesting to me.The 4 cylinder Fiat motors in my Oliver 1365 tractors have a balancer on the crank as they call it.They have zero vibration and run smooth but at low idle have sort of a 'lope' that can't be felt but able to hear it.Supposedly the there is a firing gap between some cylinders different from others.The balancer is inside the block BTW |

The 'lope' you hear, is a result of the firing order and intake/exhaust runner design.

Most of the time, four-cylinder engines with one carbeurator have the carb in center of the block, with runner pair going forward, and another pair going back... so cylinders 1 and 2 are close, 3 and 4 are close.

In a 4 cylinder 'even fire' inline four, you have a single-plane crankshaft where the two center throws are down, when the 1 and 4 throws are UP... this puts the primary oscillation of pistons in opposite of eachother... the mass of two moving up, is equated by the mass of 2 going down, and they're centered on eachother. The crankshaft flexes, but the block doesn't jump up and down. You still get secondary imbalance because the rods and throws are spinning, and the reaction of balance of the rods is going in a sinusoidal pattern, not strictly vertical, right?

So with 1 and 4 up, 2 and 3 down, you have 1 firing while 4 is on the intake exhaust stroke. A four-stroke engine goes through 720 degrees for a full four... so 1 fires, one full rotation later, 4 fires. Midway through, you've got 3, alternating with 4...

So depending on how you have the camshaft lobes placed, you either get a firing order of 1, 2, 4, 3...,or you get 1,3,4,2.

Consider the intake runner flow patterns of each.

1243 means you have airflow to the forward ports in short succession, then port flow turns to rear two, again in short succession.

Regardless of HOW the firing order IS, the result is the same- you get two cylinders pulling through the front branch, then two through the back.

This means the airflow through the runner of the FIRST two to fire is getting started for the FIRST cylinder, and when the SECOND cylinder's intake is opening, the inertia of airflow from the first cylinder's intake draw pressurizes the intake toward the SECOND in the firing order... then the intake slams shut, airflow has mass, and can compress, so doesn't stop instant, but now the demand to the THIRD cylinder in the order pulls intake flow to the back pair... the third cylinder is under a fair vacuum, after it's intake slams shut, pressure builds, then that last cylinder's intake valve opens.

The result of this, is that mixtures and charges between the cylinders will NOT be symmetrical... they'll have a 'pattern', where two cylinders are a little leaner than the others.

And THIS is the 'lope' you hear... mixture variations and airflow alteration from rear to front, and back again.

Making equal length runners REDUCES, but won't 'fix' this, because the prior cylinder's intake pressure will ALWAYS affect airflow to the NEXT.

Running four carbs, individual matched runners. and having same in the exhaust would help smooth out this inconsistency... but it'll add significant complexity.

|

Good information but no carbs on these as they are diesel motors.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(3)

Thanks(3)

orangeman wrote:

orangeman wrote: