| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Hurst

Orange Level

Joined: 11 Sep 2009

Location: Midway, Ky

Points: 1219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Need a shifter fork rod for 7000 Black belly Topic: Need a shifter fork rod for 7000 Black belly

Posted: 16 Feb 2011 at 10:04am |

|

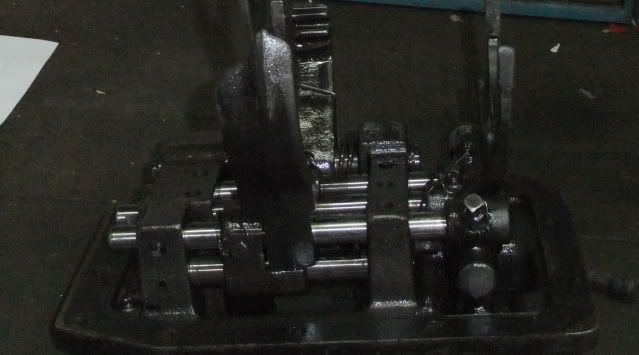

My Dad got the shifter off the transmission (gotta give credit to the old man for tackling the job considering his experience with repairs goes to about oil changes in his truck), and the 3rd/4th shifter fork rod was broken. It is part number 70260638 out of the current AGCO part book (it's mislabeled as 2nd/4th Rod). Is this something that is still available? Also will need a gasket 70260654 and possibly a fork (PN 70261262), as it has some wear (I'll post pictures later, but basically the way he described it was the shaft broke and the fork was cocked sideways a little holding the gear in).

Also, need some help on disassembly. We're worried about the detent balls and springs. He was thinking about waiting until he gets the new rod, then taking the fork off the old rod and knocking the new one through the shifter plate bore so the detent balls and springs never come out of place. Is this a possibility? Or is there a better way to replace this shifter fork rod?

Any idea what causes these rods to break? Is this a "common" problem? Anything I should have him look for inside the shifter/transmission.

Edit: Also does anyone have the spec for the thickness of the shifter fork surfaces? My Dad didn't see anything in the service manual about this spec. I'm just trying to figure out if the shifter fork is worn out.

-Hurst

Edited by Hurst - 16 Feb 2011 at 10:09am

|

|

1979 Allis Chalmers 7000

5800 Hours

|

|

|

Sponsored Links

|

|

|

Hurst

Orange Level

Joined: 11 Sep 2009

Location: Midway, Ky

Points: 1219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 10:25am Posted: 16 Feb 2011 at 10:25am |

|

|

|

1979 Allis Chalmers 7000

5800 Hours

|

|

niel ev

Silver Level

Joined: 04 Feb 2010

Points: 189

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 11:11am Posted: 16 Feb 2011 at 11:11am |

|

Hurst I took a 3/8 bolt and ground about half the bolt donw for about a inch and a half so that when I slid the shaft back in I could push the ball down and still have room for the shaft to slide in also we might have a good used shifter let me know if I can help Niel

|

|

sandylakeimplement

Orange Level

Joined: 18 Sep 2009

Location: Sandy Lake, PA

Points: 399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 11:55am Posted: 16 Feb 2011 at 11:55am |

|

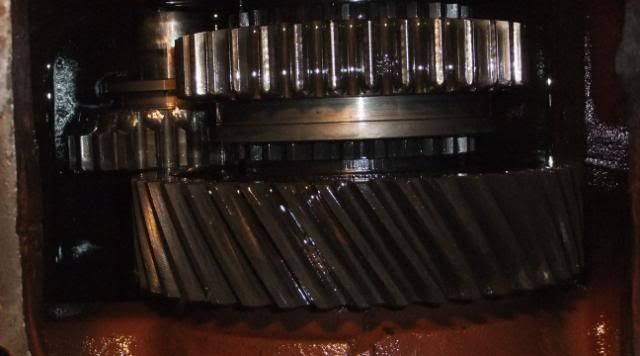

The pads look quite worn on the fork. Would indicate that the fork was having to hold the slider engaged instead of the shifting teeth of the gear & slider holding themselves engaged. While it's out make sure the interlocks are working properly & not binding. Bill

|

|

Sandy Lake Implement

Sandy Lake, PA

724-376-2489

www.sandylakeimp.com

FIND US ON FACEBOOK

|

|

Hurst

Orange Level

Joined: 11 Sep 2009

Location: Midway, Ky

Points: 1219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 12:05pm Posted: 16 Feb 2011 at 12:05pm |

|

I'll have to have him take a picture of the slider and gears to see how the teeth look. It's never had a problem with trying to jump out of gear, but maybe the forks were not adjusted properly where it was holding the gear in all the way?

Hurst

|

|

1979 Allis Chalmers 7000

5800 Hours

|

|

sandylakeimplement

Orange Level

Joined: 18 Sep 2009

Location: Sandy Lake, PA

Points: 399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 12:19pm Posted: 16 Feb 2011 at 12:19pm |

|

The slider teeth or splines will be impossible to see but one can assume that they are worn the same as the shifting teeth around the gear hub. The driving teeth around the O.D. of the gear are not a concern in this respect. The detent will hold the slider in place as initial wear occurs but the result is worn fork pads as you picture. Bill

|

|

Sandy Lake Implement

Sandy Lake, PA

724-376-2489

www.sandylakeimp.com

FIND US ON FACEBOOK

|

|

Hurst

Orange Level

Joined: 11 Sep 2009

Location: Midway, Ky

Points: 1219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 2:11pm Posted: 16 Feb 2011 at 2:11pm |

|

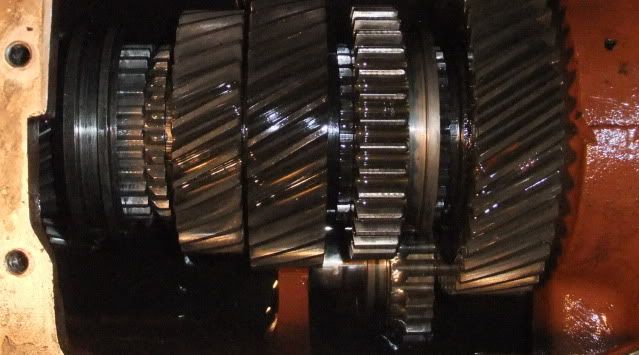

Bill, thanks for the help. Niel, I may be in contact with you about some used parts. Can the forks be built back up by a machine shop or are they available new for a reasonable price? I should have some pictures of the gears tonight from my Dad. He said the engagement teeth didn't seem to have any wear, but the reverse idler gear was pretty chewed up. Is this something that can be replaced from the top?

|

|

1979 Allis Chalmers 7000

5800 Hours

|

|

Hurst

Orange Level

Joined: 11 Sep 2009

Location: Midway, Ky

Points: 1219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 5:35pm Posted: 16 Feb 2011 at 5:35pm |

Well, some of these made me a little sick to look at them, looks like reverse might be about gone on this thing too... Is that idler able to be replaced through the top? I also should have some measurements of just how much is worn off the fork on the 3rd/4th fork tonight or tomorrow.

|

|

1979 Allis Chalmers 7000

5800 Hours

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 8:41pm Posted: 16 Feb 2011 at 8:41pm |

|

Never had a power dirrector open, but I can look at the manual, but I am sure this is a split and tear down job.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 9:06pm Posted: 16 Feb 2011 at 9:06pm |

When you get the new rail, make sure all the rails are in nutural and with cover fasened solid in a vice push the new shaft through pushing the old shaft out.

After you price the new fork you can bronz the old fork and file it back flat. MACK

|

|

Andrew(southernIL)

Orange Level

Joined: 12 Sep 2009

Location: Metropolis, IL

Points: 1086

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 9:53pm Posted: 16 Feb 2011 at 9:53pm |

|

I'm not a professional mechanic and the only transmission and rear end Ive been in is a 3020 and a 4020 but with the problem you have and the looks of that gear I think its time to bite the bullet and tear it down and put all new bearings and detents. And replace any wore looking gears and shifting cages. Also make sure all the shims are on the shafts, the 3020 I did we got it all together and it still had a problem so we had to tear it down again and while putting one of the shafts back in noticed that a shim had wore down to nothing and was gone. Could save a lot of future headache an since its already broke down now's a good time to do.

Edited by Andrew(southernIL) - 16 Feb 2011 at 9:56pm

|

|

If fishing is a sport your looking at an athlete

|

|

Hurst

Orange Level

Joined: 11 Sep 2009

Location: Midway, Ky

Points: 1219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 9:58pm Posted: 16 Feb 2011 at 9:58pm |

Andrew, that's definitely something I have thought about, but the problem right now is I'm in Philadelphia for college (until June at the earliest...) and the tractor's at home in Midway, Ky (10 hours away), so I've been calling/skyping my Dad to talk him through the tear down this far. Unfortunately, a full rear end tear down is going to be way past his comfort level, but I may consider replacing the reverse idler if that is a simple repair that doesn't require a split. If I get a chance to work on it this summer, it will be something I will consider, as all I have left to mechanically rebuild on this tractor is the powershift and transmission. I've been through the rear end, bull gears, and engine, but haven't done much with the middle of the tractor other than disassemble, clean, and reassemble the powershift valve body.

Hurst

|

|

1979 Allis Chalmers 7000

5800 Hours

|

|

Steve M C/IL

Orange Level

Joined: 01 Jul 2010

Location: shelbyville IL

Points: 691

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2011 at 10:14pm Posted: 16 Feb 2011 at 10:14pm |

|

Hurst,that gear is pretty chewed on but I bet there is still quite a bit of tooth contact lenght wise.Previous owner must have ground that a lot.Reverse don't usually have much of a load to move so it'll probably go a long time without causing trouble.What I'm saying is,probably no need to get excited about replacing it.

|

|

bena18

Bronze Level

Joined: 30 Nov 2010

Location: sw mo

Points: 49

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Feb 2011 at 9:29am Posted: 17 Feb 2011 at 9:29am |

|

Reverse idler can be changed by taking top cover of rearend,removing keeper on on idler shaft then using a small portapower in the trans and shove the shaft rearward. hang on to the gear with a welding rod wraped around the shifter fork grove. The trick is getting the right push cylinder to fit in trans.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2446

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Feb 2011 at 9:54am Posted: 17 Feb 2011 at 9:54am |

|

I have changed out several of those gears over the years.I made a bar with a hook to use as leverage to push the shaft back.Sometimes they push out fairly easily,next one can be a brute.A&I products has an aftermarket gear available,decent price too.Look down inside the tranny case to see the gear in mates to on the countershaft.Unfortunately the gear is part of the countershaft ,so complete tear down is required to fix.I think $1500 or $1600 for that countershaft and a lot of labor.OUCH!

|

|

skipwelte

Orange Level

Joined: 29 Oct 2009

Location: Anthon, Iowa

Points: 723

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Feb 2011 at 11:40am Posted: 17 Feb 2011 at 11:40am |

Im with SteveM, that gear could easily be the victim of a previous owner, you know if youve ground reverse or not. When it gets worn enough it will jump out of reverse, might be a long time if you shift it right. You can change it without a teardown, but Id be real leary of off shore gears, they might be real soft. good luck

|

|

sandylakeimplement

Orange Level

Joined: 18 Sep 2009

Location: Sandy Lake, PA

Points: 399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Feb 2011 at 11:47am Posted: 17 Feb 2011 at 11:47am |

|

From what I see in your pictures the shifting teeth don't look too bad. The reverse idler looks bad but I wouldn't put myself out to fix it right now if it is not convenient. Replace or rebuild the fork & check the interlocks would be my advice. Bill

|

|

Sandy Lake Implement

Sandy Lake, PA

724-376-2489

www.sandylakeimp.com

FIND US ON FACEBOOK

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)