| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Apr 2019 at 11:08am Posted: 07 Apr 2019 at 11:08am |

|

Yes, but as there was also water in the case, I was thinking it may be beneficial to try and give the bearings a little soak. I wasn't concerned with the bottom part of the sleeve as the water pushed the oil up :)

Thank you for ensuring I understood. I should have been more clear in my question.

|

|

|

Sponsored Links

|

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Apr 2019 at 6:43pm Posted: 07 Apr 2019 at 6:43pm |

|

Well... I made it over today to fill the cylinders with ATF and Acetone. Cylinders 1,2&4 looked better than yesterday, 3 is near the top and was strangely cruddy, thought I had found the guilty party and rejoiced! Soaked up the oil we dumped in yesterday before leaving, 12&3 were easy to dry out, but I just couldn't get #4 dry, and I could've swore we got all the coolant out yesterday... Turns out, we thought we had, but the hairline fracture in the middle of the sleeve previously hidden by crud is helping to ensure a constant supply of coolant right back in.

So, I'm thinking that I figured out how the pushrod got bent- fuel gummed up carb and tractor got parked. Some time a winter or few later it was determined that the tractor was parked in an inconvenient spot and during the first attempt to turn her over, hydro lock on cylinder 4 with a bending of the pushrod. Determine that it's not really in the way and we'll mess with it later. Decade goes by and here we are!

Looks like it's getting an overhaul!

On the plus side, I checked the hydraulics c fluid level and it was not only in the hash marks, but looked pretty decent! Hopefully there won't be any surprises when we spool that side up :)

Edited by Strokendiesel002 - 07 Apr 2019 at 6:44pm

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Apr 2019 at 9:36pm Posted: 07 Apr 2019 at 9:36pm |

|

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2019 at 8:34pm Posted: 15 Apr 2019 at 8:34pm |

|

Alright, I split her in two, pulled the blue color and then bolted her back together in case my uncle needs to move her. Need to buy a memory card for my phone and then I can text myself the pictures and upload them. Just wanted to give an update that this project isn't dead. Should I ask for a re-title or start a new thread?

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3074

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 7:13am Posted: 16 Apr 2019 at 7:13am |

I'd say keep this one alive, you've already got a good story going. Good luck on your rebuild.

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Apr 2019 at 10:02am Posted: 16 Apr 2019 at 10:02am |

|

Thanks AD, will do!

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Apr 2019 at 9:24pm Posted: 21 Apr 2019 at 9:24pm |

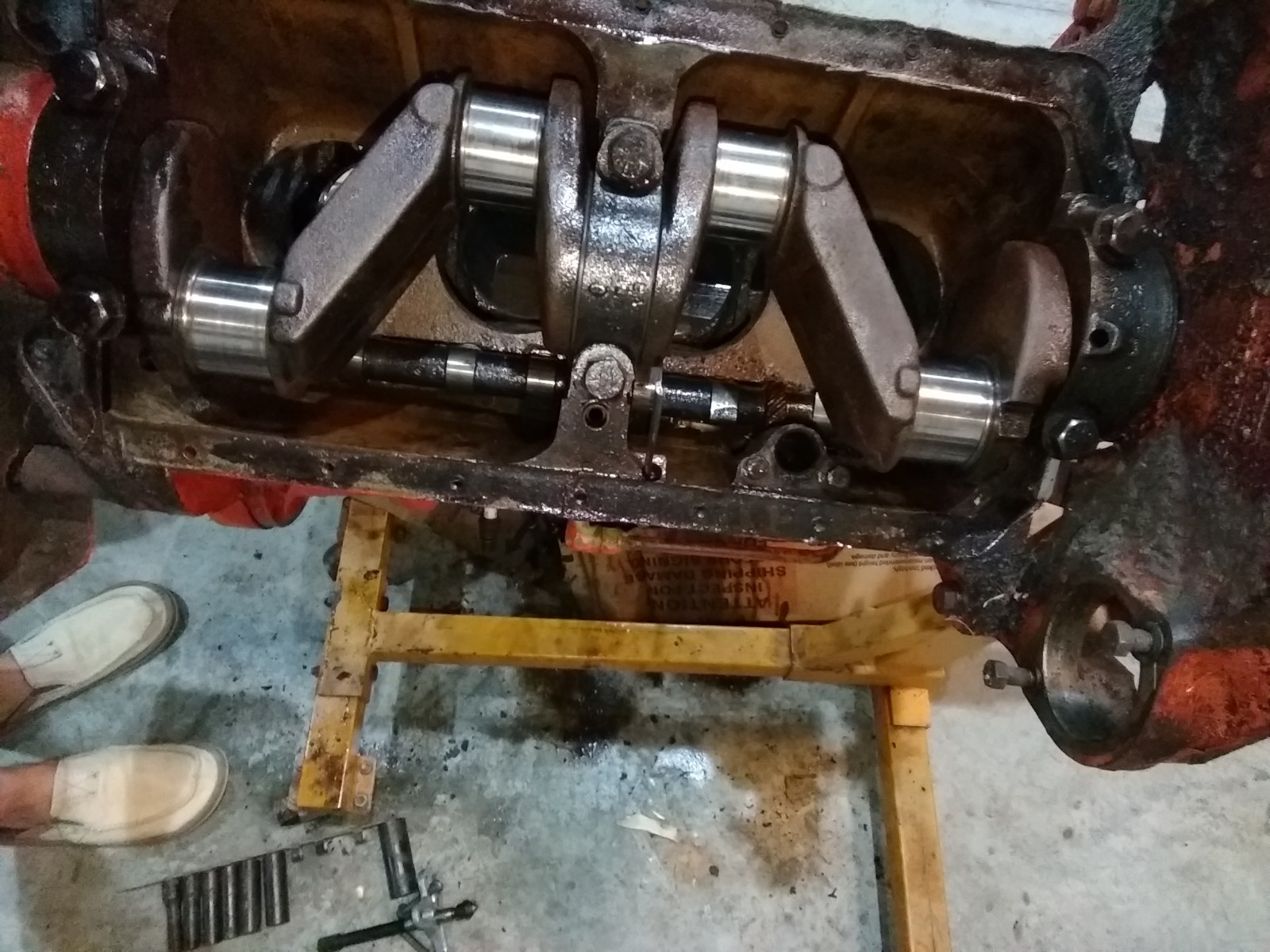

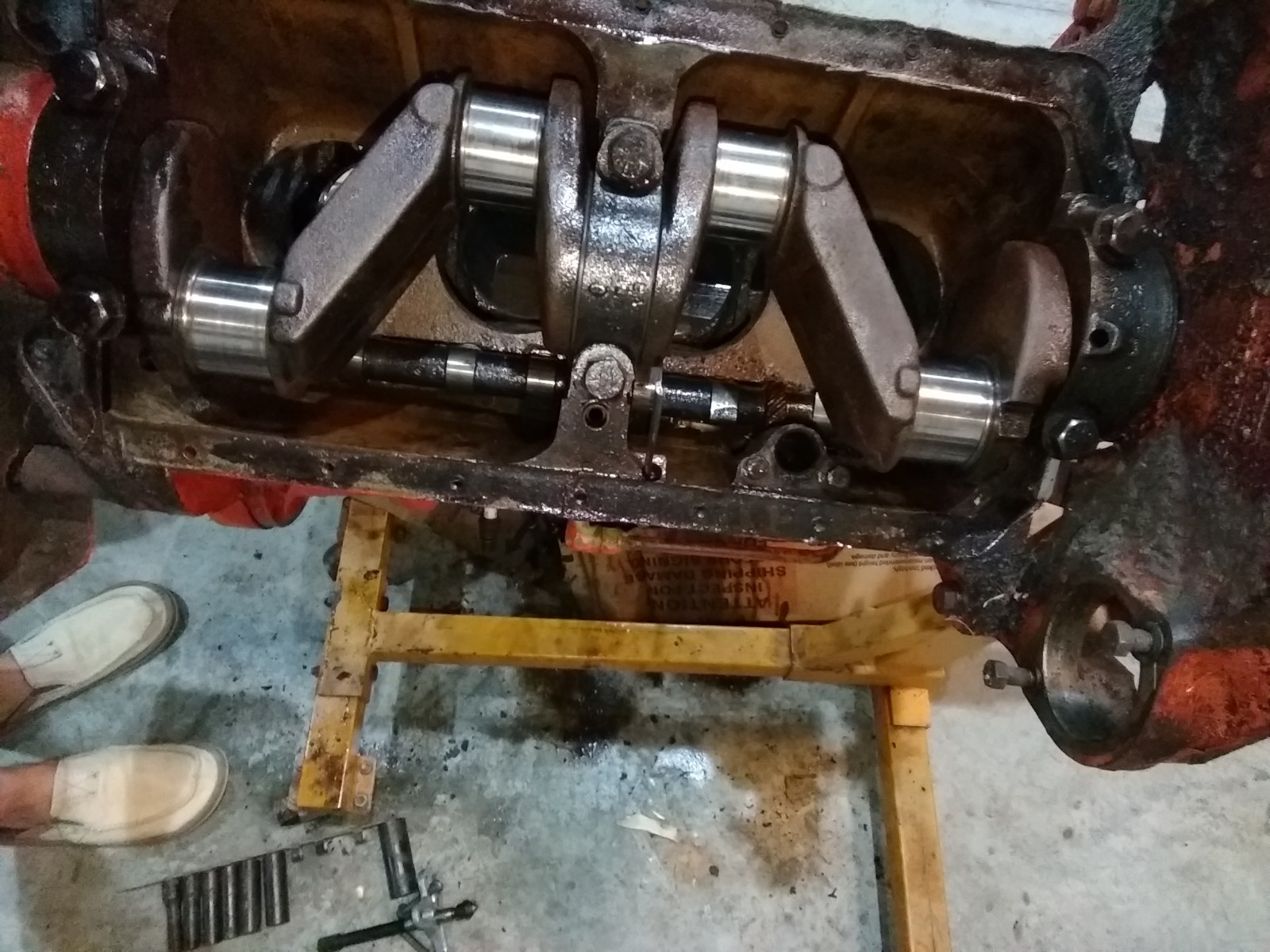

Update! Head and flywheel were dropped off at machine shop and full sleeve and gasket kit was ordered. Hoping to get said parts by Thursday for reassembly! Wife and kids are out of town, so I'm really pushing to have engine read for install by Saturday morning, as they're coming back Saturday night! I really want to replace the main bearings, since I've got it this far apart, but I'm deathly afraid of cracking the crank pulley... Any tips? My cheap puller was kind of stripped (pressure bolt) from an outboard project and is now completely stripped. So if I gotta buy something, I want to buy the right thing. Pics!

Edited by Strokendiesel002 - 21 Apr 2019 at 9:25pm

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8568

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2019 at 8:16am Posted: 22 Apr 2019 at 8:16am |

Looks like you have a project! I will be watching! Congrats on the D17 joining the family. It sounds like it needs lots of love and attention too. Mine is setting in my sons garage (lean to). Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2019 at 11:06pm Posted: 22 Apr 2019 at 11:06pm |

Thanks Sugarmaker! Pretty excited to put around the property and mow stuff down! More progress tonight... Successfully removed the crank pulley without breaking it!!! Got a puller squared up and put a fair amount of pressure, then heated as evenly as possible with a smallish rosebud torch. Popped 1/8" and repeat, used a 2x4 to hold the crank steady when applying pressure. It certainly wasn't a fast process, but it worked!

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2019 at 11:53pm Posted: 24 Apr 2019 at 11:53pm |

|

|

|

bradley6874

Orange Level

Joined: 05 Sep 2010

Location: salisbury md

Points: 1349

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2019 at 2:39pm Posted: 25 Apr 2019 at 2:39pm |

|

Put couple bolts with flat washers in place of the head bolts to hold the sleeves down cuz if you do break one of them loose and you've moved the sleeve a little bit you'll be back in for a water leak nevermind I didn't see page 2

Edited by bradley6874 - 25 Apr 2019 at 2:42pm

|

|

You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2019 at 3:41pm Posted: 25 Apr 2019 at 3:41pm |

|

Hey Bradley thanks for taking the time to read and for the tip I really appreciate it!

somebody down the line May read that and it will help save them from the potential heartache that you were trying to help save me from :)

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Apr 2019 at 10:08am Posted: 29 Apr 2019 at 10:08am |

Well between Friday and Sunday I got the new sleeves Pistons rebuilt head and 7 of the 8 pushrods installed. my uncle came over to help with prepping the crank is that it was his specialty for many years, well machining them was actually his specialty. Mama and the boys got home Saturday afternoon but Sunday afternoon we loaded up the almost completed engine and brought it back over to my uncle's which is where the tractor is. I'm hoping to finish it up on this coming Saturday!

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 May 2019 at 10:52pm Posted: 02 May 2019 at 10:52pm |

Carb is assembled with new gaskets, pressure plate is picked up, manifolds are cleaned about as good as it's gonna get without a blast cabinet. I ran my die grinder with a smaller forward facing brush in and out of every port and then let it sit for about 30 minutes in a 50/50 mix of muriatic acid and water that I drained out of the fuel tank after it's 3rd treatment. It's looking really good... Except for the 3 holes :( I'm nervous to use the liners, as I've read so many bad experiences thanks to all the fuel additives. May wind up attempting to weld it. Going to use air craft stripper to clean the outside to bare metal then give it a full acid bath, rather than just trying to fill it. Unless anyone has a solid tank they're willing to part with or a better idea :)

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Aug 2019 at 3:18pm Posted: 01 Aug 2019 at 3:18pm |

She's Alive! I wound up welding the tank after a sorry attempt to solder it. Took about 3 hours chasing holes. Not the prettiest work I've ever done, but it's no leaking! I actually put the engine back in on May 5th, and went back a week or two later to finish it, but she wouldn't start. Summer came in full swing at that point, and I just let it be. I'd been theorizing over what was wrong and came to the realization that I never truly clocked the rotor. After reading the manual and many threads, I went back out and within 20 minutes she was alive! I set the radiator in place, filled with water and put on the 3 good hose clamps I had (need 1 new one). I was planning on changing all the hydraulic fluid out before driving it, but I couldn't help myself. I had to know if it would even remotely operate, and it actually did pretty good! I wasn't quite aggressive enough with the P.D. and thought it was slipping out of "hi" and "low" when I pushed a little further and she snapped into place! So I then pulled a little further where she again snapped into low! What an awesome feeling! I do need to figure out the clutch spring- there wasn't one so I ordered one up. There were 2 washers and a cotter key on the shaft. I am assuming that I need to order a special piece that goes to the housing. Will check parts diagram, but suggestions welcome! first start!first drive!

Edited by Strokendiesel002 - 01 Aug 2019 at 3:22pm

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Aug 2019 at 3:31pm Posted: 01 Aug 2019 at 3:31pm |

Here's what has me on the struggle bus regarding the clutch   I unthreaded the rod, pulled off the big washer, removed the cotter key and slide the small orange washer up the shaft. Slid on the spring, then big washer and threaded the shaft back into the fork. Not fun, but whatever. Go to compress the spring and install the washer to find that the spring is nearly totally compressed and the washer binds on the shaft. Doh! Then common sense kicks in and I realize someone probably out a larger diameter spring on at some point and it must've rotted away, that's why there was a larger diameter washer, which was never painted orange. All it takes is time and money, right?

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Aug 2019 at 3:46pm Posted: 01 Aug 2019 at 3:46pm |

|

Well, agco parts apparently no longer provides the parts diagrams they did a few months ago. I do have a parts book for 170/175 on loan from a friend, but it just lists 2 washers and a cotter pin. Guess maybe my housing is damaged? Really open to opinions at this point.

Thanks for looking!

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 963

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Aug 2019 at 4:58pm Posted: 01 Aug 2019 at 4:58pm |

Parts books are still available on line. They changed the format so it looks different but still works. AGCO Parts Books

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Aug 2019 at 4:59pm Posted: 01 Aug 2019 at 4:59pm |

|

Thanks!

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2019 at 10:27am Posted: 26 Oct 2019 at 10:27am |

Well it's been a while, but I've been running Allis around the property doing some mowing and borrowed a hay wagon for a family friendly Halloween party. Even did my first tractor pull a few weeks back at the Racine county Fair grounds! Just had family pics taken and I really liked how these two turned out so thought I'd share   Hope everyone is doing well!

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8678

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2019 at 1:41pm Posted: 26 Oct 2019 at 1:41pm |

|

Nice picture ...lucky boys....good father

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8568

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2019 at 2:48pm Posted: 26 Oct 2019 at 2:48pm |

Stroken, Great pictures! Thanks for sharing. Your making some memories with them and the Allis tractor too! Glad you got the tractor working! Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Oct 2019 at 9:49pm Posted: 26 Oct 2019 at 9:49pm |

|

Thanks fellas!

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Sep 2020 at 10:26pm Posted: 22 Sep 2020 at 10:26pm |

|

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8568

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Sep 2020 at 6:26am Posted: 23 Sep 2020 at 6:26am |

Ahh that loader looks like it came with the tractor! Nice addition to the family! You did a great job getting this tractor operational again and now that loader will help around the farm too. ( I could use a loader tractor some days too! ) I like the picture of the Ford assisting getting the loader in place! Thanks for sharing the pictures. Regards, Chris |

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 9998

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Sep 2020 at 11:05am Posted: 23 Sep 2020 at 11:05am |

The tilt cylinders are not original. The original cylinders look like the lift cylinders. The tilt cylinders appear to be tie rod cylinders. I have a 500 loader on my series II D-17. Dealer installed it in 1972.

Great loaders.

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Sep 2020 at 11:22am Posted: 23 Sep 2020 at 11:22am |

|

Correct clay, the person I bought from said they got bent so he replaced them and threw away the originals unfortunately

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Sep 2020 at 11:23am Posted: 23 Sep 2020 at 11:23am |

|

Chris, thank you for the kind words as always :)

My uncle (same as who I got it from) was very excited to out the little Ford to work!

|

|

Strokendiesel002

Silver Level

Joined: 04 Apr 2019

Location: 53158

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Oct 2020 at 7:34pm Posted: 14 Oct 2020 at 7:34pm |

Evening! I'm getting closer to having a functional FEL! So, a friend make me up the mounting plate and ordered some 1"OD .0.5" ID tubing and am waiting on a shaft and coupler for the flywheel. I test fit the pump in the bracket tonight and I suddenly realized what others were talking about with the 1/2" bolster bolts and pump interfering. Pics:    I'm thinking that it'd be acceptable to shorten up the bolster to bracket spacers by say 1/2" and then place 1/2" spacers between the bracket and pump... Thoughts?

|

|

HD6GTOM

Orange Level

Joined: 30 Nov 2009

Location: MADISON CO IA

Points: 6627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Oct 2020 at 9:29pm Posted: 14 Oct 2020 at 9:29pm |

|

While you have it taken apart, unhook the drawbar where it hooks under the tractor and replace the double C spring that holds the snap coupler hook in place. They get weak and it will allow your plow to come unhooked. When that happens the tonge of the plow will dig into the ground and the plow will land on top of you. I still have the scar on my back when it happened to me.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)