| Author |

Topic Search Topic Search  Topic Options Topic Options

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Aug 2016 at 11:18am Posted: 24 Aug 2016 at 11:18am |

Alberta Phil wrote: Alberta Phil wrote:

Might be better off dealing with some of the suppliers on this site. I've had excellent service from any I've dealt with over the years. Also, they know Allis!

|

Yeah, I learned a lesson. Of course when I really laid in to Yesterdays Tractors and asked for support I got no return calls or email responses. They are off my list of preferred vendors.

|

|

|

Sponsored Links

|

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Aug 2016 at 11:25am Posted: 24 Aug 2016 at 11:25am |

peterh wrote: peterh wrote:

awesome story, great tractor- love the advice on this site, but love stories like this even more |

Thank you for your comments. the tractor means a lot to me. A lot of learning occurred on that seat and lots of good times with my grandpa and that tractor. I think these forums are helpful for the advice as well but as you mention I enjoy the stories too. When I was looking for photos and details I was having a hard time finding a ton of D15 info so I figured I would take lots of pics and document everything I could so that others had a resource if they were new to these tractors as far as going through certain areas of them.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Aug 2016 at 2:21pm Posted: 24 Aug 2016 at 2:21pm |

Well this isn't tractor related but I wanted to post it anyway. This was my grandpas ship that he took to Japan. He was posted in Japan after the close of WWII and then on to Korea after that.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 7:30am Posted: 26 Aug 2016 at 7:30am |

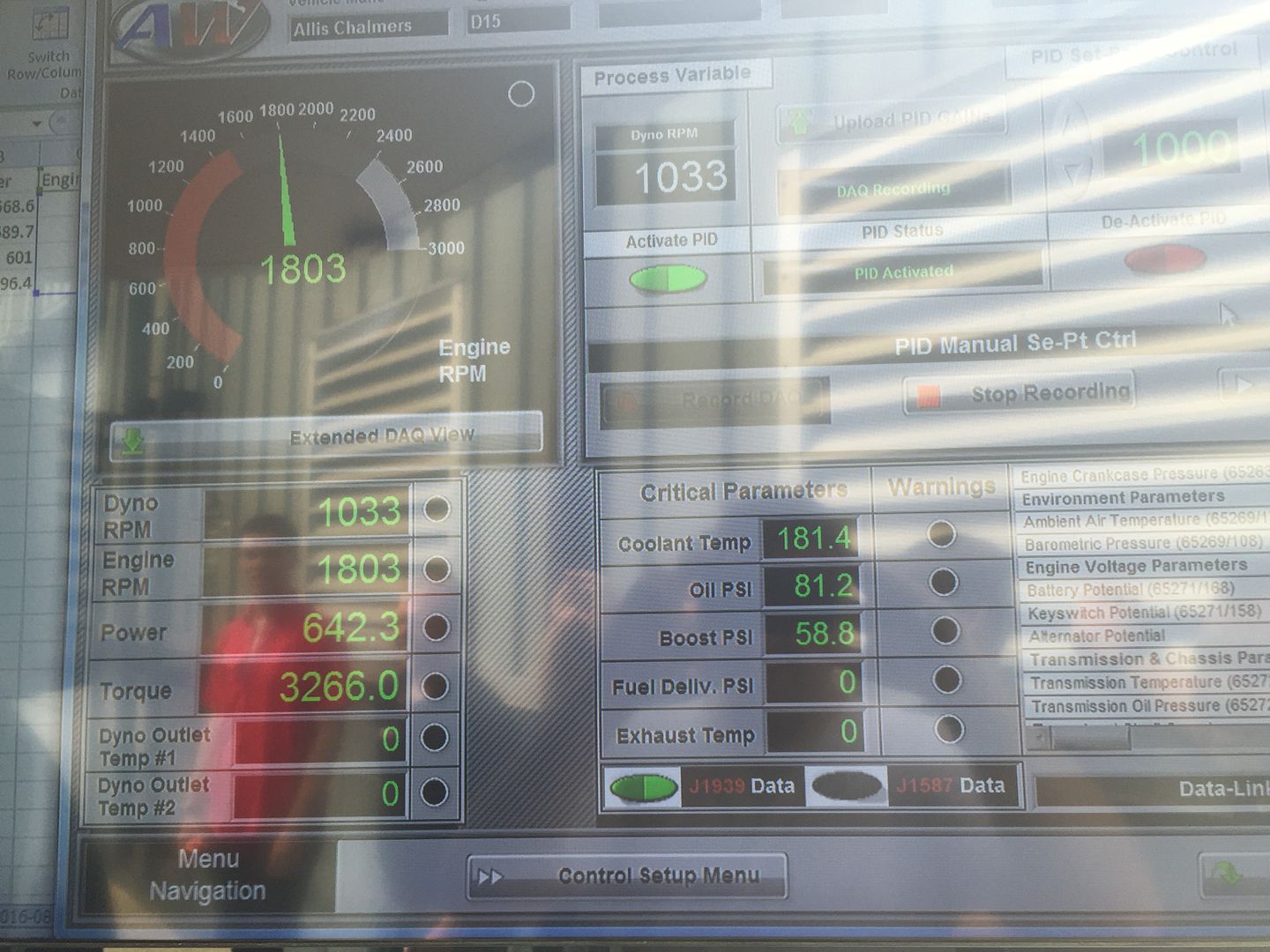

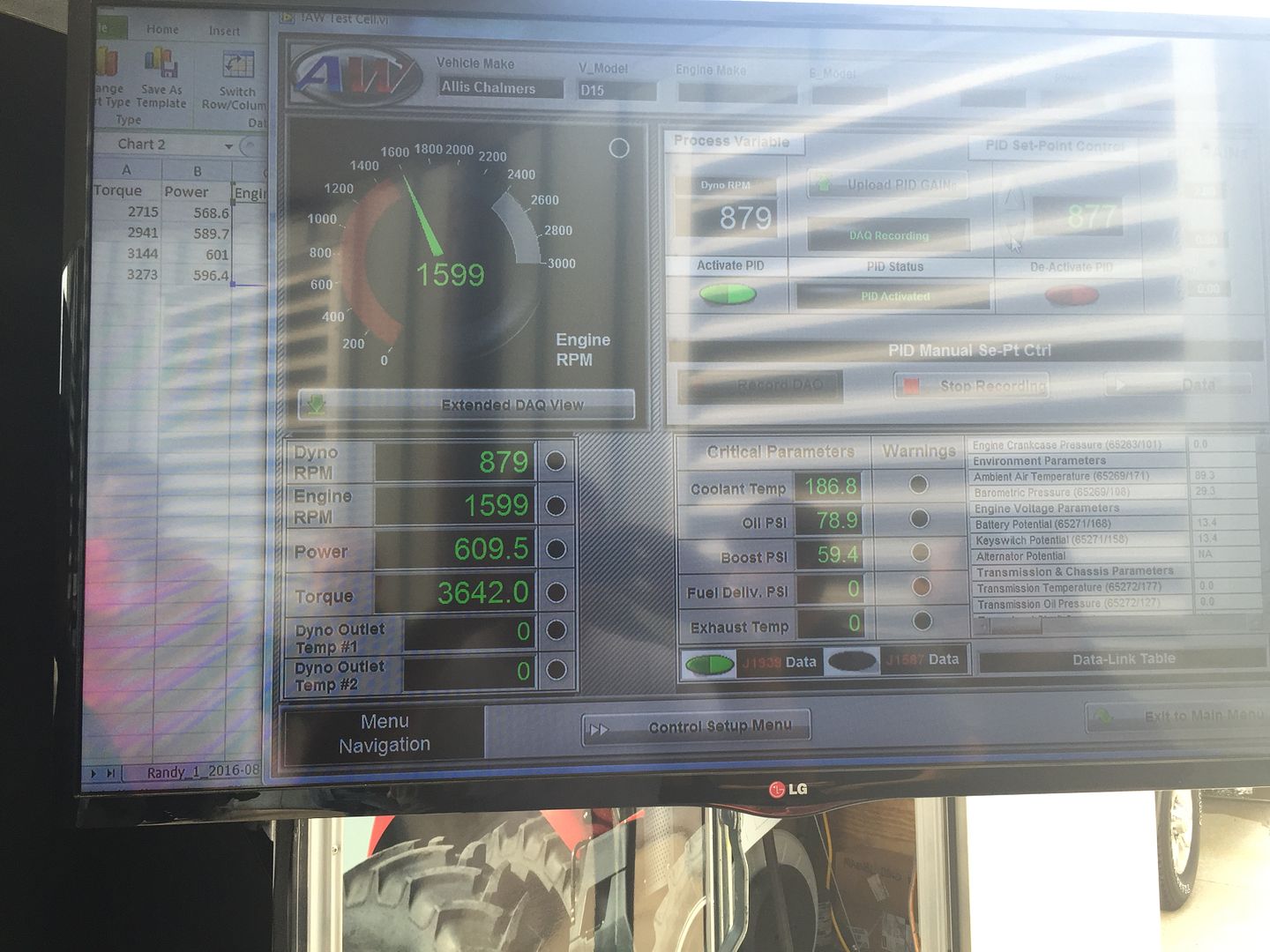

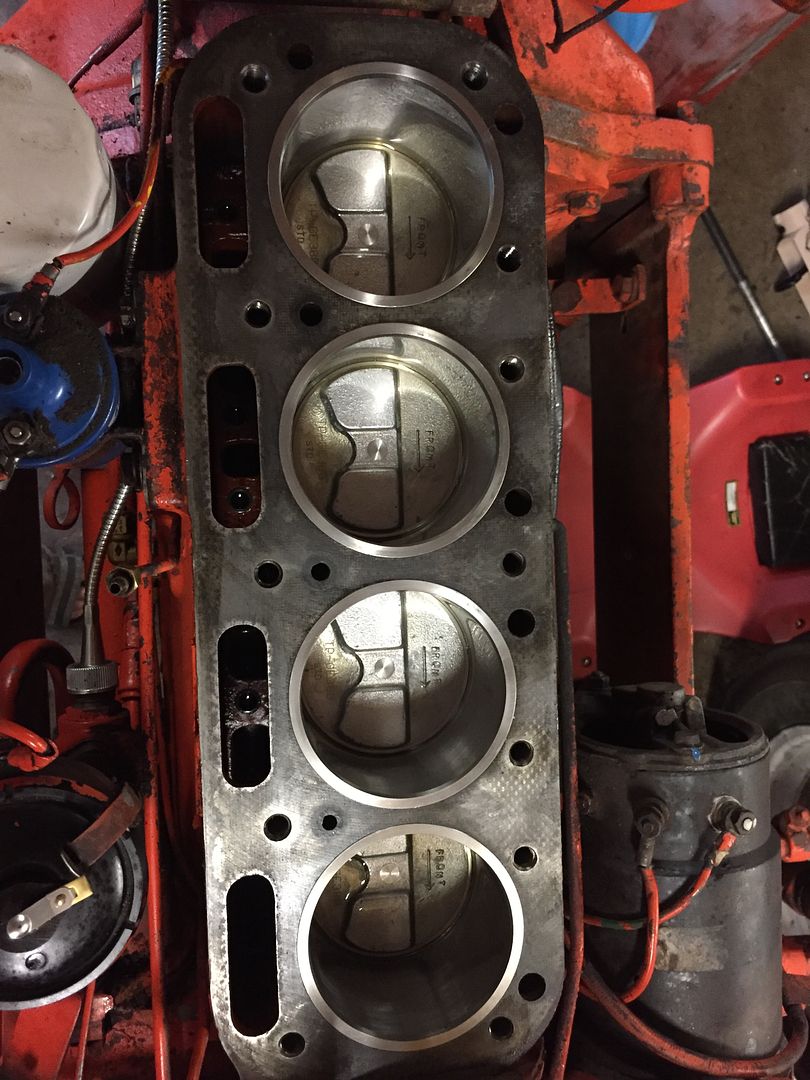

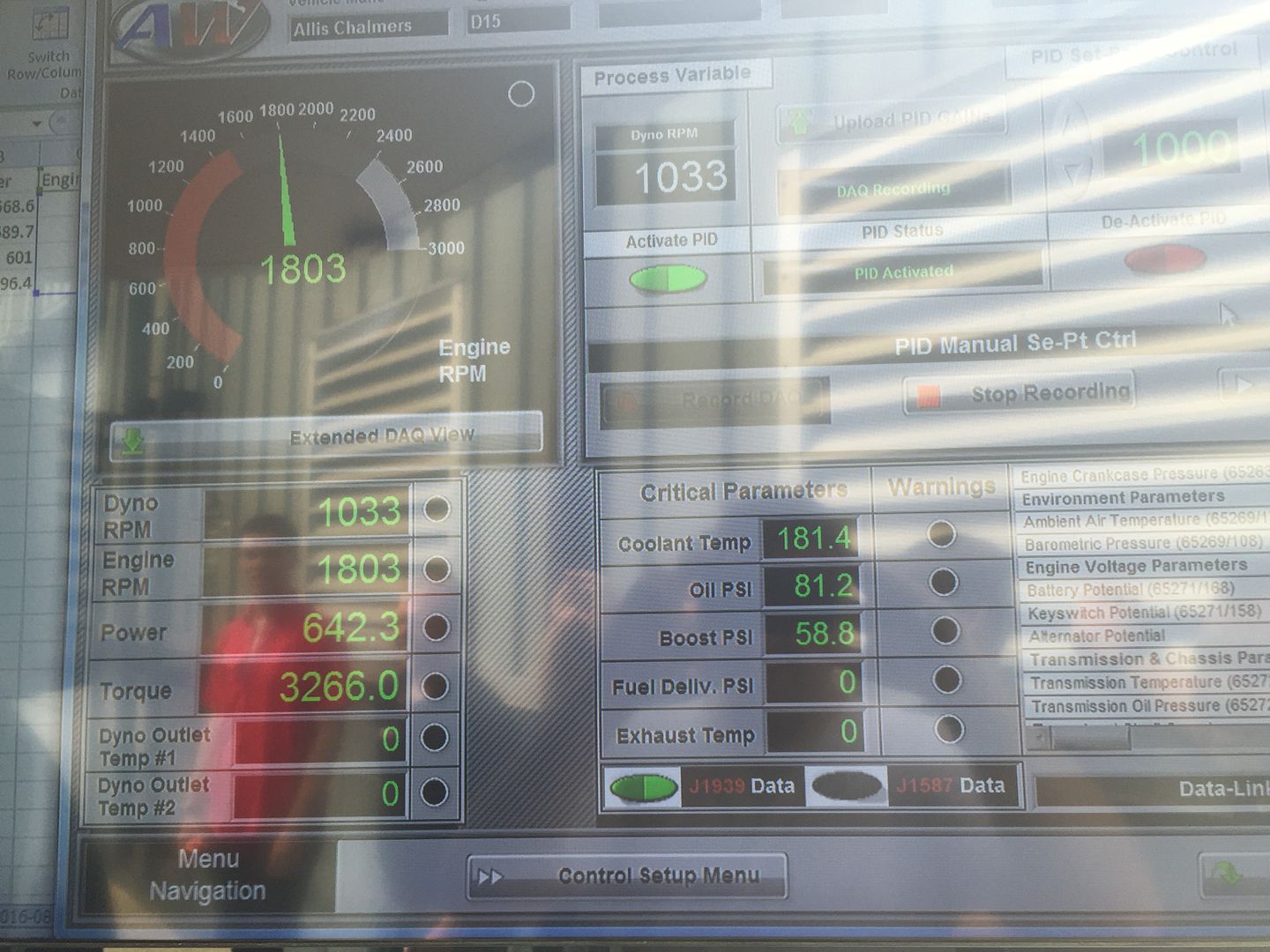

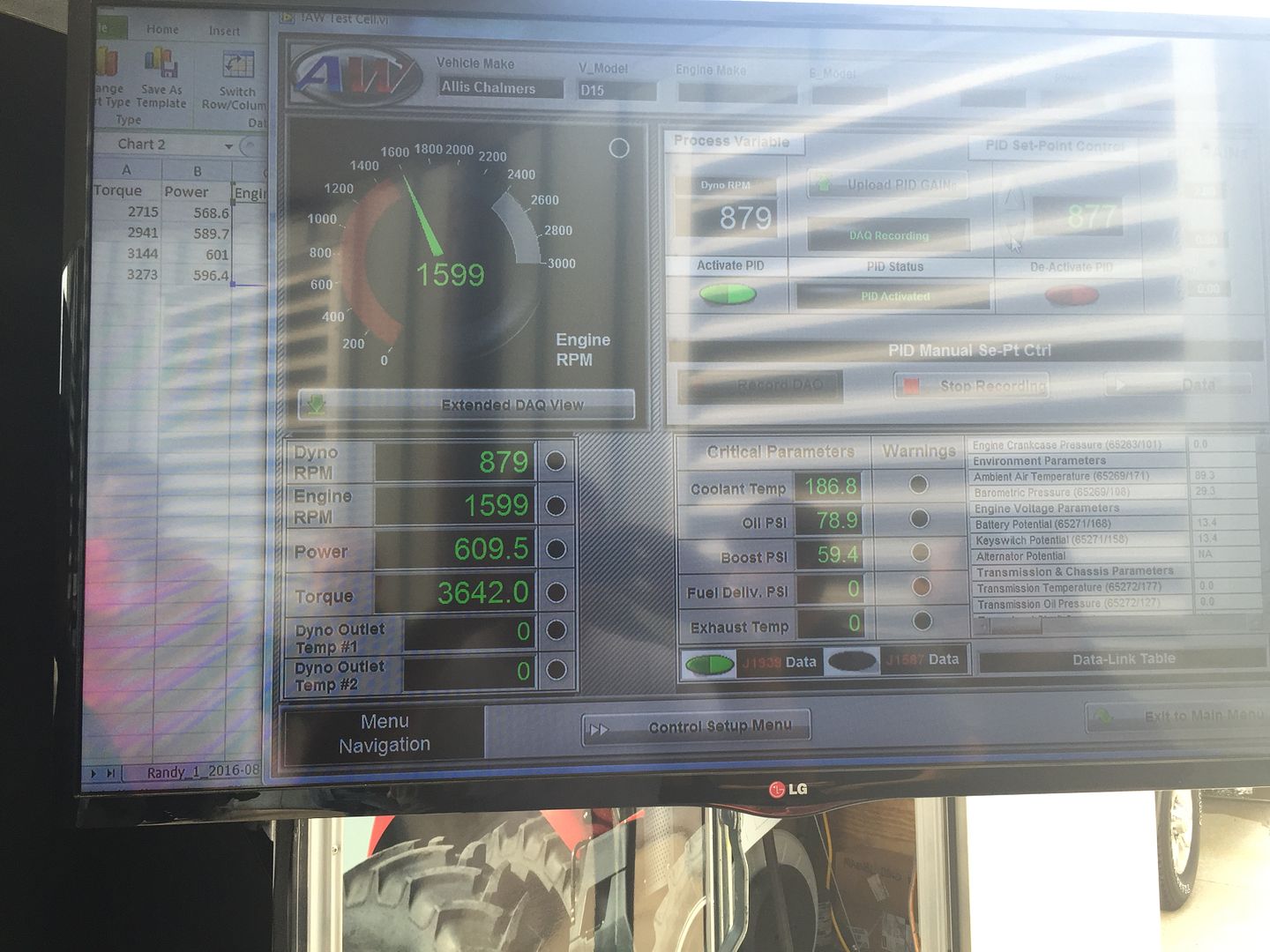

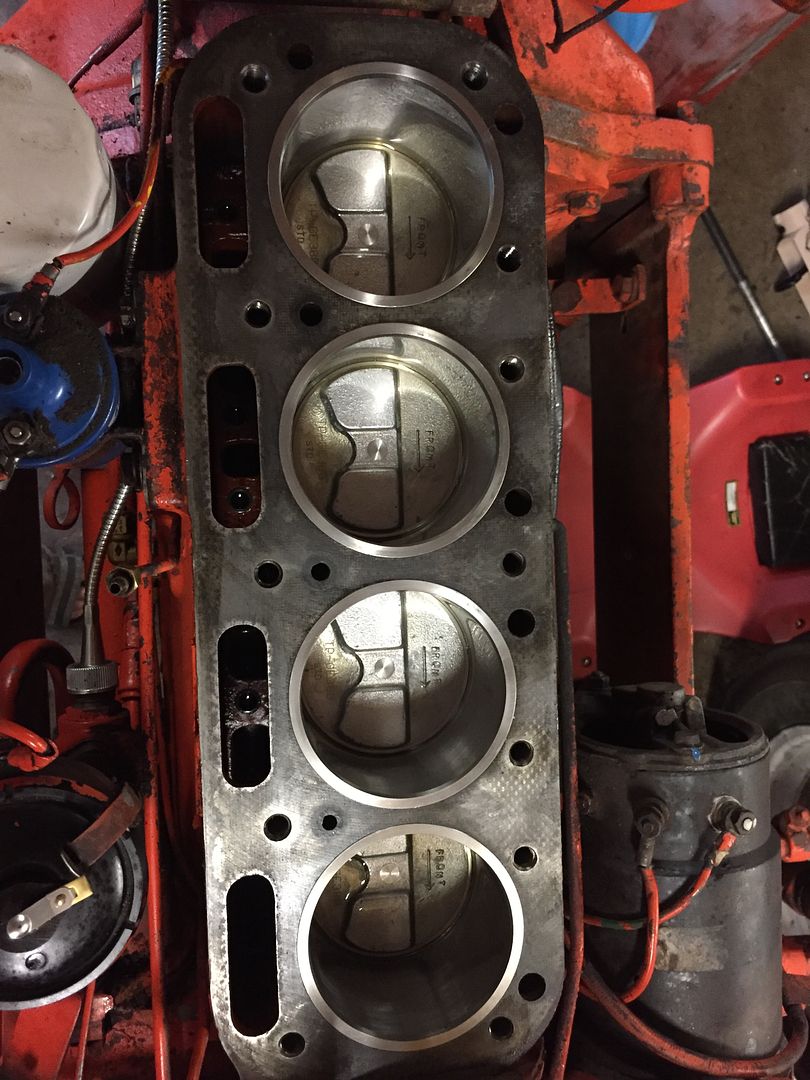

Well a little more progress. I got all my Pistons out and rods swapped over to the new Pistons. Incredibly the engine is very clean and show little to no wear on any of the bearings.  So far I only have 2 of the liners out and they are a bastard to get out. I made my own pulled but without a Torrington bearings the all thread binds up and I am using a steel rod from the underside to strike my puller base under the liner to get them to pop free.  And I have been working on the dyno that I have accessible to me to get it setup for a run in of the new motor. It's a bit big at 800 horse so it should hold whatever I throw at it with the D15!

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 7:46am Posted: 26 Aug 2016 at 7:46am |

|

Any suggestions on a break in process using the dyno? Basically I can set it to auto and take the tractor to full throttle and it will hold the PTO rpm I set it at by using load.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22307

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:22am Posted: 26 Aug 2016 at 8:22am |

|

Make sure you set the ignition timing with a timing light and at full throttle to the FIRE mark or F or F-25 whatever the flywheel is marked at. I always use lighter oil for break-in, like a 5W-20 or 5W-30.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13745

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:22am Posted: 26 Aug 2016 at 8:22am |

Hey BigRed,,,that is a great project you got goin there. Keep the pics coming,,,!! The new pistons you got, look to be the same design that were in the 149 I installed in my D14 Industrial Backhoe/loader. Did the vendor tell you what the compression bumped up to with the pop-up design?? I noticed in your pics, the driveshaft for the front mounted hydraulic pump is going to need some repairs, mine was bout that bad, and if you plan to re-install the pump,,PM me and I will give you a money savin alternative. Keep the pics comin,,,,

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:23am Posted: 26 Aug 2016 at 8:23am |

|

I know nothing about dyno's, but that is a cool looking unit!!

Great documentation! Like the picture of the ship in its work clothes too!

I agree that the status and progression pictures may just help another AC guy with a D15 project.

Lots of good resources on here too!

Don (MO) should be in your cell phone!:)

Regards,

Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:38am Posted: 26 Aug 2016 at 8:38am |

|

if this was my tractor i would vary the RPM and LOAD as opposed to just setting it to pto speed and running it for awhile, but there are varying opinions on this.

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:39am Posted: 26 Aug 2016 at 8:39am |

|

Good info thanks! Ill do some reports on what she does when I get her together, tuned a bit and hooked up to the "Judge" as we call our dyno.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:43am Posted: 26 Aug 2016 at 8:43am |

desertjoe wrote: desertjoe wrote:

Hey BigRed,,,that is a great project you got goin there. Keep the pics coming,,,!!

The new pistons you got, look to be the same design that were in the 149 I installed in my D14 Industrial Backhoe/loader. Did the vendor tell you what the compression bumped up to with the pop-up design??

I noticed in your pics, the driveshaft for the front mounted hydraulic pump is going to need some repairs, mine was bout that bad, and if you plan to re-install the pump,,PM me and I will give you a money savin alternative. Keep the pics comin,,,,

|

Joe, I wont be putting the pump back on the front. I am keeping the loader off of it. Yes the guy at Tisco that I talked to sad that the old crater pistons have not been offered for the last 11 years and everything has gone to the pop up style. As a FYI I was told that the compression with the new pistons is 8.75:1 vs the crater pistons 7.5:1. Plus these new pistons are 3.56 bore which I believe puts the G149 to 156 cubes as well.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 8:47am Posted: 26 Aug 2016 at 8:47am |

|

Joe,

Did you notice anything different in cranking speeds or load on the starter after you installed these pistons in your D14?

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 1:54pm Posted: 26 Aug 2016 at 1:54pm |

|

Guess I am late to the post here. Powermax makes the power crater pistons still. I am ordering a set for my d17 as soon as I get the crank issues sorted out. Jensales carries powermax and I think there is a vendor in here as well I just don't remember who. I know with the 226 motor you need to be careful alot of the aftermarket kits actually lower your compression.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13745

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 3:53pm Posted: 26 Aug 2016 at 3:53pm |

Hey BigRed,,,NAW,,,the original 149 engine was tore down when I bought the tractor,,so I have no clue bout the difference if any. I bought an engine from Iowa and it is the one that has the pop-up pistons, and is in the tractor as we speak,,,,I would of thought with that much difference in squish area would of bounced the compression up more than just one point,,but I didn't run the numbers before I lashed it up after the overhaul. Fact is,,,you've got me to thinkin,,and I may run a compression test on it just for funs,,,,

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 3:56pm Posted: 26 Aug 2016 at 3:56pm |

|

Joe most of the aftermarket pistons don't travel as high to leave valve clearance so the allis power crater design can give you higher compression or that is how I understand it.

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13745

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 5:36pm Posted: 26 Aug 2016 at 5:36pm |

Hey Dan,,I hear what you're sayin,,,but don't make sense to fashion a piston with the pop-ups, obviously to bump the compression ratio but then again with the flat head the 149's use, you would have to be very meticulous in verifying the piston/valve clearance,,which I did on mine,,,but can't remember what the clearance was but seems like it was way more than I would have wanted if I had bought those pistons with the idea of lookin for more horse power,,,,  I also intended to CC the total area of the combustion chamber for my curiousity,,and forgot that little tidbit,,,,,   Maybe ole BigRed will do all these checks to clear up some questions for us,,,hint,,,hint,,,,

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 5:37pm Posted: 26 Aug 2016 at 5:37pm |

Got her on the dyno today!  Look at the top of the pic. Decided to have a little fun with a 620 Stieger Quad Trac today.  Peak torque:

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13745

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 5:39pm Posted: 26 Aug 2016 at 5:39pm |

DANG,,,Big Red,,,,how many turbos did you strap on thet engine,,,,?????

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Aug 2016 at 6:22pm Posted: 26 Aug 2016 at 6:22pm |

|

It's a bone stock 620 with compound turbos. An absolute beast. Heated up 500 gallons of cold water on the dyno in the blink of an eye.

|

|

patrickmull

Orange Level

Joined: 11 Jan 2011

Location: Casey IL

Points: 893

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 7:04am Posted: 27 Aug 2016 at 7:04am |

|

looking good

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 3:39pm Posted: 27 Aug 2016 at 3:39pm |

Well she's back together and runs like a charm. My friend cut the valves, seats, and ported the heads last night and I got her all together today and tried her. Popped right off.   I'll have a video of it running in a little bit.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Aug 2016 at 10:02pm Posted: 27 Aug 2016 at 10:02pm |

Video of the second start after I adjusted valve lash. I am bumping the engine rpm up and down checking for hesitations. Prior to the build the throttle response was nowhere near this snappy. https://youtu.be/uaKb7YodlL8Hoping to be able to dial in the timing, and mixture adjustments tomorrow as well as swap from 295 Autolites to 303's. If I am correct I believe the 303's are colder than the 295's.

It's kind of weird to hit the key and not have a ton of smoke pour out if it.

Edited by bigredisb - 27 Aug 2016 at 10:10pm

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 2:35pm Posted: 28 Aug 2016 at 2:35pm |

|

You have a nice piece of family history and looks like you are going to keep it in the family so my hat is off to you. Just a word to the wise, Tisco pitons are known for burning tops of the pistons if you put to much timing into them. If you power tune for top horse power please don't go over 25* total timing in her.

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 4:52pm Posted: 28 Aug 2016 at 4:52pm |

|

That's good info for sure. I am not going for all out power. Just dependable and clean running tune. I will admit today was timing day and I was a bit bewildered for a little bit as I couldn't find any f marks on the front pulley! I did find it in the bell housing hole so life is good. It was set about 6 or 7 degrees retarded. I turned the dizzy until "F25" at wot was clearly visible in the window. The engines tone is much deeper at this setting especially at idle and the exhaust flow seems much higher as the rain cap used to bang and clang up and down with the timing retarded. I ended up giving a little more fuel on the idle and fast speed mixture screws as well to smooth her out a bit. I put points in it a year ago but I am not certain I had it at tdc and rocking the dizzy to verify they were just opening so I may need to redo that. It starts great with no kicking and runs smooth all the way through the rpm range.

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 5:42pm Posted: 28 Aug 2016 at 5:42pm |

|

You should check the timming again at full throttle. I know on the 160 gas motor it is critical that you time it at full throttle not idle.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 8:09pm Posted: 28 Aug 2016 at 8:09pm |

|

Yes I checked it at full throttle. That's what I meant with my acronym of "wot" or wide open throttle.

I also took the dizzy apart and cleaned and lubed the advance mechanism as well.

Just got done servicing the wheel bearings as well. They looked good but one was way out of adjustment (loose).

I also just ordered some decent copper plug wires from a guy that posts on here (bb electric or something like that).

Also got my bottomless toolbox off. All of the carriage bolts that pass through the tool box were spinning so I welded nuts to the heads to get them out as well as welded up some random holes in the sheet metal up front from what appears to have been wire routing for random lights.

Edited by bigredisb - 28 Aug 2016 at 8:12pm

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 10:07pm Posted: 28 Aug 2016 at 10:07pm |

|

Any of you guys have a D15 hydraulic pump you are willing to separate from? The lift has always been really "ratchety" if that makes any sense. Feels like of the 4 Pistons isn't moving oil but it still has plenty of lift power and kicks off from pressure at the top of the lift stroke easily. Just seems way to jerky in its lift but maybe it's normal?? This tractor has been that way from the day we got it so I just figured it was normal.

|

|

Dan73

Orange Level

Joined: 04 Jun 2015

Location: United States

Points: 6054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 10:12pm Posted: 28 Aug 2016 at 10:12pm |

|

Are you getting water in the oil? Almost sounds to me like a pump fighting water issues.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2016 at 10:28pm Posted: 28 Aug 2016 at 10:28pm |

|

No signs of water in the oil. I changed it a year ago and didn't find any obvious signs of metal in it either. After it has ran a while the oil is still a nice Amber color not milky at all.

|

|

bigredisb

Silver Level

Joined: 16 Aug 2016

Location: Racine WI

Points: 185

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Aug 2016 at 10:15am Posted: 29 Aug 2016 at 10:15am |

Also looking for some advice on what paint I need to be using. Persian Orange 1 or 2 for a 61? Found this great post but not sure what colors I should be using other than Crème: Paint codes

Edited by bigredisb - 29 Aug 2016 at 10:16am

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Alberta Phil wrote:

Alberta Phil wrote: