| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Hydraulic Pump - PLEASE SEE MAR 1, 2020 POST Topic: Hydraulic Pump - PLEASE SEE MAR 1, 2020 POST

Posted: 13 May 2010 at 5:03pm |

|

My D14 has a crank-driven hydraulic pump for its FEL. Pump case is labeled "Vickers Vane Pump". I can make out what looks like a model #: V235-6-1A-12. I'm curious as to the specs for this pump - have tried several searches with no joy. Can anyone suggest a good source for information? Thanks much.

Edited by Dave(inMA) - 01 Mar 2020 at 8:33am

|

|

WC, CA, D14, WD45

|

|

|

Sponsored Links

|

|

|

M Diesel

Silver Level

Joined: 26 Feb 2010

Location: Las Vegas

Points: 128

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 5:29pm Posted: 13 May 2010 at 5:29pm |

|

The older Vickers vane pump models are kinda gone. Eaton makes the brand now and has them listed on their web site, but nothing about the older units. I haven't tried contacting them yet so there may be hope?

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 6:07pm Posted: 13 May 2010 at 6:07pm |

|

I'm trying to find a source for gpm and psi for that pump. Been on the Eaton site and can't find a model with anything like V235. But someone out in Orange Land will likely know!!

|

|

WC, CA, D14, WD45

|

|

E7018

Bronze Level

Joined: 07 Dec 2009

Points: 167

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 8:57pm Posted: 13 May 2010 at 8:57pm |

|

It may be the "6" that designates volume. 6 gallons per minute at 1200 rpm. Those had maximum pressure of 2000 psi.

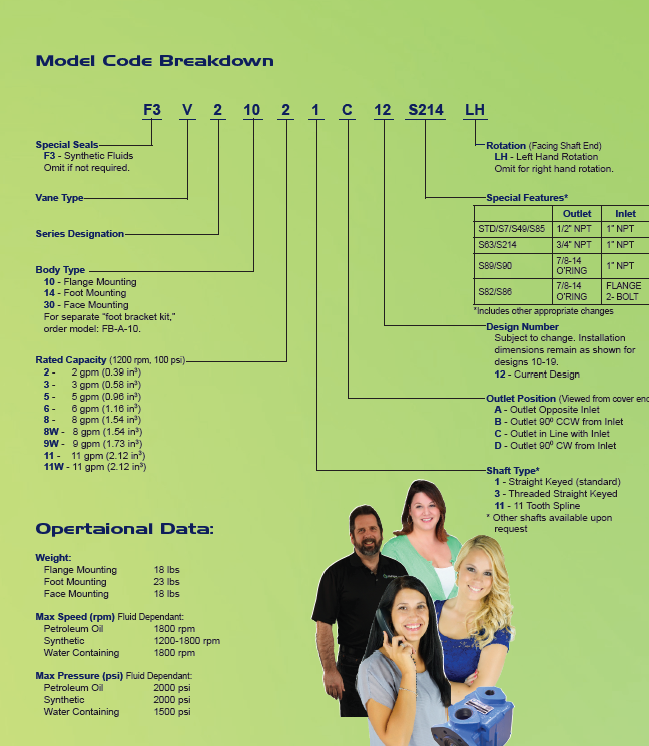

V is for vane, 2 is for series, 35 is for mounting configuration, 6 is for gpm @ 1200 rpm, 1 is for keyed straight shaft, A is for outlet opposite inlet, 12 is a design number.

Any of that right?

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 9:03pm Posted: 13 May 2010 at 9:03pm |

|

That's interesting - how do we verify? Thought I saw some potentially useful info on the Eaton site, but not sure how to apply it.

|

|

WC, CA, D14, WD45

|

|

E7018

Bronze Level

Joined: 07 Dec 2009

Points: 167

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 9:13pm Posted: 13 May 2010 at 9:13pm |

|

That pump has some age to it. Maybe put on that tractor when it was pretty new. What I found is from a Baum Iron company book from 1987. Those pumps had a center cast piece where the vanes are, that is what does the pumping. The thickness of that section is how to tell volume.

You can look around Baum hydraulics website but they don't sell Vickers anymore.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 9:58pm Posted: 13 May 2010 at 9:58pm |

|

Thanks - I'll check that out - I found their tel # and call them to see if they have any data or can confirm what you found. I don't know when the pump was installed on the tractor - might have been one that someone had on hand, or maybe it was installed in the 1980's, consistent with your book. I just checked the input/output connections - they're both on the top of the pump case.....so maybe "A" means something else!

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 May 2010 at 10:25pm Posted: 13 May 2010 at 10:25pm |

I just found an out-of-print document on the Eaton site that describes the Vickers 200 series vane pumps! This document includes a "decoder ring" for the "model #" I listed in my first post, but there are more positions in the string than I listed - will have to look further tomorrow. But it seems clear that the "6" refers to gpm at 1200 rpm. Here's the link for anyone who wants to check this out: http://hydraulics.eaton.com/products/pdfs/m2000s.pdf

Edited by Dave(inMA) - 13 May 2010 at 10:25pm

|

|

WC, CA, D14, WD45

|

|

rasman57

Silver Level

Joined: 12 Sep 2009

Location: Illinois

Points: 411

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2010 at 1:09am Posted: 14 May 2010 at 1:09am |

Dave,

I will be interested in finding out what you discover and how you go about getting your D-14 FEL going again. My 1960 D-14 with a Superior loader also has a very old crank driven pump. Mine is working great but you never know..... I am not able to look at mine as it is "up north " in Michigan and I am at home in IL but I bet the pump setup is close if not the same. Good Luck.

|

|

bigfish_Oh

Orange Level

Joined: 13 Sep 2009

Location: West Liberty,Oh

Points: 1226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2010 at 1:32am Posted: 14 May 2010 at 1:32am |

|

My D14 backhoe also has a crank driven pump. I am thinking Dad put a new one on, but I am curious now, if it is not guarded to much to see.

|

|

1941 WC sat for 29 years,started & dynoed 27 h.p.

1957 WD45 Grandpa bought new,factory p.s.,added wfe

1951 WD, factory p.s.

1960 D14 HnMk IV BkHoe 4 sale

2014 HD Tri Glide

2009 GMC CC SLT Dually

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 May 2010 at 5:56am Posted: 14 May 2010 at 5:56am |

|

Yep - another interesting project! This one could be as small as sorting out what sort of cylinder I need on the bucket or as large as a significant rebuild of the FEL frame, upgrade to 2-way cylinders on the lift arms, or.....

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2020 at 2:08pm Posted: 29 Feb 2020 at 2:08pm |

An update to this thread 10+ years later! And corrected calcs for force.

I still haven't updated the FEL hydraulics on my D14 as it continues to function. I think it's time to address the issues that need attention:

1. The hoses are developing cracks due to age and weathering. 2. There are slow leaks at several points; one in particular is leaking enough to create a 24" stain on the ground if the tractor sits for a few weeks. 3. The hydraulic control unit has always been sloppy and is slowly getting worse. And it's one of the leak sources. 4. The cycle time for the double-acting bucket cylinder is v-e-r-y slow.

Now to what I am thinking to do. I'd really appreciate your input on this since hydraulic systems are new to me.

The FEL, including the hydraulic system, is a home-built arrangement. Which explains why various parts of the hydraulic system are welding to the FEL frame. Which complicates removing parts for repair. The good news is that the hydraulic control unit is bolted onto a plate and can be removed easily. And the bucket cylinder is easily removed.

Tackling the slow cycle time for the bucket cylinder first...the outer diameter of the cylinder is ~ 4", suggesting a cylinder bore of ~ 3.5". The shaft diameter is 1.5", and the stroke is 20". The very old pump on the tractor is putting out 5 gpm (rather than the 6 gpm noted in my original post). I found a nifty calculator on the web that computes the cycle time for this cylinder:

Per this calculator, the cycle time for this cylinder is 18 seconds - on a good day when the control unit is working well. Which is hardly ever. If I replace the cylinder with one with, say, a 2" bore and a 1.25" shaft, cycle time drops to 5.3 seconds. I THINK that this cylinder would be adequate as all it does is to dump the bucket (gravity assisted) and then retract the bucket. Assuming that the pump is putting out its rated 1,000 (minimum - see p.s.) psi, then the current cylinder is capable of moving 9,600# (which feels like massive overkill); switching to the proposed cylinder cuts this to 3,100# (which might be undersized). Comments on this?

The most noticeable problem with the control unit is that I have to hold the control handles in just the right orientation for hydraulic fluid to flow. There's a lot of slop in the rods that slide in/out of the unit. It's also leaking - likely around the rods. Is this repairable or am I better off to look for a replacement unit?

I will also work on replacing the hoses and eliminating leaks. In all but one case, I suspect that new fittings and threaded ports will help a lot! One leak may require cutting the oil tank loose from the loader frame - if JB Weld doesn't cure it.

Thanks for any suggestions or comments! Dave p.s. I tracked down an out-of-print overhaul book on Eaton's website which applied to Vickers 200 (among others) series vane pumps....from which it appears that the max psi from the pump on this tractor is 2,000. I could be wrong as the "decoder ring" entries in the book differ from the markings on the pump. I also found a book entitled Hydraulic Pumps and Motors and Their Applications which indicates that the Vickers 100, 200, 300, etc series pumps operated between 1,000 and 2,000 psi.

Edited by Dave(inMA) - 01 Mar 2020 at 8:07am

|

|

WC, CA, D14, WD45

|

|

JK in Pa

Bronze Level

Joined: 12 Sep 2009

Location: Dushore, Pa.

Points: 164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2020 at 2:45pm Posted: 29 Feb 2020 at 2:45pm |

|

I installed a Vickers Vane pump on my WD many years ago. As I recall the model was V2013something. I know it spect at 13 gallons per minute at 1200 rpm and 2200psi. Worked out perfectly for my needs. Surplus Center offers I suspect Chinese pumps identical to the Vickers brand at half the price. Hope this helps.

|

|

Dave (Mid-MI)

Orange Level

Joined: 12 Sep 2009

Location: Hemlock, MI

Points: 566

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2020 at 4:10pm Posted: 29 Feb 2020 at 4:10pm |

|

Sounds like you are going in the right direction with the bucket cylinder. That should be plenty of capacity. I am assuming that the control unit is a 2 spool valve. The spools are usually held centered by springs and sealed by O-rings. You can removed the spools and replace the O-rings. You will need a small pick, like a dental tool, to remove the O-rings. A bearing or packing vendor should be able to match them with new ones. Re-install the spools carefully, with lots of lube, to prevent damaging the new O-rings.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24658

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2020 at 5:35pm Posted: 29 Feb 2020 at 5:35pm |

I found a V200 PDF using google.... 6 GPM @2000PSI this after I rebuilt my Samsung freebee 24" monitor, screen works better when the PSU is fixed.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54067

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2020 at 5:37pm Posted: 29 Feb 2020 at 5:37pm |

Another good source for Hyd help is the tech pages at surpluscenter.com. They also sell components, you never know what will show up in their stock...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Feb 2020 at 6:22pm Posted: 29 Feb 2020 at 6:22pm |

Thanks, all of you for your help. Nice to know that I'm heading in the right direction!

Based on what I found in the Eaton document, the V200 series came in many different configurations. 6 gpm would readily be one of them....as would 5. Depends on what's stamped into the pump housing.

But I'd love to see that pdf, Jay, if you still have it.

|

|

WC, CA, D14, WD45

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2020 at 8:06am Posted: 01 Mar 2020 at 8:06am |

I realized this morning that my calculations for the force exerted by a hydraulic cylinder were incorrect. I've updated my Feb 29 post to correct the numbers...here are the right results:

A. Current cylinder (3.5" bore, 1.5" piston, 1,000 psi): 9,600 lbs dump, 7800 retract. B. Proposed cylinder (2" bore, 1.25" piston, 1,000 psi): 3,100 lbs dump, 1900 retract.

I'm thinking that cylinder B is fine to dump the bucket but may not be enough to retract/hold the bucket. The bucket if completely filled will hold about 0.4 cubic yards. 0.4 cubic yards of pea stone would weigh about 1,100 lbs.....not that I have ever tried to lift such a load. A comparable amount of wet snow (more like I use it for) weighs about 225 lbs.

I'd appreciate any thoughts on this.

Thanks! Dave

Edited by Dave(inMA) - 01 Mar 2020 at 2:29pm

|

|

WC, CA, D14, WD45

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2020 at 5:28pm Posted: 01 Mar 2020 at 5:28pm |

|

I would recommend staying with the larger bore cylinder. It is not only the weight of what is in the bucket you are holding, the bigger load is the breakout force (leverage) needed to roll the bucket up when you are pushing into a pile, rolling the bucket up and lifting up as you fill the bucket. The breakout force needed is usually much higher than what it takes to hold the full bucket, once lifted clear of the pile.

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Mar 2020 at 9:12pm Posted: 01 Mar 2020 at 9:12pm |

|

Good point, Jim. Thanks. I hadn't thought about that. I'm wondering if the slop in the control valve is the cause of the poor extend/retract performance???

|

|

WC, CA, D14, WD45

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2020 at 10:32am Posted: 02 Mar 2020 at 10:32am |

|

Slop in the control handle? Is the spool moving full stroke? Do the spools center to neutral ok? You can repair slop in external linkage, which might be preventing full stroke. Some valves have external seals, of some type, which can be the source of external leaks. If you think it is leaking internally about the only fix is replacement, spools are usually fitted to the valve body bores during manufacture, no internal seals. Having to "hold the control handles in just the right orientation for hydraulic fluid to flow" would be an indication to me a new valve is in order. What size are the hoses/tubes going to the cylinder? Small internal diameter hoses, tubes, and fittings can slow things. Are you checking cycle time at, at least PTO speed?

When was the cylinder last repacked? The sealing arrangement on the piston may be getting weak and bypassing. Just some thoughts

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24658

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2020 at 10:46am Posted: 02 Mar 2020 at 10:46am |

|

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2399

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2020 at 10:05pm Posted: 02 Mar 2020 at 10:05pm |

In addition to posting the decoder ring page, Jay sent me the entire booklet. Great people on this forum indeed!

Dave

|

|

WC, CA, D14, WD45

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)