| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Morpar55

Bronze Level

Joined: 01 Nov 2021

Location: Indiana

Points: 116

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Help needed with valve identification Topic: Help needed with valve identification

Posted: 04 Nov 2021 at 6:46pm |

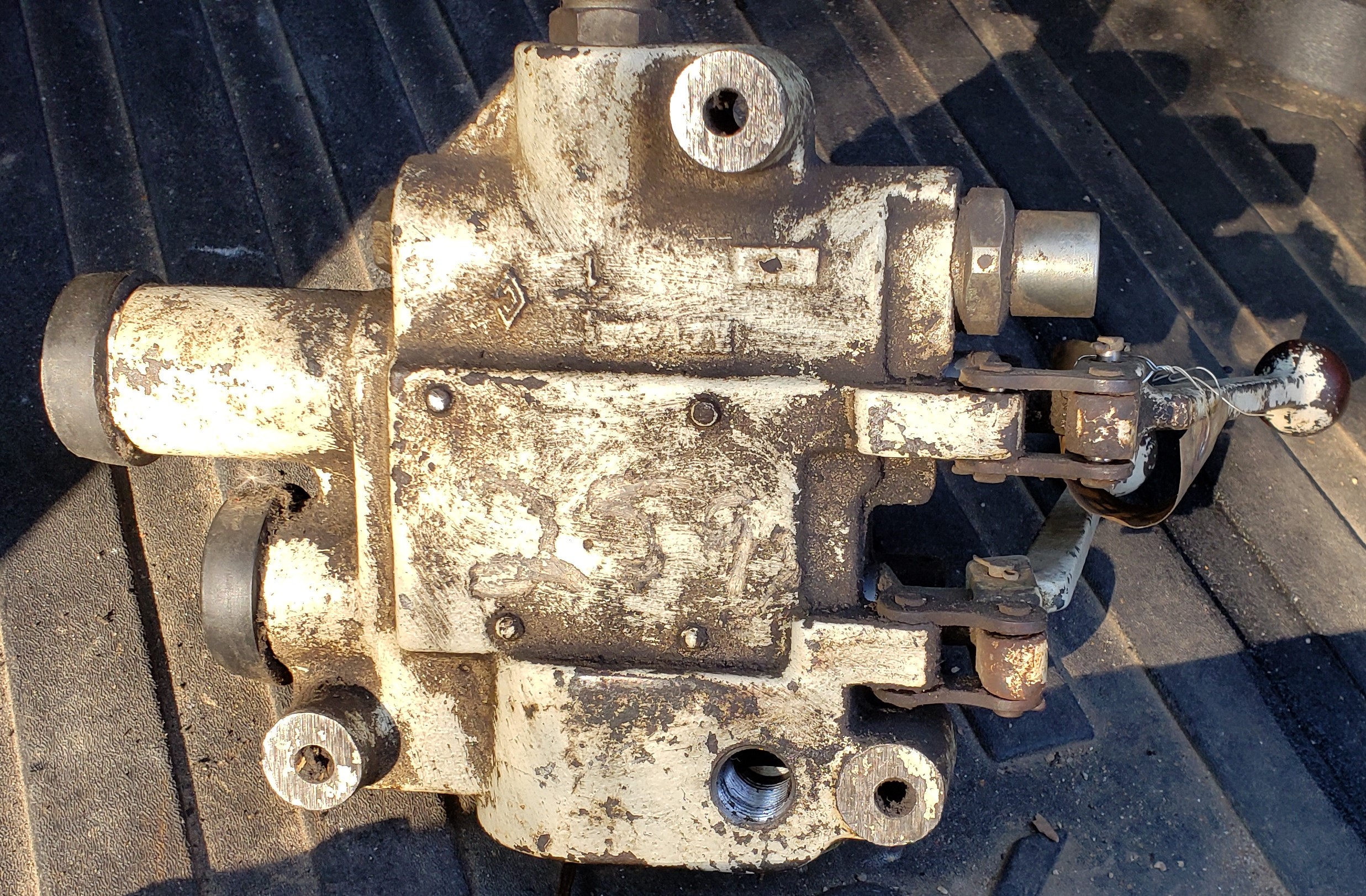

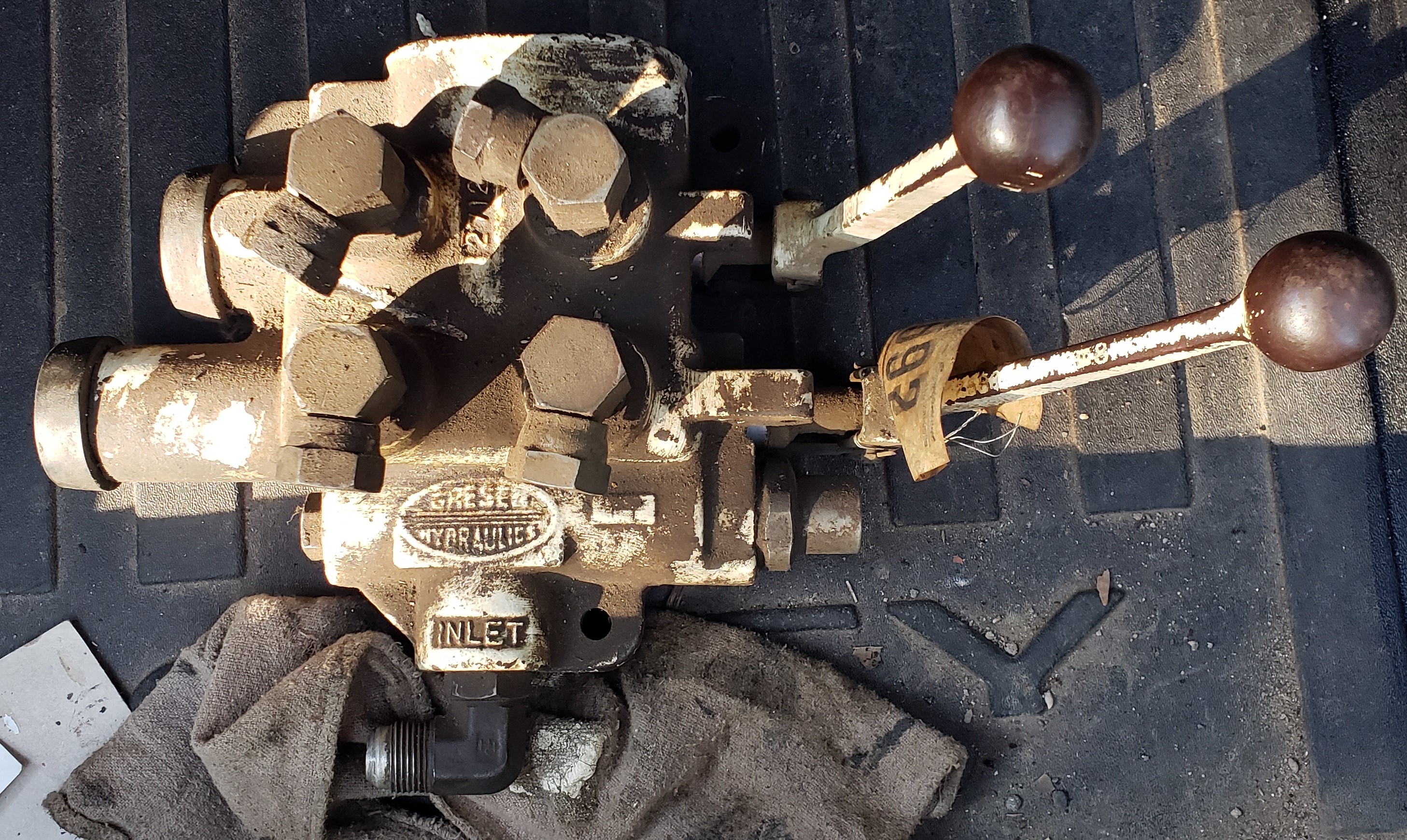

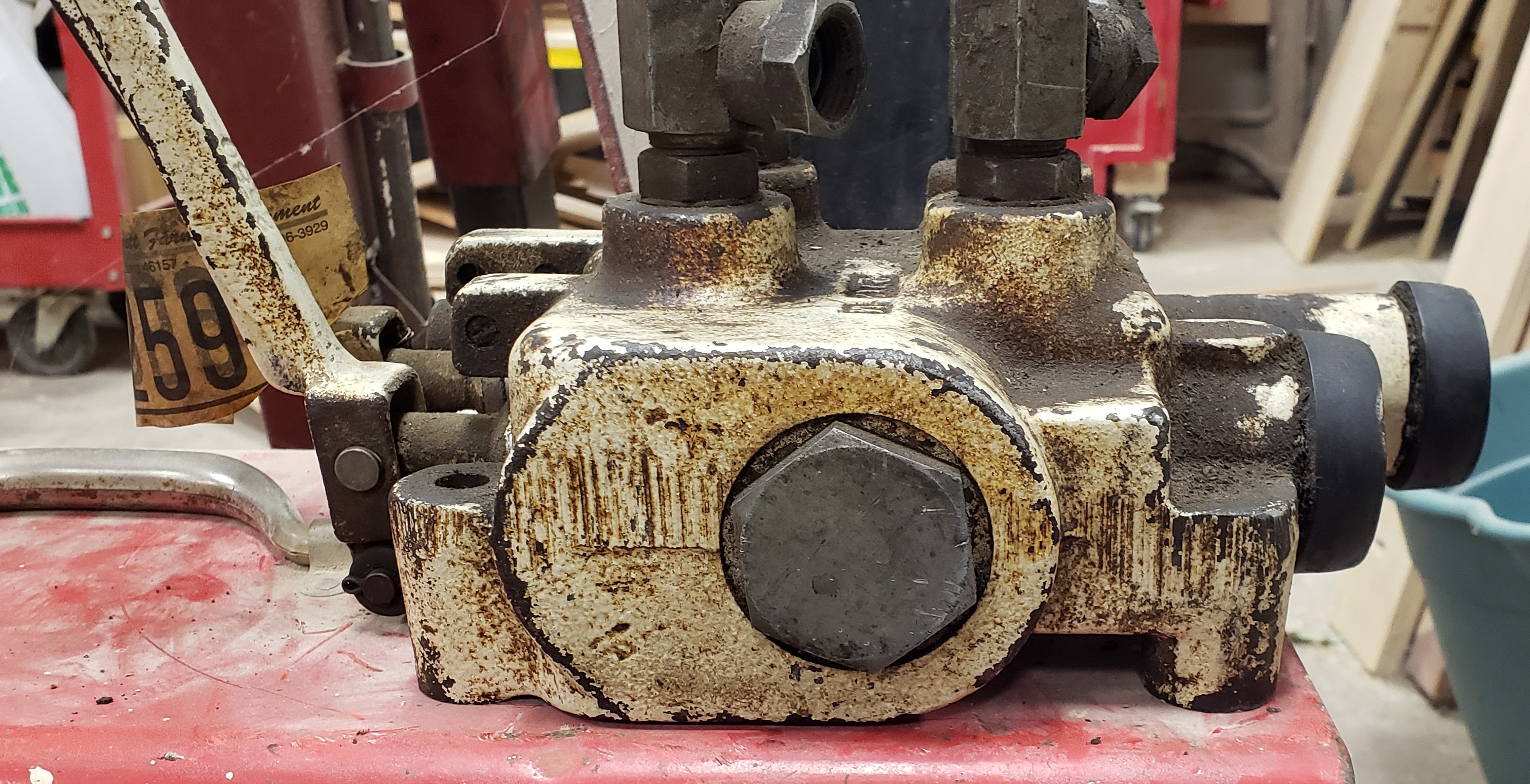

Good evening all! I went to the "local" tractor bone yard this afternoon and hopefully found a deal on a control valve for my loader. The only issue is other than the name and part number I can't seem to find any information about this control valve. I know it is a 2-spool Gresen 2712 M, it has a float option, and it is white. Past that I have no other clue as to what I have! Does this valve have the ability to control the system pressure up to what the pump can supply? And how many GPM is this valve capable of flowing? If someone can point me in the right direction for where to find these answers and more I would really appreciate it.

|

|

1959 AC D17 Gas with some updates

|

|

|

Sponsored Links

|

|

|

Morpar55

Bronze Level

Joined: 01 Nov 2021

Location: Indiana

Points: 116

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Nov 2021 at 6:49pm Posted: 04 Nov 2021 at 6:49pm |

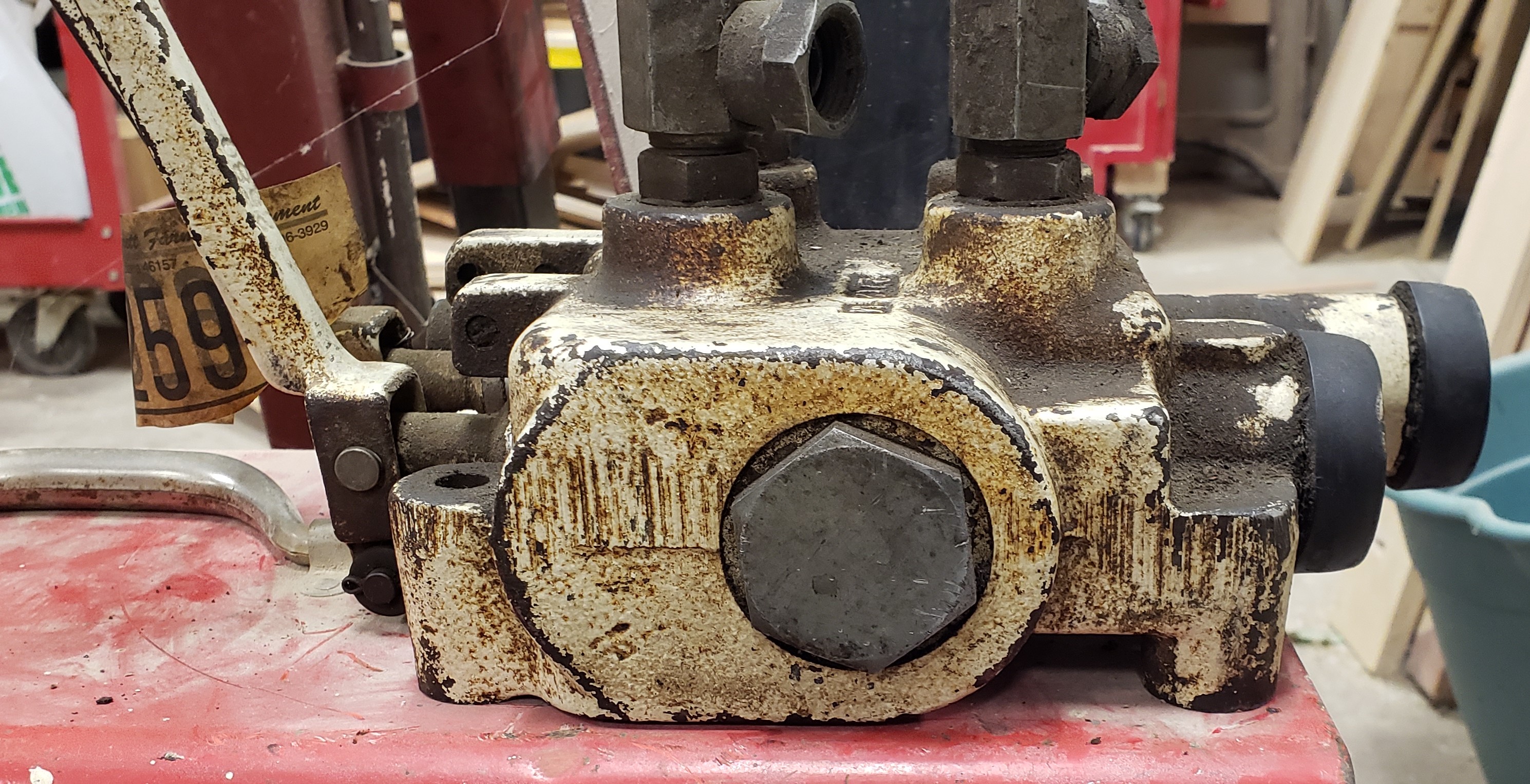

And here is the underside if it helps.

|

|

1959 AC D17 Gas with some updates

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20783

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Nov 2021 at 7:02pm Posted: 04 Nov 2021 at 7:02pm |

|

Also has to be an "open center" design valve for the system you are building. Cannot be a closed enter valve.

The size of the connections for the hoses will surely handle 10-12 GPM, and that is the size of pump you want.

Edited by DrAllis - 04 Nov 2021 at 7:05pm

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 52012

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Nov 2021 at 4:44am Posted: 05 Nov 2021 at 4:44am |

Found this post on tbn, by searching google gresen 2712.

Searched again, jd 3020 specs, found out its a cc valve, so, you are out of luck, sorry.

Suggest you look for an OC 2 spool, 12GPM valve at surplus center...

Edited by DiyDave - 05 Nov 2021 at 4:51am

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 4721

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Nov 2021 at 7:02am Posted: 05 Nov 2021 at 7:02am |

|

If you end up buying a new control valve, I would definitely recommend going to a single lever joystick valve !

|

|

Morpar55

Bronze Level

Joined: 01 Nov 2021

Location: Indiana

Points: 116

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Nov 2021 at 7:48pm Posted: 05 Nov 2021 at 7:48pm |

Okay, I am really confused here. I found the same article mentioned when I Googled "Gresen 2712 valve" and read it. Twice since it seemed to make some sense, but not much since I know squat about any tractor other than my D17 (and not a ton about it!). Keep in mind my hydraulic specific knowledge is low, but I am very comfortable with pneumatics. And when I went through Cobra mechanic school at Ft. Eustis a lifetime ago they covered them both under the term "pneudraulics". So as I am used to dealing with pneumatics an open center, 3-position valve when in the center position blocks incoming pressure and connects both sides of the actuator to the exhaust (or return in hydraulics), allowing the cylinder to move freely by outside forces. We use these at work in any area where an associate can easily interact with a clamp to make sure they can't get injured. A closed center, 3-postion valve will stop and hold the cylinder (with pressure on both sides) whenever the valve is shifted to the center position. We use these sparingly inside the lines where associates normally aren't working to make sure clamps and shifts stay where we want them. So with this in mind shouldn't a closed center valve be the choice here for a loader? What is it I am missing? And since this valve came off a working tractor how did it work anyway? Lastly, once someone explains to me why I am wrong (because I am sure I am, I just don't understand why) what do I need to look for when I take this valve back and exchange it for another one? And last, is there a way to easily make this valve work with the system I am building? Sorry if this sounds like I am being an a**, that is not my intention. I'm just completely confused on why this won't work. I already appreciate the help I have gotten so far. Thanks, Chris

|

|

1959 AC D17 Gas with some updates

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20783

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Nov 2021 at 9:33pm Posted: 05 Nov 2021 at 9:33pm |

|

The hydraulic pump you intend to use moves oil whenever it is turning. If you have a 12 GPM pump at 2,000 RPM, it will draw oil from the sump, deliver it to and THRU the valve and return the oil to sump and start all over again. The fluid travels thru the valve under very little pressure all the time the engine runs. When you activate the control valve to do work, the pressure rises to whatever it takes to lift the load. If the pressure reaches and then exceeds 2,000 psi, the built-in relief valve opens allowing the fluid to escape back to the sump to protect the hydraulic pump. The key here is the oil never stops flowing and that's why it is called an open-center system. A closed center system has the pump provide oil to the control valve and when it builds up 2,000 psi, the pump de-strokes or shuts itself off, while still maintaining this 2,000 psi of pressure between it and the control valve. No oil is moving. The pump protects itself by shutting down the oil flow. So, the difference between the systems is constant oil flowing versus oil pressurized and not flowing, but ready to go to work when the demand is there.

|

|

rw

Silver Level

Joined: 28 Oct 2009

Location: United States

Points: 384

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2021 at 9:07am Posted: 06 Nov 2021 at 9:07am |

So with this in mind shouldn't a closed center valve be the choice here for a loader? What is it I am missing? To me it seems there is different focus to open center/closed center valve when working with pneumatics vs. hydraulics. Hydraulics focus their description on the power side and pneumatics focus on the work side. This might be the source of confusion.

Open center or closed center hydraulics refers to the "pump to valve to reservoir circuit", as Dr explained. The type of hydraulic pump and valve are a system, must be matched.

The pneumatics as you describe seems to be more focused on the the cylinder and its exhaust. I suspect this is the focus in pneumatics due to being able to dump into atmosphere, where as the oil must be cycled back to a tank.

So as I am used to dealing with pneumatics an open center, 3-position valve when in the center position blocks incoming pressure and connects both sides of the actuator to the exhaust (or return in hydraulics), allowing the cylinder to move freely by outside forces. This describes about the same function as a hyd valve in 'Float' position. Both sides of the cylinder are open to the tank. As when back dragging with a loader bucket, letting the front wheels stay on the ground and the bucket floating over the surface.

A closed center, 3-postion valve will stop and hold the cylinder (with pressure on both sides) whenever the valve is shifted to the center position. This describes a hydraulic valve in the hold position. Oil would be held on both sides of a double acting cylinder and in the case of a single acting cylinder (one hose) the load side of the cylinder.

Some hydraulic loader valves can be converted from open center to closed center so keep that in mind as a possibility. Parker acquired Gresen and I have been able to get parts for Gresen recently. The link below touches on converting them.

As always lots to learn, new solutions being developed all the time.

|

|

Morpar55

Bronze Level

Joined: 01 Nov 2021

Location: Indiana

Points: 116

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2021 at 5:07pm Posted: 06 Nov 2021 at 5:07pm |

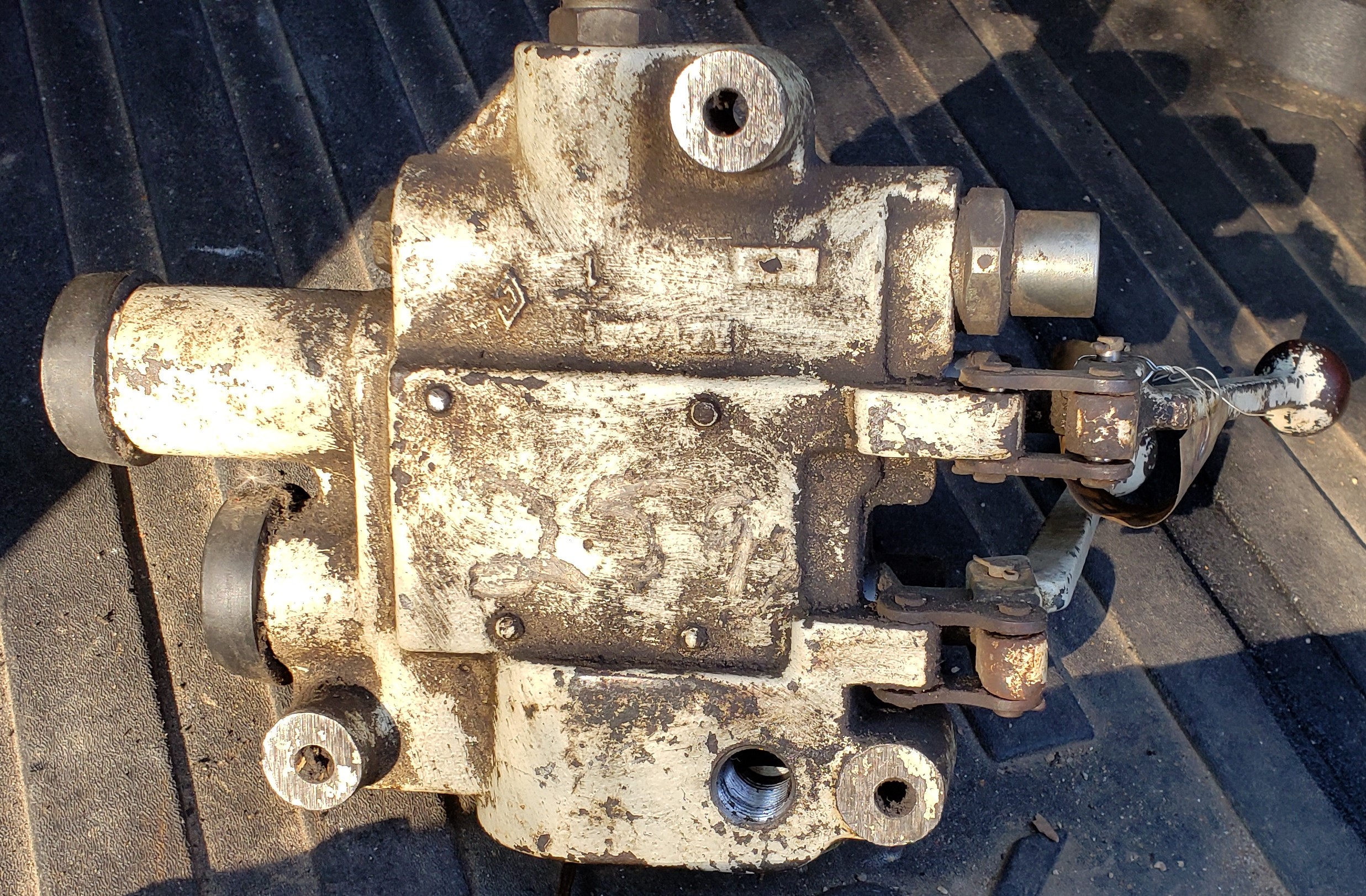

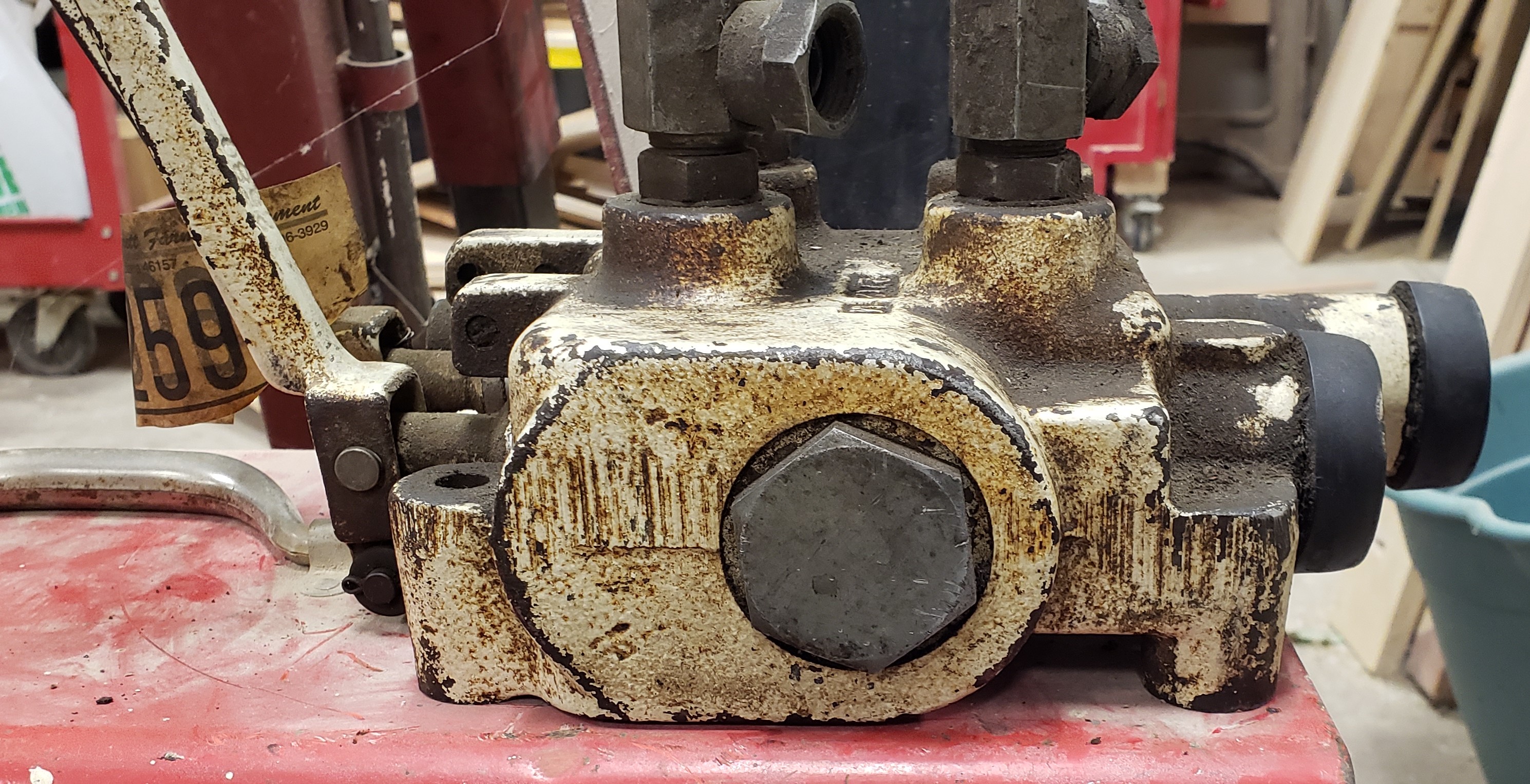

So I spent some time today going through different information about my valve, and I have yet another question. According to the document from Tejas Hydraulics these Gresen valves are all designed to be open center and can be converted to closed center with a plug. Well, when I looked at the valve a little more this afternoon I found what appears to be a big plug on the end where the fluid would return to the sump. If I take this out will I be able to make the valve work for an open center system? The diagram in the document referenced above makes me think it is, but I don't want to screw this up when I can still return it for another valve. Here is a picture of it:

|

|

1959 AC D17 Gas with some updates

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 4721

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Nov 2021 at 6:14pm Posted: 06 Nov 2021 at 6:14pm |

resized

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

resized

resized