| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Jay Tyrrell

Silver Level

Joined: 28 Jul 2011

Location: Staples

Points: 65

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: HD6G Track Adjusters Topic: HD6G Track Adjusters

Posted: 06 Feb 2012 at 9:14pm |

Split the track today to pull off the front idler and get a good look at the yoke. Not good. Gonna drill out the broken piece of track adjuster broke off in the yoke.

Any good ideas how to build a new adjuster?

Was thinking about a 1 1/2" stock, 30" long, put some threads on it and buy a big nut.

Good thing Dads a machinist!

|

|

|

Sponsored Links

|

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Feb 2012 at 10:58pm Posted: 06 Feb 2012 at 10:58pm |

I have seen that done , using a threaded rod and nut instead of internal threads . Just have to make sure you have enough rod inside the yoke so it doesn't become a bend point to allow yoke to get out of kilter to truck frame . I also have seen the yoke re threaded to allow a larger piece to fit inside and hold it in alignment.

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 12:59am Posted: 07 Feb 2012 at 12:59am |

|

Put the yoke in a forge, take heat up to glow point, drop it into waste oil (stand clear of small explosion there), then extract freed broken screw. Machine your new screw to same original thread (which is not a standard engineering one) unless female thread in yoke is completely shot. That is rare. In most cases, male thread only is shot, yoke one is salvageable. I go with a high tensile bar. A buddy told me spiggoting the new threaded bar back a way into the hex bar gives the new scew good strength after welding together. A locking nut of fair depth adds to the rigidity of the screw.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 3:59am Posted: 07 Feb 2012 at 3:59am |

Jay: See Dozers post for thread size on the HD6 in the previous HD3 Track Adjuster Thread started by hilltop. I think the 1.600 thread he is referring to applies to the HD 6 tractor, -maybe dozer will see this and clarify.

I am not aware of any 1.600 threads on any HD3 or H3 as these machines had either 1.250" B7 Threaded Rod early and 1.500" later.

HTH's....Orangeman

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 4:58pm Posted: 07 Feb 2012 at 4:58pm |

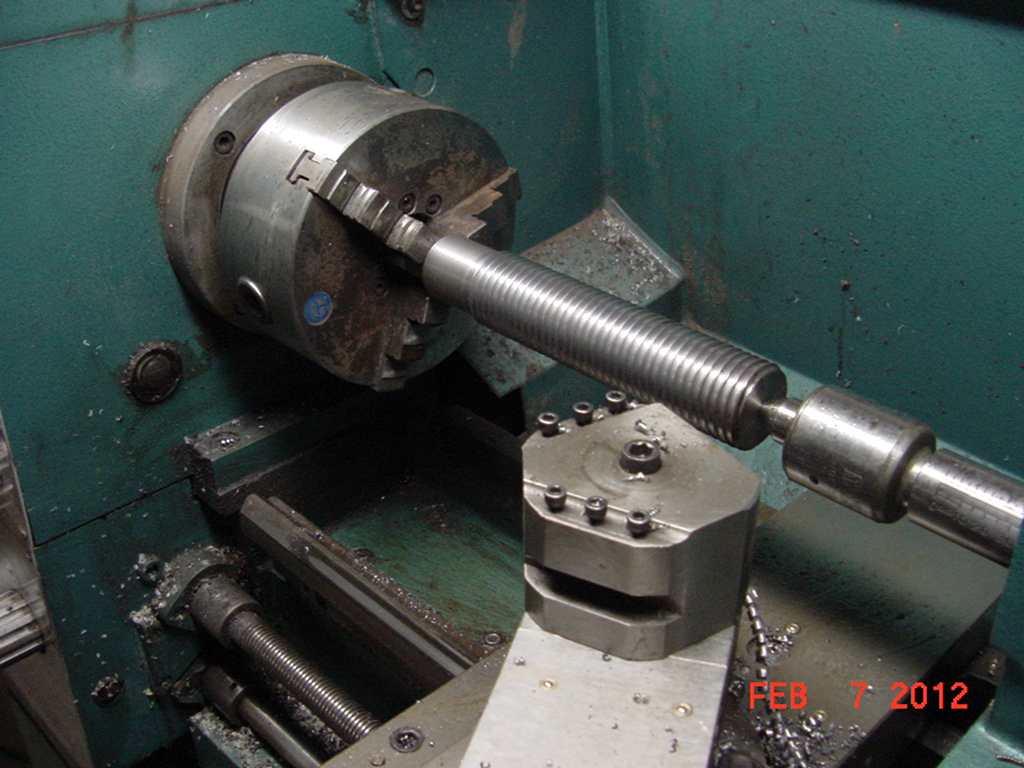

I just finished cutting the thread for my HD6G track adjuster. 1.600 x 5 1/2 TPI Perhaps it is a metric crossover but it fits into my yoke. It is not a 1 5/8 thread. I turned the shaft to 1.590 before I cut the thread. I'm going to weld it onto the old hex adjuster.

|

|

Jay Tyrrell

Silver Level

Joined: 28 Jul 2011

Location: Staples

Points: 65

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Feb 2012 at 9:26pm Posted: 07 Feb 2012 at 9:26pm |

Pretty sure the thread in the yoke is shot. The broken piece is cocked in there. I'll drill it out and probably do 1 1/2" threaded rod and big nut trick. I'll try to get some pictures posted of what we come up with.

Thanks for the help.

P.S. Hey Dozer, Your adjuster looks so short? Any idea how long they should be for a 6G?

Edited by Jay Tyrrell - 07 Feb 2012 at 9:29pm

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 42202

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2012 at 12:17am Posted: 08 Feb 2012 at 12:17am |

On the one HD5B I had I had new threads turned onto shaft, then welded that into a square tube with thick walls . It gave me a 4 sided face instead of 6 but is what i had. I cut the convex end off old adjuster and welded to square tube. Worked great.

|

|

Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel.

|

|

Jay Tyrrell

Silver Level

Joined: 28 Jul 2011

Location: Staples

Points: 65

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2012 at 6:45am Posted: 08 Feb 2012 at 6:45am |

Good idea Coke. I'll rip into it this weekend and see what I come up with.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Feb 2012 at 10:17am Posted: 08 Feb 2012 at 10:17am |

|

Responding to Jay Tyrrell

The total length of the track adjuster on an HD6G is28.62". What you see in my lathe is the threaded part. I will weld this to the hex part.

The thread that fits in my yoke measures 1.60 x 5 1/2 TPI

If this is supposed to be a metric thread it would be M40x4.6

This is not a normal metric thread either. It is interesting that to be an SAE thread it would be 1.625 diameter. To be a metric 40mm threat it would have to be 1.575 diameter. In each case it is 0.025 off. I'm considering getting some tool steel and making a tap

1 5/8 x 5.5 TPI to clean out the yoke threads.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)