| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: HD6G project Topic: HD6G project

Posted: 04 Jun 2013 at 6:46am |

I bought this "WORKING" machine on craigslist and had it delivered without seeing it. When it arrived I could not see to use it because of the oil smoke. I parked it where it is now. In 2011 I pulled the motor and replaced the crankshaft, rings, pistons, sleeves, one connecting rod, main and rod bearings. I oiled everything at assembly and preoiled the motor using a portapower to push about a gallon of motor oil into the motor via the oil pressure gage fitting. On startup I had gage pressure. I got off the machine to check for leaks. It screeeeeched and stopped.  The motor is locked up. The picture shows an air over oil tank. The blue line is 40 #/in2 from the air compressor, the red line is oil out to the motor.  I removed the oil pump output from the block and made an adaptor to connect the oil line from the air/oil tank. I pushed 3 quarts of motor oil thru the motor. The oil pressure did NOT register on the oil pressure gage. The crankshaft seems to be well oiled. The connecting rods have proper end play. Comments please. Can the camshaft bearings lock up the motor? Suggestions are appreciated.

|

|

|

Sponsored Links

|

|

|

Mactractor

Orange Level Access

Joined: 20 Jun 2011

Location: New Zealand

Points: 652

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2013 at 4:33pm Posted: 04 Jun 2013 at 4:33pm |

|

Have not heard of that with any diesel with conventional fuel system George, but pressure/time fuel system Cummins (heavily loaded camshaft) would spin cam bearings in block when not happy. Was pricing engine rebuild parts with an Allis man once, when he said many owners rebuild engines without replacing cam bushes which can loose considerable oil pressure when worn

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2013 at 9:58pm Posted: 04 Jun 2013 at 9:58pm |

|

Good comment by Mactractor and you can build on that. Also it sounds to me like you've spun a cam bearing and covered the hole that the gauge reads off of. I've had it happen to a Cummins. The block can be saved in a good machine shop by boring and sleeving back to standard. There is a guy on here quite often who has had a slue of 5&6 parts and a block might be as cheap and certainly faster. We can hope it's not that serious can't we? Leon in Fulton

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2013 at 10:30pm Posted: 04 Jun 2013 at 10:30pm |

|

Dang that's a good looking. Don't give up. Leon in Fulton

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jun 2013 at 10:33pm Posted: 04 Jun 2013 at 10:33pm |

|

Like I can't give on my typing. It's only been 55 yrs. since typing class. Leon

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 1005

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2013 at 1:47am Posted: 05 Jun 2013 at 1:47am |

Dozer,

This comment presumes that a 344 is the same layout as an ADS 516.

If so I think you'll find that the oil pressure gauge feeds off the main oil gallery on the generator side and the cam is on the other. So I doubt a spun cam bearing has cut the pressure gauge off.

The 516 flow diagram shows a "restrictor" that feeds off the main gallery back to the sump - not sure what this looks like, where it is and if it can come out.

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2013 at 3:38am Posted: 05 Jun 2013 at 3:38am |

|

Okay,Okay. So you're probably right. LOL. Leon

|

|

Lazyts

Orange Level

Joined: 05 Feb 2012

Location: Manitoba

Points: 632

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2013 at 1:14pm Posted: 05 Jun 2013 at 1:14pm |

|

Cam bushings can seize an engine, but crank bearings are more likely. If the cam is seized, you should still be able to move the crank slightly. (Gear backlash)

|

|

HD6 Merv

Orange Level Access

Joined: 03 Aug 2010

Location: New Zealand

Points: 500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2013 at 2:38pm Posted: 05 Jun 2013 at 2:38pm |

|

Not much choice but to pull each cap and check them one at a time.Is it possible you put a bearing in upside down, blocking the oil hole ?? if you never disturbed the cam I don,t think it will be a cam bearing.3306 cats only use oil splash to feed cam bearings. One thing; just make sure its not transmission or hyd pump that has seized before pulling the engine. Saw someone once who pulled a trans and was sure it was the problem; was actually stuck plates in a rear pcu ! Wasn,t me or mine either, but I was one who got job to strip trans and soon came to conclusion it wasn,t that.

|

|

tits tyres and tracks

they all cost you money

|

|

mahto48

Bronze Level

Joined: 29 Mar 2013

Location: United States

Points: 31

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Jun 2013 at 2:54pm Posted: 05 Jun 2013 at 2:54pm |

|

Sorry to say but I would be checking the mains near the back George.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jun 2013 at 7:32am Posted: 10 Jun 2013 at 7:32am |

|

I spent Sunday checking the main bearings. I forgot how much fun it is on my back with oil dripping on me applying 215 ft. lb of torque. All of the main bearings are well oiled in perfect condition. Aftermarket bearings have a lubricating hole in both shells. To me the air/oil pre oil confirmed this but it is likely that when an engine screeches to a stop it is usually the crankshaft. After retorqueing the crank I did the preoil again with more oil at higher pressure. Again the pressure did not reach the oil pressure gage. The hydraulic pump checked OK

Next I will remove the timing gear case with the motor supported on the pan and rear mounts.

Suggestions are appreciated.

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34569

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jun 2013 at 7:56pm Posted: 10 Jun 2013 at 7:56pm |

To tight of rings would be a guess...

But then maybe you did not flush all the oil galleries suffieciently enough to get garbage out and it did plug the system...

Did you loosen each and every con rod and then loosen mains until engine turned?

Is the starter happen to been engaged and got over reved?

Could it possibly be clutch assembly or something beyound or a hydraulic pump...

Running and then screeched to a stop... don't sound to good... but should be an easy find of whats sticking it.

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2013 at 5:03pm Posted: 25 Jul 2013 at 5:03pm |

|

The first picture shows the 2x6 oak boards holding the lift cylinders. These boards are part of the story.

I pumped more oil thru the motor and did not find any bearing material. I was still thinking the camshaft bearings were bad. Replacing the cam bearings requires removing the motor because the bearings are installed from the rear. (What were they thinking???)

I began removing accessories to make the motor less difficult to pull.

I removed the generator and started to remove the crankshaft hydraulic pump drive when the crank turned. I installed the air/oil tank @20psi and rotated the motor 2 revolutions. It was free. The only explaination is that the generator tensioner stopped the generator from turning. The screech that stopped the motor was the generator belt.

Today I finished putting everything back together. It started easily and sounded great. It has 50psi oil pressure.

Now is the time to remember the 2x6 oak boards. I raised the boom to take tension off the boards and blew the left lift cylinder hydraulic line. The boom has to be down to replace the line. I carefully put a mortarboat under the cylinder to catch the oil. I used a long hydraulic jack to lift the boom and remove the boards. As I lowered the boom the jack fell and tipped over the mortarboat and spilled the collected oil.

I put the split hood HD6G on Buffalo craigslist today. I need to sell it so I can buy more oil and a new hose.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2013 at 10:15am Posted: 26 Jul 2013 at 10:15am |

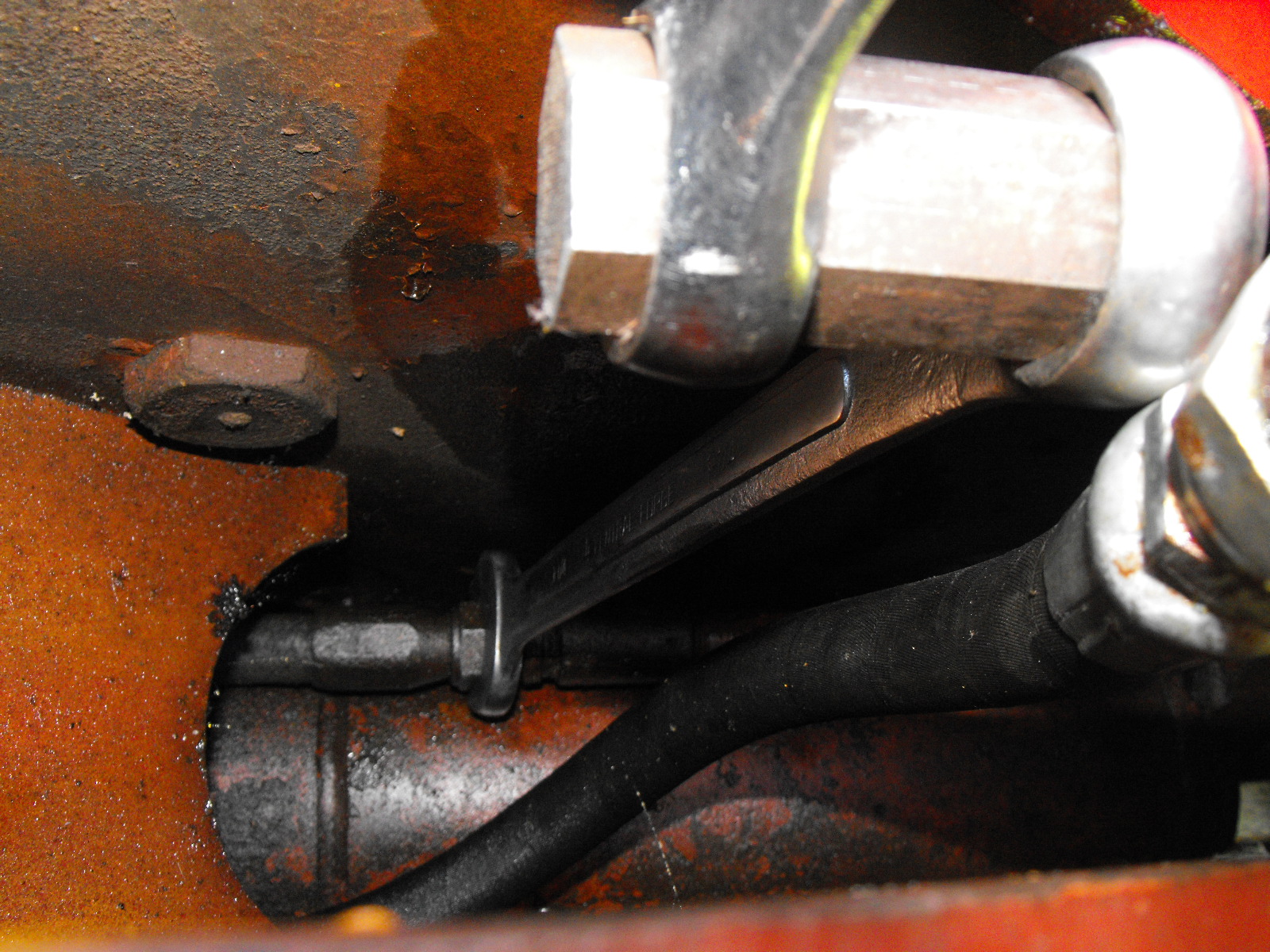

When I found where the hose connection was I didn't think I would be able to remove the hose. I used 2 wrenches and connected them with a piece of hex stock. It is a great trick enabling the wrench to go around corners.

|

|

Dozer

Orange Level

Joined: 16 Aug 2011

Location: SW New York

Points: 689

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Aug 2013 at 3:22pm Posted: 18 Aug 2013 at 3:22pm |

The project HD6G is now running. I made a video (*.WMV file) showing the machine starting and moving from the spot where it was delivered 3 years ago. I am unable to upload the wmv file. When I moved it I found it needs a steering clutch rebuild. Now that this HD6G is mobile I am trying to sell my other HD6G with the split hood.  I have my extra HD344 crankshaft for sale. I had #4 rod surface welded. The crank was reground 0.010 under. It cost me $600 for grinding and shipping.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)