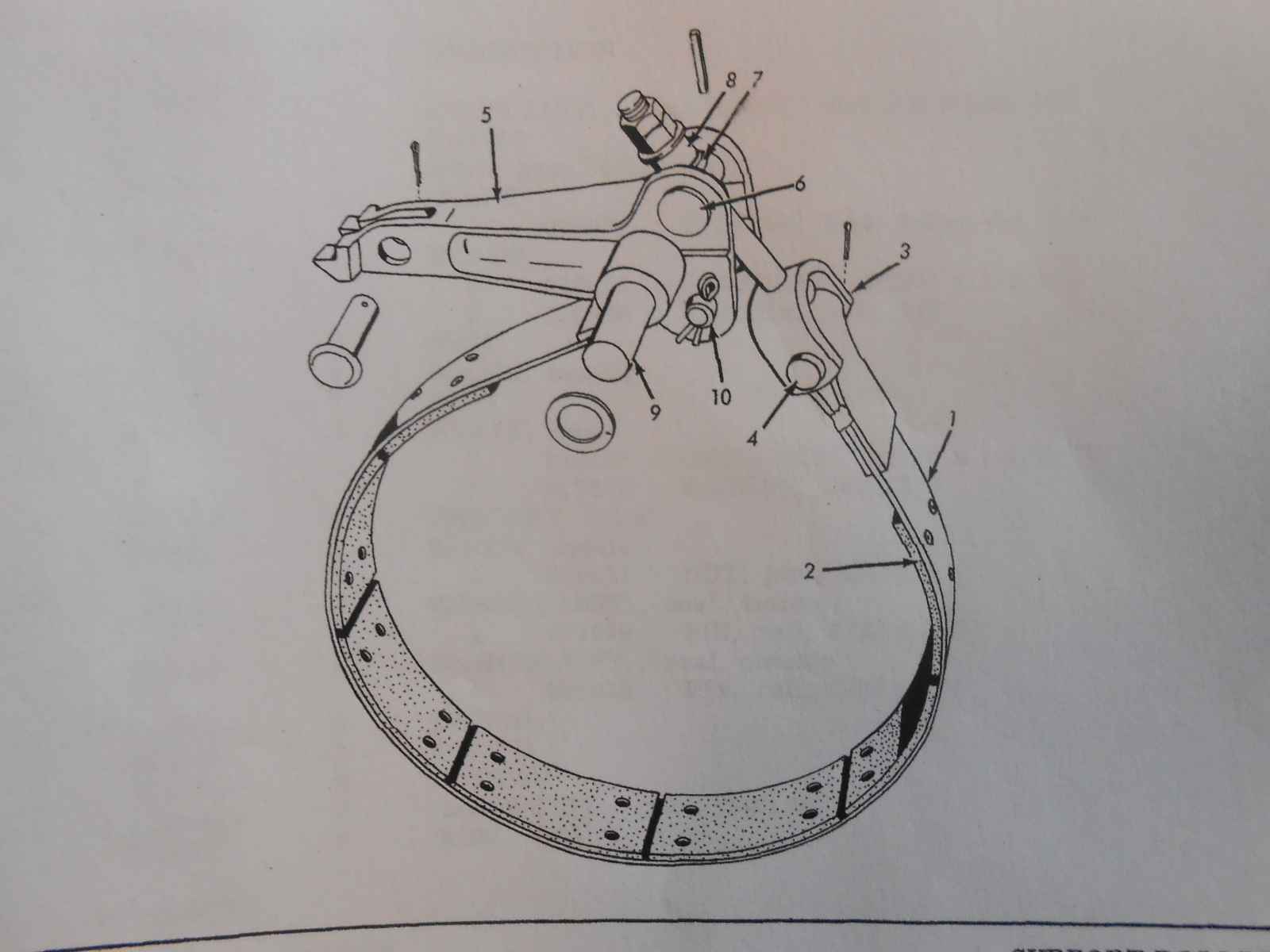

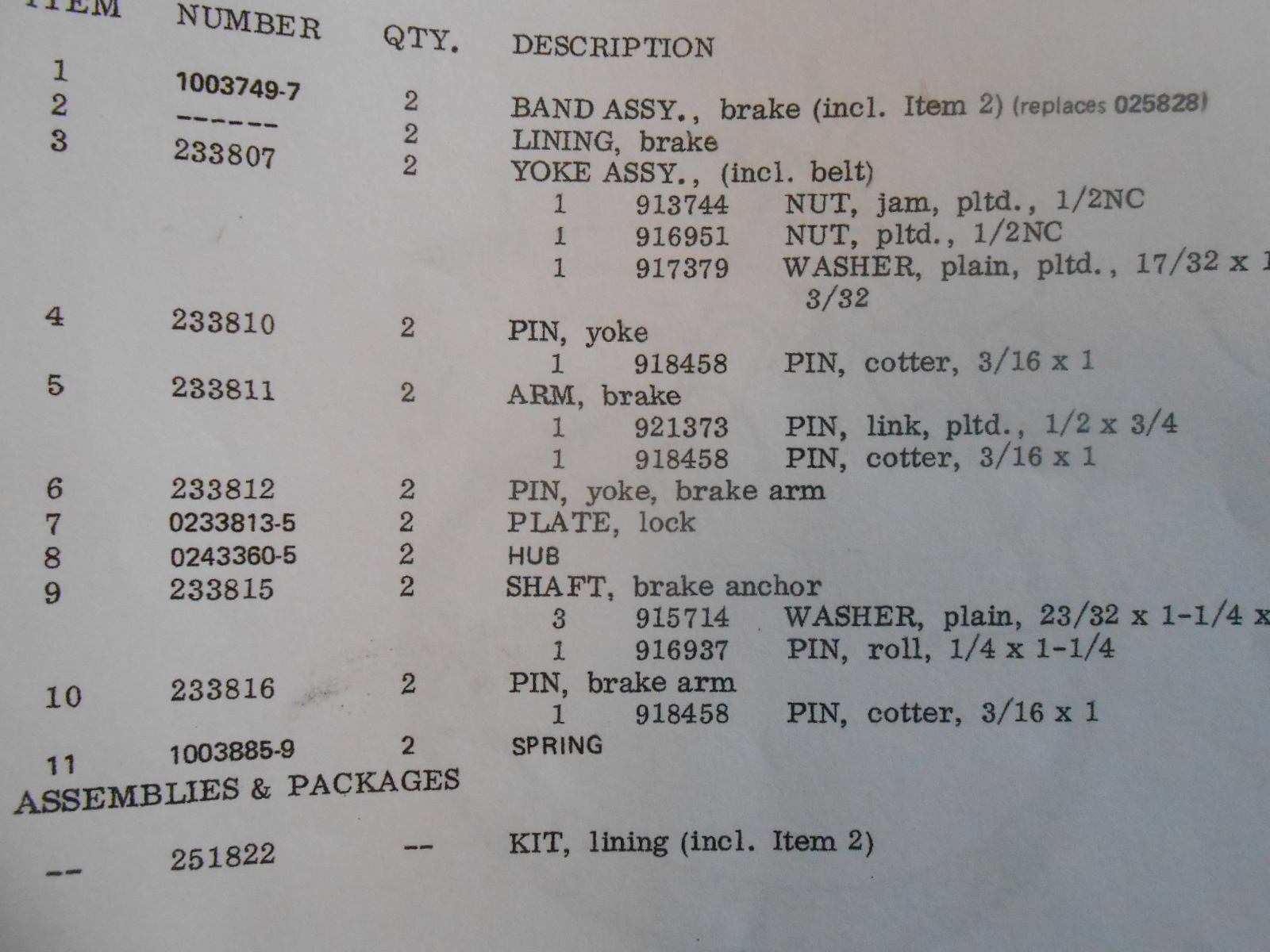

Here are the photos of the parts manual for the brake assembly on an allis H4 crawler. I am trying to remove the shaft that holds the pivot in place. On the parts page it lists two shafts for the pivot arm. is this correct. I am trying to get the brake assembly loose so I can remove it with the steering clutch. When I hit the end of the shaft it sounds like metal on metal. roll pin has been removed. surely some one on here has removed this assembly and can tell me if theres a trick to getting it out or am I just missing something. thanks

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)