| Author |

Topic Search Topic Search  Topic Options Topic Options

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Alliis Chalmers CA Wiring Topic: Alliis Chalmers CA Wiring

Posted: 30 Dec 2024 at 10:03am |

|

Hi,

I am trying to bring a CA back to life. The engine seized so I ended up taking the heads off and honing the cylinder walls. I then replaced all of the gaskets since everything was basically tore down. I sealed everything back up and am having issues with cranking.

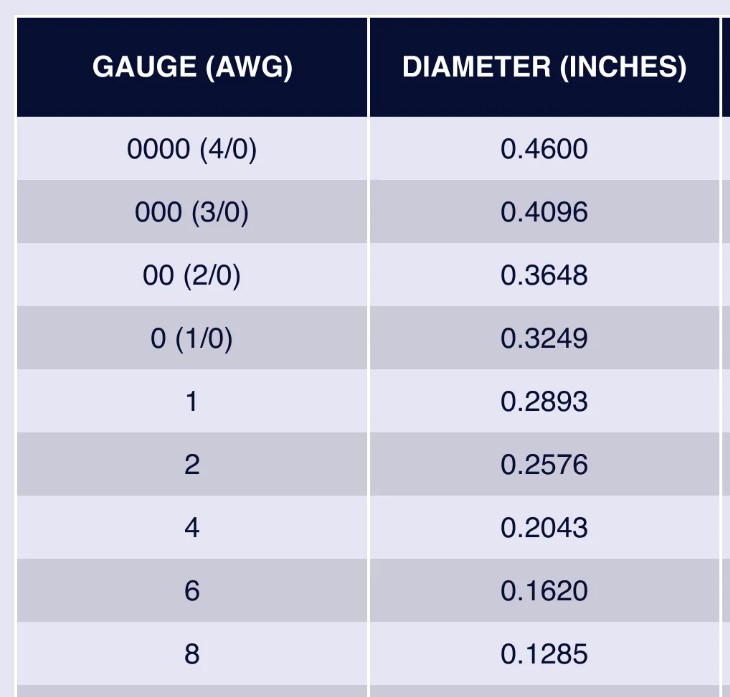

The starter is new, the positive is grounded to the frame and the negative is connected to the battery. 1 gauge wires. The battery is new and the plugs are new/gapped correctly.

Before I did that, I used the wiring diagrams posted here and re-wired it back to a positive ground. When I crank the engine, she cranks fine with no spark plugs. When I put plugs in, the engine cranks slowly and intermittently.

The electrical had been re-wired already. I intend to replace all of the wiring as the wires seem like they have seen better days and are not very bendable. It leads me to believe maybe a wire or two are corroded inside and can’t provide enough current for the system to crank.

Can anyone provide the wiring specs? Not sure which gauge(s) of wiring to buy. I’m not looking for a harness as they are expensive.

I checked all of the wires for current and connected them to the correct places on the generator, coil and cutout. What else can I check? The ammeter seems ok, but the light switch is stuck.

I also don’t know the condition of the generator and cutout, but it was a running tractor when I bought it a couple of years ago.

It sat, the engine seized, now the thing won’t crank, lesson learned. Suggestions?

Edited by pudi211 - 30 Dec 2024 at 10:06am

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 10:12am Posted: 30 Dec 2024 at 10:12am |

|

i assume it is still a 6 volt system.. By definition, they crank SLOW... an old battery might crank over with the plugs out and have trouble with the plugs installed..... Your wire being a #1 should work, but a little larger is better........... the main harness, lights, amp guage, etc have nothing to do with cranking... all you need is the two battery cables, CLEAN BATTERY terminalsl, CLEAN GROUND location, and the switch to crank the motor.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 10:15am Posted: 30 Dec 2024 at 10:15am |

|

for a test, you can install a 12 volt battery and crank the engine over... Just dont turn on the lights ... long term not a good idea with a 6 volt coil / distributor ... you could take the wire off amp meter to kill Everything except the starter / battery connection.

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22744

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 10:15am Posted: 30 Dec 2024 at 10:15am |

hopefully gets you the free manual.... best to replace 100% of the wires, one at a time. do JUST the minimum to get her cranked over, then started.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 10:59am Posted: 30 Dec 2024 at 10:59am |

|

So a short in the system won’t cause slow cranking? Yes, it’s a 6v system with a new battery. Starter and switch are new. Terminals are new and clean, ground is freshly stripped and grounded now to the frame. It was cranking fine on 1ga before I parked it. Thinking about it, I guess the battery and ground cable are the only ones that control cranking so it makes sense. I wonder if the battery is not strong enough even though it’s new.

Edited by pudi211 - 30 Dec 2024 at 11:11am

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 11:02am Posted: 30 Dec 2024 at 11:02am |

|

It does work thanks. I have tried to download the manual before without success. I plan to replace all of the wiring one at a time.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 11:04am Posted: 30 Dec 2024 at 11:04am |

|

I’ll give that a try too. No lights on the tractor currently.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 11:05am Posted: 30 Dec 2024 at 11:05am |

|

tractor is 70 years old... weak starter, weak battery are both probably causes... I would agree that changing the wire size would not be my first choice, unless you see a break / corrosion or damage in the wire.... Like i said, if you take the wire loose from the amp gauge and just have the + and - battery cables to the starter and ground bolt, that should make it crank, without worrying about a short..... starter case needs to be CLEAN and grounding bolt CLEAN also..

|

|

Like them all, but love the "B"s.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 1:04pm Posted: 30 Dec 2024 at 1:04pm |

|

Ok, I disconnected all wires except for the battery/ground cables. Same slow intermittent lope. Not a steady crank. I purchased the battery over the weekend, and I am charging it now. Starter is new and the battery is new. I also tried two different grounding points. I installed the old starter, which probably wasn't bad to begin with, and the result is the same as with the new one. The old starter actually cranked better than the new one. Thinking it just could be a crappy battery.

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 782

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 2:23pm Posted: 30 Dec 2024 at 2:23pm |

|

For 6v I use 2/0 fine wire copper welding cable

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 4:43pm Posted: 30 Dec 2024 at 4:43pm |

Cables do make a big difference.. #1 is .065 square inches cross section. 00 has a .1054 square inch cross section or 60% larger. ........... but im still not convinced thats your problem.. but would make a difference in current carry.

Edited by steve(ill) - 30 Dec 2024 at 4:51pm

|

|

Like them all, but love the "B"s.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 5:19pm Posted: 30 Dec 2024 at 5:19pm |

|

Got it. Purchased a Deka battery and will hook it up tonight. For all other wiring, is there a specification? Previous owner has a variety of different gauges. The shop manual didn't specify either.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 5:58pm Posted: 30 Dec 2024 at 5:58pm |

lights, ignition, distributor, coil.. etc... can all be 18 gauge.... Might use 16 guage to make it more BEFFY and rigid... Too much bigger and you cant get the wires into the switch box..

Generator wire to the amp guage should be 10 gague... and 10 gauge from amp to the battery.. 10 gague is good for about 30 amps... more than the generator can put out.

Edited by steve(ill) - 30 Dec 2024 at 6:00pm

|

|

Like them all, but love the "B"s.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 844

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Dec 2024 at 10:12pm Posted: 30 Dec 2024 at 10:12pm |

pudi211 wrote: pudi211 wrote:

...

I checked all of the wires for current ...

|

Please elaborate. Or did you actually check for Voltage? They are related (sorta like cousins, but they behave differently).

If you have an accurate voltmeter you take voltage drop readings of each part of the circuit; this will give you a better idea as to where the actual trouble lies.

I have found that corrosion in the tractor framework (castings) can cause poor continuity in the ground return path, a dedicated ground cable all the way to the starter was the cure.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4970

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 8:21am Posted: 31 Dec 2024 at 8:21am |

|

The battery may be new but does it have high enough cranking amps? Our CA rolled over slowly on 6V and required a really good battery but usually fired up within a rotation or 2. Eventually we changed it over to 12V. I’m like Alvin, I use 2/0 welding cable, also good quality crimp connectors. Make sure you use + and - size connectors for the battery, they are different sizes. Positive is a larger connector and most parts stores only sell the larger size. Doesn’t work well on negative post of the battery as it can’t provide the clamping force because of its large size. Our local battery supply store crimps the connectors for you if you purchase the cable and connectors from them. I have my own crimp tool which will crimp 12 different size connectors. It’s a $600 tool but was tired of getting crap cables from auto parts stores. It makes a huge difference in how a starter will spin an engine over. Money well spent and have crimped a lot of cables with it over the years for myself and my friends.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 8:41am Posted: 31 Dec 2024 at 8:41am |

It takes a given amount of POWER to turn over an engine.. POWER is volts x amps... when you double the volts from 6 to 12, it takes HALF as many amps to get the same POWER to turn the engine over..

That means that older cables, smaller cables, old starters, old battery get their problems somewhat COVERED UP as they dont have to work as hard.... If your using 6 volts EVERYTHING has to be perfect to get it to rotate.

|

|

Like them all, but love the "B"s.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 8:59am Posted: 31 Dec 2024 at 8:59am |

|

Thanks Steve. I appreciate the good advice and hopefully others will benefit from those specs.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 9:02am Posted: 31 Dec 2024 at 9:02am |

|

I'll be honest, I checked current with a light as my multi-meter was lost in my last move. Went to store and replaced it yesterday and will check voltage today.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 9:06am Posted: 31 Dec 2024 at 9:06am |

|

Appreciate it. I'll be replacing all of the wiring and ring terminals. I put a Deka battery on it yesterday and the cranking was slightly better.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 9:13am Posted: 31 Dec 2024 at 9:13am |

|

Good advice on the battery connectors and crimping. I recently melted solder inside of a connector and inserted the wire which made a tight connection. I'll check with the battery store I was at yesterday to see if they'll make cables up for me. I did notice the - post to be smaller which was a concern as that wire goes to the starter and needs a tight connection. Mine was tight, but I could twist it loose with minimal effort. The + side was locked on tight.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 844

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 10:19am Posted: 31 Dec 2024 at 10:19am |

Step #1. Check voltage at battery terminals while cranking. If it cranks slowly and the voltage barely drops, then you probably have a poor connection (high resistance) somewhere in the circuit.

If it cranks slowly and the voltage drops WAY down, like to ~3 Volts (assuming a 6 Volt battery) then you have a very heavy load such as a dragging starter or excessive friction inside the engine. Or a bad battery.

2. With meter lead on negative battery terminal (NOT on the cable terminal) and the other lead on the starter terminal, crank the engine and observe the voltage drop through the cable. Ideally it should be 0.0 Volts (zero) but there will be a slight drop. Less than 0.2 Volts is ok.

3. Do the same on the positive battery terminal to ground.

4. Do a voltage drop from the positive battery terminal to ground on the starter housing itself to test if there is a high resistance in the chassis.

I am assuming a 6 Volt Positive ground system.

Edited by Les Kerf - 31 Dec 2024 at 10:20am

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 10:31am Posted: 31 Dec 2024 at 10:31am |

|

Correct 6V positive ground. I'll do that later on. Thanks!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 12:25pm Posted: 31 Dec 2024 at 12:25pm |

|

I have a B with a Sickle and another with a Belly mower.. They share the same 12v battery . I move it back and forth 4-5 times during the summer.. I have notice a BLACK corrosion on the inside surface of the battery clamp terminals once or twice a year.. This is not the green/ white CRUD that seems to GROW on some terminals.. This is a very think BLACK coating that looks almost like it was spray painted on ??? ..... I use a sandpaper on a dowel to clean both clamps when i see it.... Few years ago one tractor would not start and i fought it a long time till i figured out the clamp was CLEAN to the eye, but had that black coating... Make sure everything is SHINNY SILVER..

|

|

Like them all, but love the "B"s.

|

|

pudi211

Bronze Level

Joined: 02 Sep 2023

Location: Delaware

Points: 27

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Dec 2024 at 2:17pm Posted: 31 Dec 2024 at 2:17pm |

|

Absolutely

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

pudi211 wrote:

pudi211 wrote: