| Author |

Topic Search Topic Search  Topic Options Topic Options

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Series 610 all terrain forklift Topic: Series 610 all terrain forklift

Posted: 17 Nov 2024 at 5:40pm |

|

Hey all. I am a timber framer, and I often cut beams larger than I can lift anymore. I bought an old AC rough terrain forklift, and it doesn't run, but I am getting close. I bought the shop manual, it's in the mail, but this thing has been tough to find info on. Based on the info I have so far, it is the same as a D15 series II. (?) I think.

I will post a pic once I figure out how. it has been fun, so far. I figured out you have to push the leftmost foot petal, and that lets the engine turn and starter crank. I don't even know what it does yet....

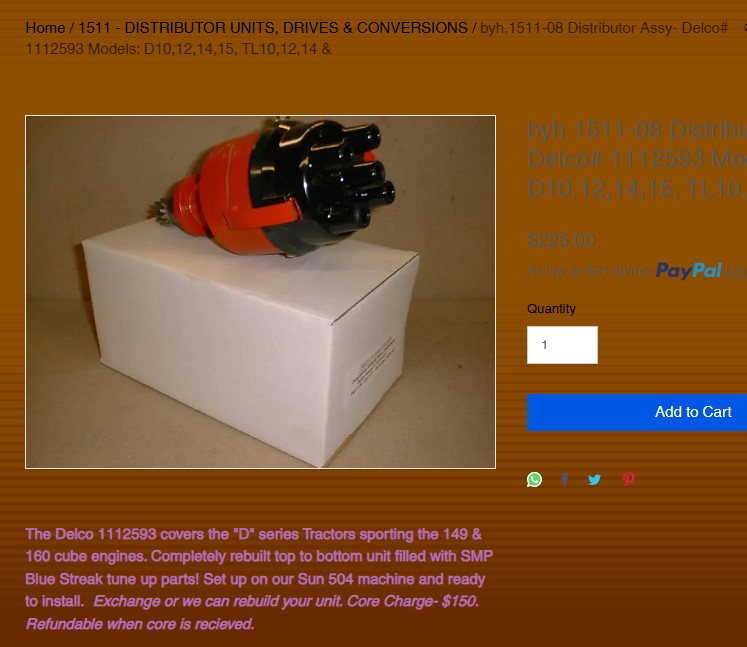

Anyways, the distributor is old and has rusted so the advance won't work. Any idea what part number I need? Thanks for any help...

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 85250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Nov 2024 at 6:32pm Posted: 17 Nov 2024 at 6:32pm |

to put in photos, click on the "POST REPLY" button at the left, below the Last Post... Then click on the GREEN TREE ICON in the heading of the BOX... and look for your photo on the phone or your computer desk top.... If the photo is 4000 x 3000 pixels and 4 MB in size, it will not load.... Open in PAINT and make it 800 x 600 size and then download.

skip down about 5 posts..

Edited by steve(ill) - 17 Nov 2024 at 6:34pm

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 85250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Nov 2024 at 6:36pm Posted: 17 Nov 2024 at 6:36pm |

you can find " parts" and maybe a complete distributor on e-bay.... Or better to call STEVE at B&B and talk to him.. He can answer all your questions, and will have any parts you need.. or a COMPLETE rebuilt distributor ready to go...

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 85250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Nov 2024 at 6:40pm Posted: 17 Nov 2024 at 6:40pm |

STEVE can also heip you with a starter / generator / wire harness if needed.... and answer ALL the questions..

|

|

Like them all, but love the "B"s.

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Nov 2024 at 7:07am Posted: 18 Nov 2024 at 7:07am |

|

thanks, I will do that today...

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 3:51pm Posted: 01 Dec 2024 at 3:51pm |

|

I got the new distributor, and it still sputters, but wont run. it sparks fine. I checked the compression and i had zero psi in 3 and only 90 in 4. 1 and 2 were 140. Not good enough to run!

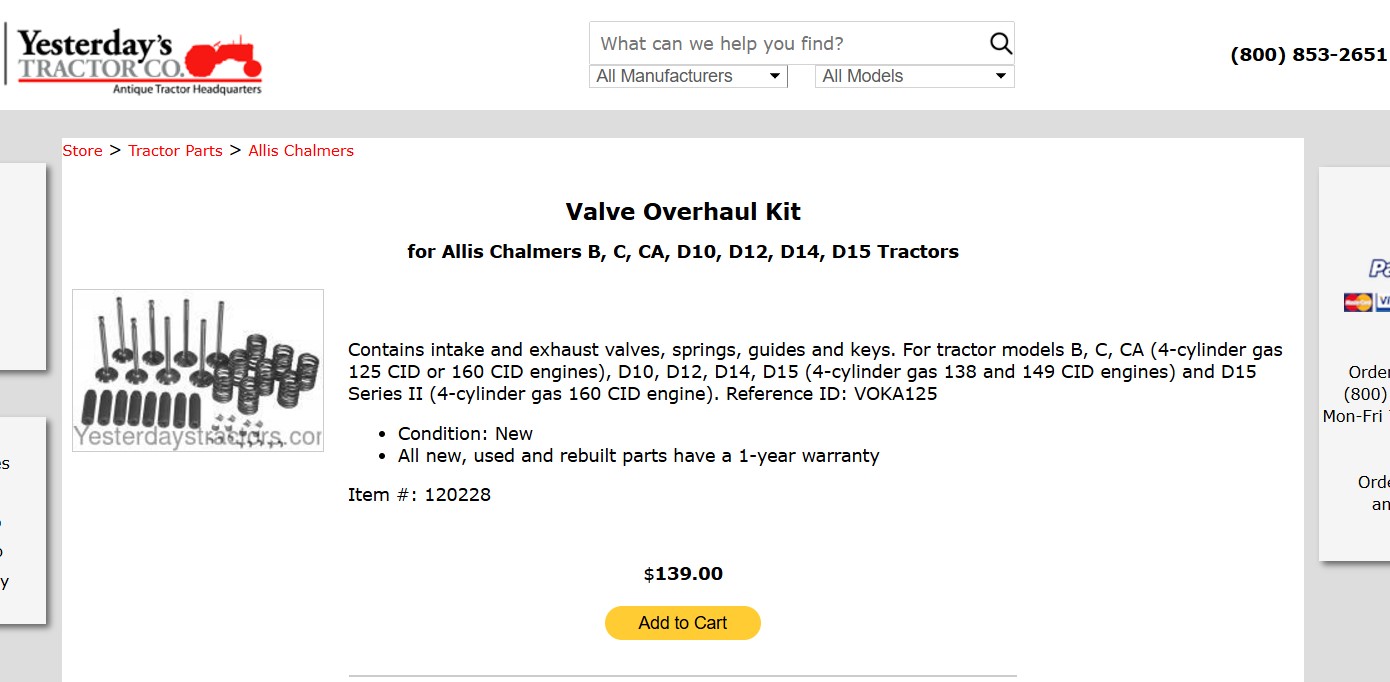

I took the head of in 15 minutes. You gotta love tractors. the valves in 3 werent seating properly, and the ex valve in 4 was chipped away. So that explains that.

gonna order some parts, and have the valve seats redone. I finally got the book on my tractor/forklift, and the book says I have a Power Crater 160 motor, but I cant find much info on them, anyone know?

apparently there was also a perkins 3 cyl that was called that as well.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 85250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 7:34pm Posted: 01 Dec 2024 at 7:34pm |

That engine series started as a 138 cubic inch in the D10- 12 ... Later that was bugger bored to 149 and many in the D14 and D15 farm tractors.... Last update was to 160 inch for the D15 series 2..... GOOD MOTOR !!

I think valves / springs / "parts" for the D14 and D15 149 motor should all fit, except the BIGGER PISTONS...

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 85250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 7:45pm Posted: 01 Dec 2024 at 7:45pm |

couple of sites list a different part number for the later D15 II engines ( i think they mean the 175 cid diesel)-- ( valve kit).. some site list them as all the same..( gas??). VERIFY with vendor prior to purchase..

Edited by steve(ill) - 01 Dec 2024 at 7:49pm

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 85250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 7:53pm Posted: 01 Dec 2024 at 7:53pm |

|

Power Crater was the later design of pistons used in several tractors... The design was a DISH or CRATER in the center of the piston that moved the gas / air mixture to a concentrated point in the center under the spark plug... Should be more efficient and more HP.

|

|

Like them all, but love the "B"s.

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5852

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 10:29pm Posted: 01 Dec 2024 at 10:29pm |

The Allis WD came out in 1948 with W Series 201 cu.in. with Flat Top Pistons. In 1953 the WD was upgraded and introduced as the WD-45. The 'W' Block was revised, the stroke was increased to give 226 cu.in. and the Flat Top Pistons were replaced with dished top Pistons. This Engine was advertised on WD-45 Brochures as: The Dynamic New WD-45 tractor with POWER-CRATER Engine https://www.ebay.com/sch/i.html?_from=R40&_trksid=p4432023.m570.l1313&_nkw=Allis+WD-45+Power+Crater+brochure&_sacat=0The G Series Engine, as it was known, was introduced in 1957 by Allis as a 149 cu.in. Engine in one of first 'D' Series Tractors, the D-14,a 6 Volt electric In 1959 Allis introduced the D-10 and D-12, de-cubed to 138 cu.in. still 6 Volt. In 1961 the G Engine was back to 149 in D-10 / 12, but with 12 Volt. About that same time the D-15 was introduced replacing the D-14, but still 149. The early D-15 were grossly underpowered for their size, esp. with D-10 and D-12's having the same Engine. So the D-15 was upgraded to a Ser.II Model with a 160 cu.in. Engine. Other mods to the 160 were a Full-Flow Oil Filter ( Fram PH8A), replacing the previous By-Pass filter (C159), a horizontal Dry Type Air Filter , replacing the Oil-Bath style. https://www.ebay.com/itm/126787463857?_skw=Allis+D-15+Ser.II+brochure&itmmeta=01JE2S5KYT1XFCHGADY8H6G8PV&hash=item1d851f2ab1:g:XhkAAOSwwVdnPgzF&itmprp=enc%3AAQAJAAAA8HoV3kP08IDx%2BKZ9MfhVJKmYvzn6K%2BECxuL65MN4XW5VpDIVzrenQznetIb4Q0iqFYokK%2B%2Bl1GlHlY2zdnICk9t5jrAZFb4FLhTBjw21KmNwGloIrebnHhYH9QLgIPiv7AGEL4iDmWrbugDqUri%2FXZ2kpszP1NQz5bUgiCRk0SR9PbdkzQ%2BcEvJ0c11oQ2csriyHO98Z1zQWDb4bX0WyWHivGrpPtcQFrpjfFBiJJiERf8rqFUN9knACjHzw2N9VQGGU8hWJTCAi7ADv3V0ExaaVhzxDT%2BkfHe7AAE27oC1gnbH7urhwYkGOcO9haVQOvw%3D%3D%7Ctkp%3ABk9SR8C_ltnwZAThis gives you a little more insight to the Allis progression from the 'B/C' Series 125 cu.in. up to the G Series 160 cu.in. Gary BTW the 500 Series and 600 Series Rough Terrain Fork Lift are NOT based on the D-15 Farm Tractor like some other Allis Industrial Models. The 500's and 600's are an extra Heavy Duty Brute all their own.

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2024 at 2:44pm Posted: 02 Dec 2024 at 2:44pm |

|

Thanks for all the info, that is all very helpful...

I gotta get this beast back up and running...

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2025 at 7:11am Posted: 31 Mar 2025 at 7:11am |

|

I got the cyl head rebuilt and back torqued on and everything looks good. Now the starter is sticking on. I guess I'll have to troubleshoot why, might just get a new one. Also I found a bent pushrod and a few small things. hopefully I ll have it running this week.

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1719

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Apr 2025 at 9:47pm Posted: 02 Apr 2025 at 9:47pm |

|

The Allis dealer I operate has a parts book for 500/600 All Terrain Forklifts, we have been helping a guy in AZ restore his 500 forklift. We'd be glad to help you with any parts needs and questions!

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2025 at 2:40pm Posted: 12 Apr 2025 at 2:40pm |

|

I got it running, but very poorly. It has equal psi on 4 with compression test. It is getting spark. It does run and rev up, but very poorly and won't stay running for any length of time.It is pretty smooth when it does, sounds OK. I am going to have to set the timing a little better, I am just guessing now, and the carb is leaking down, and it is new and has only had double filtered fuel in it. grrrr! I dont think I have ever had a carb without a sticking needle and seat. Is there any adjusting on the carb I need to do? I have the lean rich air bleed 1.5 turns out.

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2025 at 4:45pm Posted: 13 Apr 2025 at 4:45pm |

|

I had a chance to work on the forklift today. I can get it running and it runs ok, then runs with sputtering then pops and quits with a huge sucking noise out of the carb air intake. I am going to put it down for a while, cause I will be busy with work this week.

compression good on all 4. timing is close, it wont stay running long enough to check it. definitely getting fuel, no air filter to be clogged. carb is new, distributor is new from Steve in NJ.

I had the carb linkage upside down, and I would have swore that's what the problem was.

it is kicking my butt right now.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1033

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2025 at 8:54pm Posted: 13 Apr 2025 at 8:54pm |

edognight wrote: edognight wrote:

... then pops and quits with a huge sucking noise out of the carb air intake...

... timing is close,... |

Hmmm  Are you absolutely certain that you have the distributor wired for the correct rotation? If the firing order is 1-2-4-3 then either direction will have #1 and #4 correct but #2 and #3 could be swapped.

You should be able to static time that engine close enough without having it running; what method are you using to set it initially?

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2335

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2025 at 9:33pm Posted: 13 Apr 2025 at 9:33pm |

|

I use an squirt oil can with gas in it for problems like this. When it starts to run poorly, I feather a little gas into the intake of the carburetor to see if it will pick back up and run right. If it does, it's a gas issue. If it won't, it's usually a spark problem.

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Yesterday at 8:06am Posted: Yesterday at 8:06am |

|

I am just guessing on the timing. Is the rotation clockwise? If so, I am fine. 1243. I am pretty sure I have a fuel flow issue. because it runs and dies and has a pronounced sucking sound, which I think is the jets sucking air. I checked the fuel flow by removing the line to the carb and it is really slow! So I'll check that out. Also, the lean rich mixture was way out and I am trying four complete turns out. Thanks for the help....

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1033

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Yesterday at 9:37am Posted: Yesterday at 9:37am |

edognight wrote: edognight wrote:

I am just guessing on the timing. Is the rotation clockwise?.... |

Rotation is easy to verify, just remove the distributor cap and turn the engine.

Timing is too important to guess at. Get the engine sitting at Top Dead Center (TDC) on the compression stroke of #1 cylinder. Then rotate the distributor so as to have the breaker points just open. Then you can troubleshoot the fuel issues with confidence.

|

|

edognight

Bronze Level

Joined: 17 Nov 2024

Location: SC

Points: 10

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 6 hours 60 minutes ago at 12:25pm Posted: 6 hours 60 minutes ago at 12:25pm |

|

OK, I had some time to mess with it and I cannot get it started. It will run and stumble a bit and then die. I am not sure what I am doing wrong. I had the cylinder head rebuilt, and all valves are lashed to spec. it is getting good compression on all 4 cylinders. I have a new distributor from steve, I dont know if they need adjusting or not.

I set the timing by finding the compression stroke while lashing the valves. air was pushing out the spark plug hole and then I set the distributor button in about 10 degrees anti clockwise of TDC to guess on the timing. I have read that the distributor button turns clockwise.it is 1-2-4-3.

new carb and new plugs. I have the flat head idle mix screw out 1.5 turns and the lean/rich t bar screw four complete turns out. If I adjust the idle all the way up, it might stay running about 10 seconds. it is then very difficult to start. I cant keep it running long enough to set the timing with a light.

I tried the old carb and amazingly enough it did the exact same thing. I have tried every combination of choke, starter fluid, +5. 10 degrees timing, and -5 and -10. Nothing seems to work.

Something is wrong, this thing should run better than this. I am going to put it down for a while.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1033

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 28 minutes ago at 1:57pm Posted: 5 hours 28 minutes ago at 1:57pm |

edognight wrote: edognight wrote:

...Something is wrong... |

Indeed!  This is what I do in a situation like this with an unfamiliar engine that refuses to behave: DO NOT assume that anything is correct. You need to verify TDC.

Fabricate a positive stop for the piston; I use an old spark plug by grinding the crimp away that hold the porcelain, then knock it out and tap the metal part of the plug for a bolt.Screw it into the spark plug hole and adjust the bolt so as to stop the piston about a half inch from TDC. CAREFULLY rotate the engine by hand until the piston just contacts the stop bolt. Mark your crank pulley at the pointer (if there is no suitable pointer, then make one).

Rotate the engine the other way until it stops at the bolt. Mark the crank pulley there. Halfway between the marks is TDC.

Now, remove the piston stop bolt and get the engine at TDC compression stroke. Make certain that the breaker points are adjusted correctly, then rotate the distributor until the points JUST open. You need to use a test light or an ohmmeter for this. Lock the distributor down and LEAVE IT THERE!

Now, pull all four spark plugs and connect them to their respective wires.Have them lying on the engine so that you can observe the spark. You still have the engine at TDC #1 compression, right? Turn on the ignition, rotate the engine BACKWARDS a few degrees, then forward to TDC. You should see a spark at #1. Then rotate a half turn (180 degrees) and #2 should spark. Anther half turn will be #4's turn, then finally #3 at the last 180 dgrees of rotation.

If you do not get a spark at each cylinder at TDC compression for that cylinder, you need to find out why before continuing.

I will stop for now, let us know what develops.

Edited by Les Kerf - 5 hours 24 minutes ago at 2:01pm

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

edognight wrote:

edognight wrote: