| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Brinky

Bronze Level

Joined: 30 Aug 2024

Location: Uk

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis b 6v starter switch Topic: Allis b 6v starter switch

Posted: 14 Jan 2025 at 10:00am |

|

Hi, I’m still having starter trouble. All I have is a starter and 6v battery, no other electrics. The switch on the starter operated by a lever keeps burning the contact, then the starter doesn’t turn. I know I can change the contact to a stud, but then I’m not sure on the best way to switch the starter. Has anyone else done this ?

|

|

|

Sponsored Links

|

|

|

Alberta Phil

Orange Level

Joined: 13 Sep 2009

Location: Alberta, Canada

Points: 3848

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2025 at 12:52pm Posted: 14 Jan 2025 at 12:52pm |

|

That switch can be removed and the internal copper contacts cleaned up to make a more positive contact with each other, if they are not too badly worn. If it's a new replacement switch, it may have brass contacts inside which arc and burn much more readily than the original copper ones. I have had not much luck with those modern replacements.

|

|

HoughMade

Orange Level

Joined: 22 Sep 2017

Location: Valparaiso, IN

Points: 705

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2025 at 1:42pm Posted: 14 Jan 2025 at 1:42pm |

|

I took the switch/plunger off of mine and worked on the contacts on both sides with a file until they would make full contact across the whole width. No problems since.

|

|

1951 B

|

|

Brinky

Bronze Level

Joined: 30 Aug 2024

Location: Uk

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2025 at 2:00pm Posted: 14 Jan 2025 at 2:00pm |

|

The starter came with a switch, which was arcing , so I bought a replacement which arced even more, I have taken them both off several times and filled the switch and contact. Works briefly then burns again

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4702

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2025 at 2:18pm Posted: 14 Jan 2025 at 2:18pm |

|

look at your arc marks on the contact of the switch, it may only be touching on the very edges, it may need a tad of shaping. These starters have seen many years of use, the pad on the starter may be due for a change out.

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82677

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2025 at 3:54pm Posted: 14 Jan 2025 at 3:54pm |

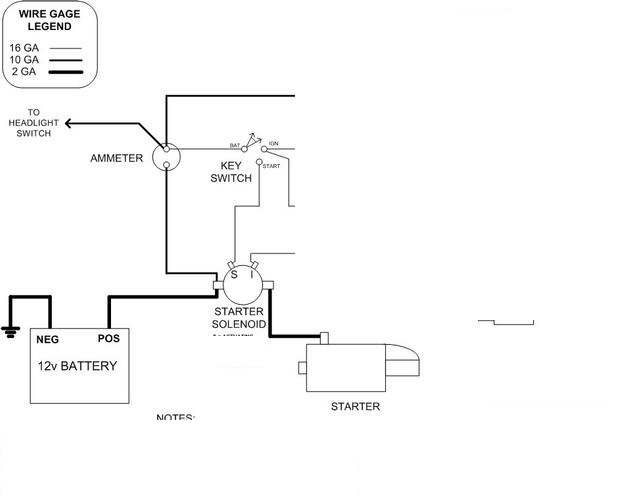

If you decide to eliminate the present push switch and put a STUD on the starter... Then you buy a SOLENOID and mount it between the battery and the starter... BIG wire to the solenoid.. BIG wire fromt the solenoid to the starter... SMALL power wire to a BUTTON or KEY... and then a small wire from the BUTTON to the solenoid.. Small wire carries a little current the pulls in the SOLENOID and it powers the starter..

Here is a portion of a diagram that shows the battery, starter, solenoid and a key ( or button)... 12 or 6 volt, pos or neg makes no difference.

|

|

Like them all, but love the "B"s.

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11891

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2025 at 10:15pm Posted: 14 Jan 2025 at 10:15pm |

If you have a local rebuilder in town, take the Starter motor to him and have him change the Starter over to a stud, and while he has it, have him run through the Starter motor to make sure all components inside are in good working order. Have him inspect the Armature and put it through some tests to make sure its good. Have him also fix you up with a Starter Solenoid and your problem is solved. Those silly switches were the worst. As time progressed, the Starter motors started failing because of the king size voltage drop at that switch. Eventually, the Armature is toast. I've done a ton of em' over the years for my customer's. BTW, since you have a B, I always tell my customer's to mount the Starter Solenoid inside the toolbox out of the elements. My B has been like that for years. Starts every time.... Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

Brinky

Bronze Level

Joined: 30 Aug 2024

Location: Uk

Points: 15

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2025 at 12:22am Posted: 15 Jan 2025 at 12:22am |

|

Thanks for the reply’s, unfortunately where I am in the UK, all the older generation that used to repair this type of thing have retired.. it also seems difficult to find a suitable 6v solenoid, will any 6v solenoid be suitable or do I need to look for a minimum rating ?

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4702

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2025 at 5:47am Posted: 15 Jan 2025 at 5:47am |

Paul, this might be a great time to reach out to another “across the pond friend “ Mark Everett, he is quite knowledgeable on Allis and a very nice person

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 23263

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2025 at 6:08am Posted: 15 Jan 2025 at 6:08am |

those contacts need to be perfectly clean( no pits or crates ) AND perfectly flat ( parallel to each other) this allows all the current thought them an minimizes arcing ( which is bad) on 'trick', after contacts have been refurbished is to QUICKLY engage the switch and LEAVE it 'on' until engine starts or 'time runs out'(10-20 seconds). Those contacts arc EVERY time they connect AND disconnect. On my CA, I think I turned the 'bar' upside down to get 'fresh' copper.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82677

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2025 at 7:26am Posted: 15 Jan 2025 at 7:26am |

will any 6v solenoid be suitable or do I need to look for a minimum rating ?

dont use one made for a riding lawn mower... but any 6v solenoid made for a CAR or TRUCK ( engine in the 125 cubic inch or bigger) should be fine..

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82677

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 15 Jan 2025 at 7:32am Posted: 15 Jan 2025 at 7:32am |

|

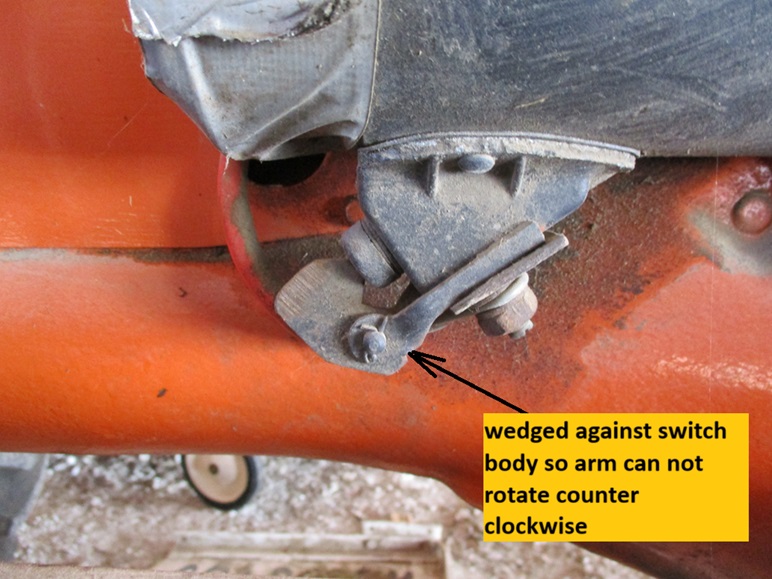

i havae a couple B tractors that i have MODIFIED with a starter solenoid.. I left the original starter switch on the tractor and made a little wedge and set screw thah holds the switch CLOSED all the time. That way it can not arc.. I have a solenoid and run the BIG CABLE from it to the original terminal on the original switch.. Didnt have to install the STUD by doing this.............. but i also use a 12v battery so the AMPS are much lower than on the 6v system..... that is a possibility for YOU , switch to a 12v system and should be a lot less LOAD on your starter switch.

Edited by steve(ill) - 15 Jan 2025 at 7:35am

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 23263

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2025 at 8:03am Posted: 15 Jan 2025 at 8:03am |

|

if running 6 volts, be sure solenoid is rated for 400 amps !

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 8:32am Posted: 16 Jan 2025 at 8:32am |

|

Paul

An example of an Allis 6 V Starter Solenoid would be the Model D-14.

The Allis P/N is 223334, the now AGCO P/N is 70223334.

Edited by Gary - 16 Jan 2025 at 8:36am

|

|

mdm1

Orange Level

Joined: 12 Sep 2009

Location: Onalaska, WI

Points: 2644

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 9:02am Posted: 16 Jan 2025 at 9:02am |

|

Steve any chance you could post a pic or a diagram on how you modified the switch?

|

|

Everything is impossible until someone does it! WD45-trip loader 1947 c w/woods belly mower, 1939 B, #3 sickle mower 1944 B, 2 1948 G's. Misc other equipment that my wife calls JUNK!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82677

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 12:27pm Posted: 16 Jan 2025 at 12:27pm |

Mike, here are a couple pictures of two different starters. The whole goal is to replace the PUSH arm on the switch with a different arm that HITS the switch case at the BOTTOM and will not rotate... at the same time the other end of the arm needs to PUSH the button in for contact.. I have made a couple and if they dont PUSH hard enough on the button, you can spot weld a tit on it and then reinstall.. in one photo you can see i just slide a piece of sheet metal in the contact point to get more push on the switch.. and then put a drop of RTV on it to hold in place.....

First one i made had a nut welded on the top and a 1/4 inch screw pointed at the BUTTON.. and you just screwed it in to hold the button down... These are much simplier, once you get the dimension right.

|

|

Like them all, but love the "B"s.

|

|

mdm1

Orange Level

Joined: 12 Sep 2009

Location: Onalaska, WI

Points: 2644

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 1:22pm Posted: 16 Jan 2025 at 1:22pm |

|

Thanks for posting. So you replaced the the switch lever with a new piece to hold the switch in engaged position then wired solenoid etc. Seams easy enough.

Edited by mdm1 - 16 Jan 2025 at 3:42pm

|

|

Everything is impossible until someone does it! WD45-trip loader 1947 c w/woods belly mower, 1939 B, #3 sickle mower 1944 B, 2 1948 G's. Misc other equipment that my wife calls JUNK!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 82677

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 3:32pm Posted: 16 Jan 2025 at 3:32pm |

|

yes... the old switch ALWAYS ENGAGED takes the place of installing a NEW STUD....Dont seem to arc or wear as long as it is Always engaged.

|

|

Like them all, but love the "B"s.

|

|

Kip-Utah

Orange Level

Joined: 14 Sep 2009

Location: Southern Utah

Points: 874

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 4:47pm Posted: 16 Jan 2025 at 4:47pm |

|

Over 20 years ago I had the Autolite starter for my C rebuilt by an old-time shop. He replaced the contact lug with a threaded stud. he then attached a compact little solenoid, about the size of the original mechanical switch directly to that stud. There were two little tabs that screwed the solenoid to the tapped holes that held the original switch on. then the large cable from the battery bolted to a short stud on the side of the solenoid. The small 14-16 gauge wires ran up through the tool box to a heavy push starter switch mounted on the top corner of the battery box. Made for a nice clean installation. It's still working great. My only regret is that the original switch was a real nice operational switch, that I didn't get back from the rebuilder. I didn't realize that the Autolite specific switches were as rare as hens teeth!! I have an Autolite starter for Dad's B that needs one right now! Went to the parts box & dug out a Delco starter to use instead!

|

|

HANSEN'S OLD ORANGE IRON. Showing, Pulling, & Going!!

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11891

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2025 at 7:57pm Posted: 16 Jan 2025 at 7:57pm |

Good move Kip! Don't get me wrong, Autolites were good Starters, the switches are just about extinct. I had a pile of them switches years ago, and that was before I got into the Tractor arena. I still have a pile of internal parts for Autolite units. Once in a great while I'll get an Autolite Starter in to rebuild. Switches though, are loooong gone..... Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)