Too bad you you lost a second pump. Checking the pressure periodically would be good maintenance and really pretty easy and quick as long as it falls in range. A lot of hydraulic power line construction equipment prescribe checking relief pressures in the preventative maintenance schedule. Some have gauges to monitor pressure while operating.

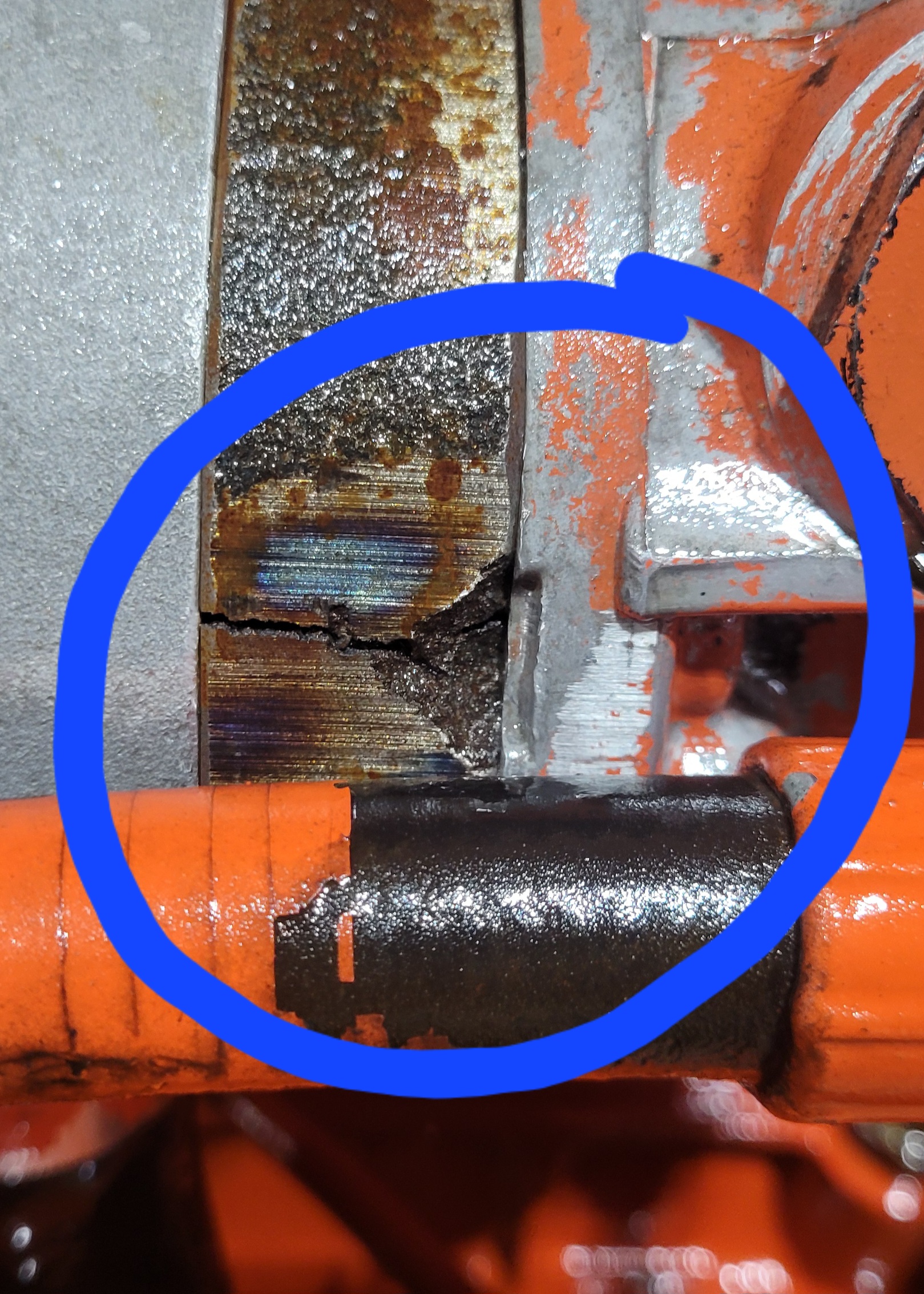

Our 190XT had some problems for a while breaking pumps, weak to lift etc. We ended up replacing the relief valve because for some reason the old one would not hold adjustment consistently. We also found the threads on the through bolts for the pump were pulled over a bit after one pump cracked. I suspect if they stretch in length slightly it wont keep the pump sections squeezed together creating a weak link that lets the pressure crack the pump housing.

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)