| Author |

Topic Search Topic Search  Topic Options Topic Options

|

twinson

Bronze Level

Joined: 17 Aug 2019

Location: IL

Points: 70

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis D17 hydo. factory options?? Topic: Allis D17 hydo. factory options??

Posted: 28 Oct 2023 at 11:23am |

|

Was there a factory option for D17's to have remotes and traction boost control over the right axel? Or is that after market?

|

|

|

Sponsored Links

|

|

|

RedHeeler79

Bronze Level

Joined: 09 Sep 2023

Location: NE Kansas

Points: 113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 12:54pm Posted: 28 Oct 2023 at 12:54pm |

|

Series IV has factory hydraulic and traction booster control levers mounted inboard of right hand fender, where the toolbox was mounted on earlier D17 models, and no levers on left side of steering column

|

|

twinson

Bronze Level

Joined: 17 Aug 2019

Location: IL

Points: 70

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 1:24pm Posted: 28 Oct 2023 at 1:24pm |

|

Was this all series IV's or just late one that had this location of controls?

Edited by twinson - 28 Oct 2023 at 1:46pm

|

|

RedHeeler79

Bronze Level

Joined: 09 Sep 2023

Location: NE Kansas

Points: 113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 1:28pm Posted: 28 Oct 2023 at 1:28pm |

|

All series IV will have hydraulic pump mounted externally at former belt pulley location and the right hand axle mounted hydraulic controls from factory. Some have additional remotes. My ‘66 only has one factory set of remotes.

|

|

RedHeeler79

Bronze Level

Joined: 09 Sep 2023

Location: NE Kansas

Points: 113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 1:31pm Posted: 28 Oct 2023 at 1:31pm |

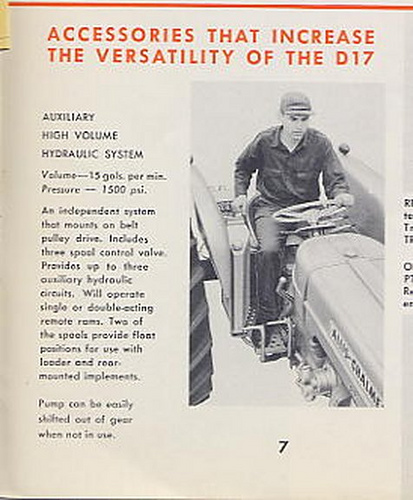

Look like this:

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 1:49pm Posted: 28 Oct 2023 at 1:49pm |

|

That's what a series 4 was all about !!! "LIVE" high volume (12 GPM) hydraulic system standard equipment (at 2,000 psi) with a factory optional category #2 three-point hitch.

Edited by DrAllis - 28 Oct 2023 at 5:28pm

|

|

Ky.Allis

Orange Level

Joined: 31 Jan 2010

Location: Kentucky

Points: 1002

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 4:23pm Posted: 28 Oct 2023 at 4:23pm |

|

How about a series 4 with snap coupler? Were the controls on right hand side or like a series 3?

|

|

RedHeeler79

Bronze Level

Joined: 09 Sep 2023

Location: NE Kansas

Points: 113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 4:38pm Posted: 28 Oct 2023 at 4:38pm |

|

The above pics are a snap coupler tractor

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2023 at 5:41pm Posted: 28 Oct 2023 at 5:41pm |

|

The new modern "live" 2,000 psi hydraulic system of the series IV D-17 is why that tractor is so valuable, especially if it has the factory optional Cat#2 3-point hitch. Summer/Fall of 1964 was an exciting time for Allis dealerships and their customers. The D-19 was replaced with a truly revolutionary looking and first of its kind operator platform tractor, the mighty One-Ninety. It too had this new "live" 2,000 psi very modern hydraulic system at the same time the D-17 IV was introduced, as the whole hydraulic valve stack was identical between the two tractors. John Deere had been trying to convince everyone that their new "closed-center" hydraulic system (3010/4010) was the future of tractor hydraulics, but this new Allis system was better in many ways. Interestingly enough, Massey basically copied Deere's closed center system (model 1100) but no one else in the industry ever did.

Edited by DrAllis - 28 Oct 2023 at 5:42pm

|

|

Nathan (SD)

Orange Level

Joined: 11 Sep 2009

Location: Day County SD

Points: 1260

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 11:11am Posted: 29 Oct 2023 at 11:11am |

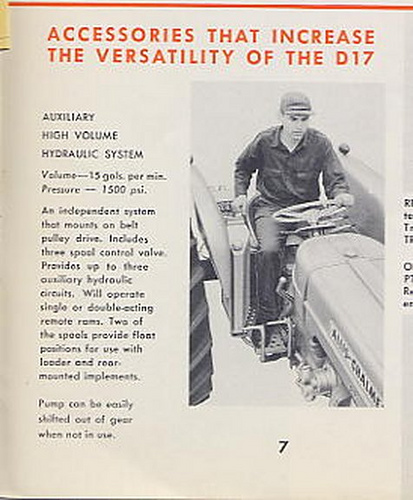

Another option

|

|

RedHeeler79

Bronze Level

Joined: 09 Sep 2023

Location: NE Kansas

Points: 113

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 12:40pm Posted: 29 Oct 2023 at 12:40pm |

|

That’s interesting! Appears to be a “series 2” in that advertisement, was there a date on it?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 1:09pm Posted: 29 Oct 2023 at 1:09pm |

|

OLD accessory!! and is dead when you push in the foot clutch !! Can't imagine they sold very many of them. The tank is right there by your right leg and a whole separate hydraulic system. 15 GPM's and only 1500 psi. My book that shows this picture is dated October 1960 and is series 2 vintage. EDIT: I just remembered I have a March 1960 sales book and this accessory wasn't offered, so it was later on in 1960 that it became available.

Edited by DrAllis - 29 Oct 2023 at 6:36pm

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 2:00pm Posted: 29 Oct 2023 at 2:00pm |

|

I think this even being offered as an option in 1960, shows that there was a NEED for hydraulics more modern than what the 1957 models were designed with. It took them until Summer/Fall of 1964 to finally get it right and standard equipment on the series IV..

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 8:47pm Posted: 29 Oct 2023 at 8:47pm |

|

After doing a little historical research, I have found out that 1500 psi was sort of the "industry standard" up until 1961, when John Deere raised the bar to 2,000 psi on the New Generation 3010/4010 tractors. Farmall was the tractor sales leader at that time and 1500 psi was their number, so A-C was making this optional system for the D-17 meet their specs, while keeping their own OEM system at 3700 psi. The D-19 was released later in 1961 and it too met Deeres 2,000 psi spec, altho at a very low 5 GPM and not a "live" system if the foot clutch was depressed.

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3536

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 10:02pm Posted: 29 Oct 2023 at 10:02pm |

|

would be kind of neat to fird one of those set ups

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3536

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2023 at 10:08pm Posted: 29 Oct 2023 at 10:08pm |

|

does the hydralics stop when you push the foot clutch on the series 4 it would be kind of hard to use the remotes for a loader and run the power director lever all on the right side

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 3:06am Posted: 30 Oct 2023 at 3:06am |

|

A little clarification is needed here after the last two posts. There was NO HYDRAULIC SYSTEM OPTION on the D-17 series 4 model. ALL series 4 D-17's had hydraulic levers to the right of the seat built into a console that included a Lift/Lower hitch lever, one or two remote (2-way) levers, a Traction Booster control lever and Position control lever. These two levers were side by side and at the rear of the console. This system was "LIVE" and used oil from the torque tube. It worked whenever the engine ran, foot clutch up or down. The two color pictures above are a series 4 tractor. *** The one black and white picture was an OPTIONAL system for PRE-series 4 models and included an oil tank, as it was a completely separate hydraulic system. It was powered by the belt pulley drive and could be shifted in and out of gear and went dead when you pushed in the foot clutch. There was NOT a Traction Booster lever included. There was NOT a position control lever either. The Traction Booster lever system was still on the steering wheel column and operated from the internal belly pump. A Position control lever never existed on an older D-17 tractor.

Edited by DrAllis - 30 Oct 2023 at 6:04am

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3536

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 11:09am Posted: 30 Oct 2023 at 11:09am |

|

i have been looking at a parts tractor series i d17d has all of the mounting bracket and two levers and valve on the left side of the tractor, it all looks the same only the oppisite side just remote vavles not lift or traction booster

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 11:11am Posted: 30 Oct 2023 at 11:11am |

|

That was a valve option that utilized the standard hydraulic pump inside the belly. Located on the left side so you could/had to use the Power Director lever. That valve was able to be dialed down to 1500 psi for brand X 2-way cylinders.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 2:40pm Posted: 30 Oct 2023 at 2:40pm |

Ky.Allis wrote: Ky.Allis wrote:

How about a series 4 with snap coupler? Were the controls on right hand side or like a series 3? |

All Series 4s had the controls on the right side regardless hitch type.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 2:42pm Posted: 30 Oct 2023 at 2:42pm |

HudCo wrote: HudCo wrote:

i have been looking at a parts tractor series i d17d has all of the mounting bracket and two levers and valve on the left side of the tractor, it all looks the same only the oppisite side just remote vavles not lift or traction booster |

Double check the serial number to confirm it really is a series 4 - don't go by the decals. Have seen several older models get new series 4 decals after a cheap repaint. All Series 4s had hydraulic controls on the RIGHT side of the seat. The tool box goes on the left side.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

1963D17

Bronze Level

Joined: 05 Jun 2021

Location: Alvord, Iowa

Points: 89

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 4:40pm Posted: 30 Oct 2023 at 4:40pm |

|

My D17 SIII has the factory three lever valve on the left hand side. One is for the lift arms and the other two control four outlets. Not live but it worked good. Had a Westendorf WL30 on it for years. Dad bought it new in 1963.

|

|

AllisFreak MN

Orange Level Access

Joined: 07 Dec 2009

Location: Minnesota

Points: 1541

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 5:23pm Posted: 30 Oct 2023 at 5:23pm |

|

Doc can you explain the procedure for "dialing down" the remote bank on the LH side of Series III and older to get to 1500 psi? Thanks.

|

|

'49 A-C WD, '51 A-C WD, '63 A-C D17 Series III, 1968 A-C One-Seventy, '82 A-C 6060, '75 A-C 7040, A-C #3 sickle mower, 2 A-C 701 wagons, '78 Gleaner M2

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3294

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 5:25pm Posted: 30 Oct 2023 at 5:25pm |

|

Many years ago we traded for a pre IV with the 3 levers on the left and a front mounted pump with pump guard/bumper . Looked factory. Had live hydraulics. Probably off a loader option for live hydraulics. Drove off a shaft w/chain coupler on the front crank pulley. Pretty neat rig. Lots of metal lines - did not have the aux reservoir.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 5:33pm Posted: 30 Oct 2023 at 5:33pm |

|

The optional valve stack to the left of the seat could be adjusted for 3700 psi (for A-C hyd cylinders) or 1500 psi (for all brand "X" cylinders). It allowed the Allis tractor high pressure hydraulic system to operate other "low" pressure cylinders without damaging them. There was a knob you turned fully Cwise or CCW to get whichever pressure you desired. It had to be set for 3700 psi to operate the lift arms or their lifting capacity was reduced.

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3536

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 8:10pm Posted: 30 Oct 2023 at 8:10pm |

|

the parts tractor with all the left side stuff i am looking at buying is a series 1

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3536

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2023 at 8:16pm Posted: 30 Oct 2023 at 8:16pm |

|

i will probley have to give 400 for all the left side stuff or 1600 for the whole tractor its deisel and i need everything from the deck up on the engine , just got a series 4 gasser from the wrecking yard , just cannot believe all the differances i have only been around series 1 d17s i did not even know that they made them in gas until i got on this forum

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Ky.Allis wrote:

Ky.Allis wrote: