| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Darwin W. Kurtz

Orange Level

Joined: 06 Apr 2010

Location: Westphalia, KS

Points: 4860

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Any ideas on fixing bent angle iron on car trailer Topic: Any ideas on fixing bent angle iron on car trailer

Posted: 10 Dec 2022 at 3:58pm |

|

Trailer was parked with big load of firewood, probably too much weight ....well Jack went sideways then broke off, trailer went down, bent one of the tongue angle irons.....any ideas on straightening without major work or completely changing hitch

Thank you

|

|

|

Sponsored Links

|

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Illinois

Points: 2050

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Dec 2022 at 5:58pm Posted: 10 Dec 2022 at 5:58pm |

|

I'd cut it off and build a proper tongue using 2X4-1/4 wall tube. I don't feel angle steel should be any part of a trailer tongue.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 10 Dec 2022 at 6:50pm Posted: 10 Dec 2022 at 6:50pm |

I dont know how heavy duty the trailer is or the size of the angle..... BUT

If the angle is bent UP at the tongue ... what i have done is get a 4 inch i beam 5 ft long and lay under the angle.. wrap a chain around the angle and the beam at both ends.. Put a bottle jack in the center between the angle and beam.. Jack up and when the chains get tight, the angle starts to bend.. Watch what your doing.. move the jack forward or back as needed to get a PUSH at the right spot.

Edited by steve(ill) - 10 Dec 2022 at 7:28pm

|

|

Like them all, but love the "B"s.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 31058

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 5:22am Posted: 11 Dec 2022 at 5:22am |

Straightening stressed angle iron adds more stress points, also tends to stretch what had gone into compression and distorts what had already been stretched. Not a good choice to straighten rather than replace, where IF do replace and is a high stress probability would increase angle thickness and overall dimension(IE 2x2 or 3x3 to 2x3 or 3x4) with wider side pointed Down.

Already done this on a trailer I sold to a BIL. Tongue was stressed by overload, cut away 2.5x2x3/16, installed 3x3x1/4.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 7:12am Posted: 11 Dec 2022 at 7:12am |

have seen that 'modification' before ....

easiest (?) repair... straighten the angle iron out best you can THEN weld a 2' length of 2by2 tubing inside the angle iron as a 'stiffener' . while you have the empty trailer upside down, do the other side ...

the guy who brought his 'modified' in didn't want me to , and yes, 3 weeks later, I DID the other side..... got a case of OV for that repair !

Edited by jaybmiller - 11 Dec 2022 at 7:13am

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 8:48am Posted: 11 Dec 2022 at 8:48am |

|

I straighten bent metal all the time.. Normally in a 20 ton press, but sometimes using a bottle jack at the location as shown above.. Have never done a " car trailer" as mine are heavy duty... but lots of tractor , mower , small trailer , frames and other parts.. If it is KINKED that is one thing.. A gradual BOW is easily straightened.

Edited by steve(ill) - 11 Dec 2022 at 8:49am

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 10:08am Posted: 11 Dec 2022 at 10:08am |

as DM says, once bent...always weak , so you will need to reenforce it. hmm, never seen a 'car hauler' with angle iron for tongue beams

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 1:19pm Posted: 11 Dec 2022 at 1:19pm |

I had a light duty 16 ft car hauler 20 years ago... had 3 x 4 angle iron for the frame and tongue... Rated at 7500 pounds... Since the trailer weight was 2000, that didnt leave much room for heavy car.... I hauled a Ford Explorer on it a few times, and a pickup truck once... When the boy bought a 7500 # BobCat, we retired that trailer and bought a 12K .

OOOPS looked back at records.. Frame and tongue were 4 x 5 x 1/4 inch thick.. Rating was 7000 pounds.

Edited by steve(ill) - 11 Dec 2022 at 1:28pm

|

|

Like them all, but love the "B"s.

|

|

Darwin W. Kurtz

Orange Level

Joined: 06 Apr 2010

Location: Westphalia, KS

Points: 4860

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 3:11pm Posted: 11 Dec 2022 at 3:11pm |

|

My jack was on the side of the tongue, welded to the angle iron instead of up in the middle of the hitch like the trailer in the picture. I bought this trailer used and it was in good shape.......but like everyone.....if you use something, something is going to happen. I don't think I have ever hauled a vehicle on it, but have hauled farm machinery alot on it and then the heavy firewood.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Dec 2022 at 3:45pm Posted: 11 Dec 2022 at 3:45pm |

YOU gotta be REAL CAREFUL with jacks in the center like in the picture !!! They're TOO close to the tailgate when you lower it....WAAY TOOOO close !!!! I bought some preholed 1/4" plates from Princess Auto ($2.50) that I plan to add BEHIND the A-tongue on my next trailer......

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 5754

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2022 at 2:24am Posted: 12 Dec 2022 at 2:24am |

Hi Darwin!

Post some pictures of the bend, so we can get a better idea of the magnitude of what you've got goin' on.

Steel used in trailer frames is generally 'non-hardening' steel, it is very ductile, so it doesn't 'work harden' much. oftentimes, it can be simply bent back, as long as it hasn't been 'stretched' into a deformation. If it HAS been stretched, then setting up a bending-back rig (like pictured above), and then warming the stretched areas to a soft red, then pushing it back to proper position, then PEENING the area that 'WAS' stretched, will give you a confident position afterwards.

I would recommend putting a backing of some sort on it, and match it on the opposite side, so that the bent area isn't likely to see concentrated stress in that area in the future.

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

Darwin W. Kurtz

Orange Level

Joined: 06 Apr 2010

Location: Westphalia, KS

Points: 4860

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2022 at 7:18pm Posted: 12 Dec 2022 at 7:18pm |

|

I have pictures on my phone......but I have no clue of knowing how to post them here, I have never gotten pictures to post on here before Please help

And thank you guys for all of your help so far

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Dec 2022 at 9:39pm Posted: 12 Dec 2022 at 9:39pm |

Darwin, most phones take photos that are 5000 x 3000 pixels or so... You need to be about 800 x 600 to get posted on this site.. Your phone photos are probably way to LARGE in MB size... Some have said you can "send" the photo to yourself, then resize and save.

I just use the computer and put all the camera photos on it.. Open the photo in PAINT or similar and resize to 800 x 600 or a little smaller...

You know you have to go to the "POST REPLY" icon below the last post... then click on the GREEN TREE ICON to get to your storage area of the photo...

|

|

Like them all, but love the "B"s.

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Illinois

Points: 2050

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Dec 2022 at 6:47am Posted: 13 Dec 2022 at 6:47am |

|

I resize to 1024X768 which still gives very good detail to the posted photo. Smaller is better to keep the attachment centered to where the viewer doesn't have to scroll around, but the small details can be lost.

|

|

A career built on repairing and improving engineering design deficiencies, shortcomings, and failures over 50 years now.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Dec 2022 at 8:02am Posted: 13 Dec 2022 at 8:02am |

Any (all ?) pictures on a 'smart phone/device' should be copied onto a PC or other computer. Never know when you'll drop phone into the small, white cistern........

I've always uploaded pictures from my PC to 'my file space' on the website, THEN grab a picture from there and copy into the 'Message' area.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 12:44pm Posted: 15 Dec 2022 at 12:44pm |

Here are two photos of Darwins trailer tongue. It is not "BENT" as much as TWISTED..

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 12:58pm Posted: 15 Dec 2022 at 12:58pm |

hmm, I'd put a BIG pipewrench ,tight where the jack was.add a 6' 'extender', then slowly,evenly push down on the bar and the angle should straighten out pretty well. It may take 4-5 pushes. You may need to raise the tongue up as high as possible,to get enough 'arc' to make it right. ideally, I'd say turn it upside down as it'd be easier,better control.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 1:03pm Posted: 15 Dec 2022 at 1:03pm |

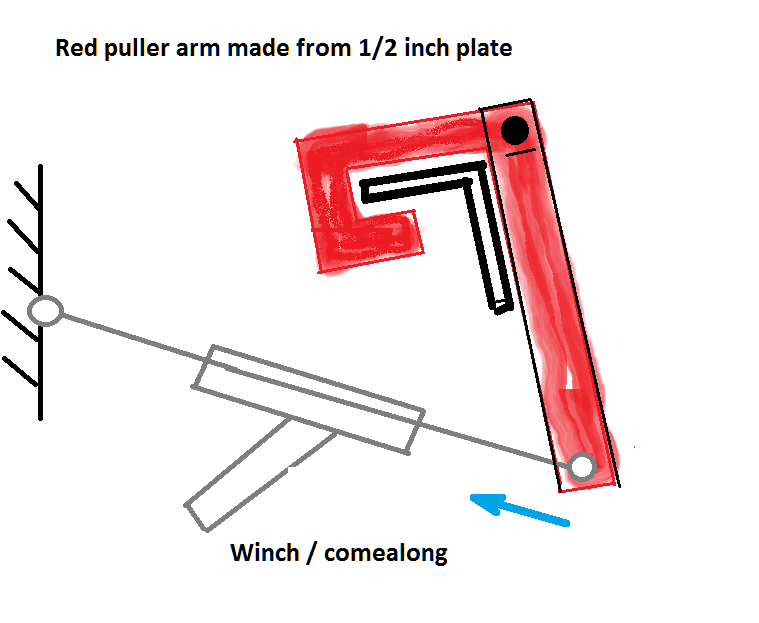

jay has the right idea, but your going to need more FORCE to bend it back.. It needs something like a 2 piece clamp that goes around the angle, with the LONG ARM as Jay said.. Then use a comealong or ratchet at the bottom and connect the other side to the corner of the tongue / trailer fame at the other side... You can tighten the clamp and the angle will start to "ROLL" back into postion.. You can move the clamp forward or backward on the tongue to get to the BAD area or where it needs it most... something like this..

you could position a 1/4 inch plate about 3 x 5 inches between the clamp and the angle iron frame if it tries to crush the angle in one area... the plate would spread the load out to a larger area while bending.

Edited by steve(ill) - 15 Dec 2022 at 1:08pm

|

|

Like them all, but love the "B"s.

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3938

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 1:10pm Posted: 15 Dec 2022 at 1:10pm |

|

apply heat and a 4’ pipe wrench. The top appears straight. The side metal has been stretched. Lots of heat bend it back and use a sledge hammer behind it for a dolly and a 3 lb smith hammer you can shrink it back. If you still want a side mounted jack weld a spreader bar either angle or boxed across to the other side. It should have had one when the jack was installed.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 1:11pm Posted: 15 Dec 2022 at 1:11pm |

aw Steve, you just need to have THREE bowls of Wheaties before you begin

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81066

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 1:18pm Posted: 15 Dec 2022 at 1:18pm |

I dont think the top of the angle is now HORIZONTAL.. I think the angles legs are still at 90 degrees to each other. Thats why i think it might be better to pull UP on the top leg while you pull INWARD on the vertical leg. ............ Daves idea of adding a STIFFENER plate between the two rails AFTER the repair, is a good idea.

Edited by steve(ill) - 15 Dec 2022 at 1:24pm

|

|

Like them all, but love the "B"s.

|

|

Darwin W. Kurtz

Orange Level

Joined: 06 Apr 2010

Location: Westphalia, KS

Points: 4860

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 4:02pm Posted: 15 Dec 2022 at 4:02pm |

|

Thanks for all your help. I t may be a little bit before I get to it.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 22448

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 5:13pm Posted: 15 Dec 2022 at 5:13pm |

|

Obvious 1st step would be to remove the tongue jack mounting piece......

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 51654

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Dec 2022 at 5:48pm Posted: 15 Dec 2022 at 5:48pm |

Before you cut the jack plate off, weld a stub out, on that rotator stub. Then an elbow up, and about an 8-10' extension, up. Hook to truck hitch, and latch securely. dump a little weight on the opposite side of the trailer. Park next to something substantial, on the bent side, and rig a come-a long to pull the 8-10' section of pipe in the opposite direction of the bend. That's my suggestion, results may vary depending on your skill and experience...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Darwin W. Kurtz

Orange Level

Joined: 06 Apr 2010

Location: Westphalia, KS

Points: 4860

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Dec 2022 at 7:57pm Posted: 17 Dec 2022 at 7:57pm |

|

I did the pipe wrench method, probably like 3 ft wrench with a 4 ft cheater pipe added, hitched it to the truckand jacked up under the receiver ass much ass it would safely go ( raised the back of the trcuk up ) didn't want it falling off the hi lift when I was trying to use the wrench.......things went to popping and after 4 or 5 trys.....it actually looks pretty good. The top came back into place really good, side could have gone a little more.......but it's a lot better than it was for sure. Jusr waiting for warm weather to weld a bar between the two tongue angles. Thanks to all you guys.....I'm happy with the fix

|

|

Darwin W. Kurtz

Orange Level

Joined: 06 Apr 2010

Location: Westphalia, KS

Points: 4860

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Dec 2022 at 7:59pm Posted: 17 Dec 2022 at 7:59pm |

|

Very sorry about the bad words, I thought I could type better than that

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)