| Author |

Topic Search Topic Search  Topic Options Topic Options

|

thendrix

Orange Level

Joined: 04 Feb 2013

Location: Fairmount GA

Points: 4879

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 160 Topic: 160

Posted: 15 Jan 2024 at 2:47pm |

|

I've had a couple of 160s offered to me and through research the only problems that have shown up have been the lift doesn't work. Is this the big drawback on these tractors? One of the tractors does have the lift problem, the other doesn't. The one with the lift problem only has around 500 hrs so I'm guessing it was either abused or neglected. Both run, go, and stop. Haven't seen them up close so I can't speak to actual condition. What are they worth?

|

|

"Farming is a business that makes a Las Vegas craps table look like a regular paycheck" Ronald Reagan

|

|

|

Sponsored Links

|

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 4663

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2024 at 6:35pm Posted: 15 Jan 2024 at 6:35pm |

It's been a long time, but my uncle had a 160 that I worked on some.

There is a filter screen (I believe) that is on the left side near the clutch pedal, that has to be kept clean. If the hydraulic pump won't pump. it can sometime be "primed" by taking off the lines and filling it with hydraulic fluid.

The hydraulic pump does seem to be a weak link on the 160, but aftermarket replacement pumps are a lot less expensive than a lot of tractors ( and readily available).

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3291

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2024 at 9:33pm Posted: 15 Jan 2024 at 9:33pm |

|

WF is exactly correct - there is also a suction strainer under the seat under a 3 bolt cap - remove it and punch some larger holes in the nylon with a ice pick and it will work better in cold weather - it will probably be covered with milky oil - in that case drain and flush and refil and clean the filters as well. You can tell if the lift issue is pump or in the rest of the 3 point system by operating the remote lever and listen to see if it 'lugs' the engine - it not then the pump is the issue - or it needs 'bleeding'

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2024 at 10:37pm Posted: 15 Jan 2024 at 10:37pm |

|

The only lift problem I have encountered with my 160 is when fluids are changed, filter change, cleaning of the hydraulic suction filter or if the suction coupler joining the 2 pipes together becomes loose sucking air into the system. That happened when I split my tractor to replace the clutches. I forgot to tighten the clamps. With that being said, a simple solution that works for me is to simply connect a 4’ hydraulic hose into the top hydraulic coupling and the other end into a clean container. Make sure the tractor hydraulic fluid is full. Operate the rear remote back and forth clearing any air in the system until a full stream comes out. Move to the second remote and repeat the procedure. Once this is done my hydraulics and lift arms return to operational condition. Refill tractor hydraulic reservoir.

Edited by AC720Man - 15 Jan 2024 at 10:40pm

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

thendrix

Orange Level

Joined: 04 Feb 2013

Location: Fairmount GA

Points: 4879

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 12:05am Posted: 16 Jan 2024 at 12:05am |

|

Thanks fellas. Any parts that are hard to find for this tractor?

|

|

"Farming is a business that makes a Las Vegas craps table look like a regular paycheck" Ronald Reagan

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 4663

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 7:23am Posted: 16 Jan 2024 at 7:23am |

AC720Man, as the hydraulic pump gets weak, the pump will stop working intermittently, especially when the tractor has set unused for a period of time. Infusing some hydraulic fluid usually will get it working and it will keep working as long as the tractor doesn't sit for an extended period. It progresses (regresses) until the pump won't work at all. Then, it's time for pump replacement. Thendrix, the 160 was built for AC by Renault, with a 3 cylinder Perkins diesel (I believe they use the same engine as the Massey Ferguson 135.) Some parts are readily available, but some parts are quite hard to find.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 11:45am Posted: 16 Jan 2024 at 11:45am |

|

My 160 has 7,500 hours on it and the original hydraulic pump. It will at some point need to be replaced, they are still available. Some parts are difficult to find. The plastic tube screen at the rear sump is NLA and is vital in keeping the fluid clean. I have a spare that I purchased from a parts tractor. I use the 3 pt and hydraulic outlets quite often especially in the summer. Winter time feeding with a carrier on the 3 point and have no issues with it not working. Maybe I’m just lucky that I have a good one.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 1:37pm Posted: 16 Jan 2024 at 1:37pm |

|

Never believe 500 hours on a 50 year old tractor! Could have stopped working, unhooked, or replaced in the past.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

Alvin M

Orange Level

Joined: 24 Jun 2018

Location: PA

Points: 764

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 2:55pm Posted: 16 Jan 2024 at 2:55pm |

|

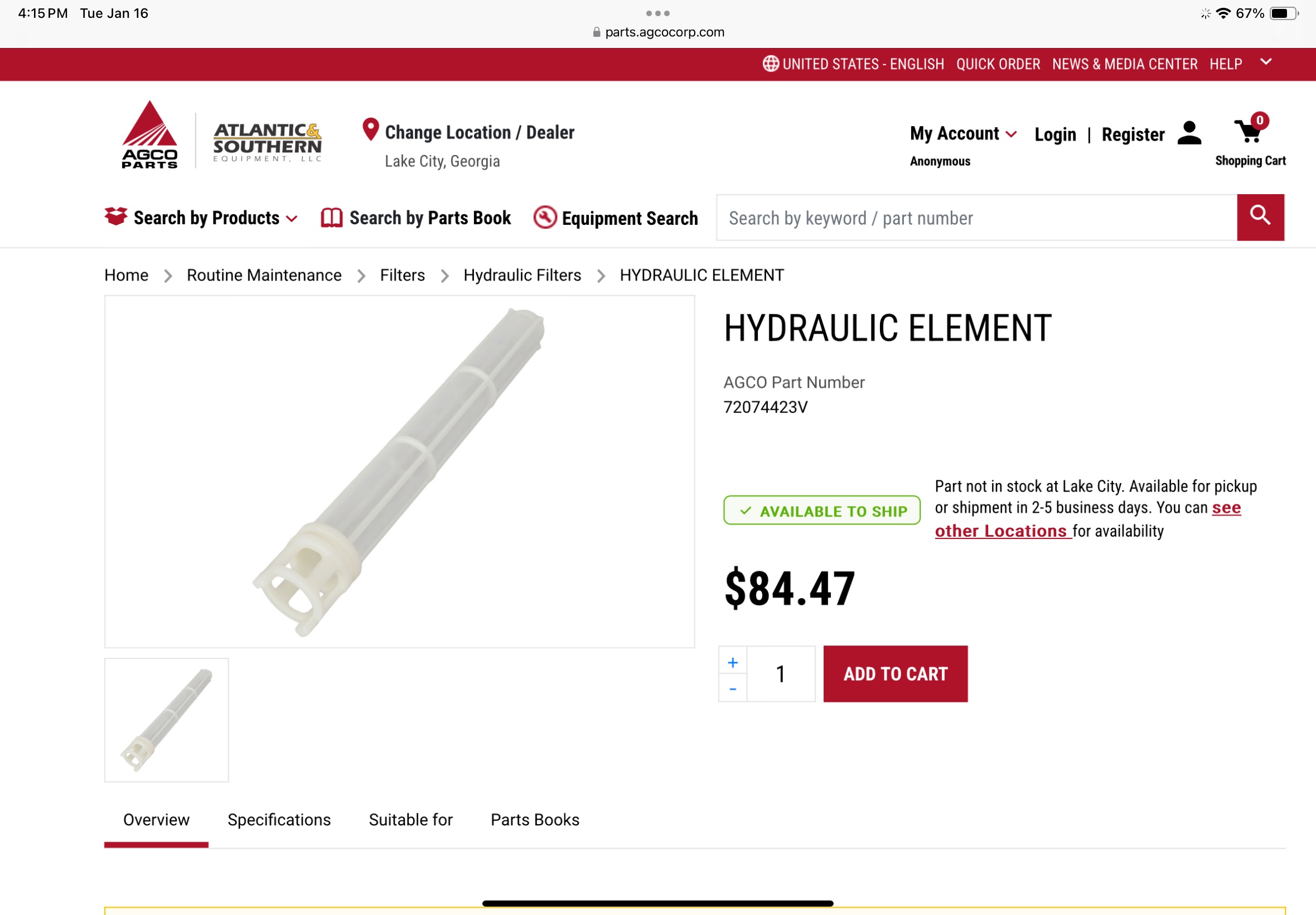

AC720Man Agco shows Part # 72074423v strainer screen for 84.47

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 3:11pm Posted: 16 Jan 2024 at 3:11pm |

|

Unless they are making them again, 2 years ago I was told by AGCO dealer they were NLA. Dealer search resulted in none available.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3291

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 3:23pm Posted: 16 Jan 2024 at 3:23pm |

|

VERY few parts - new - are available. Many moons ago the head of Deutz Allis was a guy who's brother in law was a big wig in Renault - we did our best to see what they could do for us - he got canned before we got any results.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4647

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 3:24pm Posted: 16 Jan 2024 at 3:24pm |

that "V" at the end of the part number usually means it's part of their Vintage line of parts

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2024 at 7:04pm Posted: 16 Jan 2024 at 7:04pm |

|

If I didn’t already have a spare I would get one. My original is still in good shape.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)