| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Sickle section removal Topic: Sickle section removal

Posted: 13 Feb 2024 at 4:36pm |

I have been removing the old and worn out sickle sections from the

bar on my new-to-me 82T mower. I use the hand grinder to grind the

head off one side of the rivet and then push the remainder out with my

riveting too. It has gone pretty well, but now I am where the drive

connects to the bar. I am wondering how to to remove the rivets in this

area. I do not want to mess up the drive with the grinder and I also

do not want to carve up the underside of the sickle bar. It looks like

the rivets are original, you can tell they have been there a long time.

What has everyone else done to prevent damage?

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

|

Sponsored Links

|

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10624

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 5:21pm Posted: 13 Feb 2024 at 5:21pm |

|

Lay the blade on a anvil or heavy vise with the section vertical, bar solid against vise or anvil horizontal. Take a hammer and drive-shear the section off of bar. Wear eye protection. Done a bazillion over the years, no problem. HTH Tracy

|

|

No greater gift than healthy grandkids!

|

|

Macon Rounds

Orange Level

Joined: 18 Feb 2010

Location: Pittsburgh Pa

Points: 2143

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 6:28pm Posted: 13 Feb 2024 at 6:28pm |

I would just buy a new one with bolt on sections.... Makes replacing them a snap. I have done what you are doing and it is time consuming and frustrating. Also repairing riveted sections in the field is :( Webb Cutting Components out of Nebraska..... They are awesome. Been using them for years. You will be MUCH MUCH HAPPIER with bolt on sections ... FYI: If you are intent on replacing all your sections. Webb also has a kit to replace rivets with bolts. I have also done that.

|

|

The Allis "D" Series Tractors, Gravely Walk behind Tractors, Cowboy Action Shooting !!!!!!! And Checkmate

|

|

Macon Rounds

Orange Level

Joined: 18 Feb 2010

Location: Pittsburgh Pa

Points: 2143

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 6:33pm Posted: 13 Feb 2024 at 6:33pm |

|

To answer you question on the THICK drive section. I drill them MOST of the way thru with smaller drill bit.

Then knock them out.

Edited by Macon Rounds - 14 Feb 2024 at 7:54am

|

|

The Allis "D" Series Tractors, Gravely Walk behind Tractors, Cowboy Action Shooting !!!!!!! And Checkmate

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 51651

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 7:12pm Posted: 13 Feb 2024 at 7:12pm |

I'd take an old cold chisel and grind it on one side only. The bigger the chisel the better. don't grind it real shallow, if you do, it won't shear the rivet right. Put the lower bar section in a vise, and using a large hammer, shear the rivets off. They are soft, whack 'em good and they pop right off. Takes less time than a grinder!

Back in my prime, it was 1 lick per rivet...

Edited by DiyDave - 13 Feb 2024 at 7:15pm

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 4722

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 7:23pm Posted: 13 Feb 2024 at 7:23pm |

|

I have a lever type sickle rivet tool that makes it a breeze to remove sections and re-rivet them. Yes you have to remove the knife from the machine, however the ease in which it works after that makes it a much better system than even the bolt on sections which can come loose along with the plus that your hands don't have to work in a confined space around the guards and sickle sections. I always carried a spare knife and could swap knives quicker than most could get the wrenches out to unbolt a section. I haven't used it in awhile since not haying any more and it buried in the barn or I go get a picture.

Edited by PaulB - 14 Feb 2024 at 3:14pm

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Macon Rounds

Orange Level

Joined: 18 Feb 2010

Location: Pittsburgh Pa

Points: 2143

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 7:38pm Posted: 13 Feb 2024 at 7:38pm |

|

If you ever used bolt on sections you will never go back to rivets...

With bolt on sections you don't have to remove the knife.

Remove one rock guard change the section and you are back in business...

Whether you broke a section or just have a dull one.

You can be back in business in 15 min.....

No agonizing over removing the knife and all that is involved in that.

|

|

The Allis "D" Series Tractors, Gravely Walk behind Tractors, Cowboy Action Shooting !!!!!!! And Checkmate

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81064

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 7:45pm Posted: 13 Feb 2024 at 7:45pm |

|

I changed over to the bolt from the rivets.. They give you a handful of LONG ONES to go on the first couple by the drive... I cut a LOT of TRASH and sticks/ small trees... Break 2-3 per season.. Bolts make it easy to switch them out as needed. .... Grinder works good for rivet removal.

Edited by steve(ill) - 13 Feb 2024 at 7:46pm

|

|

Like them all, but love the "B"s.

|

|

Ed (Ont)

Orange Level

Joined: 08 Nov 2009

Location: New Lowell, Ont

Points: 1289

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 7:55pm Posted: 13 Feb 2024 at 7:55pm |

|

Good air chisel should work on the rivets. I did a few as a kid but dad did most of them. We used to grind them off.

|

|

dp7000

Bronze Level

Joined: 26 Sep 2021

Location: Winchester Kent

Points: 138

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 8:13pm Posted: 13 Feb 2024 at 8:13pm |

|

I always did it the way Tracy said. Never had a problem.

Out in the field I put the blade on the front weights of the tractor using same technique. Used a broke section corner to drive spent rivets out.

Edited by dp7000 - 13 Feb 2024 at 8:16pm

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 51651

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 8:53pm Posted: 13 Feb 2024 at 8:53pm |

Always used a big sharp chisel, rivets are soft. Back in my prime, one whack per rivet, faster than a grinder...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 9:10pm Posted: 13 Feb 2024 at 9:10pm |

|

I’ve done it both ways, coal chisel and a 4 1/2” grinder. Chisel causes less damage but if your careful and patient the grinder does a good job. I switched to bolts also, easy and quick to change the sections. Also, no damage.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

im4racin

Orange Level

Joined: 12 Jun 2017

Location: Garrison ND

Points: 931

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 9:31pm Posted: 13 Feb 2024 at 9:31pm |

|

I do similar to Tracy but use a bench vise with the section pointed down and about 1 turn from clamped o the section. Keeps things from getting it of hand when working alone

|

|

1963D17

Bronze Level

Joined: 05 Jun 2021

Location: Alvord, Iowa

Points: 89

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Feb 2024 at 10:42pm Posted: 13 Feb 2024 at 10:42pm |

|

Bench vise closed nearly tight. Hit the sections. Two people works best.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Feb 2024 at 3:04pm Posted: 14 Feb 2024 at 3:04pm |

Macon Rounds wrote: Macon Rounds wrote:

I would just buy a new one with bolt on sections....

Makes replacing them a snap.

I have done what you are doing and it is time consuming and frustrating.

Also repairing riveted sections in the field is :(

Webb Cutting Components out of Nebraska.....

They are awesome. Been using them for years.

You will be MUCH MUCH

HAPPIER with bolt on sections ...

FYI: If you are intent on replacing all your sections.

Webb also has a kit to replace rivets with bolts.

I have also done that.

|

I already did buy the bolt on kit from Webb. The fun part has been removing these rivets.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

8070nc

Orange Level Access

Joined: 21 Mar 2019

Location: North Carolina

Points: 505

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Feb 2024 at 6:17pm Posted: 14 Feb 2024 at 6:17pm |

|

We got a brand new F2 in 1981 i think. I was running it and something knocked a section loose on the cutter bar. It had rivited sections. We didnt have any real tools back then so we would use a chisel to cut the heads off rivets. I put a pair of vise grips on the chisel. When I hit the chisel something said poof and the entire widshield of a brand new F2 was in the header. The whole thing. Needless to say my Dad was not impressed. None impressed

|

|

1984 80780

1957 D14

DES 300 with 25000 engine

616 tractor

|

|

dr p

Orange Level

Joined: 24 Feb 2019

Location: new york

Points: 1149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Feb 2024 at 6:28pm Posted: 16 Feb 2024 at 6:28pm |

|

Think my grandfather had a benchtop tool for that called a"sickle servicer"

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3938

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 17 Feb 2024 at 1:59pm Posted: 17 Feb 2024 at 1:59pm |

|

We carried a short section of RR track with out mowing lay it down set the spine of the sickle on the edge of the track points down and strike the section hard from the back the sevtion will shear the rivets right off. Poke the remaining part out with a pin punch.put the section back in put new rivets in lay on flat top of track and set with a rivet set and hammer only takes a couple minutes and your done. In the shop we used the big vice dont tighten on section need another person to hold the other end up

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4508

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 17 Feb 2024 at 7:13pm Posted: 17 Feb 2024 at 7:13pm |

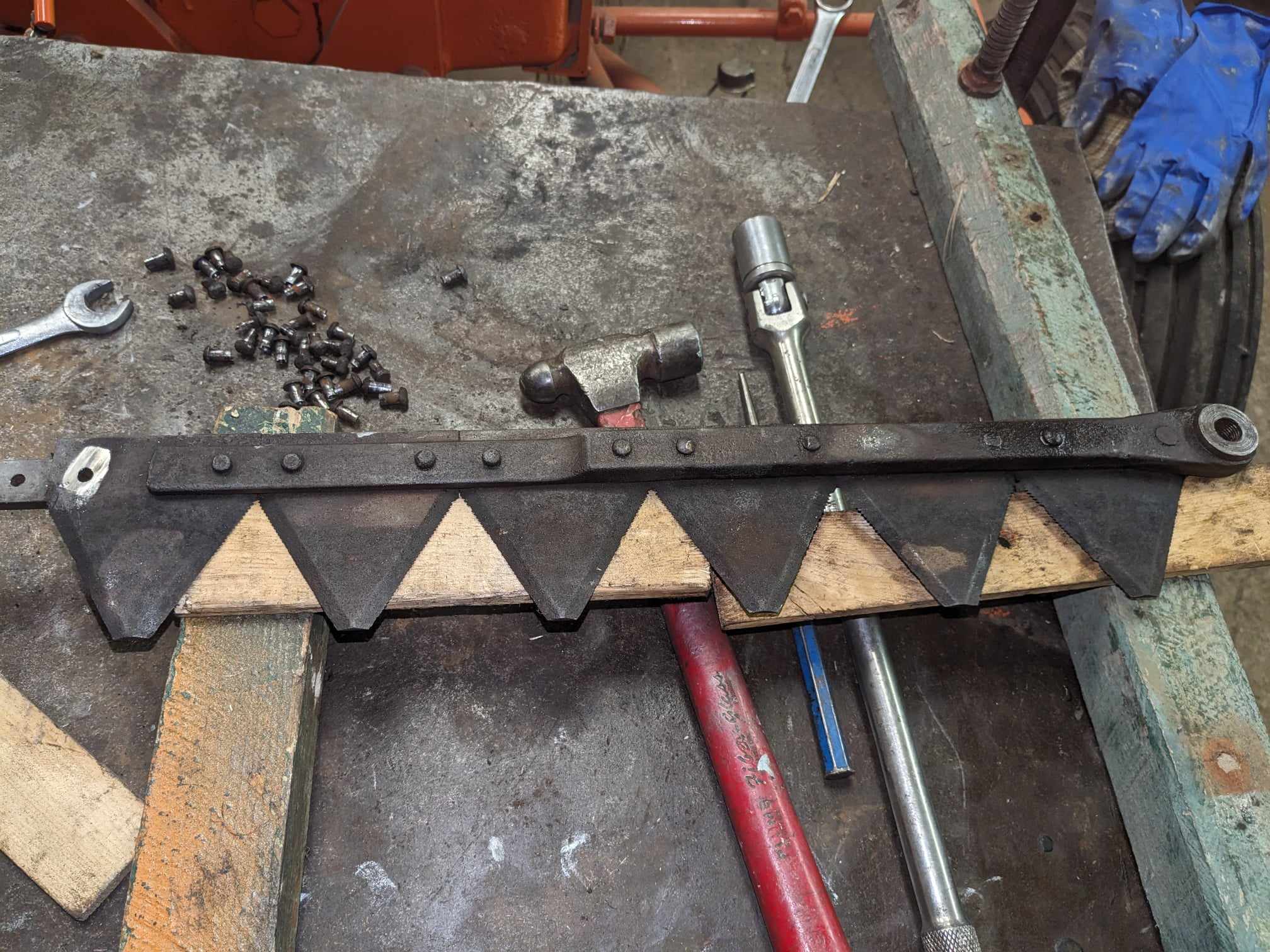

Is this tool? They work very if you want to use rivets. Was not sure they still made this with all the bolt on sections today. The knife is set to pop the sections off, the upper area is the rivet set.

Edited by Ray54 - 17 Feb 2024 at 7:15pm

|

|

dr p

Orange Level

Joined: 24 Feb 2019

Location: new york

Points: 1149

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Feb 2024 at 7:04am Posted: 18 Feb 2024 at 7:04am |

|

Yup but i think gramps had a red one

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8235

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Feb 2024 at 9:51am Posted: 18 Feb 2024 at 9:51am |

|

Hammering on a rivet has a tendency to stretch the bar. The proper set tool would help but still be careful. Just using a hammer is where you get in trouble. I've seen some where you could slip a post card between 2 sections. That adds up downstream then your register goes to crap.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 1986

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Feb 2024 at 8:30pm Posted: 18 Feb 2024 at 8:30pm |

Would you guys use one of those Johnson sickle servicers on the teeth that are sandwiched between the bar and the drive bracket? I have one of those tools as well, but haven't tried to use it for teeth located under the drive bracket. I know it's the bees knees for the teeth that are riveted only to the bar, where you're only shearing the rivet between the tooth and the bar as you force the tooth off.

Will it shear the rivet at the top and bottom edge of the teeth, when they're under the drive bracket like that? With no damage to anything you want to keep?

I have been drilling that handful of drive bracket rivets out with my drill press but maybe I am being too cautious.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 1986

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Feb 2024 at 8:36pm Posted: 18 Feb 2024 at 8:36pm |

dr p wrote: dr p wrote:

Yup but i think gramps had a red one |

The Johnsons at least used to be red. The ones I've picked up at auctions are. Interesting to see the new ones showing blue paint.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Feb 2024 at 12:42pm Posted: 19 Feb 2024 at 12:42pm |

The Johnson tool I used was red also. I can remember the spot we worked on 2, 18 foot Gleaner combine knifes. But other details not so much, other than out in the field and not much shade on a hot day. We would have used a chisel to cut the heads  or maybe left those section alone under the drive plate. As way before battery tools and generators being handy. But I also did a pair of knifes for my double knife New Holland swather.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Macon Rounds wrote:

Macon Rounds wrote: