| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 9:16am Posted: 15 Jul 2024 at 9:16am |

Hi guys, I've been slowly working on this mower over the summer. I'm almost finished rebuilding the gearbox becasue it leacked and was full of grease. While waiting for a bearing I'm working on the frame

There are 2- 1/4x2x2 angle irons that run underneath from the front of the mower to the gearbox to support lifting. These were all bent up and torn off behind the gearbox so I don't know how far back they should go.

I'm replacing these with new. The way the holes line up it looks like these should be 5' long and run from the front of the mower clear to the back. It seems like that would make good lifting support as you'd be lifting from the front middle and back. Can anyone confirm on their mower if they have these supports underneath and were they attach?

The issue I'm solving is the gearbox is sitting on top of angle irons welded on top on the frame and my replacement angle irons are bolted underneath the frame. This leaves a 1/4" gap or more (the thickness of the main frame) between my new irons underneath and the irons that the gear box sit on.

I think I'm going to make a shim out of some 1/4 stock to fill up the gap, but this wasn't there originally so I'm curious if the underneath supports aren't supposed to go all the way to the back which is causing the issue

|

|

|

Sponsored Links

|

|

|

Kenny L.

Orange Level Access

Joined: 12 Sep 2009

Location: NEIOWA

Points: 1362

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 11:54am Posted: 15 Jul 2024 at 11:54am |

|

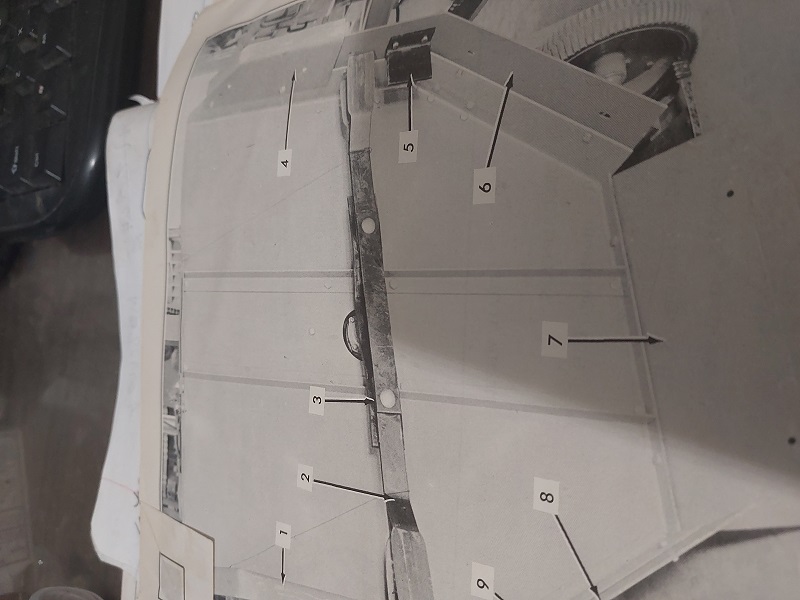

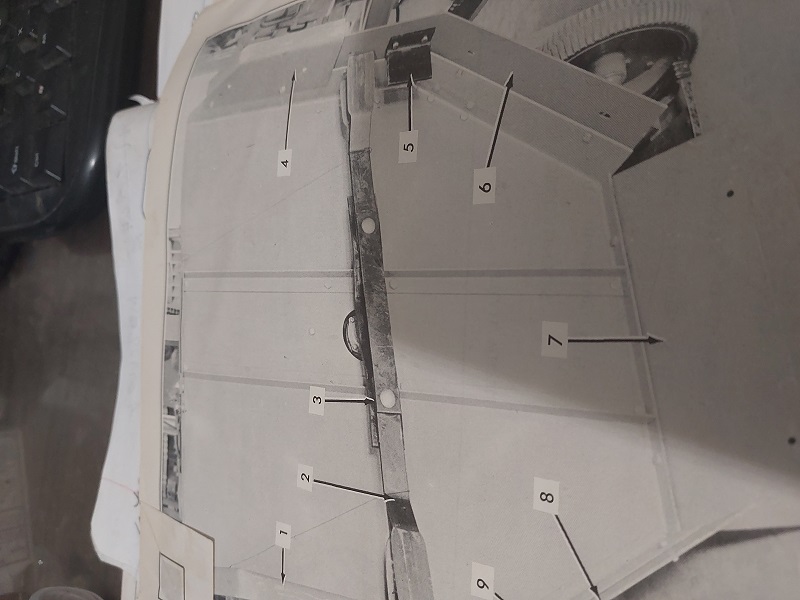

Dave, in my operators manual and parts list for the 160 rotary mower it show two angles running from the front all the way to the back. HTH Kenny

|

|

Kenny L.

Orange Level Access

Joined: 12 Sep 2009

Location: NEIOWA

Points: 1362

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 12:07pm Posted: 15 Jul 2024 at 12:07pm |

here a picture that's in my manual.

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1153

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 1:14pm Posted: 15 Jul 2024 at 1:14pm |

|

I swear blades on the 160 and 172 are nearly impossible to take off... The cotter keys basically rusted into the slots so I can't get the castle nuts off, and they point "up" so room to get an impact on there is non-existent.

|

|

Dave (NE)

Orange Level

Joined: 12 Sep 2009

Location: Eagle Nebraska

Points: 2157

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 1:39pm Posted: 15 Jul 2024 at 1:39pm |

|

Well, I went out, crawled on the ground and took a look at my shredder. I confirm, what Kenny is saying, that the angle irons do run all the way from the front to the back on either side of the gear box. There is one bolt at the front, two by the gear box, and another bolt at the back for each angle iron. Hope that helps. Dave

|

|

Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 2:17pm Posted: 15 Jul 2024 at 2:17pm |

|

Thanks guys that's exactly what I wanted to know. I installed my new ones the same way. Front to back. I'l make a couple shims to take up the space in the middle and clamp everything together tight.

|

|

Dave (NE)

Orange Level

Joined: 12 Sep 2009

Location: Eagle Nebraska

Points: 2157

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jul 2024 at 5:17pm Posted: 15 Jul 2024 at 5:17pm |

|

did you ever come up with a slip clutch?

|

|

Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2024 at 5:40am Posted: 16 Jul 2024 at 5:40am |

|

No, Either going to buy a new Tractor Supply clutch or just put it back together with only 2 instead of 4 1/4 bolts and see how it goes.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4120

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2024 at 8:31am Posted: 16 Jul 2024 at 8:31am |

garden_guy wrote: garden_guy wrote:

I swear blades on the 160 and 172 are nearly impossible to take off... The cotter keys basically rusted into the slots so I can't get the castle nuts off, and they point "up" so room to get an impact on there is non-existent.

|

Yep, that's pretty much the way bush-hog's are across the board. Nuts up, the button head on the bolt doesn't drag stuff around like the other side would. Reminds me, haven't sharpened the blades on the Mohawk yet this year. Seems like if you put a little anti-seize on things and service every year, things come apart easier.

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1153

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2024 at 11:08am Posted: 16 Jul 2024 at 11:08am |

IBWD MIke wrote: IBWD MIke wrote:

garden_guy wrote: garden_guy wrote:

I swear blades on the 160 and 172 are nearly impossible to take off... The cotter keys basically rusted into the slots so I can't get the castle nuts off, and they point "up" so room to get an impact on there is non-existent.

|

Yep, that's pretty much the way bush-hog's are across the board. Nuts up, the button head on the bolt doesn't drag stuff around like the other side would. Reminds me, haven't sharpened the blades on the Mohawk yet this year. Seems like if you put a little anti-seize on things and service every year, things come apart easier.

|

Yeah I wound up doing this number to sharpen mine since I couldn't take them off:

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2024 at 11:51am Posted: 16 Jul 2024 at 11:51am |

|

Whatever works! My gearbox is off and the blades lying on the ground. They should be a lot easier to getoff when you can hold them and not lying on your back

|

|

Dave (NE)

Orange Level

Joined: 12 Sep 2009

Location: Eagle Nebraska

Points: 2157

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2024 at 2:08pm Posted: 16 Jul 2024 at 2:08pm |

|

That's how I sharpen mine, too!

|

|

Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain.

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1104

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jul 2024 at 6:40pm Posted: 16 Jul 2024 at 6:40pm |

|

I took a loader tractor and flipped it so the hitch was in the air, much easier to work in there.

I rebuilt the gear box on mine because the races were cracked but the gears were fine.

|

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD45

|

|

ac hunter

Orange Level

Joined: 05 Jan 2011

Location: OHIO

Points: 1065

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2024 at 7:24am Posted: 17 Jul 2024 at 7:24am |

Nice mowers. Bet AC didn't build a lot of those. Am wondering if anyone knows where to get a wheel like the tail wheel in Dave's mower picture. Looks like the depth gauge wheels on my AC snap coupler field cultivator. Mine are pretty shot, expecially the rubber. I have looked on the internet but can't find anything. May not have found the right source though. Thanks.

|

|

Dave (NE)

Orange Level

Joined: 12 Sep 2009

Location: Eagle Nebraska

Points: 2157

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 Jul 2024 at 8:12am Posted: 17 Jul 2024 at 8:12am |

|

Good luck finding the wheel. Or even the tire. The tire is a 4x16 semi-pneumatic tire. I needed a tire and eventually got one that is used as a gauge wheel on a White 5100 planter. Is not 100% correct, as the tire is at an angle and not flat, but works. Ironically, a few months ago I was at an auction with Allis stuff. In a pile, I found a wheel and tire that was an exact match to the original. Go figure!

|

|

Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain.

|

|

ac hunter

Orange Level

Joined: 05 Jan 2011

Location: OHIO

Points: 1065

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Jul 2024 at 11:49am Posted: 18 Jul 2024 at 11:49am |

|

Thanks Dave. I was kind of thinking the tire was n't even available anywhere. Maybe I'll see about your planter wheel suggestion.

|

|

Dave (NE)

Orange Level

Joined: 12 Sep 2009

Location: Eagle Nebraska

Points: 2157

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Jul 2024 at 12:47pm Posted: 18 Jul 2024 at 12:47pm |

|

I worked with Mark Wells of Wells Implement in Plymouth NE to figure things out. The Agco part number is 71506603. He thought Agco may have the tire for a Landoll planter. You may try that also. Dave

|

|

Do not argue with an idiot. He will drag you down to his level and beat you with experience. Mark Twain.

|

|

1963D17

Bronze Level

Joined: 05 Jun 2021

Location: Alvord, Iowa

Points: 90

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Jul 2024 at 11:25pm Posted: 19 Jul 2024 at 11:25pm |

|

I have that same mower on my D17. The overunning clutch was shot. I bought an overunning adapter from tractor supply that goes between the tractor and the pto shaft. It works well.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3073

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2024 at 7:56am Posted: 26 Jul 2024 at 7:56am |

part number 2009269 is pictured with arrows pointing at it. Does anyone have One of these for sale?

The one on the left side of the mower is homemade. Homemade one has a "X" in the picture and is missing the adjustment holes.

|

|

ac hunter

Orange Level

Joined: 05 Jan 2011

Location: OHIO

Points: 1065

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2024 at 8:01am Posted: 27 Jul 2024 at 8:01am |

|

Thanks, Dave (NE). I wiil contact Mr. Wells and see how that goes. Thanks for the part #.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

garden_guy wrote:

garden_guy wrote: