| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7334

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 303 Baler PTO shaft removal Topic: 303 Baler PTO shaft removal

Posted: 20 Oct 2024 at 9:06am |

|

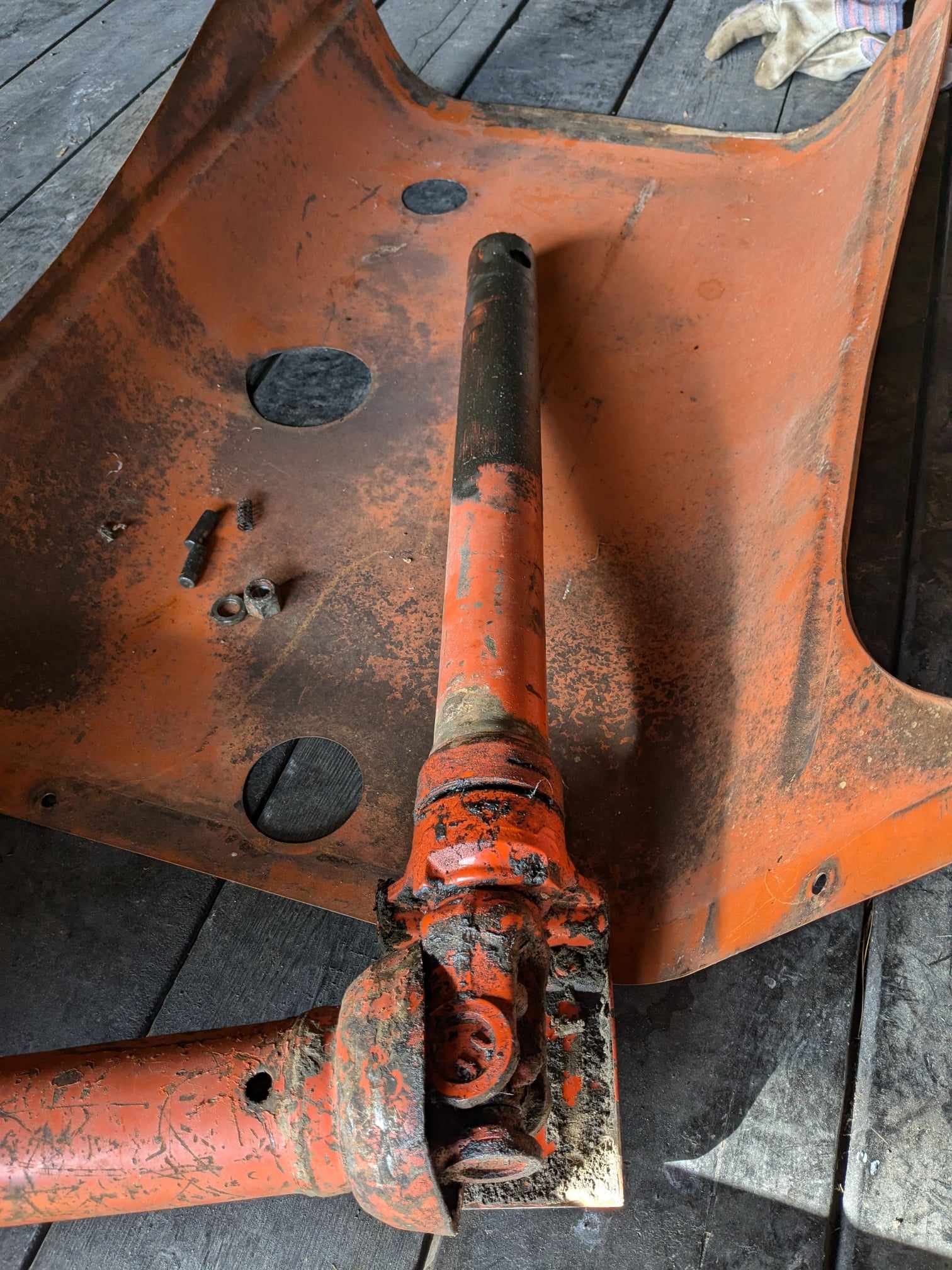

How do you remove the PTO shaft from the flywheel? I suspect taking apart the U joint would be the easiest, but don't know how they come apart. The shaft got bent slightly so it will not telescope.

Thanks in advance!

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

|

Sponsored Links

|

|

|

Lars(wi)

Orange Level Access

Joined: 14 Sep 2009

Location: Permian Basin

Points: 7219

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Oct 2024 at 9:38am Posted: 20 Oct 2024 at 9:38am |

|

Taking apart the u-joint may not help. You still have the remaining 1/2 of the joint attached to the flywheel.

I’m not familiar with the 303, but removing any shields/guards, looks for a ‘set bolt’ or maybe even a bold that goes all the way thru the u-joint and shaft, more than like likely a key shaft or two the u-joint slides on to.

|

|

I tried to follow the science, but it was not there. I then followed the money, and that’s where I found the science.

|

|

im4racin

Orange Level

Joined: 12 Jun 2017

Location: Garrison ND

Points: 936

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Oct 2024 at 7:08pm Posted: 20 Oct 2024 at 7:08pm |

|

There is a nut holds the yoke that is the over running clutch onto the slip clutch. The slip clutch is half to the flywheel with three 3/8 bolts

|

|

orangereborn

Orange Level

Joined: 12 Sep 2009

Location: NW WI

Points: 1438

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2024 at 3:17pm Posted: 21 Oct 2024 at 3:17pm |

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7334

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2024 at 3:47pm Posted: 21 Oct 2024 at 3:47pm |

im4racin wrote: im4racin wrote:

There is a nut holds the yoke that is the over running clutch onto the slip clutch. The slip clutch is half to the flywheel with three 3/8 bolts |

It doesn't look like the nut can be removed with the U joint in place (unless a box end wrench will fit in there???). Socket or open end wrench doesn't look like it will fit.

I did look at the 3 bolts holding the slip clutch to the flywheel - they will not come out all the way unless I take apart the slip clutch.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8241

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2024 at 4:58pm Posted: 21 Oct 2024 at 4:58pm |

|

Are both pieces bent or just the piece that slides inside?

|

|

im4racin

Orange Level

Joined: 12 Jun 2017

Location: Garrison ND

Points: 936

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2024 at 6:08pm Posted: 21 Oct 2024 at 6:08pm |

|

It will take a regular box end. Ratcheting version won’t fit. It will go round and round one way. Not the other. Don’t remember if removing or assembly was the easier way but it’s not bad at all

|

|

orangereborn

Orange Level

Joined: 12 Sep 2009

Location: NW WI

Points: 1438

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Oct 2024 at 11:50pm Posted: 21 Oct 2024 at 11:50pm |

|

I modified a box wrench to fit...If too tight a crack with hammer and chisel. Loosen the nut before any thing else...

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7334

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Oct 2024 at 2:43pm Posted: 22 Oct 2024 at 2:43pm |

SteveM C/IL wrote: SteveM C/IL wrote:

Are both pieces bent or just the piece that slides inside? |

Don't know. The shields aren't bent. Once the shaft comes off, I will have to figure out how the shield comes off to see whether it is one section bent, or both.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7334

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2024 at 3:53pm Posted: 30 Oct 2024 at 3:53pm |

Update: 15/16" Box end wrench was able to fit the nut on the flywheel

and the shaft came off easily. Next issue is removing the shields from

each end of the shaft. Parts book shows a snap ring by the U joint, but

I have not seen it up close in person. Anyone have any hints?

Edited by DSeries4 - 30 Oct 2024 at 3:54pm

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

im4racin

Orange Level

Joined: 12 Jun 2017

Location: Garrison ND

Points: 936

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Oct 2024 at 9:43pm Posted: 30 Oct 2024 at 9:43pm |

|

On the shaft on the hood. There is a small slot near the support bag. That is the snap ring slot. Push it in on all the slots and slide shield off. On the other side line up hole with the roll pin and drive out. The yoke will slide off the shaft and shield will slide off

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7334

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 7 hours 16 minutes ago at 8:19am Posted: 7 hours 16 minutes ago at 8:19am |

|

Next issue: for reinstalling the shields over the shafts, how do you lock the snap ring into the 3 slots?

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

im4racin

Orange Level

Joined: 12 Jun 2017

Location: Garrison ND

Points: 936

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 5 hours 26 minutes ago at 10:09am Posted: 5 hours 26 minutes ago at 10:09am |

|

Use a screwdriver to walk ring back into the guard. Then turn until detents pop into the slots. If you can line bumps up with slots it will snap in easier

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

im4racin wrote:

im4racin wrote: