| Author |

Topic Search Topic Search  Topic Options Topic Options

|

PawPaw

Bronze Level

Joined: 21 Feb 2024

Location: NE Indiana

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 190xt front spindle Topic: 190xt front spindle

Posted: 24 May 2024 at 1:30am |

|

My neighbor broke the spindle on his 190xt and asked if I knew how to replace one. I’ve never done one and figured this would be the place to ask for advice. Thanks for any help you can give

|

|

|

Sponsored Links

|

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8241

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 8:45am Posted: 24 May 2024 at 8:45am |

|

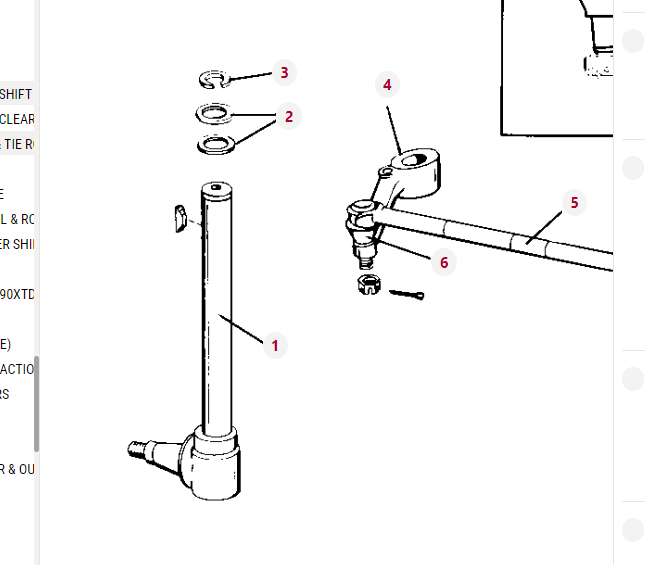

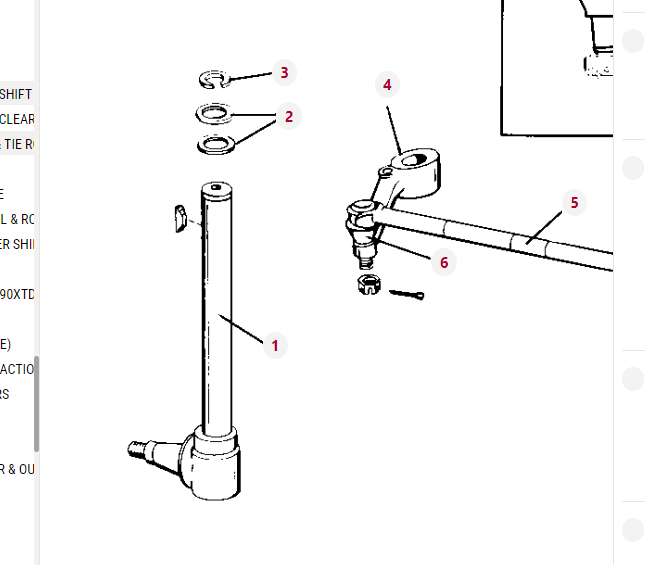

Just know the steering arm has to be removed and key dug out before spindle can slide out.

|

|

PawPaw

Bronze Level

Joined: 21 Feb 2024

Location: NE Indiana

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 10:46am Posted: 24 May 2024 at 10:46am |

|

Thank you Steve I’ll pass that on to him.

|

|

Acdiesel

Orange Level

Joined: 15 Jun 2012

Location: Rochester Ohio

Points: 2548

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 10:51am Posted: 24 May 2024 at 10:51am |

Remove snap ring, remove steering arm, remove key and spindle assy. should come out the bottom. Hopefully no one welded the snap ring on top of the spindle or else some grinding will be required to remove.

|

|

D19 diesel,D17 diesel SER.3 D14 NF,D14 WF, D15 SER.II wf

D15 SER.2 DIESEL,D15 ser.II nf

D12 SER.I, D10 Ser.II

2-720'S

Gmc,caterpillar

I'm a pharmacist (farm assist) with a PHD (post hole digger)

|

|

rw

Silver Level

Joined: 28 Oct 2009

Location: United States

Points: 383

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 2:36pm Posted: 24 May 2024 at 2:36pm |

|

The point made earlier about the woodruff key is vital. You will have to get the steering arm off the spindle then remove the key and then it will through the bore. The best recommendation I have heard is to raise the front end pull the axle beam,turn it upside down. Then sledge hammer the steering arm off the spindle. Might heat it a bit as you hammer. I didn't do that and wish I had tried. I was advised to cut a slit in the arm to relieve the grip when I did mine 35 or so years ago. It is a tight interference fit when you have new parts and it holds well as designed. We welded our steering arm back to the spindle after slitting it. Been OK so far and do keep it lubed.

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 8108

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 3:25pm Posted: 24 May 2024 at 3:25pm |

|

Seen alot of them welded on too- not Allis factory weld either

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8241

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 10:00pm Posted: 24 May 2024 at 10:00pm |

|

flipping it over and pounding off is what I did on one 8070. Not a pleasant task but it worked . Seemed all wrong. Pounded back on and still tight after 10yrs. Must have something to protect arm from hammer when reinstalling.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81271

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 May 2024 at 11:05pm Posted: 24 May 2024 at 11:05pm |

can you drive a pickle fork between the arm and axle housing ?? or no room ? Heat ?

flipping it sounds like a lot of work... I like the SPLIT IT with a die grinder idea..

Edited by steve(ill) - 24 May 2024 at 11:09pm

|

|

Like them all, but love the "B"s.

|

|

PawPaw

Bronze Level

Joined: 21 Feb 2024

Location: NE Indiana

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2024 at 5:27am Posted: 25 May 2024 at 5:27am |

|

I talked to the neighbor last night and he has it changed. The broken one had been welded at some time. The broken one came out fairly easy and he is back up and going. Thanks again for the advice

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 3736

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2024 at 7:59am Posted: 25 May 2024 at 7:59am |

I really hate seeing weld on spindles. Seems to be popular in the Red camp also. Had to change a thrust bearing in my 1066 once. Steering arm welded to spindle, broken all the way around mind you. Still wound up grinding on it for about an hour with a carbide burr to get it apart.

Another thing, pretty sure those spindles aren't just 1010 steel! My guess would be 1045, could be higher alloy than that even. Just because you can strike an arc on something doesn't mean you should!

I've got some sort of an issue with a steering arm/key/spindle on my 185. Toe in won't stay put. Not the tie rods either. It's nice to have plenty of tractors to fill in when one is sick!

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 8108

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2024 at 8:03am Posted: 25 May 2024 at 8:03am |

|

Why did the put such big tires on the front ? Turning puts so much stress on stuff- It kills me to see the front higher than the back , dont make sence

Edited by DougG - 25 May 2024 at 8:04am

|

|

mruhlig77

Orange Level

Joined: 19 Aug 2014

Location: central Indiana

Points: 578

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2024 at 8:35am Posted: 25 May 2024 at 8:35am |

|

Will have to look ...might have a used one here from a broken axle...are left and rights the same...Mark

|

|

mruhlig77

Orange Level

Joined: 19 Aug 2014

Location: central Indiana

Points: 578

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2024 at 8:50am Posted: 25 May 2024 at 8:50am |

|

Walked out and looked....have the axle assembly but no spindles...oh well

|

|

mruhlig77

Orange Level

Joined: 19 Aug 2014

Location: central Indiana

Points: 578

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2024 at 8:52am Posted: 25 May 2024 at 8:52am |

|

I walked out and looked...have the front axle assembly..but no spindles..

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)