| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dale

Silver Level

Joined: 11 Sep 2009

Location: Ontario

Points: 375

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: HD6G-Need Help-Clutches seized Topic: HD6G-Need Help-Clutches seized

Posted: 11 Nov 2022 at 6:20am |

Well, the cost of sitting and not being used I guess.

Been in dry, not heated storage for about 6 years. Rubber boots intact so likely no mice issue (which was the reason rebuilt clutches). Just before being parked both clutches rebuilt with new parts. Everything worked as it should.

Went to move it. Starts like a charm. Moves forward and reverse like it should. Won't turn either way. Drove it around. Used backhoe (factory tractomotive unit) to turn it. No luck

Any ideas how to break them free. Any help sure appreciated.

|

|

|

Sponsored Links

|

|

|

Coke-in-MN

Orange Level Access

Joined: 12 Sep 2009

Location: Afton MN

Points: 41609

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 11 Nov 2022 at 7:42am Posted: 11 Nov 2022 at 7:42am |

|

If fiber discs - probably some rust - or you got mice up through the drain hole (3/4 hole) in bottom of case .

Can try pipe plug in case drain , block clutch levers back to release clutches , fill case with diesel , let set for time , try again with diesel still in cases . Machine against immovable object and with clutches still blocked cycle master clutch to load clutch packs .

OR remove clutches and free up on bench - install HD11 bi-metal friction plates

|

|

Faith isn't a jump in the dark. It is a walk in the light. Faith is not guessing; it is knowing something.

"Challenges are what make life interesting; overcoming them is what makes life meaningful."

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2022 at 8:05am Posted: 11 Nov 2022 at 8:05am |

|

Did you use the brake pedal for turning and you should have 2 inch max free travel on brake pedal and you should have 3 inchs free travel at the top off stering cluch lever

|

|

Transaxial

Bronze Level

Joined: 19 Apr 2014

Location: Tofield,Alberta

Points: 96

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2022 at 11:10am Posted: 11 Nov 2022 at 11:10am |

|

My 1969 Champion 562 grader has a stuck clutch. I believe it is a multi disc wet clutch and the oil is milky so indicates water. I have owned this grader for 20? years and it has been stuck before so I would just start it in gear after warming it up and put it to work while holding the clutch pedal down. Usually not very long while working it the clutch would break free and work normally. About 12 - 14 years ago my cousin was doing a private subdivision and wanted to buy a grader. I didn't really want to sell it but told him I would sell him a 1/2 share so we both still have access. He lives about 24 miles away so it is feasible to just drive the grader if either of us needs it. He phoned me a month ago and said the grader is yours. Come and get it. I am done with it but the clutch is stuck. Haven't been able to get it freed up this time. That little 4 - 71 in it just runs like a dream. It is not an Allis but wondering if anyone has experience with a stuck wet clutch like this? This grader has always sat outside but the clutch is enclosed in the housing so oil doesn't leak or get contaminated. Except for water apparently.

|

|

Dale

Silver Level

Joined: 11 Sep 2009

Location: Ontario

Points: 375

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Nov 2022 at 5:42pm Posted: 11 Nov 2022 at 5:42pm |

Thanks for the replies everyone. Good advice that will help me.

Thanks again

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Nov 2022 at 12:16am Posted: 12 Nov 2022 at 12:16am |

Like the others said, in your case, they'll probably break loose with a little working. My left clutch hasn't broken loose, even with soaking, hammering, clutching, and driving the tractor around with the lever tied back. Trouble with these, if the clutch plates are stuck in the hub or drum, you can't pull the clutch out . I sure hate to have to cut up a 300$ drum to get it out.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

Dale

Silver Level

Joined: 11 Sep 2009

Location: Ontario

Points: 375

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Nov 2022 at 7:48pm Posted: 13 Nov 2022 at 7:48pm |

I hope you're correct.

I replaced the clutches because mice ate the rubber boot on one side and built a nest. You know the rest of the story. At least with one working you could manoeuvre using forward and reverse. With both frozen we had to use the backhoe to swing the rear end to turn at all.

Likely won't be until spring before I get at this project-sometimes I think if I didn't have bad luck I'd have no luck at all

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Nov 2022 at 8:04am Posted: 14 Nov 2022 at 8:04am |

doctorcorey wrote: doctorcorey wrote:

Like the others said, in your case, they'll probably break loose with a little working. My left clutch hasn't broken loose, even with soaking, hammering, clutching, and driving the tractor around with the lever tied back. Trouble with these, if the clutch plates are stuck in the hub or drum, you can't pull the clutch out . I sure hate to have to cut up a 300$ drum to get it out.  |

After pulling your brake band pin/pins on the frozen side, tie the upper brake shoe back exposing the brake drum surface. Using strong bungee straps, tie your clutch release handles back in the normally released position and elevate the tracks clear of the ground/floor. Grab a torch with a small rosebud tip and while the frozen clutch assy. is spinning and driving the track, "play" the torch on the surface of the brake drum. Bring the temperature up but it doesn't need to be red in color. The purpose is to expand the internal diameter of the drum until clutch release pressure overcomes the bind and the clutch will release suddenly. You will see this with the release handles wanting to move from the tension of the bungee straps pulling. I've done exactly this on a couple tractors that have sat for years and elevating the temperature of the parts does work, but takes time. Just don't "dwell" in a single spot of the drum or mechanism for any length of time as no need to destroy parts unnecessarily. You can also do this to the clutch hub but the heat could be detrimental to the pressure plate springs. Really no need to get anything hot enough to cook seals, but heat will help break any bonds.

Have you tried a bar in the sprocket teeth between the track frame yet? While holding the stuck clutch handle back, ease the main clutch in as you don't want to break parts. This will load the steering clutch much harder than normal usage will. Before doing this ensure your track is tighter than normal:

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2022 at 3:15pm Posted: 15 Nov 2022 at 3:15pm |

|

I have thought about using a 'heavy bar' to block the sprocket. I just don't want to torture this old tractor unless I have to. On the other hand, when the tracks were stuck bad, the clutch did slip multiple turns, but then the track broke loose, and here I am. I suppose the strain on the finals (with blocking the sprocket) couldn't be any worse than when the clutch slipped with the tracks stuck. I had considered that I might have stripped some of the clutch plate splines, and just jammed the whole thing into a warped, twisted mass. When I have finished 'rebuilding' this hokey sheet metal exhaust manifold, I'll give it a whirl. Thanks.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 12:03am Posted: 23 Nov 2022 at 12:03am |

|

Well, I tried it with the 'heavy bar' in the track sprocket. It was heavy, solid tool steel and it bent it into a nice curve. That clutch isn't going to break loose this way. I will try the heating process. If this doesn't work, I will be forced to cut the drum. How to do that is something I'd appreciate any info as to what apparatus to use to cut it. That's a lot of metal to remove.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 9:36am Posted: 23 Nov 2022 at 9:36am |

|

Did you try to pull out the stering cluch before cutting the stering cluch drum and did you knock on drum easly with a hammer it could help.

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 9:55am Posted: 23 Nov 2022 at 9:55am |

That bar to block the track sprocket should have been at least 1.500" in diameter or it would bend far to easily under the force the sprocket will impart. It would also need to firmly bottomed into the gullet of the sprocket teeth and anchored to stay there.

Another thing you can do is remove the front brake band pin, (through the side of the case) unbolt the clutch assembly, then remove it from the tractor. Place the clutch assembly into a shop press and put about five tons of force on the pressure plate and soak the assembly with a penetrate. Let this dwell but keep it wet. Apply and release pressure repeatedly but don't deform parts. Once a minute amount of movement happens the assembly should break free. You will probably need to disassemble the clutch to further derust and clean things up.

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 11:50am Posted: 23 Nov 2022 at 11:50am |

Codger wrote: Codger wrote:

That bar to block the track sprocket should have been at least 1.500" in diameter or it would bend far to easily under the force the sprocket will impart. It would also need to firmly bottomed into the gullet of the sprocket teeth and anchored to stay there.

Another thing you can do is remove the front brake band pin, (through the side of the case) unbolt the clutch assembly, then remove it from the tractor. Place the clutch assembly into a shop press and put about five tons of force on the pressure plate and soak the assembly with a penetrate. Let this dwell but keep it wet. Apply and release pressure repeatedly but don't deform parts. Once a minute amount of movement happens the assembly should break free. You will probably need to disassemble the clutch to further derust and clean things up. |

I can't remove the clutch. I already unbolted it, and it is wedged in there. Without being able to push the inner hub in enough to clear that lip, it won't come out. I'm going to try heating the drum. I know the throwout action is ok because the hub on the track side of drum moves outwardly when the clutch is disengaged. It's tantalizing, because as I mentioned before, when I first put in the main clutch and engaged, that stuck clutch broke free and turned for several revolutions. It was shuddering and rough, but it did turn. Now it's jammed to h#$ll. Hopefully the heat will work. Thanks..

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 11:52am Posted: 23 Nov 2022 at 11:52am |

gemdozer wrote: gemdozer wrote:

Did you try to pull out the stering cluch before cutting the stering cluch drum and did you knock on drum easly with a hammer it could help. |

I hammered around the perimeter pretty good with a flat-nosed air hammer.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 12:27pm Posted: 23 Nov 2022 at 12:27pm |

It is the driven discs that are frozen via rust to the drum usually. This is where the heat comes into play. Surprised you cannot depress the center hub as all I've worked with will move.

Play the heat while the drum is spinning with the declutch handle pulled back. If the heat works it will let go with a snap. I know that is rehash but important.

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 3:16pm Posted: 23 Nov 2022 at 3:16pm |

Codger wrote: Codger wrote:

It is the driven discs that are frozen via rust to the drum usually. This is where the heat comes into play. Surprised you cannot depress the center hub as all I've worked with will move.

Play the heat while the drum is spinning with the declutch handle pulled back. If the heat works it will let go with a snap. I know that is rehash but important.

|

Once the driving hub is unbolted from the clutch pack, the clutch hub has to move towards the drum side (slide a bit deeper into the drum) to clear the flange so I can get the whole pack to lift out. If the driven discs are frozen to the drum, the whole clutch pack cannot move further into the drum. Or, I am missing something, but I'm no stranger to taking difficult,, rusted things apart. I'll try some heat and vibration and time.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 5:56pm Posted: 23 Nov 2022 at 5:56pm |

I understand what you are saying but I have never seen any steering clutch assys "piloted" onto a flange type mount. All have been a slight compression, or interference fit between the driving, and driven flange(s). Many dry clutch setups have been rusted to the mating companion flanges and this can take force to separate. Upward pressure from a crane and high frequency vibration along with heat work well together. Those are just my observations and maybe your setup is different?

I helped on an HD5 many years ago that had been pulled from a river and sat a couple years afterward. The clutches were stuck badly and I used a shop gantry for the upward force and an oak 2X4 with a 12lb sledgehammer impacting from the side and when it came free, was violent. I didn't have enough force with the crane to pick the tractor up, but was close. I used chain straps from my rollback truck to wrap the drum as it offered little rebound action when stretched and released, but did not score the drum friction surface. I had prior removed the brake shoes in pieces which were replaced with new.

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 10:31pm Posted: 23 Nov 2022 at 10:31pm |

Codger wrote: Codger wrote:

I understand what you are saying but I have never seen any steering clutch assys "piloted" onto a flange type mount. All have been a slight compression, or interference fit between the driving, and driven flange(s). Many dry clutch setups have been rusted to the mating companion flanges and this can take force to separate. Upward pressure from a crane and high frequency vibration along with heat work well together. Those are just my observations and maybe your setup is different?

I helped on an HD5 many years ago that had been pulled from a river and sat a couple years afterward. The clutches were stuck badly and I used a shop gantry for the upward force and an oak 2X4 with a 12lb sledgehammer impacting from the side and when it came free, was violent. I didn't have enough force with the crane to pick the tractor up, but was close. I used chain straps from my rollback truck to wrap the drum as it offered little rebound action when stretched and released, but did not score the drum friction surface. I had prior removed the brake shoes in pieces which were replaced with new. |

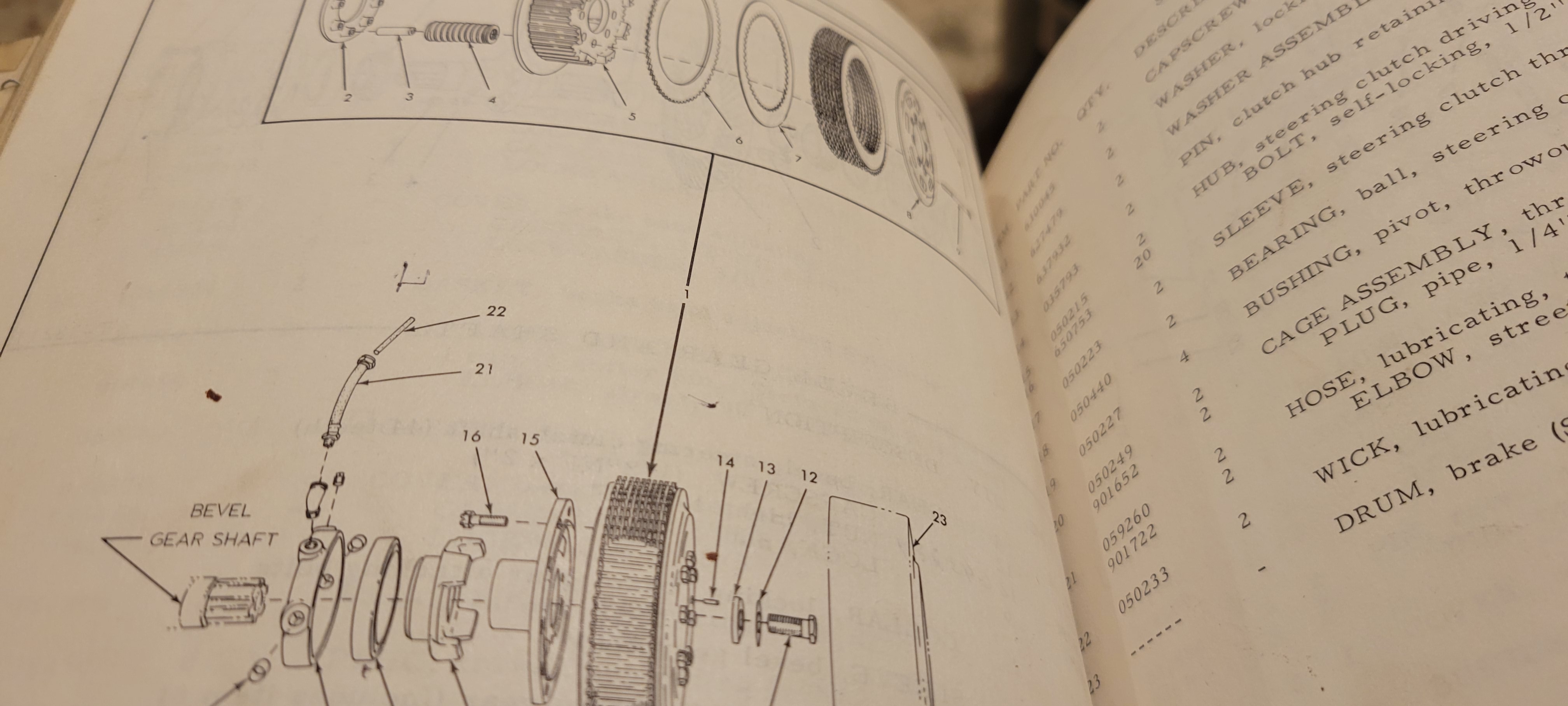

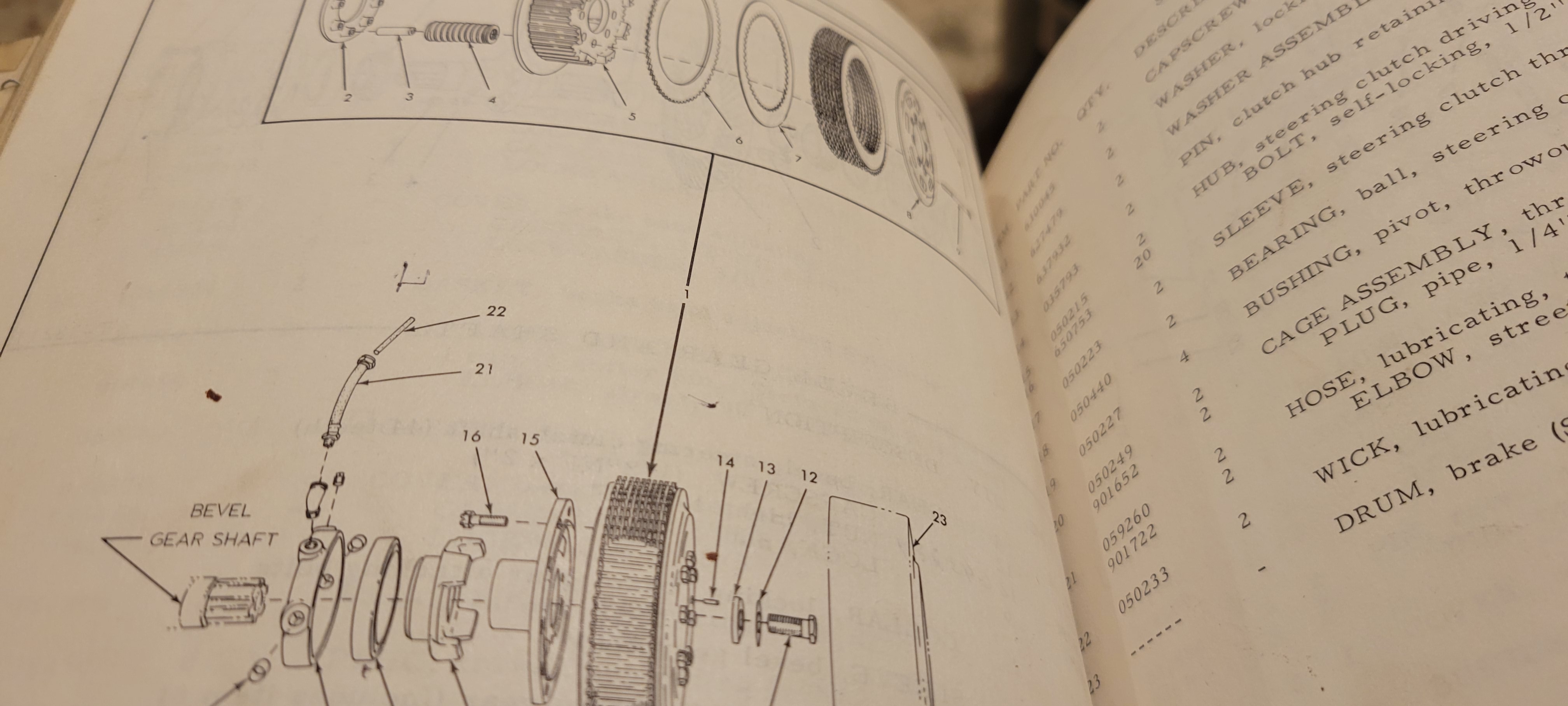

OK, I think I see where the wires are crossed. Notice part #15 ('steering clutch driving hub) in the pic. Notice the small lip on the flange just inside the bolt pattern. I couldn't move the clutch pack toward the drum to clear that lip. Prying with wedges and screwdrivers finally, could barely spread it far enough to see that lip, and I felt the driving hub was flexing, not moving the clutch pack. It couldn't have been tighter if it still had bolts in it. I think if I unbolt the whole mess again, and use a small portapower, pushing the drum from the finals end, and heat and beat on the drum, it might let go enough to get the clutch out.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

gemdozer

Orange Level

Joined: 17 Sep 2009

Points: 989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2022 at 10:42pm Posted: 23 Nov 2022 at 10:42pm |

|

You could make sure with your finger each side drum if all the bolts are removed and no head bolts brook in if can have side bitt loosed try with a screw driver to separate a bit the flange to the drum more far try with shisel and he has to be loose complet side and you could knock on the drum and instaled a small chaine or slingne he should loosed the other side

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Nov 2022 at 6:23am Posted: 24 Nov 2022 at 6:23am |

I remember that small lip now but normally the clutch should have just a bit of clearance when the bolts are removed. I wonder if you have some "rust jacking" going on inside the clutch assy causing this to be swollen and forcing the gap closed?

I think the heating of the drum and/or parts while they spin with the release handle tied back would be my first choice as hydraulic pressure against the parts that are frozen could damage the bearings or shaft that drives the final on that side. As Hector referred all the bolts did come out and none twisted off?

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Nov 2022 at 7:17am Posted: 24 Nov 2022 at 7:17am |

|

|

|

Ages Cat

Orange Level

Joined: 12 Sep 2009

Location: Hutchinson, MN

Points: 688

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2022 at 1:04pm Posted: 27 Nov 2022 at 1:04pm |

I have had this issue with (3) tractors. HD-5, HD-6 and HD-11. We disassembled all tractor steering clutches. Unless the fibre clutches are removed and bi-metalic discs installed, the fibre will attract moisture and rust. All drive teeth were coated with anti seize compound also. You need to be able to steer it with the levers and not oversteer with the brakes. The drums can be beat with a sledge hammer, an old fix, but unless you rust proof it, it will happen again. When we buy our next HD-6, it will have wet clutches.

|

|

Curt Anderson

HD3, HD5B, HD6AG,HD6B dozer, I-400,615, 616,620,720,ACP25 lift truck, 1956 D Grader, AC 540 loader, AC #84 plow, Simplicity tractors, Agco MT225, Agco 2025,

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2022 at 2:10pm Posted: 27 Nov 2022 at 2:10pm |

Ages Cat wrote: Ages Cat wrote:

I have had this issue with (3) tractors. HD-5, HD-6 and HD-11. We disassembled all tractor steering clutches. Unless the fibre clutches are removed and bi-metalic discs installed, the fibre will attract moisture and rust. All drive teeth were coated with anti seize compound also. You need to be able to steer it with the levers and not oversteer with the brakes. The drums can be beat with a sledge hammer, an old fix, but unless you rust proof it, it will happen again. When we buy our next HD-6, it will have wet clutches. |

thanks for the advice. As I said before, clutch pack is apparently rusted to the point of being seized in the drum. It can't be removed until that condition is changed. I went ahead and plugged the housing and added 5 gal of diesel fuel. I will rotate the drum daily. After a week of that, the hammering will commence. These drums appear to be made of nodular or ductile iron. Is that correct? I don't want to crack the drum. I think if I had used the diesel from day one, I wouldn't be in this fix.

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2022 at 6:45pm Posted: 27 Nov 2022 at 6:45pm |

|

Broken link removed.

Edited by Codger - 27 Nov 2022 at 10:52pm

|

|

doctorcorey

Orange Level

Joined: 17 Jul 2011

Location: S. KC Missouri

Points: 589

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2022 at 10:38pm Posted: 27 Nov 2022 at 10:38pm |

|

Codger, link you provided doesn't go anywhere..what was it about?

|

|

Semper Fi USMC 1958 HD6G, 1959 MF 203 loader, 1960 Case 420B Backhoe, MF 65 Tractor/Loader Diesel

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2022 at 10:45pm Posted: 27 Nov 2022 at 10:45pm |

|

HD-6 clutches and procedures. I'll look into it and find a way to send it.

|

|

Codger

Orange Level

Joined: 23 Dec 2020

Location: Utopia

Points: 2041

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Nov 2022 at 10:50pm Posted: 27 Nov 2022 at 10:50pm |

Go here: https://www.tractorparts.com/

Scroll down to HD-6 - HD6G Steering Clutch Parts and look around on that page. Lot of good information along with parts supplies.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

doctorcorey wrote:

doctorcorey wrote: