| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Dec 2018 at 5:40pm Posted: 03 Dec 2018 at 5:40pm |

From the numbers on your pump in that first photo

PSB6A 90EH 4363

From some notes I made when I had the HD 11 service manual

90EH says a 9 mm plunger - Allis also used 100EH with 10 mm

That pump number says 516G engine above #95455

Or it mightn't

Should be 4363A and it looks like your number has been over-stamped so maybe a pump change/recondition somewhere along the line. If the second digit was an 0 then it could have been 4083 which went with HD 11B, F, S

The tag on the head gives the head part number. If it has an R in it the head was reconditioned

Edited by Ian Beale - 03 Dec 2018 at 5:46pm

|

|

|

Sponsored Links

|

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Dec 2018 at 8:26pm Posted: 03 Dec 2018 at 8:26pm |

Garlic Pete I looked up that post you mentioned. Great info thank you very much. No hurry on the photo's the text is quit informative. I also book marked it. In fact if anyone is reading this it's here https://www.allischalmers.com/forum/an-auction-for-the-rest-of-us_topic144296_page2.html

Ian you mentioned something in that thread about the plunger being stuck in a up or down position. Up you thought it may block fuel from leaking off into the injectors and down, I gathered it may dump fuel to them. I haven't read the whole thread yet but is it possible the plunger is stuck down and fill the cylinders with fuel? If so this gives me wishful thoughts about the oil being way over filled.

My service manual will be here this week and possibly the parts manual. Weather permitting I should be able to start taking this beast apart soon and see what I actually am dealing with, aside from all the obvious damage. My goal is just to move it under it's own power down the hill near the GMC, even better would be to get it to the house on a concrete slab. If it runs and the brakes work I'd be off to a really good start.

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Dec 2018 at 8:52pm Posted: 03 Dec 2018 at 8:52pm |

Ian Beale wrote: Ian Beale wrote:

From the numbers on your pump in that first photo

PSB6A 90EH 4363

From some notes I made when I had the HD 11 service manual

90EH says a 9 mm plunger - Allis also used 100EH with 10 mm

That pump number says 516G engine above #95455

Or it mightn't

Should be 4363A and it looks like your number has been over-stamped so maybe a pump change/recondition somewhere along the line. If the second digit was an 0 then it could have been 4083 which went with HD 11B, F, S

The tag on the head gives the head part number. If it has an R in it the head was reconditioned

|

I tried manipulating the original photo to bring out the numbers better not 100% sure but it looks like a 0 under the 3. I might be able to get a different angle with a different lens if not I can for sure get a clear shot of the all the numbers when its removed.

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 2:39am Posted: 04 Dec 2018 at 2:39am |

Gawd! That was a while ago.

If the plunger is stuck at the top of its stroke it is past the spill port so diesel can't enter.

If it is at the bottom it can. And might go further if the distributor slot is aligned with a port - but should only be to one injector. But as the engine isn't running there will be sfa fuel pressure and if that gets past the injector valvery you have a heap more problems. I'd guess the diesel tank would need to be full to even get fuel up that high.

I'd reckon that if you got fuel in the oil sitting like that one has it would have come via leaks in the pump itself. There are two o-rings that seal the transfer pressure space below the head for instance - they aren't special if you need them. And the seal on the transfer pump shaft can leak. It is just a standard industrial seal.

Another 2 cents worth

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 11:28am Posted: 04 Dec 2018 at 11:28am |

|

Sounds very positive to me. This gives me hope that the engine it self isn't destroyed

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 3:19pm Posted: 04 Dec 2018 at 3:19pm |

|

"Conjure up no more spirits than you can conjure down"

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 7:16pm Posted: 04 Dec 2018 at 7:16pm |

|

Yeah I know but I try to hope for the best. I have learned many things about this machine thanks to you guys.

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 8:28pm Posted: 04 Dec 2018 at 8:28pm |

Ronnie

I've just been looking at your pump photos on Page 2 and I hope I'm wrong for your sake. Go to the third one.

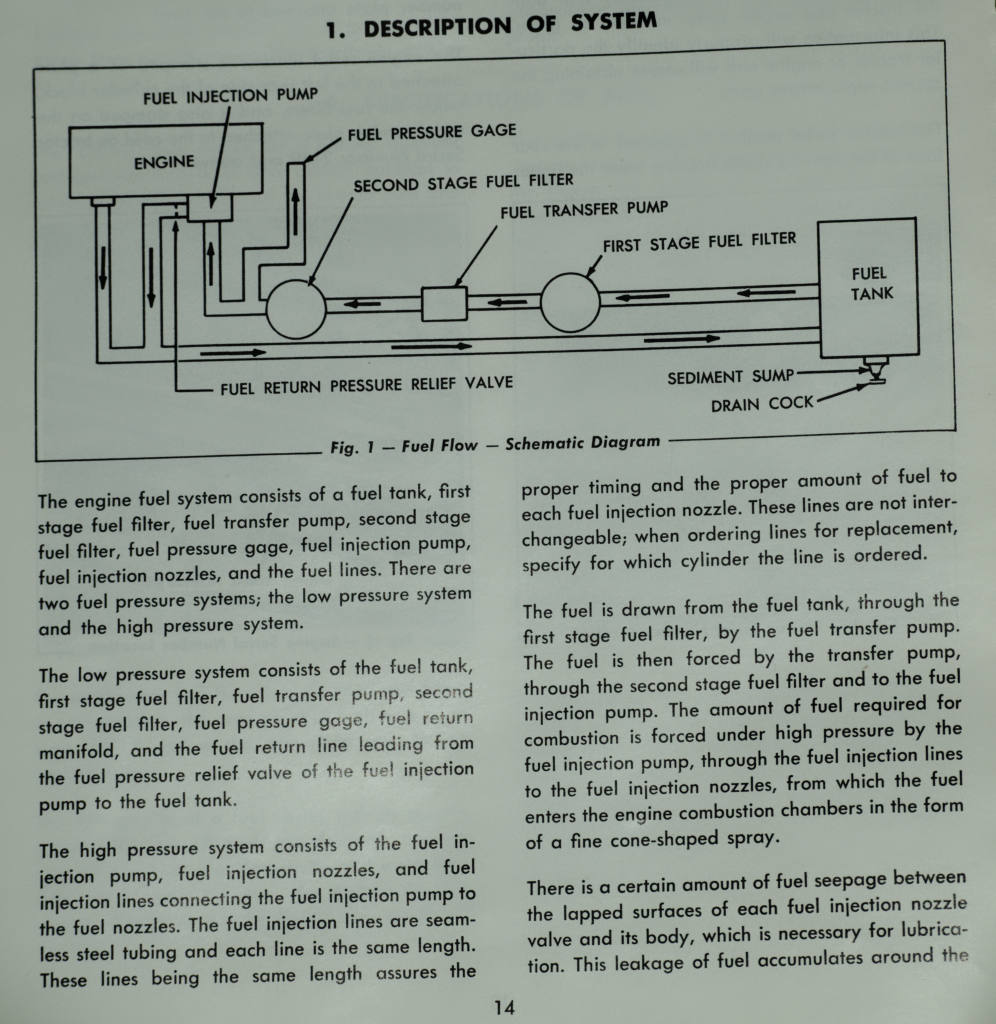

The filter you can see is the primary. Diesel feed is from the tank, through it, then to the transfer pump and through the secondary to the injection pump.

The hexagon at the back of the head section just in front of the rectangular cover of the top of the govenor section at the rear of the pump is the stud with the square section O-ring.

Then just above it on the back of the head is a brown fuzzy area - which is where the fuel feed hose from the secondary filter is supposed to connect to the head. The other end of that hose should connect to the T-fitting from the front of the secondary filter which is just shows in the photo. So the head has been open to the weather since Joe Fiddler left it.

And if the hose that is clamped on that T fitting comes from the diesel tank then it is connected so it bypasses both filters and the transfer pump if the hose to the head was connected. All this needs checking though.

Would it run like that? We first started the engine from our grader on an engine stand with a temporary tank. It did have the plumbing correct but the "reconditioned" injector pump was missing the bottom O-ring for the head so it had a massive diesel leak to the sump and less than design transfer pressure. It ran like that. So I guess the answer with yours would be "maybe" - but I doubt it would have made much power. What would have been fed to the pump as well as diesel if it did doesn't bear thinking about.

IMO the pump is your first port of call.

Today's 2 cents worth

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 10:04pm Posted: 04 Dec 2018 at 10:04pm |

Here is a close view. Hopefully you are not looking at these on a phone lol I think I see what you are saying. The hole on the head should have something in it besides rust or mud. So they left the system open which doesn't surprise me one bit. Oh and I also seen a number on the head. Looks like there is a R stamped in it. - First the small one - Still large but I had to make it smaller than I wanted to meet the 2mb requirement. -Hole I think you are talking about

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Dec 2018 at 11:48pm Posted: 04 Dec 2018 at 11:48pm |

Ronnie

That is the hole. The detail of the first one was ok after I went and had a look at our grader and was reminded of where things went. IIRC that port feeds in below the head but that is where the plunger and the gear train that spins the distributor block are so water and /or dirt wouldn't be your friend.

Assuming you can find that missing hose - I'm not sure what the hose material is called. It is reinforced and what we get has a blue fabric outer.

The head number on one of our pumps is HD 4606AR, which should be an EH 100. (Correction to previous - 10 mm and 9 mm diameter plungers). The other one (that works) has a damaged plate. There is a little spring clip in the plunger area that (IIRC) holds the plunger tappet in the assembly. You need to be gentle taking the head off or it will get damaged.

If you set about taking the injectors out the thread on the end under the dust cover is 22 mm, don't remember which thread number. A piece of our 3/4 water pipe was just right to make an adapter. I could use a slide hammer as they are out in the open (well relatively) on the grader. Someone else had to make a puller due to restricted room on the loaders - in an earlier post(s).

I have a .pdf that lists many of the head numbers - from September 1976 so not much use to either of us.

In case of the worst might be worth finding out if Hector Gemme (Spelling?) who posts here has anything - he had a wrecking yard up in Canada

Later - those injector threads are 22 x 1.5 mm

Edited by Ian Beale - 05 Dec 2018 at 1:48am

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Dec 2018 at 9:55am Posted: 05 Dec 2018 at 9:55am |

|

Whats the difference in the pumps? Besides the plunger. Would a 100 work? A couple of quick searches leads me to believe the 100 is easier to obtain. I am thinking the 100 delivers more fuel. If they mount properly are they adjustable to some degree

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Dec 2018 at 2:22pm Posted: 05 Dec 2018 at 2:22pm |

Ronnie

Allis used both on HD 11's. The ADS516 (supercharged Buda) used 100EH. That "master workshop manual" I borrowed covered all HD 11's and has a list of pumps and the models that used them. It only had Allis numbers for the pump, didn't have actual head numbers. I have some sketchy notes as for a while it looked like we might have to run our grader without a supercharger. Seems the 90Eh ones are timed at 32 degrees and the 100EH ones at 28.

Under the lid of the govenor section there are various things that look adjustable. I've never tried. There might be some indications of what does what in that listing I gave you - I haven't been there.

A complete 100 pump would certainly bolt up. And probably a 100 head on a pump that had a 90. Some later heads didn't use that oil feed via the bolt and square washer and needed some sort of extra to work on oil-feed pumps - I don't have details. My listing of heads doesn't give alternatives for any numbers we've mentioned so probably not a problem here.

I'd guess that a 100 pump at worst might run a bit rich. At least with a diesel if it were to run lean you'll only be down on power - you won't burn the engine.

You can get a look inside your pump when it is on the engine by taking off the cover that has the shut-off in it - the one with 2 screws below the head. That will give you a look at the drive gear for the head and the general condition in there. There is a marked tooth on that gear you have to use for timing so you need to know where the pump drive was if you take the head off. And (IIRC) there is a loop in the oil return line from the bottom of the pump which might tell you if the last thing that went through was oil.

So seems to me that your pump has to come off because of the risk of damage from turning the engine. And then you'll know where you stand with the pump.

And once it is off you can explore the engine as to stuck or not etc.

Also if it is an early model your starter might be a Dyer drive type. If it is burnt you can use an M40 IIRC.

Close to all I can think of on this

Edited by Ian Beale - 05 Dec 2018 at 2:26pm

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Dec 2018 at 4:30pm Posted: 05 Dec 2018 at 4:30pm |

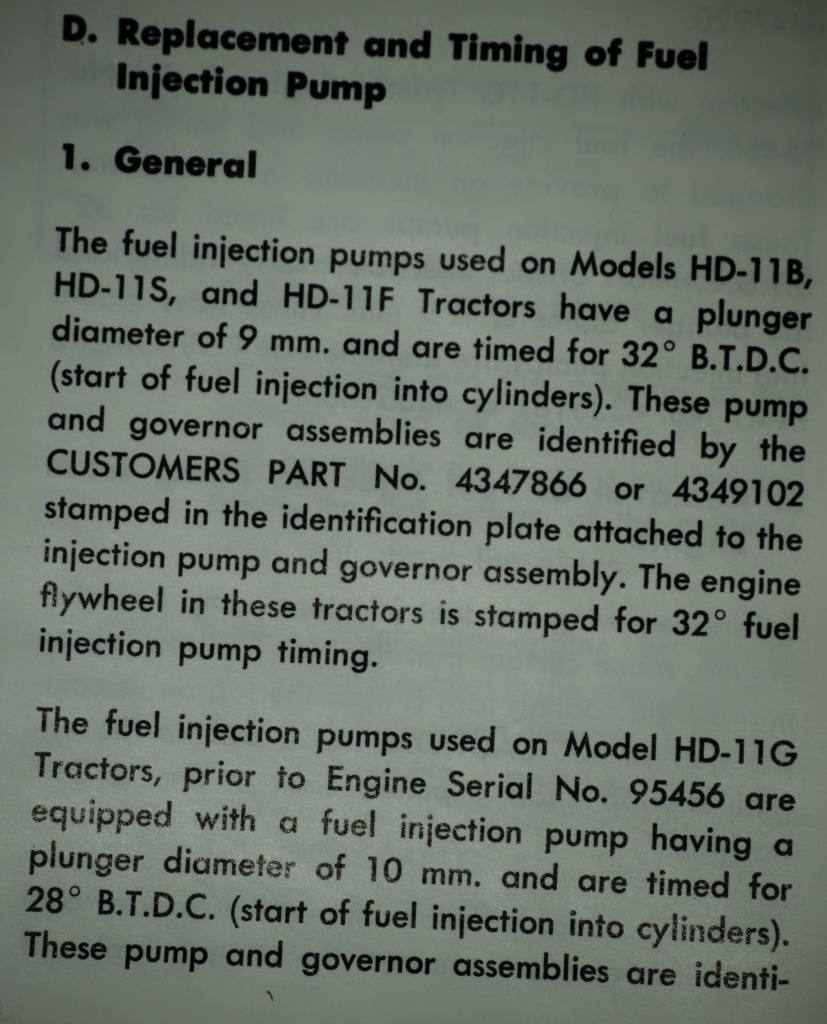

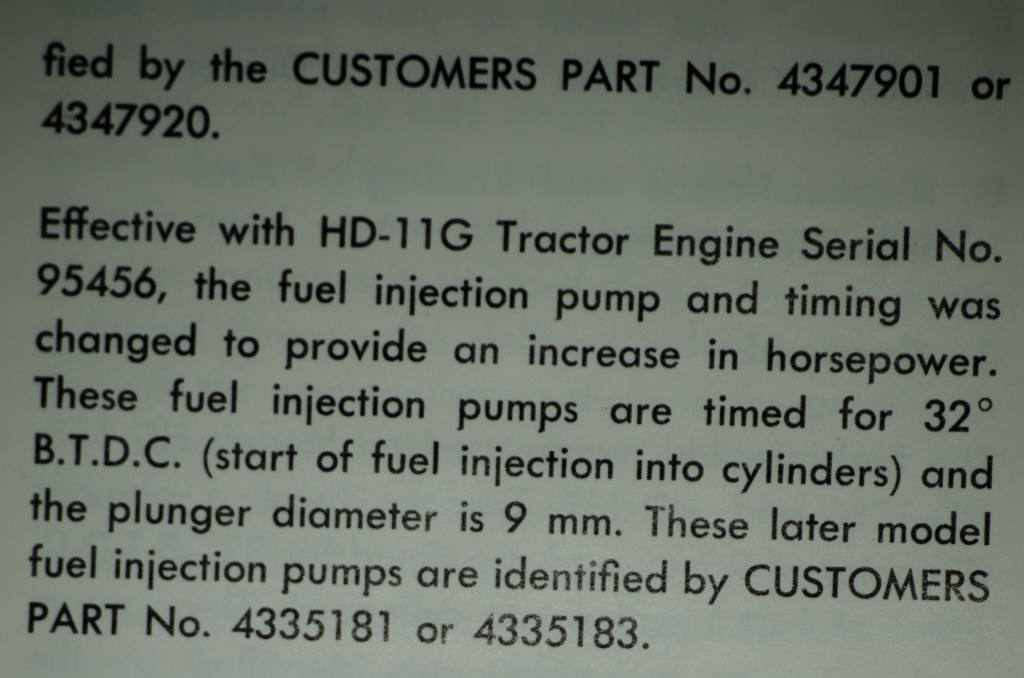

Ok came in for a quick break. I picked up my service manual. I'll post the actual contents of the pages later but from a short read they used 3 different pumps. The 90eh has two different timings 28 and 32 and the 100 has 28. Depending on engine serial number. So it appears any can be used but if I remember correctly the one with 32 was to increase the HP. According to the SM the engine tag is supposed to be near the starter hopefully it's still there. Publication date is June of 58. AC Mel I can't thank you enough for helping with the service manual :) Obviously further research is needed before I attempt to change or fix anything. Currently in the attic rewiring some shorted plugs, rather be working on the loader.

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Dec 2018 at 7:39pm Posted: 05 Dec 2018 at 7:39pm |

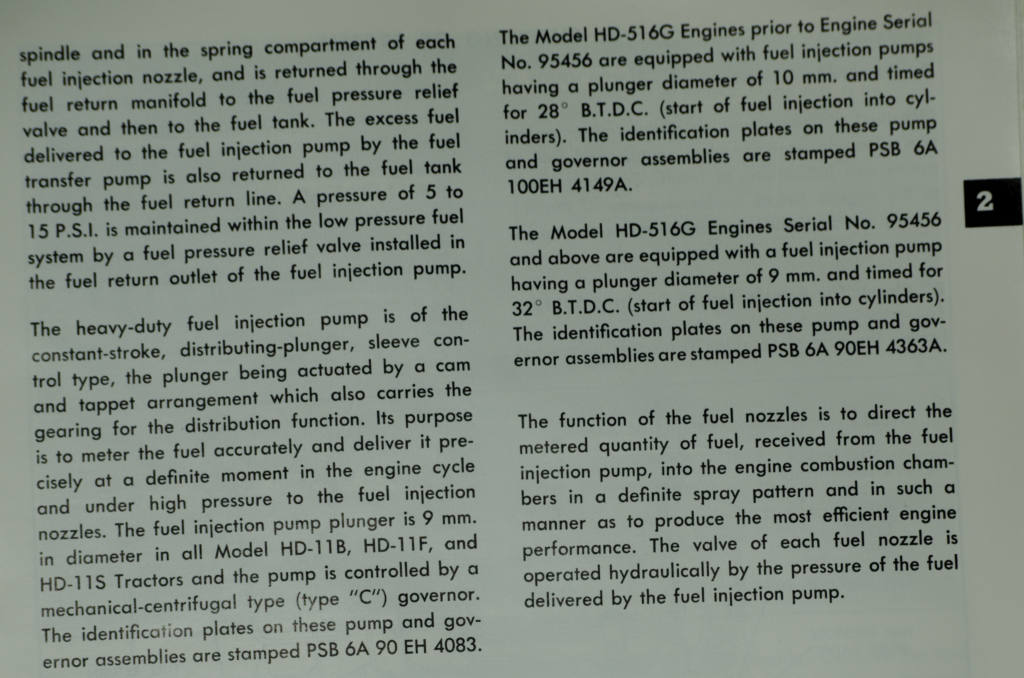

So here are 4 pages on the fuel injection. Hopefully this will help someone besides myself.

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 3:16am Posted: 06 Dec 2018 at 3:16am |

Ronnie

I'm guessing covered in there (but not stated) is the change from Budas with Lanova injection to direct injection with the 10000/11000 series engines. (Lanova ones have the injectors on the lhs of the engine and "energy cells" on the right).

Just looking at that list it looks like early ones might have had 9 mm plungers at 28 degrees. The graders had 10 mm at the same timing. Which seems to make sense as they would have needed more fuel to keep up with the supercharger.

IIRC the later direct injection ones got similar horsepower to the supercharged Budas without the blower, turbos even more. Seems some then used the blower drive pulley for the fan etc

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 8:16am Posted: 06 Dec 2018 at 8:16am |

Yeah I don't remember when they changed engine design. I do remember that they changed the piston. The newer one was more/deeper concave. I wonder if this allowed a bigger cam to get more Mixture into the cylinder, maybe they changed the duration of the valves. They had to of changed something else in order to compensate for a larger combustion chamber. I have to look but I don't think they increased the liters. It's still 8.5L. You can only do so much with 516 cubic in. and 8.5L before having to go bigger.

I am curious on your grader what is the injector pop off pressure? This one says 2100psi new, used is 2k.

Now I am really curious about the pumps as well. In the 10mm plunger did they keep the same stroke of the plunger or did they shorten it? In non forced induction systems I am thinking they would have to shorten it to keep the same mixture. Or is the amount fuel delivered controlled by the volume of the head?

Seems to me the heart of a diesel is the injection pump, needs to be in a perfectly healthy condition.

I realize this is getting into the very technical aspects and some of my questions may seem trivial but it really does help me understand how all this works together. I am not trying to reinvent the wheel just want to understand the how and why of the invented wheel.

One last thing according to the re-stamped pump# on my engine it's the 9mm @ 32 degrees. It looks like the original number may have been for the 28 degree. Right now I can only assume the 9mm pumps are interchangeable with the only difference being the timing gear.

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 2:21pm Posted: 06 Dec 2018 at 2:21pm |

2100/2000 psi

For what went on with stroke in the pump I guess you'd need an AMBAC parts book or two pumps to compare

|

|

Steve allis dozer

Silver Level Access

Joined: 10 Apr 2011

Location: Australia

Points: 232

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 7:09pm Posted: 06 Dec 2018 at 7:09pm |

All them cans of either would indicate that the pump is worn , once the American bosch pumps with single plunger get worn out they don't produce enough pressure while cranking over with the starter to open the injectors ! the either spins them over fast enough to open the injectors , when the pump is worn sometimes at low idle they will just stop as per not enough revs to keep the injector tips popping ! A fuel pump Dude over here thinks that an american bosch pump from an international can be fitted as you can still get parts for them (just have to make new injector lines )

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 8:53pm Posted: 06 Dec 2018 at 8:53pm |

Steve allis dozer wrote: Steve allis dozer wrote:

All them cans of either would indicate that the pump is worn , once the American bosch pumps with single plunger get worn out they don't produce enough pressure while cranking over with the starter to open the injectors ! the either spins them over fast enough to open the injectors , when the pump is worn sometimes at low idle they will just stop as per not enough revs to keep the injector tips popping !A fuel pump Dude over here thinks that an american bosch pump from an international can be fitted as you can still get parts for them (just have to make new injector lines ) |

Probably explains why they were excessively cranking it as someone suggested earlier, think it was DMiller. I honestly think that this is why it caught fire and did not really get touched by the big fire in 92. No starting system is designed for extended cranking. Modern cars have safety devices to keep you from catching your car on fire. I forget which car it was, when I worked for GM they recalled for this very issue. People were just holding the key until it caught fire. I can see it now one holding the starter button and the other loading it with ether until all the magic smoke was gone.

The International pump sounds possible. Do you know what the pump number would be or what model it would be for? I was wondering if any of the modern pumps would work. If it mounted properly, provides the right pressure, same volume of fuel and can/is timed correctly, I suspect anything would work. I am still a bit new to diesels and almost ready for my test subject lol. The other issue is would you be able to find pluming capable of handling this type of pressure that won't leak under heavy vibration. I think it's entirely possible. Can't be any worse than putting a Ford engine in a GM.

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 9:05pm Posted: 06 Dec 2018 at 9:05pm |

Ian Beale wrote: Ian Beale wrote:

2100/2000 psi

For what went on with stroke in the pump I guess you'd need an AMBAC parts book or two pumps to compare

|

I did catch something today when I was reading this again

In the diagram it's called the control sleeve and somewhere in there it said something about it controlling the amount fuel, not pressure but the actual volume. So many questions and nothing to compare to :( You have a couple of old pumps you care to mic? lol This is kind of specific to design not sure if I can find specs this detailed.

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 9:16pm Posted: 06 Dec 2018 at 9:16pm |

Control sleeve chamber It would be interesting to know what the volume difference is between the 90 and 100 pumps. If it's possible to make this chamber equal Are the control sleeves just a different size Can the control sleeve be changed Anyone care to mic some dead pumps :)

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 9:42pm Posted: 06 Dec 2018 at 9:42pm |

Steve AD

Likely an Ambac 100. The injection lines come off the head at an angle. I've heard of that possibility. But also that the parts situation is heading south.

Also worth reading about them

If you can replace an AMBAC 100 with a Bosch A series inline then why not a PSB replacement for a possibility?

I vaguely remember seeing something about some military 516's having Stanadyne pumps too - no details

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Dec 2018 at 9:47pm Posted: 06 Dec 2018 at 9:47pm |

RonnieJones wrote: RonnieJones wrote:

Control sleeve chamberIt would be interesting to know what the volume difference is between the 90 and 100 pumps. If it's possible to make this chamber equal Are the control sleeves just a different size Can the control sleeve be changed Anyone care to mic some dead pumps :) |

Think you'll find that it is the position of the spill sleeve that counts and that it varies the spill cutoff depending on govenor control setting

|

|

Lazyts

Orange Level

Joined: 05 Feb 2012

Location: Manitoba

Points: 627

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2018 at 2:25pm Posted: 07 Dec 2018 at 2:25pm |

Later Allis engines in 8000 series tractors and N series combines used the American Bosch stuff too- not sure how they would fit. I think the old ones ran at engine speed and the Roosa Master runs 1/2 engine speed? That old crawler looks like a big project- bad injection pump, bad undercarriage and unknowns between... not impossible but I see alot of work ahead! If you want to move it, you will likely find the brake bands stuck to the drums in the rear end- just a heads up.. they can be loosened off pretty easy, but those tractors are really hard to move if they won't roll!

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2018 at 3:18pm Posted: 07 Dec 2018 at 3:18pm |

A bit more on pumps here. Check Injpumped's comment

We got the engine going with what we had so this went no further

Edited by Ian Beale - 07 Dec 2018 at 3:20pm

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 7970

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Dec 2018 at 5:23pm Posted: 07 Dec 2018 at 5:23pm |

Ian Beale wrote: Ian Beale wrote:

Steve AD

Likely an Ambac 100. The injection lines come off the head at an angle. I've heard of that possibility. But also that the parts situation is heading south.

Also worth reading about them

If you can replace an AMBAC 100 with a Bosch A series inline then why not a PSB replacement for a possibility?

I vaguely remember seeing something about some military 516's having Stanadyne pumps too - no details

|

You can do the inline swap on a 8000 426 because the pump drive you need is on a 7000 426. Doubt there is a half speed drive for that old bird.

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Dec 2018 at 8:40am Posted: 08 Dec 2018 at 8:40am |

Lazyts wrote: Lazyts wrote:

Later Allis engines in 8000 series tractors and N series combines used the American Bosch stuff too- not sure how they would fit. I think the old ones ran at engine speed and the Roosa Master runs 1/2 engine speed? That old crawler looks like a big project- bad injection pump, bad undercarriage and unknowns between... not impossible but I see alot of work ahead!If you want to move it, you will likely find the brake bands stuck to the drums in the rear end- just a heads up.. they can be loosened off pretty easy, but those tractors are really hard to move if they won't roll! |

Unfortunately it is going to be alot of work. I wasn't expecting it to be easy and frankly a little disappointing in the shape it's in. The electrical stuff is easily fixable. On the other hand this makes me wonder how bad of shape the engine is in as well. It obviously wasn't well taken care of.

I see some do repowers with a Detroit and I think Cummins. This might be a better option but hard to say at this point.

I have been looking at the N5 fuel system and have been trying to find stuff on the Roosa Master. I haven't found much on either.

For the same price of an old unreliable injection pump a more modern one may work but still diggin around on this.

When we started this adventure going on 3 years now. This is why I stayed away from diesel pickup trucks. I knew injection pumps where pricey and the most likely to fail.

We have 3 really big projects that we would like to do and this would help immensely to get those done. So I need do lot's of praying, research and finish up the honey do list on her palace.

|

|

NomoreJohnDeere

Silver Level

Joined: 24 Jul 2017

Location: Missouri Ozarks

Points: 308

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Dec 2018 at 1:21pm Posted: 08 Dec 2018 at 1:21pm |

|

"three really big projects"

you just answered your question

this machine is a big project in itself, it will be one thing after another

If you had another one like it up and going how good of a spare would this one be?

If you had "messing around to do" then this one would be a possible project to mess around with.

If it had undercarriage I wouldn't be so pessimistic

Edited by NomoreJohnDeere - 08 Dec 2018 at 1:21pm

|

|

HD3

|

|

Ian Beale

Orange Level

Joined: 03 Oct 2011

Location: New South Wales

Points: 932

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Dec 2018 at 2:08pm Posted: 08 Dec 2018 at 2:08pm |

Ronnie

The AMBAC pumps run at engine speed.

Also looking at the photo of your oil cooler shows oil pipe fittings from a very early engine. Later ones used different oil pipes or hose.

Those fittings would indicate that the oil filter has bell and filter element above the base where with later ones it is below.

Edited by Ian Beale - 08 Dec 2018 at 2:11pm

|

|

RonnieJones

Silver Level

Joined: 28 Nov 2018

Location: California

Points: 75

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Dec 2018 at 9:37pm Posted: 08 Dec 2018 at 9:37pm |

NomoreJohnDeere

Well considering the hard to find parts are what seems to go bad probably not much of a good donor from what I know about it at this point. I'll know more when I can get a vehicle to it.

Ian Beale I went the other day to look for the engine tag. It's partially melted and none of the numbers are even close to readable, only somewhat legible was"lmers MFG" and USA. Pretty sure the filter does sit on top of the base.

It's gonna take me a bit to source these parts. After the new year I'll start asking around. I do know there is some old machines up here. Who knows maybe I'll find a good barn find.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Ian Beale wrote:

Ian Beale wrote: