| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 5816

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Silly belt-pulley question... Topic: Silly belt-pulley question...

Posted: 19 May 2010 at 2:23am |

|

Hi All-

I'll admit- I'm a total moron when it comes to AC belt pulley systems. I've got a WD here that I'm trying to bring back to life... I've checked out every control linkage to make sure everything moves and operates as expected... but the belt-pulley confounds me... I've looked this thing over closely, and I've checked my IM manual, and find no method to engage or disengage the belt pulley. It spins free, like it's disengaged... seems to me that when I attempt to spin it, it should only spin free if the clutch and transmission are both disengaged...

What's the secret here- is there an engagement mechanism hiding in here?

|

|

|

Sponsored Links

|

|

|

Nathan (SD)

Orange Level

Joined: 11 Sep 2009

Location: Day County SD

Points: 1264

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2010 at 2:29am Posted: 19 May 2010 at 2:29am |

|

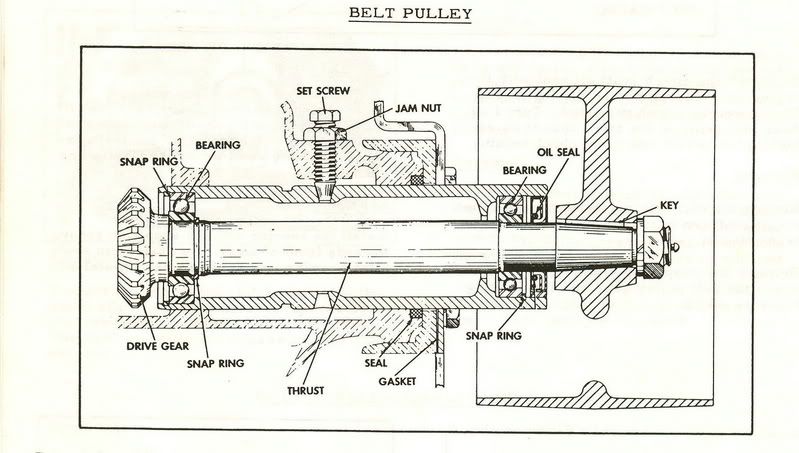

You need to loosen the bolt on top of the cast housing and push the pulley into the tractor to engage it and then reset the bolt. The pulley will then spin anytime the clutch is engaged.

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4705

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2010 at 5:03am Posted: 19 May 2010 at 5:03am |

see if this helps any

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22823

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2010 at 6:39am Posted: 19 May 2010 at 6:39am |

|

DO NOT Attempt this while the tractor is running.There should be a chisel mark on the frame rail to line up with a mark on the belt pulley housing. They might be painted over.

Edited by CTuckerNWIL - 19 May 2010 at 6:42am

|

|

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 5816

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2010 at 6:54am Posted: 19 May 2010 at 6:54am |

|

Thanks guys- I suspected it wasn't pushed in far enough, but had no documentation to support it.

Yeah- I won't do it while running... I don't trust the clutch release that much, and the result would be really hard on those gears... and my arms. I'm guessing that checking gear lash while it's running would be kinda difficult, too.

|

|

David Grubb

Bronze Level

Joined: 14 Sep 2009

Location: Rochester, Il

Points: 133

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2010 at 11:10am Posted: 19 May 2010 at 11:10am |

|

Maybe I missed it in the instructions but the pulley should have no more than 1/8" end play between the frame and pulley rim when you find the correct hole for the set screw.

|

|

Dave

|

|

Bill Long

Orange Level

Joined: 12 Sep 2009

Location: Bel Air, MD

Points: 4556

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2010 at 3:31pm Posted: 19 May 2010 at 3:31pm |

If I recall there are a series of holes around the pulley housing that are a little closer each That gives an adjustment so the gear backlash can be adjusted to a reasonable amount.

The WC came with a belt pulley standard. When the WD was developed it was noted that belt pulleys were not used that much, thereby a belt pulley was not standard equipment on the WD but an option. However, it was the same as a WC pulley.

Good Luck!

Bill Long

ps: Be sure to study the directions above closely.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)