| Author |

Topic Search Topic Search  Topic Options Topic Options

|

rt_smallengines

Bronze Level

Joined: 01 Feb 2015

Location: New England

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis Chalmer B110 Help Topic: Allis Chalmer B110 Help

Posted: 01 Feb 2015 at 3:10pm |

Hello, Over the summer I received a 1968 allis chalmers b110 from my mailman (really nice guy). It sat for 20 odd years (thankfully before they used ethanol in gas) and after 4 days of cleaning the carb out, removing a broken starter mount bolt, and other stuff I managed to get her running.

First and foremost, the throttle was original stuck in the IDLE position and i managed to free it up. THE PROBLEM: this tractor has a 10hp briggs and stratton horizontal shaft and the governor does absolutely nothing. When it fired up the throttle took off and i dove for the key. For the time being, in order to drive it home I adjusted the governor linkage to only let the throttle barely open up and I added a return spring to force the governor to the idle position so it wouldnt take off.

My questions, two things:

What is wrong with the governor, I assume I have to pull the motor apart. Is it once of those chincy plastic gears? Is it easy to find a new replacement?

Second question, Once the new governor is installed, how do I correctly readjust the throttle/governor linkage (the one with the two nuts that the throttle cable attaches too and the other end attaches to the governor arm) so the motor properly achieves full throttle at what I presume is 3600 rpm and Idle.

If anyone has a pdf of the manual for one of these motors too it would be greatly appreciated. I am a college student and don't have much money but I would really love to get this machine running since it is in almost prestine cosmetic condition given its age.

Thanks alot, Ron

|

|

|

Sponsored Links

|

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2581

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 3:25pm Posted: 01 Feb 2015 at 3:25pm |

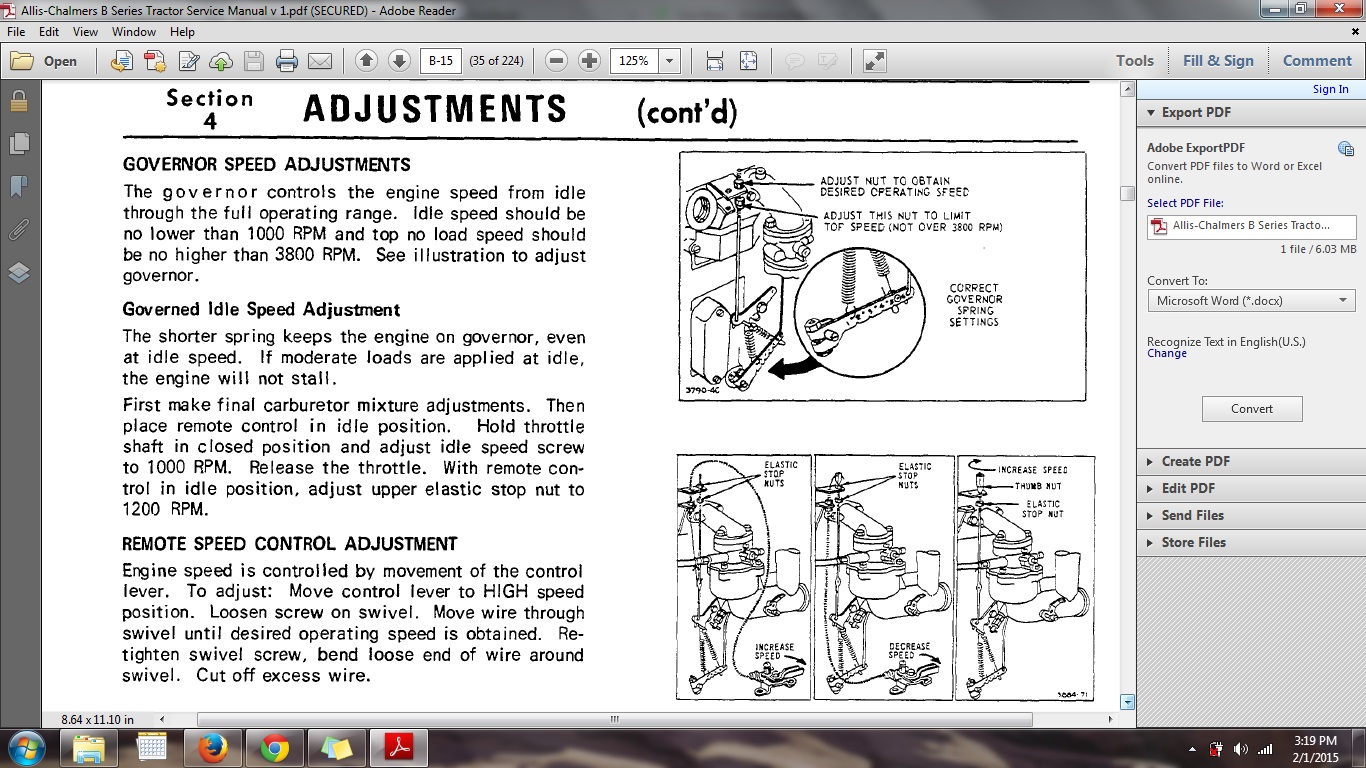

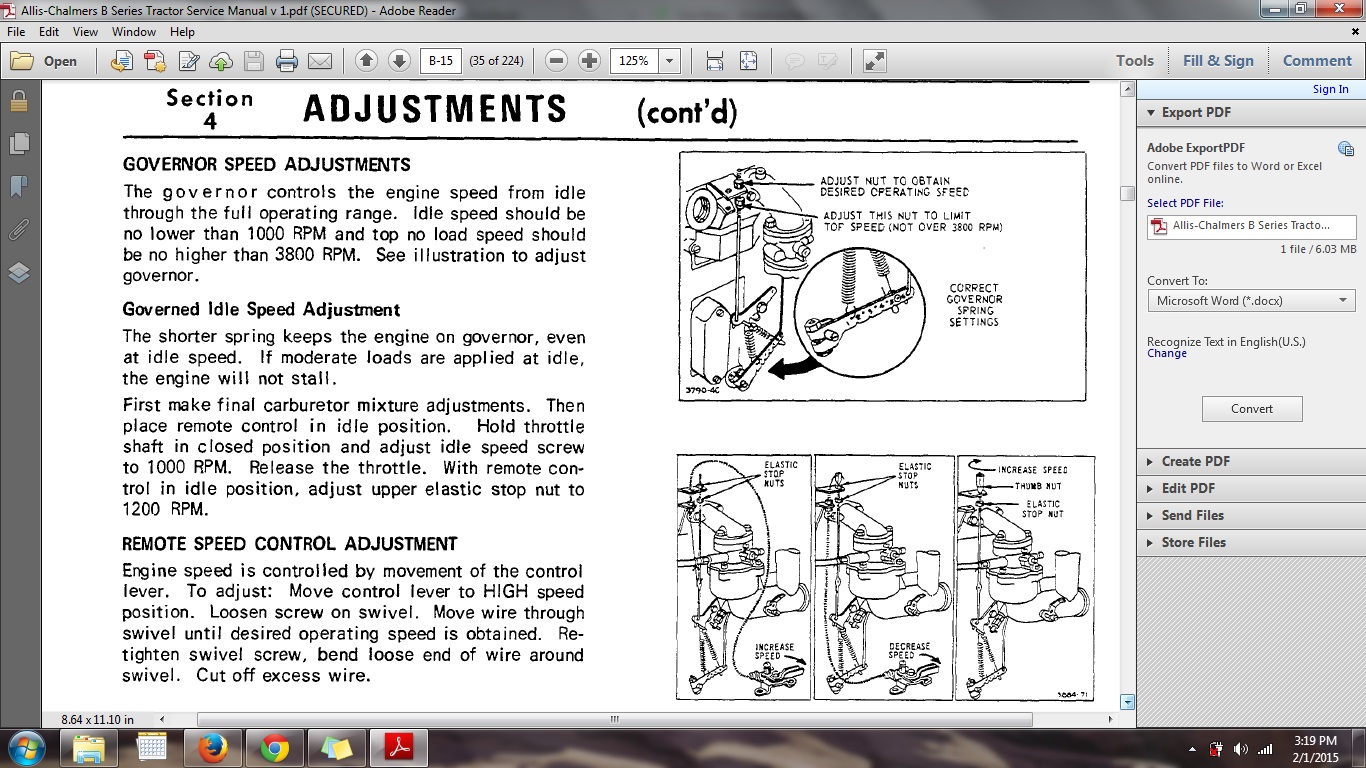

Couple shots from my B110 manual. One on carb adjustment, one on setting the gov. It's possible when you put the carb back on you missed some linkage attachments or something. You can get a manual rpm gauge to set the RPM. any parts store should have one. I have a dial type that you hold on the end of the front of the crankshaft. AaronSEIA

Edited by AaronSEIA - 01 Feb 2015 at 3:27pm

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5911

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 3:31pm Posted: 01 Feb 2015 at 3:31pm |

|

RT

Welcome to the Allis Forum.

I had to adjust the Governor on my HB-112 a couple years ago.

Here is a link to a Video I watched, showing how to adjust it.

https://www.youtube.com/watch?v=DjYVKRv612g

Also here is a link to a website dedicated specifically to Allis / Simplicity Garden Tractors

http://www.simpletractors.com/Main/AC_models.htm

Gary

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4060

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 3:32pm Posted: 01 Feb 2015 at 3:32pm |

|

more than likly ether it is hooked back up wrong or the gov shaft has been moved on arm loosen arm hold carb linkage at WOT turn shaft counter clockwise tighten arm 35in lbs. check linckage for any binding set springs top no load 3600rpms

|

|

rt_smallengines

Bronze Level

Joined: 01 Feb 2015

Location: New England

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 3:45pm Posted: 01 Feb 2015 at 3:45pm |

Thanks so much this is awesome! I just found the whole manual on slideshare and I downloaded it so I can view everything now. I was pretty sure It was hooked up correctly but when I go home spring break I should follow that procedure in the manual exactly and it will properly configure the governor?

@Hudco Shouldn't I readjust the throttle first so it opens up properly? If the governor doesnt work how do I know when it is at 3600 rpm, the rpms just keep increasing if I open the throttle. I guess I should undo my band aid job first and then try to hook the springs back up properly and adjust the nuts without burning my hand on the muffler lol.

|

|

rt_smallengines

Bronze Level

Joined: 01 Feb 2015

Location: New England

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 3:58pm Posted: 01 Feb 2015 at 3:58pm |

Thanks for the screen shots, and the links to the website and video. Hopefully Everything will work once I verify the governor is hooked up correctly because it seems like it would be a pain the remove and split the motor (drive shafts gotta be disconnected). When I get home I will post some pictures of the linkage to show you guys.

I really appreciate the help, Ron,

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2581

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 4:25pm Posted: 01 Feb 2015 at 4:25pm |

|

The motor can be pulled in about 15 to 20 minutes. Not a bad job. I'd make sure the throttle cable works smooth ($35 will buy a new locking cable), make sure the carb is set right, and make sure the springs and all linkage is adjusted right before I start digging into the governor itself.

AaronSEIA

|

|

rt_smallengines

Bronze Level

Joined: 01 Feb 2015

Location: New England

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2015 at 6:20pm Posted: 01 Feb 2015 at 6:20pm |

Ok thats good to know, I wasn't sure if you had to remove the gas tank, and other stuff to get to the bolts that hold the driveshaft to the flywheel. The throttle cable is very smooth, I need to find the other governor spring and ill reconfigure the motor back to how it was before. The front grill and everything has to come out to remove the motor right?

Another question, sometimes when I try to shift at higher rpm even with the clutch pedal down all the way it grinds when i try to put it in gear and I have to quickly push it hard to shift. Other times it shifts normally. And there is no parking break leaver sticking out of the side of the frame either.

I probably won't be able to work on this until march but hopefully when I get to it you guys are still around.

I appreciate the help, Ron

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4060

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2015 at 8:56am Posted: 02 Feb 2015 at 8:56am |

|

ststic govenor adjustment is done before any of the other adjustments are made then never [rarly] touched agian

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2581

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2015 at 5:11pm Posted: 02 Feb 2015 at 5:11pm |

Take the 2 side covers off and you can get in there with a ratchet and 9/16socket. Use a long screw driver or pry bar to wedge the drive bolts so you can break them loose. Only need to do the 2 that go on the engine. Get them both loose before you take them out. Be careful not to drop the spacer. Hard to find and retrieve if you do. Here is a link to the Simplicity operators manual. It will tell you now to set the clutch and brake. The tranny brake is tied in with the clutch. On mine I have to use the brake to shift. Fully stopped or she'll grind. http://bsintek.basco.com/BriggsDocumentDisplay/default.aspx?filename=heCFEN8arG7rE4CG.5kbp796DqThe park brake "lever" is actually a 5/16 threaded rod bent at an angle. You push the clutch in, then tighten the rod down and it clamps the clutch rod holding the brake. You'll understand once you see it in the manual. Manual also has parts breakdowns and Simplicity numbers. Everything but the hood and seat is the same. The B110 is Simplicity 2110 mfg #'s 990432, 433, 496, 497. 432 and 433 are push button start, 496 and 497 are key switch start. 433 and 497 are hyd lift. AaronSEIA

|

|

rt_smallengines

Bronze Level

Joined: 01 Feb 2015

Location: New England

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2015 at 11:09pm Posted: 02 Feb 2015 at 11:09pm |

Thank you for the manual it is very detailed and includes everything. SHown on page 42-43, you wouldn't happen to know the belt size for the drive belt that goes to the transmission on the right hand side of the tractor would you? Mine is cracked in like 4 places. And ill have to look at the parking break because I know the spot on the frame where that lever should be sticking out and its missing but the frame is all enclosed around there so I can't get at it. Glad to know the motor is that easy to remove.

Thanks again, Ron

|

|

AaronSEIA

Orange Level

Joined: 11 Sep 2009

Location: Mt Pleasant, IA

Points: 2581

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Feb 2015 at 3:44pm Posted: 03 Feb 2015 at 3:44pm |

|

If it has the stock 6" pulley on the tranny it's a 5/8x42. Little trick I've learned. If you Google the belt part number someone is silly enough to put the dimensions in their listing of it. Then you can go buy local.

I think you can reach in with the side panels removed and get to the brake deal. Honestly, I've never used mine. I have one on my B10 (same basic setup) and it's rather clumsy to use.

You do need to remove the grill and shroud to pull the engine as the front of the crank sticks through. 2 bolts each side and one in the front.

AaronSEIA

|

|

rt_smallengines

Bronze Level

Joined: 01 Feb 2015

Location: New England

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2015 at 11:40pm Posted: 05 Feb 2015 at 11:40pm |

Yeah it doesn't have the hi low range its a stock setup so I'll grab a new one when I work on it. Thanks again, hopefully I'll have her straightened out by the summer. I'll get some pics posted when I get home.

-Ron

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)