| Author |

Topic Search Topic Search  Topic Options Topic Options

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1888

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Starting a 616 restoration Topic: Starting a 616 restoration

Posted: 24 Jul 2014 at 10:49am |

|

|

|

|

Sponsored Links

|

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1888

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Jul 2014 at 10:58am Posted: 24 Jul 2014 at 10:58am |

|

The hood is sitting in the barn. the cooling fan is vacuum style, should it be a blower?

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4059

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Jul 2014 at 11:25am Posted: 24 Jul 2014 at 11:25am |

|

looks good was the end of the crankshaft tapered had to give $500 for the one we got with bad engine

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1888

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Jul 2014 at 5:01pm Posted: 24 Jul 2014 at 5:01pm |

|

Are you talking the front stub shaft? It is straight and too large for the clutch/pulley

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1888

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Jul 2014 at 5:05pm Posted: 24 Jul 2014 at 5:05pm |

|

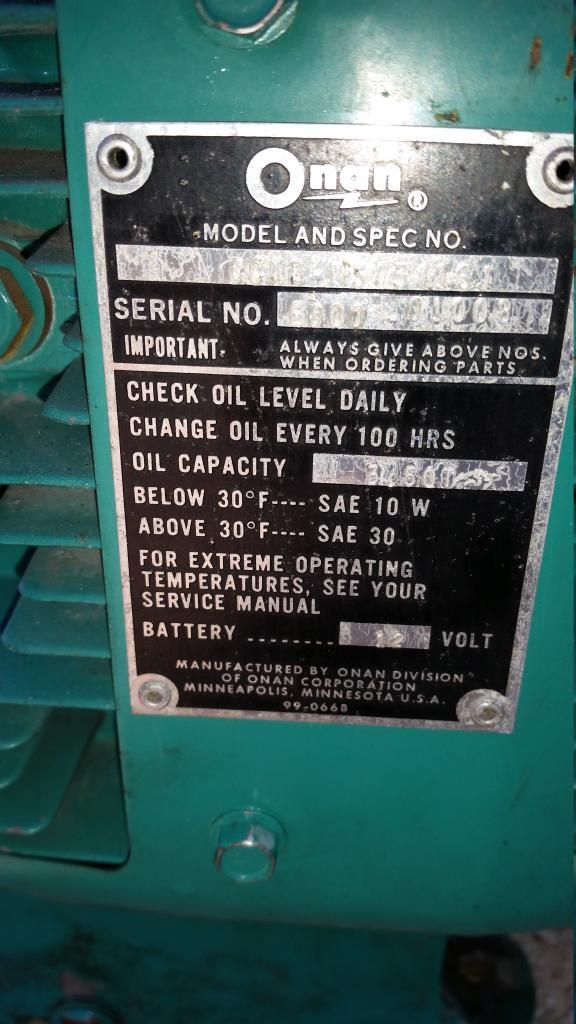

Also should there be engine mounts or were the Onan base configured differently to raise the motor. Should the fan be blower or vacuum style. What size of pulley should be on the hydro side.

|

|

coggonobrien

Orange Level Access

Joined: 14 Nov 2010

Location: Eastern Iowa

Points: 1888

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Jul 2014 at 10:55pm Posted: 24 Jul 2014 at 10:55pm |

|

i'm wondering if i just need to do an oil pan swap to the correct style

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4059

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2014 at 9:39am Posted: 25 Jul 2014 at 9:39am |

|

on the 720 we done the engine bolted directly to the frame and the front shaft pto side of engine was1 7/16 if iremember right with asleave to make it go to a clutch with a larger bore when we put the briggs we had to biuld a motor mount 3 3/8 tall to line up with clutch

|

|

Toscani NE SD

Orange Level

Joined: 21 Jan 2011

Location: Milbank S.D.

Points: 369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2014 at 7:44pm Posted: 27 Jul 2014 at 7:44pm |

|

have a machine shop mill the inside clutch radius to your onan crank size,thats what I did to mine

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 12070

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2014 at 7:00am Posted: 29 Jul 2014 at 7:00am |

|

Well, the engine looks like my engine other than the flywheel and crankshaft. My flywheel is a large cast iron version half the size of the one that's on your engine. Obviously, the engine is for some other application, but can't see why you couldn't use it with some mod's. Also, my engine was bolted directly to the frame but does have a bolt/nut setup on the bottom of the engine mounting tabs on all four corners located between the engine and frame which lifts the engine a tick. Kinda' strange when I first pulled the engine out this Spring, but its gonna go back in the way it came out. I've was working on and off the engine a while back, and I left the stud/nut setup alone. HTH

Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)