| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Freewheeling

Bronze Level

Joined: 05 Nov 2017

Location: Wisconsin

Points: 170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Unable to post Topic: Unable to post

Posted: 24 Jun 2025 at 9:57pm |

I have a oil leak from the PTO that appeared to be from the bottm retainer bolt hole. I discovered that the idiot previous owner used 3 different length bolts and two of them were worn 1/4" + below the head including the bottom one. The two retainer holes the crap bolts were in (top & bottom) were out of round and the faces were ground down. The mating housing hole for the bottm bolt was sloppy when threaded. Of course there are high spots by the retainer bolt holes.

There were 5 shims between the retainer and the housing and a gasket between the shims and housing but none between the retainer and the shims.

The shaft has some small dings and scratches that I [polished out. The seal looks OK but is some off-brand so I'll repkace it.

Does anyone have a nice retainer (part # 207617)? Should there be a gasket between the retainer and the shims? My book doesn't show one. What's the process for the shims? It appars that National 50135 seal would be correct. Yes?

Thanks.

|

|

|

Sponsored Links

|

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3085

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2025 at 6:47am Posted: 25 Jun 2025 at 6:47am |

|

What tractor are you working on?

|

|

Freewheeling

Bronze Level

Joined: 05 Nov 2017

Location: Wisconsin

Points: 170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2025 at 7:11am Posted: 25 Jun 2025 at 7:11am |

|

An IB.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2025 at 8:43am Posted: 25 Jun 2025 at 8:43am |

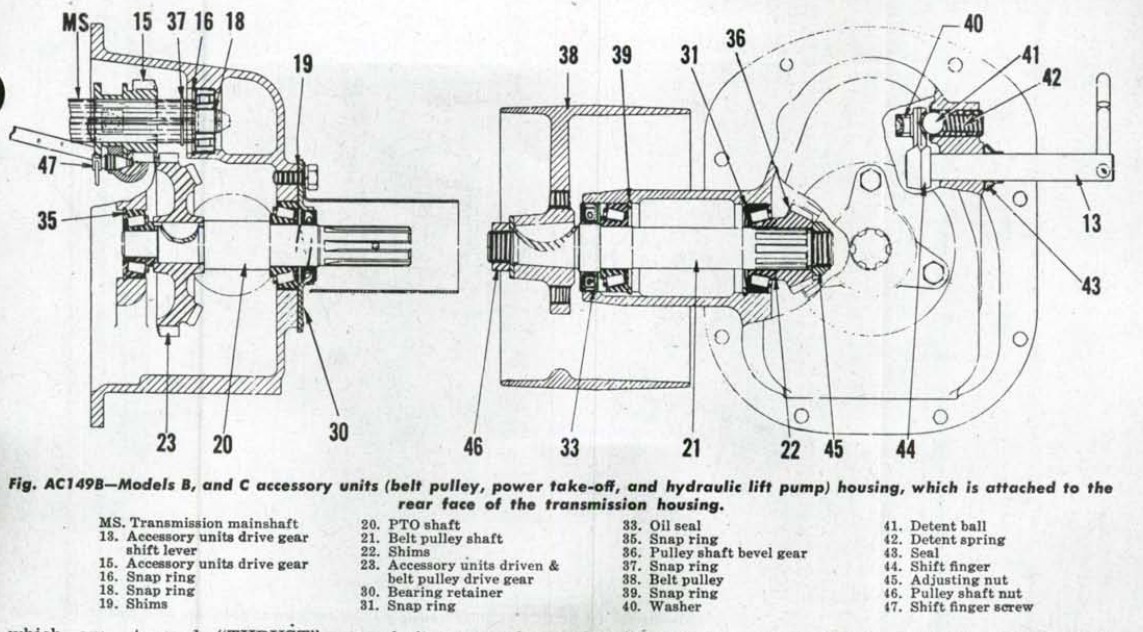

all of these parts are the same as the B and C tractors... your "retaner ring" or "seal holder" is just that... clamps the bearing IN and holds the seal in place... you adjust the PRELOAD on the bearings by adding or taking away shims.. sometimes there is a thin paper gasket between the steel shims to help SEAL from an oil drip.. This should be VERY THIN.. you can also wipe on a VERY THIN layer of RTV (.001 inch) to for a "gasket".......... clearance on the bearing should be at zero or maybe a couple thousandth loose.. Dont CRUNCH the bearings... kind of like adjusting front wheel bearings on an older car....remember, adjust till it drags, then back off one flat on the nut ???

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2025 at 8:47am Posted: 25 Jun 2025 at 8:47am |

|

if you have trouble with the bolt threads or holes, you can put teflon tape on the threads and pipe dope to seal up any problems... can also fill holes with RTV is you wish..

|

|

Like them all, but love the "B"s.

|

|

Freewheeling

Bronze Level

Joined: 05 Nov 2017

Location: Wisconsin

Points: 170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 6:59am Posted: 26 Jun 2025 at 6:59am |

Thanks. I was pretty sure the retainer would be the same on the IB as the B & C. However, the gentleman that thinks he has one claims the part # on mine (207617) is not for an IB. The "setup and repair parts manual" for my '45 model C shows it as #206729. I know that automotive part #'s change over time and I suppose Allis did also.

The gasket actually looks good but perhaps RTV is the better option. The shims all had some rust and crud on them so I cleaned them up with 400 grit. A couple had ridges by the bolt holes. It probably is because the original 1" bolt has a 1/4" shoulder to prevent the shims from catching on the thread. Two of the bolts they used did not. I removed the ridges. My concern with the loose hole is that it may strip in the casting. I assume the bolts are grade 2 so normal torque would be 21 ft/lbs but using anything on the threads would reduce that to ??? I don't want to distort the retainer and don't even want to think about helicoil. I'm not sure how critical it will be since the bolts on the left & right re closer to the bottom bolt than to the top. Thoughts?

|

|

Freewheeling

Bronze Level

Joined: 05 Nov 2017

Location: Wisconsin

Points: 170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 7:26am Posted: 26 Jun 2025 at 7:26am |

Dumb statement re. the shoulder bolt. Duh. Not enough coffee.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 7:38am Posted: 26 Jun 2025 at 7:38am |

there is no pressure on the shimssss / gaskets / retainer... this is just a bucket of oil... Clean / Flat / a little RTV film and you should be good... Like i said, you can put some teflon tape and pipe dope on the bolts if you need a better seal or tighter threads... your right about the TORQUE... dont take much .... its just a cover on an oil tank..

make sure the bolts are long enough to go thru the case by one thread and get all the engagement you can..

Edited by steve(ill) - 26 Jun 2025 at 7:39am

|

|

Like them all, but love the "B"s.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1485

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 8:31am Posted: 26 Jun 2025 at 8:31am |

Freewheeling wrote: Freewheeling wrote:

... My concern with the loose hole is that it may strip in the casting... |

I would clean that hole with brake cleaner and use Loctite, it will last long enough to be SEP (Someone Else's Problem)

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89114

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 26 Jun 2025 at 8:56am Posted: 26 Jun 2025 at 8:56am |

|

if the threads are REALLY BAD, JB weld a 2 inch long stud or althread into the hole.. let it set for 24 hours, then use a washer and nut on the outside.

|

|

Like them all, but love the "B"s.

|

|

Freewheeling

Bronze Level

Joined: 05 Nov 2017

Location: Wisconsin

Points: 170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2025 at 1:07am Posted: 29 Jun 2025 at 1:07am |

I like the JB Welded stud idea. Thanks. I'm not an RTV fan so seldom use it. The original gasket is .005" but I can't find gasket material that thin. I've used tracing paper which is .001". Think that will work?

If I use RTV I assume i should lay a thin bead and then spread with my finger. Yes?

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Freewheeling wrote:

Freewheeling wrote: