| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Mattman

Silver Level

Joined: 20 Dec 2012

Location: Plover, WI

Points: 231

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7040 pressure plate conundrum Topic: 7040 pressure plate conundrum

Posted: 18 May 2025 at 8:00am |

|

I did my research...... So I thought. I split my 7040 powershift this morning (serial 6146). I had purchased a torque limiter disc ( Agco 70268718 4 pad) which is what Agco says I should be using. I also bought a second belleville washer to add some holding strength. I pulled it apart today to find it has a pressure plate with blue springs and a 6 pad disc. I have a couple questions. Has anyone ever added washers or put in heavier springs to acheive a better hold on a pressure plate TL? Is the 4 pad disc compatible? I'm assuming it is from past forum chatter about the advantages of a 4 pad vs a 6 pad. Is anyone interested in my belleville washer? I'm actually kind of pleased to find a pressure plate. It seems like a better design to me. Am I wrong?

|

|

|

Sponsored Links

|

|

|

Mattman

Silver Level

Joined: 20 Dec 2012

Location: Plover, WI

Points: 231

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

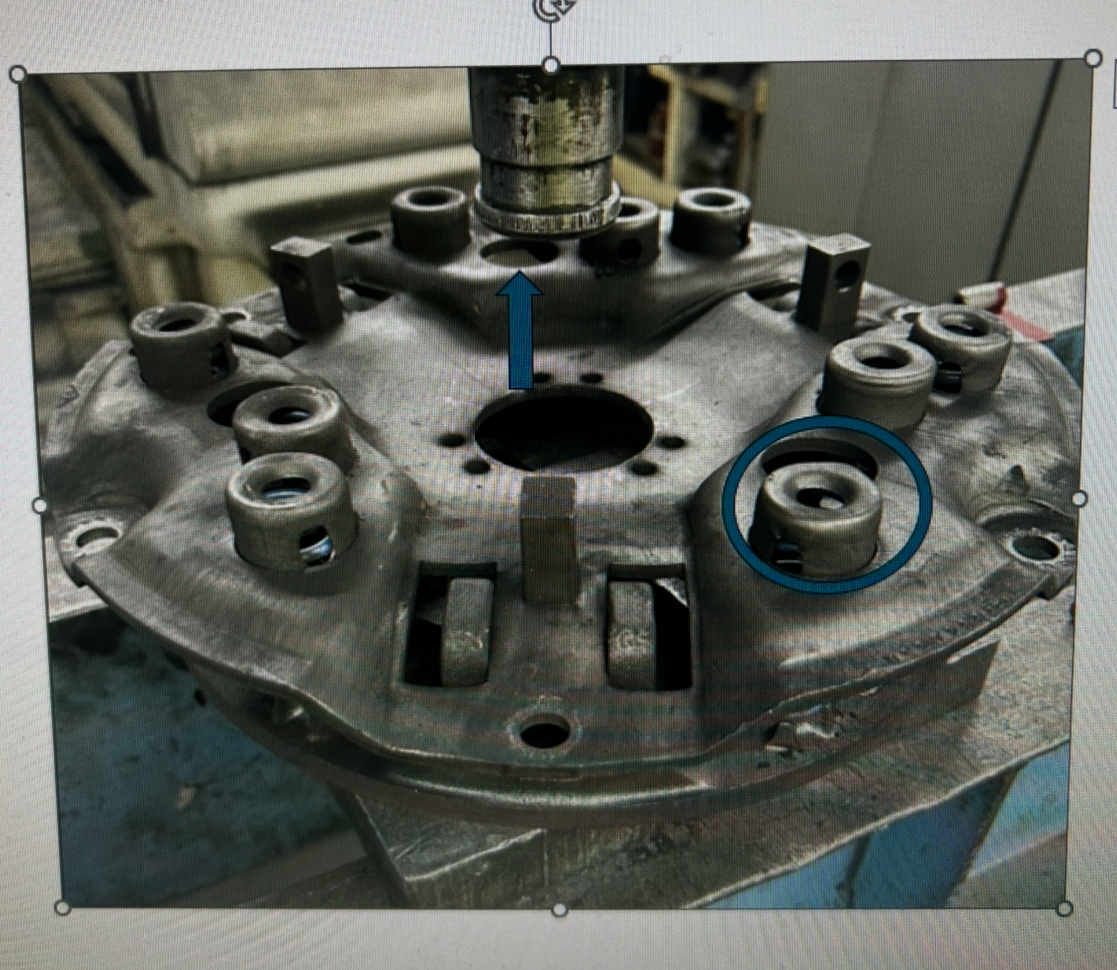

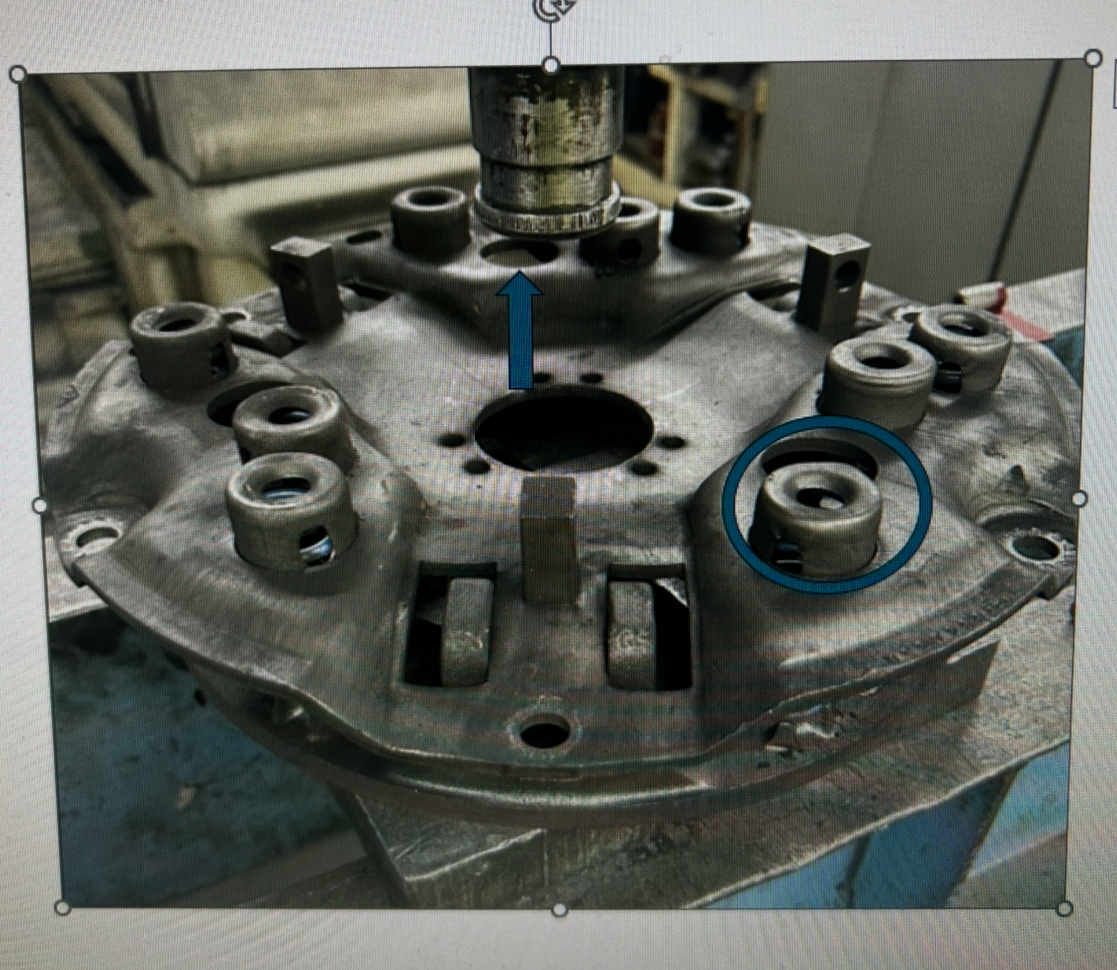

Posted: 18 May 2025 at 8:17am Posted: 18 May 2025 at 8:17am |

|

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2025 at 10:21am Posted: 18 May 2025 at 10:21am |

I don't have much experience with the 7000/8000 tractors and if I'm wrong someone will correct me and we'll both learn. I don't think a 2nd belleville washer would have worked in the first place. When the 1st washer is compressed, the gap is less than the thickness of the washer. Ergo, if you added a 2nd washer there would be no room for the washer to flex when the torque limited disc slips. It would be bottomed out, negating the purpose of the torque limited in the first place.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22316

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 May 2025 at 10:53am Posted: 18 May 2025 at 10:53am |

|

I think I may have been among the first to "double-spring" the Power Director type torque limiter back in late 1976 on a strong 7080 tractor. You must use longer grade 8 bolts (at least 1/4" longer/maybe 1/2" longer) and add a 1/2" lock washer under the stool to make up for the second Belleville pressure spring thickness. It works good and can still slip a little bit under severe shock loads. The early Power Shift transmissions used the coil spring design flywheel and pressure plate design because they were concerned (in prototypes ) that they may need release fingers and a throw out bearing to uncouple the engine for easier severe cold weather starting. As it turned out, that feature was really never needed, so they dropped that design and made both transmissions the same torque limiter style. If that was my 7040 pressure plate, and knowing what your intentions are, I'd buy 6 Gleaner combine feeder beater slip clutch springs (M2-L2) and stick them inside of six of the existing springs, equally spaced. The Gleaner springs might have to be shortened a bit with a cutting disc, and you'd have to measure that, but it will make things so they don't slip with more HP.

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3547

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2025 at 8:25am Posted: 19 May 2025 at 8:25am |

|

Lot of debate, but the 4 disc will hold better than the 6 disc due to the physics of more pressure per square inch - there are different center torque spring heaviness in some aftermarket units we have seen. Just follow Doc's suggestion.

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22316

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2025 at 7:32pm Posted: 19 May 2025 at 7:32pm |

|

If all T.L. disk pads are the same square inches in size, and assuming the same pressure plate squeeze on each disk, the 4 pad disk will transmit more torque than the 6 pad disk will.

|

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2025 at 9:00pm Posted: 19 May 2025 at 9:00pm |

|

I wouldnt bother trying to modify that style to add more holding power, my 7060 is well over stock hp trying to compensate with higher fuel pressure for a worn injection pump head and that style holds the power just fine. What you do gain is a flywheel that's at least 2x heavier than the Belleville washer style, and does it ever hold rpm better through a tough spot.

|

|

Mattman

Silver Level

Joined: 20 Dec 2012

Location: Plover, WI

Points: 231

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2025 at 9:27am Posted: 20 May 2025 at 9:27am |

I discovered that pressure plate only had 9 of 12 springs installed. I'm assuming this was a factory setting thing. I have ordered 12 new springs and cups, along with a new disc, and resurfacing both plates. I think this will do what I need. Thanks for all the help everyone.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22316

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2025 at 10:01am Posted: 20 May 2025 at 10:01am |

|

12 springs over 9 springs will be an improvement IF THEY ARE THE SAME SPRING PRESSURE. Springs are colored for a reason, as the color code tells a clutch builder what pressure it can make. If you install 12 new springs of a lesser pressure rating, you may not gain anything. You are trying to see to it that no slippage occurs for tractor pulling. So, with that in mind if you are going to err, you want to err to the tight side. You're not liking the Gleaner springs dropped inside of what you've got (which absolutely works--done it many times) so, to be more sure than the way you are going about it, drop a 3/4" lock washer down inside of every spring cup. Assemble it and see if the coil springs are collapsed, which they won't be. I would continue shimming until you can visually see the coil springs are ALMOST collapsed when the pressure plate is assembled, with a 4-pad clutch disc. There is nothing more embarrassing in front of a grandstand full of people than to have your rear wheels stop turning while the engine hasn't choked yet.

|

|

Mattman

Silver Level

Joined: 20 Dec 2012

Location: Plover, WI

Points: 231

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2025 at 8:02am Posted: 21 May 2025 at 8:02am |

|

Thanks Doc. I actually should have stated that I also plan on putting washers or the springs you recommended in as well. I don't want to have to split her again. My disc is a 4 pad so I should be good there.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

I discovered that pressure plate only had 9 of 12 springs installed. I'm assuming this was a factory setting thing. I have ordered 12 new springs and cups, along with a new disc, and resurfacing both plates. I think this will do what I need. Thanks for all the help everyone.

I discovered that pressure plate only had 9 of 12 springs installed. I'm assuming this was a factory setting thing. I have ordered 12 new springs and cups, along with a new disc, and resurfacing both plates. I think this will do what I need. Thanks for all the help everyone.